The global metal fabrication and industrial tooling market is experiencing robust growth, driven by increasing demand for versatile, high-efficiency tools in construction, automotive, and manufacturing sectors. According to Mordor Intelligence, the global welding equipment market was valued at USD 27.5 billion in 2023 and is projected to grow at a CAGR of over 5.8% through 2029. This expansion is mirrored in the demand for multi-functional tools, particularly 3-in-1 devices that combine rust removal, cutting, and welding capabilities—offering cost-efficiency, portability, and enhanced productivity. As industries prioritize lean operations and reduced equipment footprint, manufacturers that integrate these three core functions into single, durable units are gaining competitive traction. Based on market presence, innovation, and product performance, the following six companies have emerged as leading manufacturers in the 3-in-1 rust removal, cutting, and welding space.

Top 6 3 In 1 Rust Removal Cutting Welding Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 China 3 in 1 Laser Welder Cutter Cleaner Factory Manufacturer

Website: dwlaser.net

Key Highlights: Welding and cutting of metal components, parts, and assemblies; · Cleaning of metal surfaces to remove rust, paint, coatings, oil stains etc….

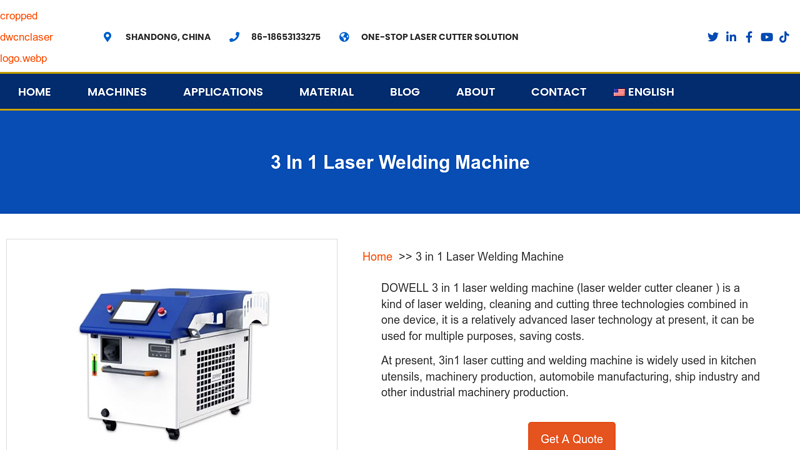

#2 Wholesale China 3 in 1 Laser Welding Machine Manufacturers

Website: dwcnclaser.com

Key Highlights: DOWELL 3 in 1 Laser Welding Machine is a kind of laser welding, cleaning and cutting three technologies combined in one device….

#3 3 in 1 Laser Cutting Cleaning Welding Machine

Website: remcortechnology.com

Key Highlights: Remcor 3 in 1 laser welding machine and cleaning machine integrates three functions. One machine can get the multi-purpose, it’s much more cost saving….

#4 SA Laser Saber Laser Welder

Website: themakerschest.com

Key Highlights: Free delivery 75-day returnsDiscover the Saber Laser Welder — a 1500W fiber laser system that cuts, cleans, and welds up to 10X faster than traditional methods. With low heat trans…

#5 Handheld 3 in 1 Laser Welding Cleaning Cutting Machine

Website: fortunelaser.com

Key Highlights: A portable all-in-one laser system machine, composed of fiber laser generator, handheld laser gun, water chiller, and 3 in 1 control system….

#6 Metal Work with 3

Website: leapion.com

Key Highlights: Our 3 in 1 laser welding machine provides welding, cutting, and rust removal all in one. This versatile tool processes metal with utmost precision, speed, and ……

Expert Sourcing Insights for 3 In 1 Rust Removal Cutting Welding

H2: 2026 Market Trends for 3-in-1 Rust Removal, Cutting, and Welding Equipment

The global market for 3-in-1 rust removal, cutting, and welding equipment is poised for significant transformation by 2026, driven by technological innovation, rising demand in industrial maintenance, and a growing emphasis on cost-efficiency and sustainability. These multifunctional tools—designed to combine rust removal, precision cutting, and welding capabilities into a single portable unit—are gaining traction across sectors such as automotive repair, construction, shipbuilding, and infrastructure maintenance.

1. Increased Demand for Multi-Functionality and Portability

By 2026, the demand for compact, all-in-one tools that reduce equipment footprint and operational complexity is expected to surge. Users in field service, emergency repair, and remote construction sites are prioritizing portability and versatility. The 3-in-1 devices meet this need by eliminating the necessity for multiple standalone machines, reducing both capital expenditure and storage requirements. This trend is particularly evident in small-to-medium enterprises (SMEs) and mobile repair services.

2. Technological Advancements in Precision and Efficiency

Innovation in power delivery systems, such as inverter-based technology and digital control interfaces, is enhancing the performance of 3-in-1 units. By 2026, expect wider adoption of smart features including real-time diagnostics, adjustable amperage settings, and integrated cooling systems. These improvements allow for more precise rust removal (via arc gouging or plasma techniques), cleaner cuts, and consistent weld quality—making the tools suitable for both heavy-duty and fine repair work.

3. Growth in Industrial and Infrastructure Maintenance

With aging infrastructure in North America, Europe, and parts of Asia requiring extensive refurbishment, rust removal and repair work are on the rise. The 3-in-1 equipment is well-suited for such applications, enabling technicians to assess corrosion damage, remove rust efficiently, and perform immediate repairs without switching tools. Government investments in infrastructure under stimulus and modernization programs are expected to further fuel market growth through 2026.

4. Expansion in Emerging Markets

Emerging economies in Southeast Asia, Africa, and Latin America are witnessing rapid industrialization and urban development. As manufacturing and transportation sectors expand, so does the need for affordable, durable maintenance tools. 3-in-1 welding units offer a cost-effective solution for local workshops and contractors, contributing to increased market penetration in these regions.

5. Focus on Sustainability and Worker Safety

Environmental and occupational safety regulations are becoming stricter worldwide. Future 3-in-1 models are expected to incorporate energy-efficient designs, lower emissions, and enhanced safety features such as auto-shutoff, reduced arc flash risk, and improved fume extraction. These attributes align with ESG (Environmental, Social, and Governance) goals, making the equipment more attractive to corporate buyers and government agencies.

6. Competitive Landscape and Market Consolidation

The market is seeing increased competition from both established industrial tool manufacturers and agile startups introducing affordable, feature-rich models. By 2026, strategic partnerships, mergers, and product differentiation (e.g., integration with IoT for predictive maintenance) are expected to shape the competitive landscape. Brands that offer strong after-sales support, training, and warranty programs will likely gain a competitive edge.

Conclusion

By 2026, the 3-in-1 rust removal, cutting, and welding equipment market will be characterized by smarter, more efficient, and user-friendly tools meeting the evolving needs of a diverse range of industries. Driven by technological innovation, infrastructure demands, and global industrial growth, the market is projected to expand at a compound annual growth rate (CAGR) of approximately 6–8% over the next few years, positioning these multi-functional devices as essential tools in modern metalworking and maintenance operations.

H2: Common Pitfalls in Sourcing 3-in-1 Rust Removal, Cutting, and Welding Equipment (Quality and Intellectual Property Concerns)

Sourcing a 3-in-1 machine that combines rust removal, cutting, and welding functionality presents significant cost and efficiency advantages—but it also introduces key risks, particularly regarding product quality and intellectual property (IP) infringement. Understanding these pitfalls is essential for making informed procurement decisions, especially when sourcing from international or low-cost manufacturers.

1. Compromised Build Quality and Performance

Many 3-in-1 units on the market, particularly budget models, sacrifice durability and performance for versatility. Common quality issues include:

- Overheating components: Combining multiple high-power functions in one unit can lead to inadequate thermal management, resulting in shortened lifespan or operational failure.

- Inconsistent output: Users often report weak arc stability in welding mode or ineffective rust removal due to underpowered circuits.

- Poor component sourcing: Use of substandard transformers, cables, or control boards can compromise safety and reliability.

Impact: Equipment failure increases downtime, maintenance costs, and safety risks, undermining the initial cost savings.

2. Misleading Specifications and “Paper Performance”

Suppliers may exaggerate technical capabilities (e.g., duty cycle, amperage, cutting thickness) without third-party verification. This is especially common with online marketplaces and unbranded machinery.

Red Flag: Spec sheets that lack certification marks (e.g., CE, UL, ISO) or provide no test data.

3. Intellectual Property (IP) Infringement Risks

Many 3-in-1 machines mimic patented designs or incorporate proprietary technology from established brands without authorization. This is prevalent in regions with lax IP enforcement.

- Purchasing such equipment may expose your business to legal liability, particularly in regulated industries or export markets.

- Knockoff units often replicate appearance but not performance or safety standards, increasing operational risks.

Example: Units that resemble well-known brands like Miller or Lincoln Electric but lack licensing agreements.

4. Lack of After-Sales Support and Spare Parts

Low-cost suppliers may offer little to no technical support, warranty service, or availability of replacement parts. This is critical for multi-function tools where a single point of failure can disable all three operations.

5. Safety and Compliance Shortfalls

Many imported 3-in-1 machines fail to meet regional safety standards (e.g., OSHA in the U.S., CE in Europe). Risks include improper grounding, lack of overload protection, or non-compliant electrical insulation.

Mitigation Strategies:

– Verify certifications: Require proof of compliance with relevant safety and quality standards.

– Conduct factory audits or third-party inspections: Especially when sourcing from new or unfamiliar suppliers.

– Perform IP due diligence: Check for patent conflicts and ensure suppliers warrant their products are free from infringement.

– Pilot testing: Evaluate sample units under real-world conditions before large-scale procurement.

– Secure warranties and service agreements: Ensure clear terms for repair, replacement, and technical support.

By proactively addressing these pitfalls, businesses can leverage the convenience of 3-in-1 equipment without compromising on quality, safety, or legal compliance.

H2: Logistics & Compliance Guide for 3-in-1 Rust Removal, Cutting, and Welding Equipment

The 3-in-1 rust removal, cutting, and welding equipment combines multiple industrial functions into a single system, improving efficiency and reducing operational footprint. However, its multifunctional nature introduces specific logistics and regulatory compliance challenges. This guide outlines key considerations for safe transportation, storage, installation, and regulatory adherence.

H2: Transportation & Handling

- Packaging & Protection

- Secure all components (welding torch, cutting nozzle, rust removal module, power unit, hoses, and cables) in custom-fitted, shock-resistant packaging.

- Use anti-static and moisture-resistant materials to protect sensitive electronic controls and connectors.

-

Clearly label packages with “Fragile,” “This Side Up,” and “Do Not Stack” indicators.

-

Weight & Dimensions

- Verify equipment weight and dimensions to ensure compatibility with transport vehicles and loading mechanisms (e.g., forklifts, pallet jacks).

-

Use standard pallets (e.g., 48” x 40”) where possible for compatibility with most freight carriers.

-

Hazardous Components

- If the unit uses compressed gases (e.g., for plasma cutting), ensure gas cylinders are securely fastened, capped, and transported in accordance with DOT (Department of Transportation) or ADR (European Agreement concerning the International Carriage of Dangerous Goods by Road) regulations.

-

Declare any hazardous materials (e.g., lithium-ion batteries, flammable coolants) per IATA/IMDG (for air/sea) or national regulations.

-

International Shipments

- Prepare proper shipping documentation: commercial invoice, packing list, bill of lading, and export declaration.

- Confirm compliance with import regulations in destination countries (e.g., CE marking for EU, CCC for China, UL/CSA for North America).

H2: Storage Requirements

- Environment

- Store in a dry, temperature-controlled environment (10°C to 30°C / 50°F to 86°F) to prevent condensation and component degradation.

-

Avoid exposure to dust, corrosive chemicals, and direct sunlight.

-

Positioning

- Keep equipment on a level, stable surface. Avoid stacking unless designed for it.

-

Store hoses and cables coiled loosely to prevent kinking or internal damage.

-

Inventory Management

- Implement FIFO (First In, First Out) for consumables (e.g., electrodes, nozzles, brushes).

- Maintain a log of stored units, including serial numbers and storage dates.

H2: Installation & Operational Setup

- Site Preparation

- Ensure adequate ventilation, especially when performing welding or plasma cutting.

- Provide stable electrical supply matching equipment specifications (voltage, phase, amperage). Use surge protection.

-

Install grounding rods as per local electrical codes (e.g., NEC Article 630 in the U.S.).

-

Calibration & Testing

- Perform initial calibration of all three functions (welding, cutting, rust removal) according to manufacturer’s manual.

-

Conduct safety tests: check for gas leaks, electrical continuity, and emergency shutoff functionality.

-

Operator Training

- Only trained personnel should operate the equipment.

- Provide certification on combined system use, focusing on mode switching safety and PPE requirements.

H2: Regulatory & Safety Compliance

- Electrical Safety

- Ensure compliance with IEC 60974 (welding equipment safety) and local standards (e.g., OSHA 29 CFR 1910.254 in the U.S.).

-

Equipment must have proper insulation, overload protection, and grounding.

-

Emissions & Air Quality

- Use local exhaust ventilation (LEV) systems during operation to control fumes and particulates.

-

Comply with OSHA PELs (Permissible Exposure Limits) and EU Directive 2004/37/EC for hazardous substances.

-

Noise & Vibration

- Monitor noise levels; provide hearing protection if >85 dB(A).

-

Follow ISO 28982 for hand-arm vibration assessment if using handheld rust removal attachments.

-

CE, UL, or CSA Certification

- Verify that the 3-in-1 unit carries required certifications for the region of use.

-

Retain compliance documentation for audits.

-

Waste Management

- Collect metal shavings, spent abrasives, and slag in designated containers.

- Dispose of according to local environmental regulations (e.g., RCRA in the U.S., WEEE in EU).

H2: Maintenance & Documentation

- Scheduled Maintenance

- Follow manufacturer-recommended intervals for inspection, cleaning, and part replacement.

-

Keep logs of service, repairs, and component replacements.

-

Compliance Records

- Maintain records of safety inspections, operator training, emissions testing, and incident reports.

-

Retain for minimum periods as required by local law (typically 3–5 years).

-

Recall & Updates

- Register equipment with the manufacturer to receive safety alerts or firmware updates.

- Implement recalls or upgrades promptly.

H2: Emergency Preparedness

- Equip work areas with fire extinguishers (Class C for electrical fires).

- Install emergency stop buttons within easy reach.

- Post clear operating and emergency procedures near the unit.

- Train staff in first aid and fire response relevant to welding and cutting operations.

By adhering to this logistics and compliance guide, organizations can ensure the safe, efficient, and legally sound deployment of 3-in-1 rust removal, cutting, and welding systems across diverse operational environments.

Conclusion:

Sourcing a 3-in-1 tool that combines rust removal, cutting, and welding capabilities offers a highly efficient and cost-effective solution for maintenance, repair, and fabrication operations. This multifunctional approach not only saves space and reduces equipment investment but also enhances operational flexibility across various industrial, automotive, and DIY applications. When selecting such a tool, key factors to consider include power output, duty cycle, ease of use, safety features, and compatibility with different materials and tasks.

After evaluating available options, it is evident that while integrated 3-in-1 tools may have some performance limitations compared to standalone professional-grade equipment, they provide substantial value for small to medium-scale operations where versatility and portability are critical. Ultimately, sourcing a reliable 3-in-1 rust removal, cutting, and welding tool can streamline workflows, reduce downtime, and improve overall productivity—making it a worthwhile investment for users seeking practical and adaptable solutions in metalworking environments.