The global laser welding machine market is experiencing robust growth, driven by increasing demand for precision manufacturing across industries such as automotive, electronics, and medical devices. According to Mordor Intelligence, the laser welding market was valued at USD 3.85 billion in 2023 and is projected to grow at a CAGR of over 7.5% from 2024 to 2029. This expansion is fueled by advancements in laser technology, automation integration, and the rising adoption of 3-in-1 multifunctional systems that combine welding, cutting, and cleaning capabilities into a single platform. As manufacturers seek greater efficiency, reduced operational costs, and improved weld quality, the demand for integrated 3-in-1 laser welding solutions has surged. Recognizing this trend, several key players have emerged as leaders in developing versatile, high-performance systems tailored to modern production needs. The following analysis highlights the top eight manufacturers pioneering innovation in the 3-in-1 laser welding space, based on technological capability, market presence, and product scalability.

Top 8 3 In 1 Laser Welding Machine Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

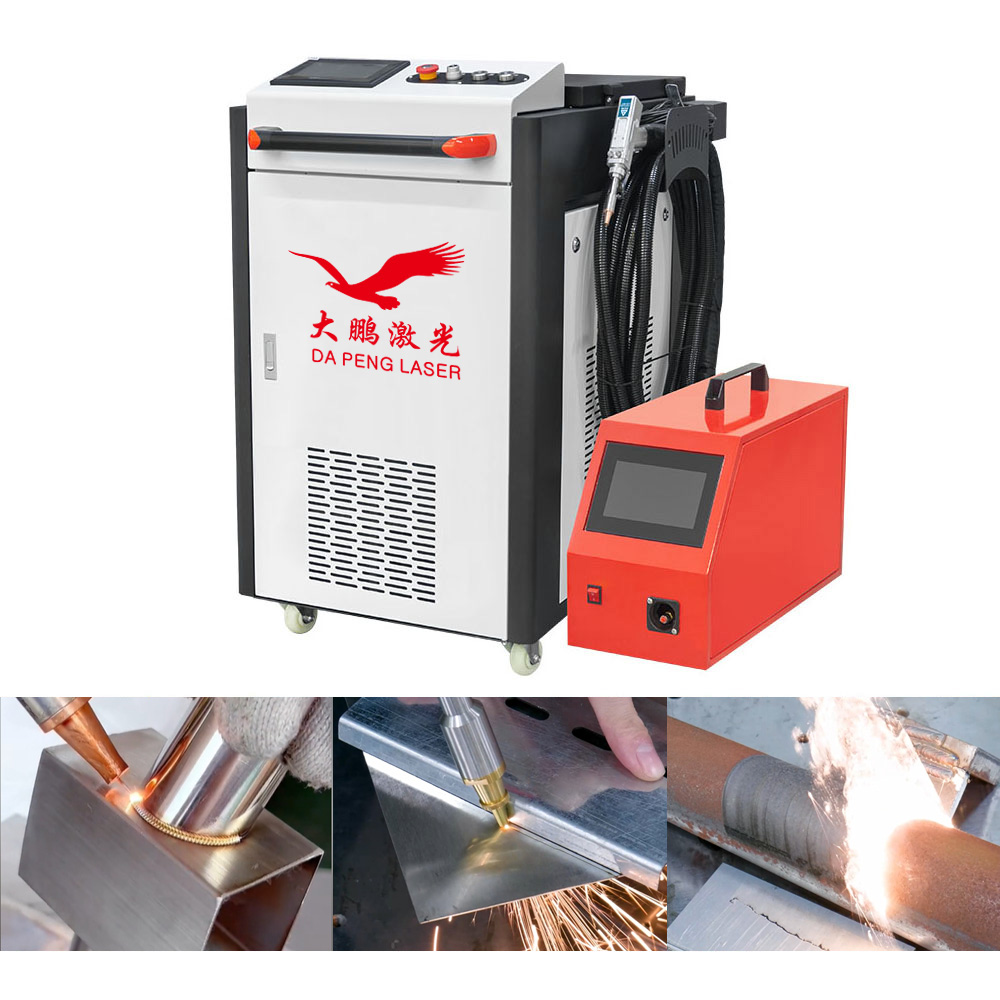

#1 Wholesale China 3 in 1 Laser Welding Machine Manufacturers

Website: dwcnclaser.com

Key Highlights: DOWELL 3 in 1 Laser Welding Machine is a kind of laser welding, cleaning and cutting three technologies combined in one device….

#2 Denaliweld

Website: denaliweld.com

Key Highlights: Ultra-portable laser welding machine (48.5 lbs) with dual welding/seam cleaning. Patented CUAL laser ensures precision on thin metals. Pre-set modes +….

#3 Professional Laser Cutting Machine Welding Machine Manufacturer

Website: goldmarklaser.com

Key Highlights: We specialized in design, manufacture fiber laser cutting machine, laser welding machine, laser cleaning machine. Spanning over 20,000 square meters, our modern ……

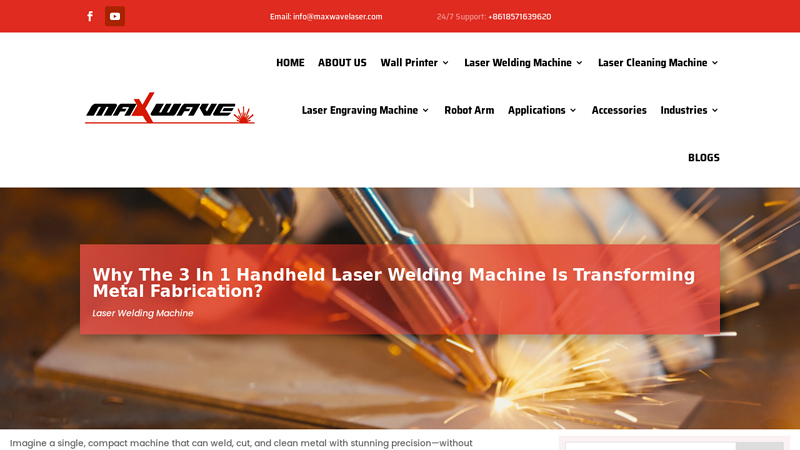

#4 Smart & Efficient 3 in 1 Handheld Laser Welding Machine

Website: lasermaxwave.com

Key Highlights: This advanced 3 in 1 handheld laser welding machine processes metal at speeds up to 120mm/s (adjustable), enabling metalworkers to complete jobs significantly ……

#5 Handheld Laser Welding Machine, Handheld Laser Cleaning …

Website: kaihuanlaser.com

Key Highlights: Laser welding is a high-precision process using a focused laser beam to melt and join materials, known for its versatility and low heat impact in diverse ……

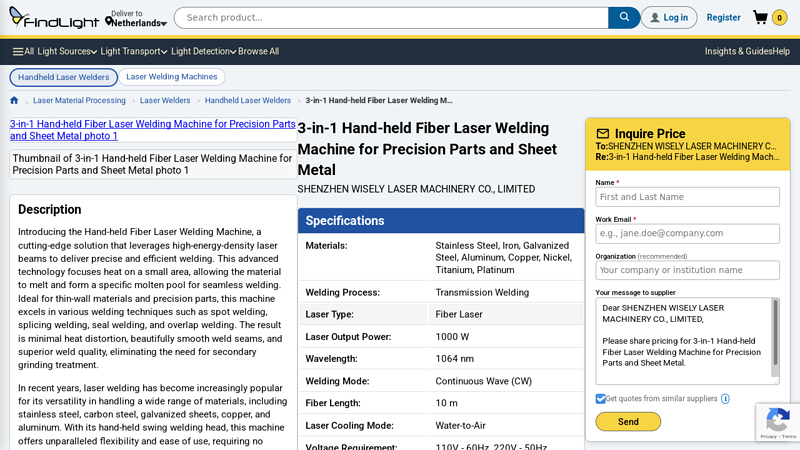

#6 3

Website: findlight.net

Key Highlights: 6-day delivery 30-day returnsThis Hand-held Laser Welder with 3-in-1 Laser Machine offers high performance in Laser Welding, Laser Cleaning and Laser Cutting….

#7 IPG Photonics

Website: ipgphotonics.com

Key Highlights: IPG Photonics manufactures high-performance fiber lasers, amplifiers, and laser systems for diverse applications and industries. Discover your solution….

#8 Best 3 In 1 Laser Welding Machine Factory and Manufacturers …

Website: fortunelaser.com

Key Highlights: 3 in 1 laser welding machine Manufacturers, Factory, Suppliers From China, For high quality gas welding & cutting equipment supplied on time and at the ……

Expert Sourcing Insights for 3 In 1 Laser Welding Machine

H2: 2026 Market Trends for 3-in-1 Laser Welding Machines

The global market for 3-in-1 laser welding machines is poised for significant transformation by 2026, driven by technological innovation, expanding industrial automation, and rising demand for high-precision manufacturing across key sectors. These multifunctional machines—combining laser welding, cutting, and cleaning in a single system—are becoming increasingly vital in industries such as automotive, aerospace, electronics, and medical device manufacturing. Below are the key market trends expected to shape the 3-in-1 laser welding machine landscape in 2026:

-

Increased Adoption in Electric Vehicle (EV) Manufacturing

The rapid growth of the electric vehicle industry is a major catalyst. 3-in-1 laser welding machines offer high-speed, precision joining of lightweight materials like aluminum and high-strength steel, essential for EV battery packs and structural components. As automakers scale EV production to meet 2030 emission targets, demand for integrated laser systems will surge. -

Advancements in Fiber Laser Technology

By 2026, fiber lasers are expected to dominate the 3-in-1 segment due to their superior energy efficiency, longer lifespans, and enhanced beam quality. Innovations such as higher power outputs (up to 6 kW and beyond) and improved beam modulation will enable deeper weld penetration and greater process stability, expanding applications in heavy industry. -

Integration with Industry 4.0 and Smart Manufacturing

Connectivity and automation are central to the evolution of 3-in-1 systems. By 2026, most new machines will feature IoT-enabled sensors, real-time monitoring, AI-driven process optimization, and seamless integration with digital twins and MES (Manufacturing Execution Systems). This enables predictive maintenance, reduced downtime, and consistent weld quality. -

Growing Demand in Asia-Pacific Markets

China, India, South Korea, and Japan will remain the fastest-growing markets due to expanding manufacturing bases, government initiatives promoting advanced manufacturing, and rising investments in automation. Chinese OEMs are also becoming key innovators and cost-effective suppliers, increasing global competitiveness. -

Sustainability and Energy Efficiency Focus

As industries prioritize carbon reduction, the energy-efficient nature of laser welding—compared to traditional arc welding—will boost adoption. 3-in-1 systems reduce the need for multiple machines, lowering energy consumption and factory footprint, aligning with ESG (Environmental, Social, and Governance) goals. -

Customization and Modular Design

Manufacturers are increasingly offering modular 3-in-1 systems that can be tailored to specific production needs. This flexibility allows small and medium enterprises (SMEs) to adopt laser technology without significant upfront investment, broadening market reach. -

Rising Competition and Price Optimization

With more players entering the market—including both established industrial giants and agile startups—competition will intensify. This is expected to drive price reductions and faster innovation cycles, making 3-in-1 laser systems more accessible across diverse industrial segments.

In summary, the 3-in-1 laser welding machine market in 2026 will be characterized by technological convergence, broader industrial integration, and strong regional growth—particularly in high-tech manufacturing hubs. Companies that invest in智能化 (smart manufacturing), sustainability, and application-specific solutions will be best positioned to capture market share.

Common Pitfalls When Sourcing a 3-in-1 Laser Welding Machine (Quality & IP)

Sourcing a 3-in-1 Laser Welding Machine (combining welding, cleaning, and cutting) requires careful due diligence, especially concerning quality and intellectual property (IP). Falling into these common pitfalls can lead to costly downtime, subpar results, legal issues, and reputational damage.

Quality-Related Pitfalls

Overlooking Core Component Specifications

Many suppliers emphasize high power ratings (e.g., 2000W, 3000W) but downplay critical details like laser source brand (IPG vs. generic), beam quality (M² value), cooling system efficiency, and motion control precision. Low beam quality results in poor weld penetration and inconsistent results. Always verify the actual components used—not just the advertised power—and request third-party test reports.

Prioritizing Price Over Build and Safety Standards

Extremely low-cost machines often cut corners on structural integrity, electrical safety, and user protection. Look for certifications like CE, FDA, or ISO—beware of fake or self-issued certificates. Poorly built machines risk overheating, mechanical failure, and unsafe operation, increasing long-term maintenance costs and safety liabilities.

Insufficient After-Sales Support and Training

A machine is only as good as the support behind it. Many suppliers, especially offshore ones, offer limited technical assistance, delayed spare parts delivery, or no on-site training. Ensure the supplier provides comprehensive documentation, accessible technicians, and training programs—critical for maintaining quality output and minimizing downtime.

Inadequate Testing and Performance Validation

Relying solely on demo videos or claims without hands-on testing is risky. Conduct material trials with your actual workpieces to assess weld strength, cutting precision, and cleaning effectiveness. Poorly calibrated machines may perform well in demos but fail under real production conditions.

Intellectual Property (IP) Pitfalls

Purchasing Machines with Infringing Technology

Some suppliers, particularly in competitive manufacturing hubs, may use cloned or reverse-engineered laser sources, control software, or optical components. This exposes buyers to legal risks, including import seizures, cease-and-desist orders, or liability if the original IP holder takes action. Always ask for IP compliance documentation and verify the authenticity of key components.

Lack of Software Licensing and Updates

The control software in 3-in-1 machines often contains proprietary algorithms. Unlicensed or pirated software can lead to instability, lack of updates, and legal exposure. Confirm that the software is properly licensed and whether future updates are included—essential for maintaining performance and security.

Ambiguous Warranty and Service Rights

If core components are counterfeit or unlicensed, manufacturers may void warranties or refuse service. This leaves you without recourse when failures occur. Clarify warranty terms upfront and ensure they cover genuine, IP-compliant parts.

Exposure to Supply Chain Disruptions

Using IP-infringing machines can lead to sudden supply chain interruptions if authorities crack down on counterfeit components. This can halt production and force costly machine replacements. Sourcing from reputable suppliers with transparent supply chains mitigates this risk.

Avoid these pitfalls by conducting thorough supplier audits, demanding transparency on components and IP, and prioritizing long-term reliability over initial cost savings.

Logistics & Compliance Guide for 3-in-1 Laser Welding Machine

Product Overview

The 3-in-1 Laser Welding Machine combines laser welding, cleaning, and cutting functionalities into a single industrial unit. Due to its advanced technology, high-power laser components, and electrical systems, specific logistics and compliance requirements must be met to ensure safe transportation, import/export, and operational use.

Regulatory Compliance

International Trade & Export Controls

- Export Classification: The machine likely falls under the Wassenaar Arrangement due to its laser power output. Verify the Export Control Classification Number (ECCN) – commonly 6A003.b.4 for lasers exceeding specific power thresholds.

- Licensing Requirements: Check if an export license is required from your country’s commerce department (e.g., Bureau of Industry and Security in the US). High-power lasers may require authorization for shipment to certain countries.

- End-Use Documentation: Provide a statement of end-use and end-user where required to comply with dual-use regulations.

Electrical & Safety Standards

- CE Marking (Europe): Must comply with:

- Machinery Directive 2006/42/EC

- Low Voltage Directive 2014/35/EU

- EMC Directive 2014/30/EU

- Laser Safety EN 60825-1

- UL/CSA Certification (North America):

- UL 1740 (Standard for Safety for Robots and Robotic Equipment)

- Compliance with FDA 21 CFR 1040.10 for laser products

- Other Markets: Confirm local requirements (e.g., CCC in China, PSE in Japan, RCM in Australia).

Laser Safety Certification

- IEC 60825-1 Compliance: Required for classification of laser products. The machine must be labeled with appropriate laser class (typically Class 4 for industrial welding lasers).

- Protective Features: Must include emergency stop, interlocks, warning labels, and protective enclosures.

- User Training Documentation: Provide safety manuals and training materials compliant with OSHA (US) or equivalent workplace safety regulations.

Packaging & Handling

Packaging Requirements

- Robust Crating: Use wooden export crates with internal foam or custom molded inserts to prevent movement.

- Shock & Vibration Protection: Include vibration-dampening materials; consider ISO 13355:2016 for vibration testing simulation.

- Moisture Protection: Use desiccant packs and moisture barrier bags, especially for humidity-sensitive electronic components.

- Labeling:

- “Fragile”

- “This Side Up”

- “Do Not Stack”

- Laser warning labels

- Proper shipping name and UN number if batteries are included

Handling Instructions

- Weight & Dimensions: Confirm equipment weight (often 300–800 kg) and dimensions for lifting equipment needs.

- Lifting Points: Use only designated lifting points; do not lift by control panels or hoses.

- Forklift Access: Ensure skid base allows for forklift entry on all sides if applicable.

Transportation & Logistics

Freight Mode Selection

- Sea Freight (FCL/LCL): Most cost-effective for heavy machinery. Use 20’ or 40’ dry containers. Ensure proper securing inside the container.

- Air Freight: Faster but expensive; suitable for urgent deliveries or remote locations.

- Overland Transport: Use specialized flatbed or lowboy trailers for domestic or regional delivery.

Required Documentation

- Commercial Invoice

- Packing List

- Bill of Lading (Sea) or Air Waybill (Air)

- Certificate of Origin

- Export License (if applicable)

- CE or UL Certificate

- Technical Specifications and User Manual

- Laser Safety Compliance Declaration

Customs Clearance

- Harmonized System (HS) Code: Typically 8456.30 (Laser machining centers) or 8515.21 (Laser welding machines). Confirm locally.

- Duties & Taxes: Research import tariffs, VAT, and any anti-dumping duties in the destination country.

- Customs Broker: Engage a licensed broker familiar with industrial machinery and laser equipment regulations.

Installation & On-Site Compliance

Site Preparation

- Floor Load Capacity: Verify floor can support machine weight (≥500 kg/m² recommended).

- Power Supply: 3-phase 380V/400V, 50/60 Hz; stable voltage with surge protection.

- Ventilation & Fume Extraction: Required for laser welding fumes; comply with OSHA or local air quality regulations.

- Laser Controlled Area: Establish a designated zone with interlocks and warning signs per ANSI Z136.1 or EN 12254.

Commissioning & Training

- Factory Acceptance Test (FAT): Conduct prior to shipment.

- Site Acceptance Test (SAT): Perform upon installation.

- Operator Training: Mandatory training on laser safety, emergency procedures, and maintenance.

Aftermarket & Maintenance Compliance

- Spare Parts Logistics: Maintain inventory of critical parts (laser lens, nozzles, filters) with traceable certification.

- Software Updates: Ensure compliance with cybersecurity standards if connected to networks.

- End-of-Life Disposal: Follow WEEE (EU) or equivalent regulations for electronic waste; lasers may contain hazardous materials.

Key Contacts & Support

- Manufacturer’s Technical Support

- Local Regulatory Authorities (e.g., OSHA, HSE, DGUV)

- Freight Forwarder & Customs Broker

- Certified Laser Safety Officer (LSO) – required in many jurisdictions

Note: Regulations vary by country. Always consult local authorities and legal experts before shipping or operating the machine.

Conclusion: Sourcing a 3-in-1 Laser Welding Machine

After thorough evaluation of technical specifications, supplier capabilities, cost considerations, and long-term operational requirements, sourcing a 3-in-1 laser welding machine represents a strategic investment in enhancing manufacturing efficiency, versatility, and product quality. The integration of welding, cleaning, and cutting functionalities into a single system streamlines production processes, reduces equipment footprint, and lowers overall operational costs.

Key advantages include improved precision, reduced heat distortion, minimal post-processing needs, and increased automation potential—making it ideal for industries such as automotive, aerospace, electronics, and metal fabrication. Careful selection of a reputable supplier offering reliable after-sales support, training, and warranty coverage is critical to ensuring optimal performance and return on investment.

Furthermore, aligning the machine’s specifications with current and future production demands ensures scalability and adaptability in a competitive market. In conclusion, sourcing a high-quality 3-in-1 laser welding machine not only boosts productivity but also strengthens long-term manufacturing capabilities, positioning the organization at the forefront of technological advancement.