The global demand for durable and versatile material handling equipment has driven significant growth in the hand truck manufacturing sector, particularly for multi-functional models like 3-in-1 aluminum hand trucks. According to Grand View Research, the global material handling equipment market was valued at USD 174.1 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. This growth is fueled by rising e-commerce logistics, warehouse automation, and increased focus on worker safety and efficiency across industrial and retail sectors. Aluminum hand trucks—lightweight, corrosion-resistant, and capable of transitioning between flat, stair-climbing, and platform modes—are becoming essential tools in modern supply chains. As demand surges, a handful of manufacturers have distinguished themselves through innovation, quality, and global reach. Here are the top six manufacturers leading the 3-in-1 aluminum hand truck market today.

Top 6 3 In 1 Aluminum Hand Truck Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Global Industrial™ Aluminum 3

Domain Est. 1997

Website: globalindustrial.com

Key Highlights: In stock Rating 5.0 (76) Converts in an instant from a standard two-wheel hand truck to either a 500 lb. capacity 45 degree incline truck or a four-wheel platform truck….

#2 3 in 1 Aluminum Hand Truck A

Domain Est. 1997

Website: dutro.com

Key Highlights: This heavy duty and lightweight hand truck features a 550 pound capacity and 10 inch flat free steel rim polyurethane wheels, it effortlessly handles items of ……

#3 Milwaukee Hand Trucks

Domain Est. 1999

Website: milwaukeehandtrucks.com

Key Highlights: Milwaukee has an extensive number of standard and specialty style hand trucks available in steel, aluminum, different handle styles, wheel options and load ……

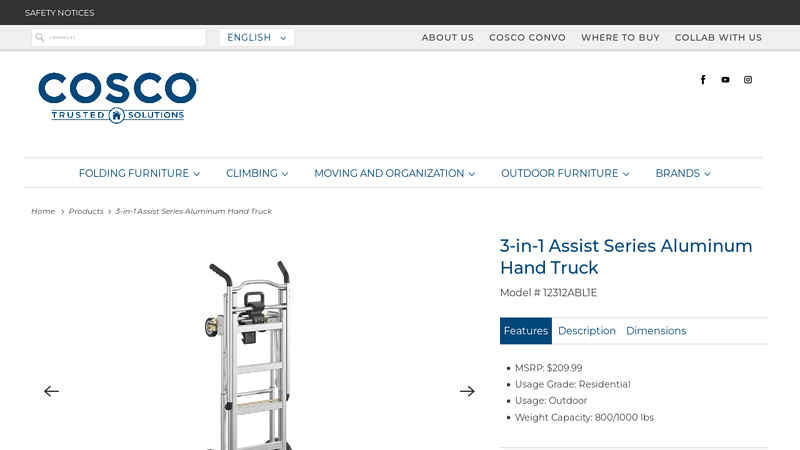

#4 3

Domain Est. 2001

Website: coscoproducts.com

Key Highlights: 3-in-1 Assist Series Aluminum Hand Truck · MSRP: $209.99 · Usage Grade: Residential · Usage: Outdoor · Warranty Details: 5 Year Limited · Weight Capacity: 800/1000 ……

#5 Hand Trucks & Dollies

Domain Est. 2003

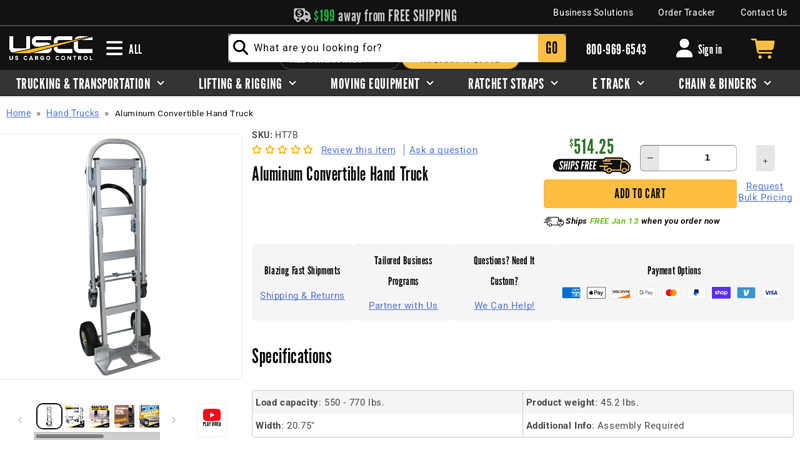

#6 Aluminum Convertible Hand Truck

Domain Est. 2005

Expert Sourcing Insights for 3 In 1 Aluminum Hand Truck

H2: 2026 Market Trends for 3-in-1 Aluminum Hand Truck

The global market for 3-in-1 aluminum hand trucks is poised for significant transformation by 2026, driven by evolving industrial needs, technological advancements, and shifting consumer preferences. These multi-functional material handling tools—combining features such as a hand truck, folding ramp, and lifting platform—are gaining traction across logistics, warehousing, retail, and home moving sectors. Below are key market trends expected to shape the 3-in-1 aluminum hand truck industry in 2026:

-

Increased Demand for Lightweight and Durable Equipment

Aluminum’s high strength-to-weight ratio makes it ideal for hand trucks used in labor-intensive environments. As industries prioritize worker safety and ergonomics, demand for lightweight yet robust 3-in-1 aluminum models will rise. By 2026, manufacturers are expected to focus on advanced aluminum alloys that enhance durability without compromising portability. -

Growth in E-Commerce and Last-Mile Delivery

The continued expansion of e-commerce fuels the need for efficient, versatile handling tools in last-mile logistics. 3-in-1 aluminum hand trucks offer logistical flexibility for delivery personnel managing diverse package sizes and delivery conditions. This trend will drive product innovation and increased adoption in urban delivery fleets. -

Rising Emphasis on Ergonomic and Multi-Functional Designs

With growing awareness of workplace injuries, companies are investing in ergonomic equipment. The 3-in-1 design meets this need by reducing physical strain through integrated ramp and lift functions. By 2026, expect more models with padded handles, anti-slip surfaces, and improved load distribution to enter the market. -

Sustainability and Recyclability of Materials

Aluminum is 100% recyclable and has a lower environmental footprint compared to steel. As sustainability becomes a key purchasing criterion, especially among corporate buyers and government institutions, aluminum-based hand trucks will gain a competitive advantage. Brands highlighting eco-friendly manufacturing processes will appeal to environmentally conscious consumers. -

Integration of Smart Features

While still in early stages, some manufacturers are exploring smart enhancements such as load sensors, integrated scales, or IoT connectivity for fleet tracking. Though not yet mainstream, by 2026, premium 3-in-1 aluminum hand trucks may begin incorporating these features, particularly in industrial and logistics applications. -

Expansion in Emerging Markets

Developing regions in Asia-Pacific, Latin America, and Africa are witnessing rapid growth in infrastructure and logistics sectors. As these markets modernize their material handling practices, there will be increased demand for affordable, versatile tools like the 3-in-1 aluminum hand truck. Localized production and distribution will likely expand to meet this demand. -

Competitive Pricing and Product Differentiation

As more players enter the market, competition will intensify. Success will depend on innovation, brand trust, and value-added features. Companies that offer modular designs, extended warranties, or customizable options will stand out in a crowded marketplace.

In summary, the 2026 outlook for 3-in-1 aluminum hand trucks is positive, characterized by innovation, sustainability, and expanding use cases across industries. Manufacturers who align with ergonomic, environmental, and efficiency trends will be best positioned to capitalize on this growing market.

Common Pitfalls When Sourcing a 3-in-1 Aluminum Hand Truck (Quality & IP)

Sourcing a 3-in-1 aluminum hand truck—typically combining a hand truck, dolly, and stair climber—requires careful attention to both quality and intellectual property (IP) considerations. Overlooking these aspects can lead to product failures, legal risks, and reputational damage. Below are key pitfalls to avoid:

Overlooking Material and Structural Integrity

One of the most frequent quality pitfalls is assuming all aluminum hand trucks offer the same durability. Sourcing from suppliers using substandard aluminum alloys (e.g., non-6000-series) or inadequate wall thickness can result in frames that bend or crack under load. Ensure suppliers specify aerospace-grade or industrial-grade aluminum (such as 6061-T6) and provide load test certifications. Avoid units with poor weld quality or visible seams, which indicate weak structural joints.

Ignoring Load Capacity and Real-World Testing

Many suppliers advertise high load capacities that aren’t validated under real-world conditions. A 3-in-1 hand truck may claim to support 300 lbs, but without independent testing or third-party verification (such as ISO or ANSI standards), these claims can be misleading. Always request performance data, user testing reports, or video demonstrations under maximum load, especially on stairs or uneven surfaces.

Compromising on Wheel and Bearing Quality

The functionality of a 3-in-1 hand truck heavily depends on its wheels and bearings. Sourcing models with low-grade plastic wheels or non-sealed bearings leads to premature wear, noise, and failure on rough terrain. Look for polyurethane or solid rubber tires paired with sealed ball bearings for smoother operation and longevity. Avoid suppliers who don’t disclose wheel material or bearing specifications.

Failing to Verify Design Originality and IP Rights

A major IP risk arises when sourcing designs that mimic branded or patented 3-in-1 hand trucks. Many innovative configurations (e.g., specific hinge mechanisms, folding systems, or stair-climbing wheel arrangements) are protected by utility or design patents. Sourcing a look-alike product without verifying freedom to operate can expose your business to infringement lawsuits, customs seizures, or forced product recalls.

Relying on Incomplete or Unverified Certifications

Suppliers may claim compliance with safety or quality standards (e.g., CE, RoHS, or ISO 9001) without providing valid certification documentation. Always request up-to-date, verifiable certificates from accredited bodies. Absence of proper documentation may indicate non-compliance, raising liability concerns—especially if the product is sold in regulated markets.

Neglecting After-Sales Support and Spare Parts Availability

A high-quality hand truck is only as reliable as the support behind it. Sourcing from suppliers who don’t offer spare parts (e.g., replacement wheels, brackets, or pins) or technical support can render the product obsolete after minor damage. Ensure the supplier provides a parts list, warranty terms, and responsive customer service to support long-term usability.

Skipping On-Site or Third-Party Inspections

Relying solely on product samples or supplier promises without independent quality checks is a critical oversight. Conduct pre-shipment inspections or hire a third-party inspection agency to audit manufacturing batches. This helps catch defects in welding, assembly, labeling, or packaging before shipment, reducing the risk of receiving subpar goods.

Assuming All “3-in-1” Designs Are Equal

Not all 3-in-1 mechanisms function the same way. Some designs require complex setup or lack intuitive transitions between modes, reducing user safety and efficiency. Evaluate ergonomics, ease of transformation, and user feedback. Avoid designs that compromise stability in any mode—especially when climbing stairs—due to poor weight distribution or weak locking mechanisms.

By proactively addressing these quality and IP-related pitfalls, businesses can source reliable, legally compliant 3-in-1 aluminum hand trucks that meet customer expectations and withstand real-world use.

Logistics & Compliance Guide for 3-in-1 Aluminum Hand Truck

Product Overview

The 3-in-1 Aluminum Hand Truck is a versatile material handling solution combining a standard dolly, stair-climbing feature, and convertible flatbed design. Constructed from lightweight yet durable aluminum, it is ideal for transporting boxes, appliances, and other bulky items across various environments. Understanding logistics and compliance requirements ensures safe, efficient distribution and use.

Packaging & Shipping Specifications

Proper packaging safeguards the hand truck during transit and meets shipping carrier standards. Each unit should be:

– Securely boxed in a double-wall corrugated cardboard container with internal foam or cardboard supports to prevent movement.

– Labeled with handling icons (e.g., “Fragile,” “This Side Up”) and a barcode for tracking.

– Shipped in standard pallet configurations: typically 10–12 units per pallet, stretch-wrapped and corner-protected.

– Accompanied by a packing slip and bill of lading detailing contents, weight, and destination.

Weight & Dimension Guidelines

Accurate dimensional data is crucial for freight classification and storage:

– Unit Weight: Approximately 12–15 lbs (5.4–6.8 kg)

– Dimensions (folded): 36″ H x 14″ W x 8″ D (91 x 36 x 20 cm)

– Palletized Load Height: ~60″ (152 cm), including pallet

– Total Pallet Weight: ~180–200 lbs (82–91 kg)

These specifications align with standard LTL (Less Than Truckload) freight classifications (e.g., NMFC 150 or similar) and facilitate efficient warehouse racking.

Import/Export Compliance

For international shipments, ensure adherence to relevant regulations:

– HTS Code: 8427.90.00 (Other hand trucks and similar hand-propelled vehicles)

– Country of Origin Marking: Clearly labeled on packaging and product (e.g., “Made in China”)

– Documentation: Commercial invoice, packing list, bill of lading, and certificate of origin required.

– Trade Agreements: Verify eligibility under USMCA, GSP, or other applicable tariff reductions based on manufacturing location.

Safety & Regulatory Standards

The hand truck must comply with safety standards applicable in target markets:

– United States: Meets ANSI/ITSDF B56.20 safety standards for hand trucks and manual platform trucks.

– European Union: Complies with EN 1757-4:2021 for non-motorized industrial trucks, including stability and load capacity requirements.

– Load Capacity Certification: Rated for 600 lbs (272 kg); clearly marked on frame with safety warnings.

– REACH & RoHS: Aluminum and plastic components free of restricted substances (e.g., lead, phthalates, cadmium).

Labeling & User Documentation

Include clear labeling and instructions to ensure proper use and regulatory compliance:

– Product Label: Permanent label on frame indicating model number, load capacity, manufacturer, and compliance marks (e.g., CE, ANSI).

– User Manual: Multilingual instruction sheet covering assembly (if required), safe operation, maintenance, and weight limits.

– Warning Labels: Affixed near handle and platform areas, advising against overloading and improper use.

Warehousing & Handling Best Practices

Optimize storage and handling in distribution centers:

– Store upright or on edge to prevent deformation; avoid stacking unpacked units.

– Use pallet jacks or forklifts with care to prevent damage to pallets and packaging.

– Maintain a dry, climate-controlled environment to prevent corrosion or material degradation.

– Rotate stock using FIFO (First In, First Out) to ensure freshness and compliance with warranty timelines.

End-of-Life & Environmental Compliance

Support sustainability and regulatory requirements for product disposal:

– Recyclability: Constructed of >95% recyclable aluminum; encourage end-user recycling.

– WEEE Compliance (EU): Mark with “crossed-out wheeled bin” symbol if applicable; partner with authorized e-waste handlers.

– No Hazardous Waste Designation (US): Non-regulated under RCRA when discarded due to absence of toxic materials.

Quality Assurance & Inspection Protocols

Ensure consistent product compliance through regular quality checks:

– Pre-shipment inspection (PSI) for overseas suppliers, verifying dimensions, load testing, and labeling accuracy.

– In-line production audits focusing on weld integrity, wheel durability, and surface finish.

– Annual third-party testing for compliance with ANSI or EN standards.

Summary

Efficient logistics and strict compliance are essential for the successful distribution of the 3-in-1 Aluminum Hand Truck. By adhering to packaging standards, international trade regulations, safety certifications, and environmental guidelines, suppliers and distributors can minimize risks, reduce delays, and ensure customer satisfaction across global markets.

Conclusion:

Sourcing a 3-in-1 aluminum hand truck presents a strategic opportunity to enhance material handling efficiency, reduce physical strain, and improve operational versatility across various environments. The combination of lightweight aluminum construction, multi-functional design (typically serving as a hand truck, dolly, and stair climber), and robust durability makes it an ideal choice for industries such as logistics, warehousing, retail, and facilities management.

When sourcing, key considerations include material quality, load capacity, ease of maneuverability, and supplier reliability. Sourcing from reputable manufacturers ensures compliance with safety standards and long-term cost savings through reduced maintenance and increased product lifespan. Additionally, bulk sourcing or establishing long-term supply agreements can yield favorable pricing and consistent availability.

In conclusion, investing in a high-quality 3-in-1 aluminum hand truck not only improves workplace efficiency and safety but also demonstrates a commitment to durable, adaptable, and ergonomic solutions. Careful supplier evaluation and attention to product specifications will ensure optimal performance and return on investment.