The global wire rope market is experiencing steady expansion, driven by rising demand across construction, mining, marine, and material handling industries. According to a report by Mordor Intelligence, the wire rope market was valued at USD 8.97 billion in 2023 and is projected to reach USD 11.78 billion by 2029, growing at a CAGR of 4.7% during the forecast period. This growth is fueled by increased infrastructure development, particularly in emerging economies, and the need for high-strength, durable lifting and rigging solutions. As demand for safety and performance intensifies, manufacturers are focusing on advanced metallurgy, corrosion resistance, and load capacity innovations. In this competitive landscape, a select group of industry leaders stands out for their engineering excellence, global reach, and consistent product strength—making them key players in shaping the future of heavy-duty wire rope solutions.

Top 8 3 8 Wire Rope Strength Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Industrial Wire Rope Supply Company, Inc.

Domain Est. 1997

Website: industrialrope.com

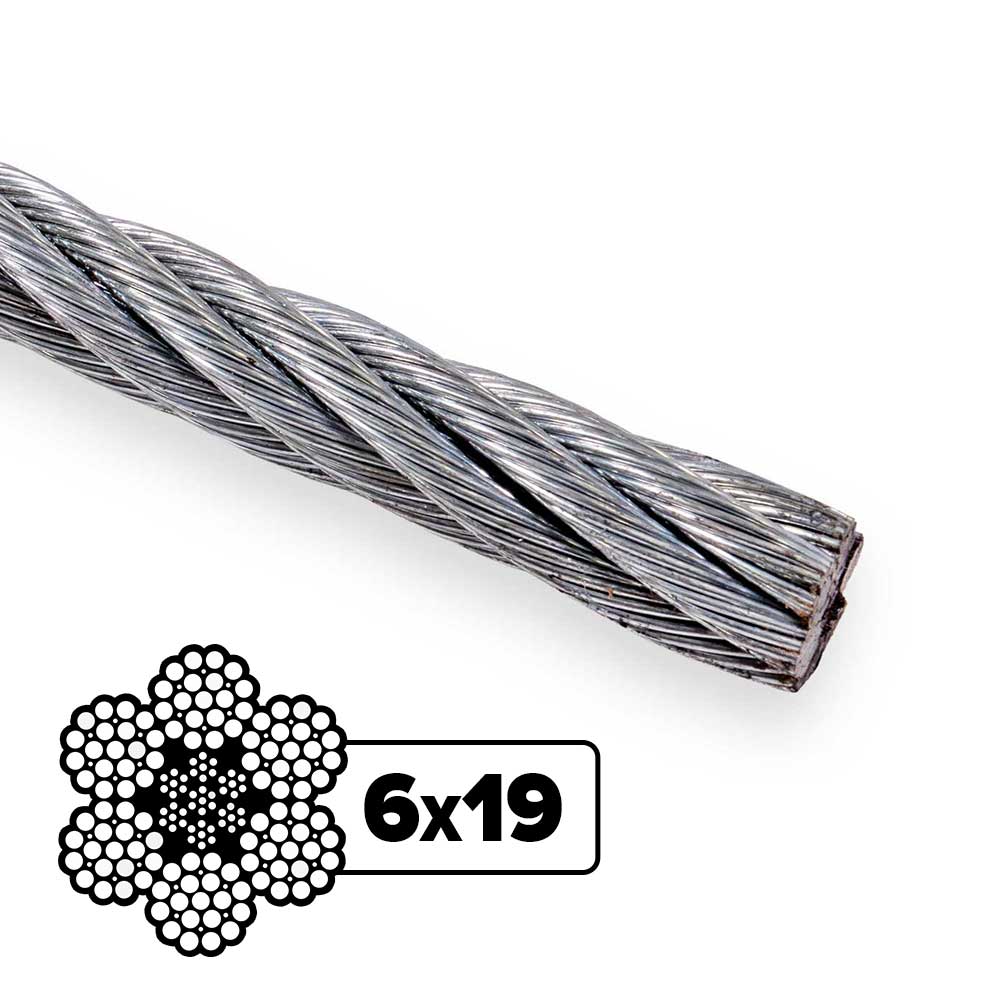

Key Highlights: Industrial Wire Rope can offer a complete line of ropes made in the USA, as well as wire rope made outside of the USA. We handle 6×19 & 6×36 ……

#2 Wire Rope

Domain Est. 1997

Website: loosco.com

Key Highlights: We manufacture and stock wire rope to industry standards and specifications in stainless steel, galvanized steel, and a variety of other alloys….

#3 Southwest Wire Rope Products

Domain Est. 1996

Website: southwestwirerope.com

Key Highlights: We offer a complete range of lifting products including wire rope slings, nylon slings, chains, shackles, thimbles, and other products….

#4 Tri-Flex® Wire Rope Sling

Domain Est. 1996

Website: slingmax.com

Key Highlights: Tri-Flex® Wire Rope Slings offer strength, flexibility, and cost savings—ideal for heavy lifting, steel erection, and machinery moving applications….

#5 Wire Rope + Steel Cable from Bishop Lifting

Domain Est. 1996

Website: lifting.com

Key Highlights: 2–3 day delivery3/8″ 6×19 Class Wire Rope – 15100 lbs Breaking Strength. Approved Vendor. 3/8″ 6×19 Class Wire Rope – 15100 lbs Breaking Strength. $1.10. 2 ……

#6 Wire Rope

Domain Est. 1998 | Founded: 1930

Website: hanessupply.com

Key Highlights: 30-day returnsHanes Supply has been manufacturing rigging wire ropes since 1930. We are fully staffed with expert wire rope splicers and create quality ……

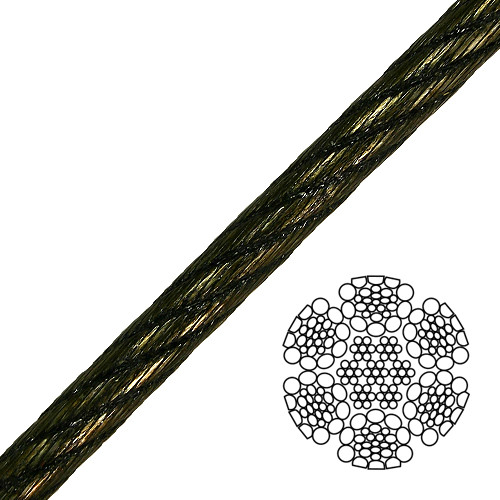

#7 IWRC High-Strength Wire Rope

Domain Est. 1999

#8 3/8″ 6×19 Galvanized Wire Rope – EIPS IWRC

Domain Est. 2005

Website: uscargocontrol.com

Key Highlights: In stock Rating 5.0 (1) Made of strong Extra Improved Plowed grade steel (EIPS), this galvanized wire rope belongs to the 6×19 class, which is known for flexibility and abrasion-…

Expert Sourcing Insights for 3 8 Wire Rope Strength

H2: 2026 Market Trends for 3/8-Inch Wire Rope Strength

The global market for 3/8-inch wire rope, particularly valued for its balance of strength, flexibility, and durability, is poised for strategic evolution by 2026. Driven by industrial growth, infrastructure development, and technological advancements, demand for high-strength 3/8-inch wire ropes is expected to rise across key sectors. Below are the primary market trends anticipated to shape the landscape in 2026:

1. Rising Demand in Construction and Infrastructure

With large-scale infrastructure projects expanding in emerging economies—especially in Asia-Pacific, Africa, and Latin America—there is growing reliance on durable lifting and rigging solutions. The 3/8-inch wire rope, commonly used in cranes, hoists, and suspension systems, benefits from its optimal load capacity (typically ranging from 4 to 8 tons depending on construction and material). As governments invest in transportation networks, renewable energy installations, and urban development, demand for reliable wire rope products will escalate.

2. Shift Toward High-Tensile and Corrosion-Resistant Grades

By 2026, end-users are expected to increasingly favor wire ropes made from improved materials such as galvanized steel, stainless steel, and polymer-coated variants. These enhancements significantly boost tensile strength and resistance to environmental degradation—especially critical in marine, offshore, and chemical processing industries. The standard 3/8-inch wire rope with 6×19 or 6×36 constructions will see greater adoption of high-strength grades (e.g., 1960–2160 N/mm² tensile strength), improving safety and longevity.

3. Integration of Smart Monitoring and IoT Technologies

The industrial focus on predictive maintenance and operational safety is driving innovation in “smart” wire ropes. By 2026, wire rope manufacturers may incorporate embedded sensors into 3/8-inch ropes to monitor real-time load, wear, and fatigue. This trend, especially prominent in mining, oil & gas, and elevator applications, supports compliance with stringent safety regulations and reduces downtime—adding measurable value beyond raw strength.

4. Sustainability and Circular Economy Pressures

Environmental regulations will increasingly influence material sourcing and recycling practices. Wire rope producers are expected to adopt greener manufacturing processes and promote end-of-life recycling programs. In response, demand may shift toward recyclable high-strength steel alloys, with lifecycle assessments playing a greater role in procurement decisions.

5. Regional Market Dynamics

While North America and Europe maintain steady demand due to industrial maintenance and modernization, the fastest growth is projected in Asia-Pacific, led by China, India, and Southeast Asian nations. These regions are expanding port facilities, wind farms, and high-rise construction—all key users of 3/8-inch wire rope. Additionally, localization of manufacturing hubs may reduce lead times and import dependency, boosting regional market resilience.

Conclusion

By 2026, the 3/8-inch wire rope market will be shaped by a convergence of material innovation, digital integration, and infrastructure expansion. Strength remains a core performance metric, but it will be increasingly evaluated alongside durability, safety intelligence, and environmental impact. Companies that adapt to these trends—offering high-strength, technologically enhanced, and sustainable wire rope solutions—will gain a competitive edge in the evolving industrial landscape.

Common Pitfalls When Sourcing 3/8-Inch Wire Rope: Quality and IP (Ingress Protection) Considerations

When sourcing 3/8-inch wire rope, overlooking key quality and environmental protection (IP) factors can lead to premature failure, safety hazards, and increased long-term costs. Below are critical pitfalls to avoid:

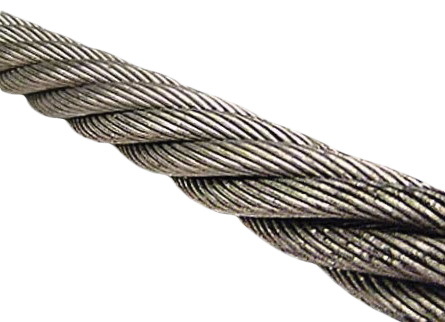

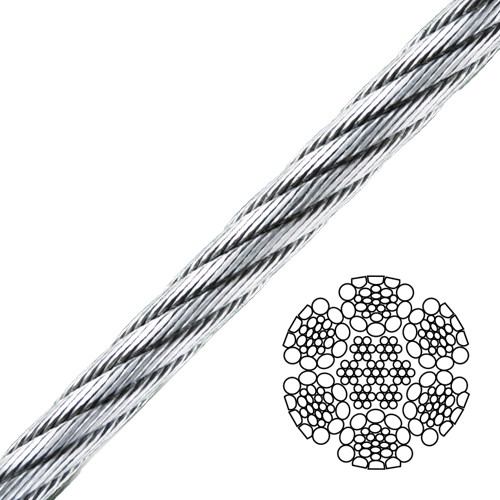

Ignoring Wire Rope Construction and Material Quality

Many buyers focus solely on diameter and price, neglecting the internal construction (e.g., 6×19, 6×36, or 7×7 strand patterns) and material grade (e.g., galvanized vs. stainless steel). Low-quality wire rope may use substandard steel or inadequate lubrication, reducing tensile strength and fatigue resistance. Always verify the minimum breaking load (MBL) specifications and ensure the rope meets recognized standards such as ASTM or ISO. Choosing the wrong construction for the application—like using a rigid 6×19 in a high-flex environment—can lead to rapid wear and failure.

Overlooking Environmental Compatibility and IP Ratings

While wire rope itself isn’t typically assigned an IP (Ingress Protection) rating like electrical enclosures, the associated fittings, terminations, and hoisting systems often are. A common mistake is sourcing wire rope for outdoor or corrosive environments (e.g., marine, chemical, or high-humidity settings) without ensuring corrosion-resistant materials. Using non-galvanized or non-stainless rope in such conditions accelerates rust and internal degradation. Additionally, if the rope is part of a system with sealed components (e.g., winches or motor housings), neglecting the IP rating of those components can expose the entire assembly to moisture and debris, compromising performance.

Failing to Match Rope to Application Requirements

Different applications demand different rope characteristics. Using general-purpose wire rope for high-cycle lifting, overhead rigging, or dynamic loads may result in fatigue failure. Similarly, not considering factors like bending radius, fleet angle, or fleet angle in sheave systems leads to accelerated wear. Always confirm that the rope’s design factor (safety factor) aligns with industry standards for the intended use—typically 5:1 for general lifting, higher for critical applications.

Purchasing from Unverified or Non-Certified Suppliers

Sourcing from suppliers without proper certifications (e.g., ISO 9001, third-party testing reports) increases the risk of counterfeit or substandard products. Reputable suppliers provide mill test certificates (MTCs) verifying tensile strength, chemical composition, and compliance. Skipping due diligence can result in receiving rope with inconsistent quality, incorrect specifications, or undocumented performance history.

Neglecting Proper Inspection and Maintenance Planning

Even high-quality wire rope degrades over time. A frequent oversight is not establishing a routine inspection and maintenance schedule based on the operating environment. Failing to inspect for broken wires, corrosion, kinks, or deformation can lead to unexpected failures. Ensure the sourced rope is compatible with inspection protocols and lubrication requirements to extend service life.

By addressing these pitfalls—prioritizing construction quality, environmental resilience, application fit, supplier credibility, and maintenance—you ensure reliable and safe performance of 3/8-inch wire rope in your operations.

Logistics & Compliance Guide for 3/8″ Wire Rope Strength

When handling, transporting, or utilizing 3/8-inch wire rope, understanding its strength characteristics and aligning logistics and compliance procedures accordingly is essential for safety, regulatory adherence, and operational efficiency. This guide outlines key considerations related to strength specifications, handling, storage, transportation, inspection, and compliance standards.

Understanding 3/8″ Wire Rope Strength Specifications

The strength of 3/8″ wire rope depends on several factors, including construction (e.g., 6×19, 6×36), material grade (e.g., IPS, EIPS, EEIPS), and core type (fiber or steel). Typical minimum breaking strengths (MBS) for common configurations are:

- 6×19 Fiber Core (FC), Improved Plow Steel (IPS): ~20,000 lbs (89 kN)

- 6×19 Steel Core (IWRC), EIPS (Extra Improved Plow Steel): ~24,000 lbs (107 kN)

- 6×36 Rotation-Resistant, EEIPS: ~26,000 lbs (116 kN)

Always verify manufacturer specifications, as actual strength values can vary. The Working Load Limit (WLL) is derived by dividing MBS by the appropriate design factor (typically 5:1 for general lifting), resulting in a WLL of approximately 4,000–5,200 lbs for most 3/8″ wire ropes.

Handling and Transportation Best Practices

Proper handling during logistics prevents damage that could compromise strength:

- Coiling and Unreeling: Always unreel wire rope from a spool or reel rotating on a shaft. Never unreel from a fixed spool, as this can cause kinking or birdcaging.

- Lifting and Moving Spools: Use appropriate lifting equipment (e.g., cranes with spreader bars) to avoid damaging flanges or deforming the rope.

- Avoid Dragging: Never drag wire rope across surfaces; use skids or conveyors to prevent abrasion and core damage.

- Environmental Protection: Protect spools from moisture, UV exposure, and corrosive agents during transit using weather-resistant covers or sealed containers.

Storage Requirements to Maintain Strength Integrity

Improper storage can accelerate wear and reduce effective strength:

- Indoor Storage: Store in a dry, well-ventilated area away from humidity, chemicals, and temperature extremes.

- Elevated Placement: Keep spools on wooden pallets or racks to avoid ground moisture.

- Avoid Stacking: Do not stack spools unless designed for it; excessive weight can crush lower units.

- Coil Support: If stored in coils (not on spools), ensure they are hung or supported to prevent deformation.

Inspection and Maintenance Compliance

Regular inspection is required by OSHA, ASME B30.9, and other standards to ensure continued strength and safety:

- Frequent Inspection (Daily/Pre-Use): Check for broken wires, kinks, crushing, corrosion, and deformation. Remove from service if 6 randomly distributed broken wires in one lay or 3 consecutive broken wires are found.

- Periodic Inspection (Monthly/Quarterly): Conduct detailed examination by a qualified person, measuring diameter loss (discard if reduced by 5% or more) and assessing core condition.

- Recordkeeping: Maintain inspection logs with dates, findings, and actions taken to demonstrate compliance during audits.

Regulatory and Industry Standards

Ensure compliance with relevant codes and standards:

- OSHA 29 CFR 1910.184 & 1926.251: Governs safe use, inspection, and handling in general industry and construction.

- ASME B30.9 – Slings: Specifies requirements for alloy steel chain, wire rope, and synthetic slings, including use, inspection, and marking.

- Wire Rope Users’ Guide (Wire Rope Technical Board): Offers best practices for selection, installation, and maintenance.

- ISO 4309:2010 – Cranes – Wire Ropes: International standard for care and maintenance in crane applications.

Label all wire rope with identification tags indicating size (3/8″), grade, MBS, WLL, and last inspection date for traceability.

Training and Personnel Certification

Personnel involved in handling or inspecting 3/8″ wire rope must be trained in:

- Safe rigging practices

- Identification of wear and damage

- Correct use of slings and fittings

- Emergency procedures for rope failure

Employers must document training as part of their safety compliance program.

Disposal and End-of-Life Procedures

Retire wire rope when it no longer meets safety standards:

- Cut into manageable sections to prevent reuse.

- Recycle through certified metal recyclers; wire rope is typically 100% recyclable.

- Maintain disposal records for compliance and environmental reporting.

By following this logistics and compliance guide, organizations can ensure the safe and effective use of 3/8″ wire rope while adhering to industry regulations and preserving rope strength throughout its service life.

Conclusion for Sourcing 3/8-inch Wire Rope Strength:

When sourcing a 3/8-inch wire rope, understanding its breaking strength and working load limit is critical to ensuring safety, reliability, and optimal performance in lifting, rigging, or securing applications. The actual strength of the wire rope depends on several factors, including its material (typically galvanized steel or stainless steel), construction (e.g., 6×19, 6×36), tensile strength (ranging from 220,000 to 300,000 psi), and the presence of a core (fiber or steel).

On average, a high-quality 3/8-inch diameter steel wire rope has a minimum breaking strength between 7,000 and 10,000 pounds, with 10,200 lbs being a common rating for EIPS (Extra Improved Plow Steel) grade. To ensure safety, the working load limit (WLL)—typically 1/5 of the breaking strength—is usually around 2,000 to 2,040 pounds, depending on the safety factor applied.

In conclusion, when sourcing a 3/8-inch wire rope, it is essential to:

– Confirm the breaking strength and WLL based on application requirements.

– Select the appropriate type and grade for environmental and load conditions.

– Source from reputable suppliers that provide certification and meet industry standards (e.g., OSHA, ASME, ISO).

– Inspect regularly and adhere to proper installation and usage practices.

Choosing the right 3/8-inch wire rope ensures operational safety, extends service life, and reduces the risk of failure in critical applications.