The global PVC piping market is experiencing robust growth, driven by increasing demand across construction, water treatment, and agricultural irrigation sectors. According to a report by Mordor Intelligence, the global PVC pipes and fittings market was valued at USD 54.63 billion in 2023 and is projected to reach USD 77.84 billion by 2029, growing at a CAGR of 6.04% during the forecast period. This expansion is fueled by infrastructure development in emerging economies, rising focus on water conservation, and the cost-effectiveness and durability of PVC materials. As demand for reliable plumbing solutions grows, 3″ and 4″ PVC tees—critical components in pipeline branching systems—have become essential in both residential and industrial applications. With market dynamics shifting toward quality, scalability, and compliance with international standards, identifying leading manufacturers in this niche is crucial for sourcing professionals and project planners. Based on market presence, production capacity, certifications, and customer reviews, the following ten companies stand out as top manufacturers of 3″ and 4″ PVC tees worldwide.

Top 10 3 4 Pvc Tee Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 JM Eagle™

Domain Est. 2007

Website: jmeagle.com

Key Highlights: JM Eagle is the innovative leader that combines advanced technology with superior customer service to create the industry’s most sophisticated and diverse ……

#2 Cantex PVC Conduit

Domain Est. 1996

Website: cantexinc.com

Key Highlights: CANTEX is the largest manufacturer of PVC electrical conduit, fittings, and boxes in the United States. Our extensive range of PVC electrical products includes ……

#3 PVC Tees & Tee Fittings

Domain Est. 2004

Website: distributioninternational.com

Key Highlights: 30-day returnsDistribution International supplies PVC tees from major manufacturers like Johns Manville Zeston, Proto, PIC Plastics, and Speedline. Browse our ……

#4 3/4″ BARB TEE PVC SCH 40

Domain Est. 1995

#5 Spears Manufacturing, PVC & CPVC Plastic Pipe Fittings & Valves

Domain Est. 1996

Website: spearsmfg.com

Key Highlights: ISO9001 Certified – PVC & CPVC Sch 40 and 80 fittings molded from 1/8 – 14 inch….

#6 3/4″ Schedule 40 White PVC Threaded Tee

Domain Est. 1996

Website: usplastic.com

Key Highlights: In stock $15.08 deliveryThese injection molded PVC pipe fittings are corrosion resistant and produced to schedule 40 dimensions. Ideal applications include potable water, water, …..

#7 PVC Schedule 40 Pressure Pipe & Fittings

Domain Est. 1997

Website: charlottepipe.com

Key Highlights: PVC schedule 40 is highly durable, with high-tensile and high-impact strength. It is easy to install and has better sound-deadening qualities than PVC schedule ……

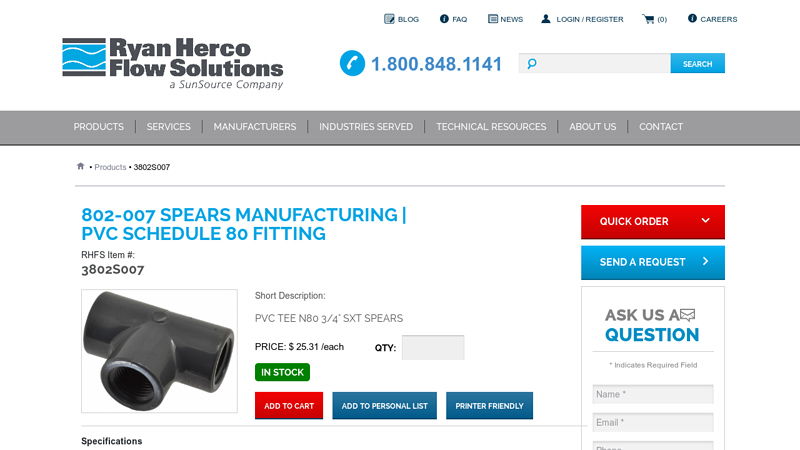

#8 802-007 Spears Manufacturing PVC Pipe & Fittings

Domain Est. 1999

Website: rhfs.com

Key Highlights: In stock $1,000 delivery802-007 Spears Manufacturing PVC Pipe & Fittings. Short Description: PVC TEE N80 3/4″ SXT SPEARS. PRICE: $ 25.31 /EACH. QTY: In Stock….

#9 Advanced Drainage Systems

Domain Est. 2000

Website: adspipe.com

Key Highlights: Advanced Drainage Systems provides high-performing, durable pipe and innovative stormwater management solutions. Discover our industry-leading products ……

#10 Charlotte Pipe 3/4 In. Schedule 40 PVC Tee

Domain Est. 2020

Expert Sourcing Insights for 3 4 Pvc Tee

H2: 2026 Market Trends for 3″ and 4″ PVC Tee Fittings

The market for 3-inch and 4-inch PVC tee fittings is poised for steady growth and transformation through 2026, driven by infrastructure development, sustainability initiatives, and advancements in material technology. These fittings, essential components in plumbing, irrigation, and industrial piping systems, are seeing shifts influenced by regional demand, regulatory changes, and evolving construction practices.

1. Infrastructure Investment Driving Demand

A key driver for the 3″ and 4″ PVC tee market is the global push for infrastructure modernization. In North America and Europe, aging water and wastewater systems are being upgraded through government-backed programs such as the U.S. Infrastructure Investment and Jobs Act. These projects emphasize durable, corrosion-resistant materials like PVC, increasing demand for standardized fittings such as tees. Similarly, in emerging economies across Asia-Pacific and Africa, rapid urbanization is fueling new water supply and sewage projects, where PVC piping systems—due to their cost efficiency and ease of installation—are preferred.

2. Growth in Sustainable Construction and Green Building

Sustainability is reshaping construction material preferences. PVC, while historically scrutinized for environmental impact, is benefiting from advancements in recyclable and lead-free formulations. By 2026, building codes and green certifications (e.g., LEED, BREEAM) are expected to increasingly recognize high-performance, recycled-content PVC fittings. Manufacturers are responding by introducing eco-friendly 3″ and 4″ PVC tees with lower carbon footprints, appealing to environmentally conscious developers and municipalities.

3. Technological Advancements and Product Innovation

Innovation in PVC materials—such as the development of molecularly oriented PVC (PVC-O) and reinforced composites—is enhancing the strength, pressure rating, and longevity of large-diameter fittings. These improvements make 3″ and 4″ PVC tees more competitive with traditional materials like metal or concrete in high-stress applications. Additionally, smart piping systems incorporating sensors are beginning to integrate standardized fittings, paving the way for intelligent water management networks.

4. Supply Chain Resilience and Regional Manufacturing Shifts

Post-pandemic supply chain disruptions have prompted companies to regionalize production. By 2026, localized manufacturing of PVC fittings is expected to rise, particularly in Southeast Asia and Latin America, reducing dependency on imports and shortening lead times. This shift supports faster project execution and aligns with “buy local” procurement policies in public infrastructure.

5. Competitive Landscape and Pricing Pressures

The market for 3″ and 4″ PVC tees remains highly competitive, with numerous regional and global players. Price volatility in raw materials (e.g., vinyl chloride monomer) continues to impact margins, but economies of scale and process optimization help stabilize costs. Brands emphasizing quality, certifications (ASTM, ISO), and technical support are gaining market share over generic alternatives.

Conclusion

By 2026, the market for 3″ and 4″ PVC tee fittings will be characterized by robust demand from infrastructure and sustainable building sectors, innovation in material science, and a more resilient supply chain. Stakeholders who align with regulatory trends, invest in sustainable production, and offer value-added solutions will be best positioned to capitalize on this growth.

Common Pitfalls When Sourcing 3/4″ PVC Tee Fittings (Quality and IP Considerations)

Sourcing 3/4″ PVC tee fittings may seem straightforward, but overlooking critical quality and International Protection (IP) rating factors can lead to system failures, safety hazards, and costly replacements. Below are common pitfalls to avoid:

Poor Material Quality and Non-Compliance

One of the most frequent issues is receiving PVC tees made from substandard or recycled materials. Low-quality PVC may contain impurities, lack UV resistance, or fail to meet ASTM D1785 or other relevant standards. This can result in brittle fittings that crack under pressure or degrade prematurely when exposed to sunlight or chemicals. Always verify that the fittings are certified to industry standards and request material test reports from suppliers.

Inaccurate Dimensional Tolerances

Inconsistent or incorrect dimensions—such as mismatched socket depths, uneven branch angles, or out-of-spec inner diameters—can lead to improper solvent welding. This increases the risk of leaks, joint failure, or flow restrictions. Ensure suppliers adhere to standard dimensional specifications (e.g., ASTM D2466 for socket dimensions) and consider conducting random sampling inspections upon delivery.

Misunderstanding or Ignoring IP Ratings

While PVC fittings themselves are not typically assigned IP ratings—a classification system for enclosures’ protection against solids and liquids—confusion often arises when these tees are used in electrical conduit systems. Sourcing a PVC tee without verifying its compatibility with the required environmental protection (e.g., dust-tight or water-resistant enclosures) can compromise the entire system’s IP integrity. Confirm that the overall assembly, including seals and conduit connections, meets the desired IP65, IP66, or other applicable ratings.

Inadequate Pressure and Temperature Rating Verification

Not all 3/4″ PVC tees are rated for the same pressure or temperature conditions. Using a fitting with insufficient pressure rating (e.g., in a high-pressure irrigation or industrial system) can lead to catastrophic failure. Always cross-check the manufacturer’s pressure rating (typically listed in psi or bar) and ensure it exceeds the maximum operating conditions of your application, including surge pressures.

Lack of UV or Chemical Resistance

Standard PVC degrades when exposed to sunlight or certain chemicals. If the tee is intended for outdoor or industrial use, sourcing a non-UV-stabilized or chemically incompatible fitting can result in rapid deterioration. Look for UV-resistant or CPVC variants when needed, and confirm chemical compatibility with the transported media.

Sourcing from Unverified Suppliers

Purchasing from unqualified or offshore suppliers without proper auditing increases the risk of counterfeit or non-compliant products. These fittings may look identical but fail under real-world conditions. Always vet suppliers, request certifications, and consider third-party testing for critical applications.

By addressing these common pitfalls—focusing on material quality, dimensional accuracy, environmental suitability, and supplier reliability—you can ensure reliable, long-lasting performance of 3/4″ PVC tee fittings in your piping systems.

Logistics & Compliance Guide for 3″ x 4″ PVC Tee

Product Overview

The 3″ x 4″ PVC Tee is a plumbing fitting used to connect three sections of pipe, allowing flow in two directions from one inlet. It features one 4-inch socket and two 3-inch sockets, typically made from Schedule 40 or 80 PVC (Polyvinyl Chloride). This guide outlines key logistics and compliance considerations for the handling, transportation, and regulatory requirements of this product.

Material Specifications & Standards

The 3″ x 4″ PVC Tee must comply with relevant industry standards to ensure safety, durability, and performance. Key standards include:

– ASTM D1785: Standard specification for PVC (Polyvinyl Chloride) Plastic Pipe, Schedules 40, 80, and 120.

– NSF/ANSI 14: Standard for plastic piping system components and related materials.

– NSF/ANSI 61: Health effects standard for products in contact with drinking water.

– ASME B16.22: For dimensions and pressure ratings (where applicable).

Manufacturers must provide certification that the product meets these standards, especially when used in potable water systems.

Packaging & Handling Requirements

Proper packaging ensures product integrity during storage and transport:

– Unit Packaging: Individual tees should be sealed in polybags or bundled in shrink-wrapped groups to prevent dirt and moisture ingress.

– Bulk Packaging: For large shipments, use sturdy cardboard boxes or wooden crates with internal dividers to prevent abrasion and deformation.

– Palletization: Stack packaged units on standard 48″ x 40″ pallets. Secure with stretch wrap and corner boards. Max stacking height: 6 feet to prevent bottom-load crushing.

– Handling: Use forklifts or pallet jacks; avoid dragging. Protect from sharp objects and extreme temperatures.

Storage Conditions

To maintain material integrity:

– Store indoors in a dry, well-ventilated area.

– Avoid direct sunlight and UV exposure (PVC degrades under prolonged UV).

– Temperature range: 40°F to 100°F (4°C to 38°C).

– Keep away from oils, solvents, and corrosive chemicals.

– Store horizontally on flat surfaces; avoid leaning against walls.

Transportation Guidelines

Ensure safe and compliant shipping:

– Mode of Transport: Suitable for truck, rail, or sea freight. Air freight acceptable for small quantities.

– Hazard Classification: Non-hazardous under DOT, IATA, and IMDG regulations.

– Load Securing: Pallets must be tightly secured in containers or trailers to prevent shifting.

– Documentation: Include packing list, commercial invoice, and certificates of compliance (ASTM, NSF).

– Labeling: Outer packaging must display:

– Product name and size (3″ x 4″ PVC Tee)

– Quantity per package

– Handling symbols (e.g., “Protect from Sunlight,” “Do Not Stack Above Line”)

– Manufacturer name and contact information

Regulatory & Compliance Documentation

Ensure full compliance with regional and international regulations:

– Country-Specific Approvals:

– USA/Canada: NSF-61 and CSA B137.3 certification required for potable water applications.

– EU: CE marking per Construction Products Regulation (CPR) if applicable; compliance with EN 1329 or EN 1452 standards.

– Australia/NZ: WaterMark certification under AS/NZS 1477.

– Import Documentation: Provide Harmonized System (HS) Code: 3917.32 (Plastic pipe fittings). Include country of origin and material declaration.

– RoHS & REACH: Confirm PVC compound is free from restricted substances (e.g., phthalates, heavy metals).

Environmental & Safety Considerations

- Recyclability: PVC is recyclable (Resin ID Code 3). Provide disposal guidance to end users.

- Workplace Safety: During installation, follow OSHA guidelines for cutting and handling (dust control, eye protection).

- Fire Safety: PVC is combustible; store away from ignition sources. Material safety data sheet (MSDS/SDS) must be available.

Quality Control & Traceability

Implement quality assurance practices:

– Batch numbering on packaging for full traceability.

– Random sampling and pressure testing per ASTM standards.

– Maintain records of compliance certificates for minimum 5 years.

Summary

Proper logistics and compliance management for 3″ x 4″ PVC Tees involves adherence to material standards, secure packaging, climate-appropriate storage, compliant transportation, and complete documentation. Ensuring these practices helps meet regulatory requirements, reduce product damage, and support safe, reliable installations in residential, commercial, and industrial applications.

Conclusion for Sourcing 3″ and 4″ PVC Tees:

After evaluating suppliers, material quality, pricing, and lead times, sourcing 3″ and 4″ PVC tees from reliable manufacturers or distributors ensures cost-effectiveness, product durability, and compliance with industry standards (such as ASTM D2241 or NSF). It is recommended to partner with suppliers offering certified materials, consistent stock availability, and competitive pricing—particularly those capable of providing bulk order discounts without compromising on quality. Additionally, considering factors like local availability, shipping costs, and warranty support will further optimize the procurement process. By securing these fittings from reputable sources, the overall integrity and longevity of the piping system can be maintained efficiently.