The global ceramics and glass manufacturing market is experiencing steady expansion, with the industrial kiln segment playing a pivotal role in production efficiency and cost optimization. According to Mordor Intelligence, the global industrial kiln market was valued at USD 33.7 billion in 2023 and is projected to grow at a CAGR of 5.8% from 2024 to 2029. This growth is driven by rising demand in construction, automotive, and advanced ceramics industries, particularly across Asia-Pacific and Latin America. As capital-intensive equipment, new kilns represent a significant investment—prompting increasing interest in high-performance, cost-effective second-hand kilns. Manufacturers with robust refurbishment programs and verifiable performance data are now gaining traction among small to mid-sized producers seeking to balance quality and affordability. Below, we explore nine leading manufacturers whose second-hand kilns are frequently available on the resale market, backed by reliability, technical documentation, and strong industry reputations.

Top 9 2Nd Hand Kilns For Sale Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Kilns Listings

Domain Est. 2001

Website: pottersweb.net

Key Highlights: For Sale Kilns Continental USA Dec 3rd, 2025 The following models are at the Olympic factory and can be shipped or picked up. FACTORY SECONDS and USED need …Missing: hand manufa…

#2 Items for Sale at Georgies’ Portland store!

Domain Est. 1996

Website: georgies.com

Key Highlights: Barely used – excellent condition. This kiln retails for $5200. Max temp 2408°F, 4.94 cubic ft, 21.65″ diam, 22.44″ deep, 9kW. 3ph power is ideal …Missing: 2nd manufacturer…

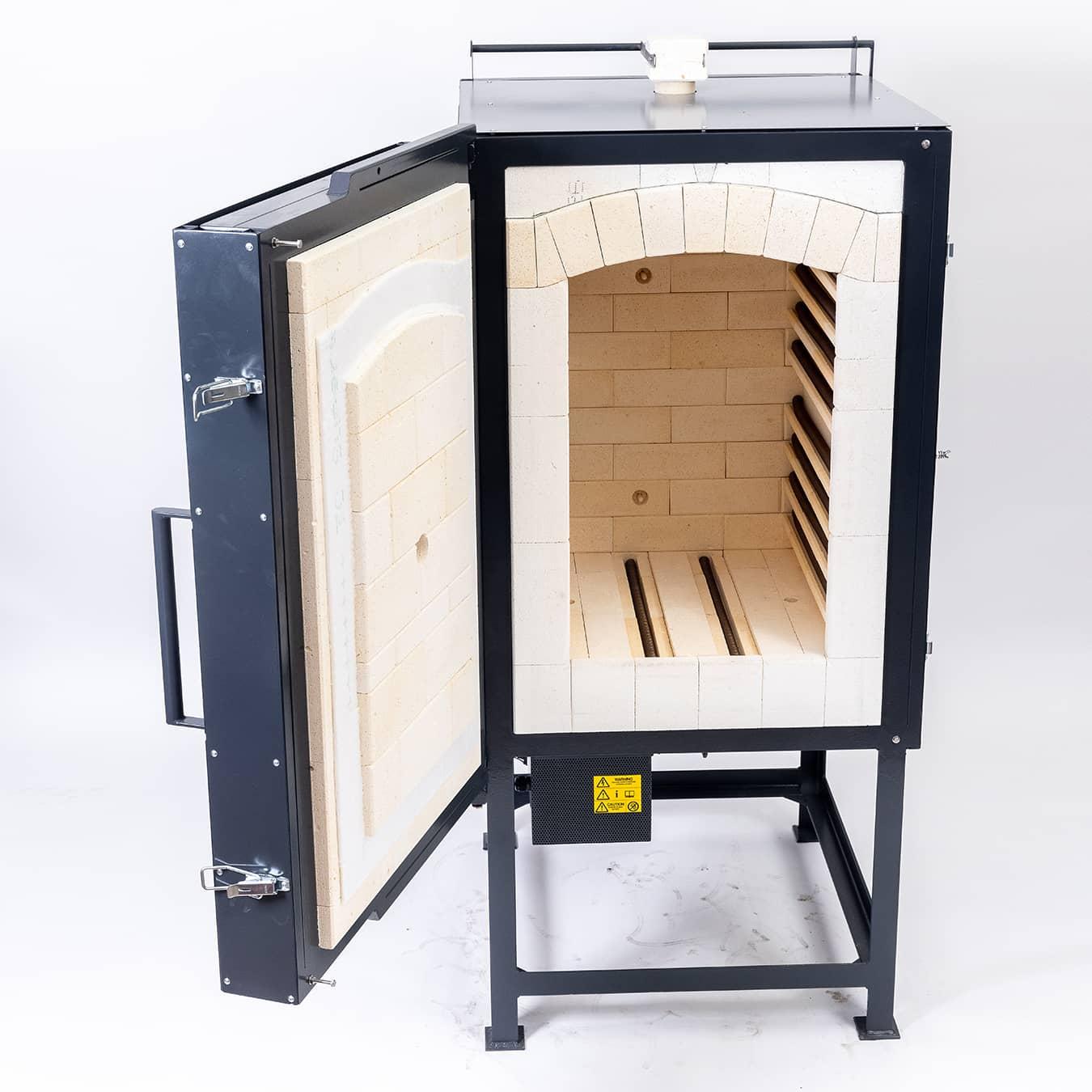

#3 L&L Pottery, School and Industrial Kilns

Domain Est. 1997

Website: hotkilns.com

Key Highlights: Find strong, easy-to-care-for electric pottery kilns. They are ideal for potters, schools, and businesses that require precision and long-lasting …Missing: 2nd hand…

#4 Northern Kilns

Domain Est. 2003

Website: northernkilns.com

Key Highlights: Premium handmade kilns built to last. Kilns Range British made. Built to last All our kilns are handmade by our specialist team at our workshops in Lancashire….

#5 Kilns We Sell

Domain Est. 2022

Website: allkilnservices.com

Key Highlights: We are proud to be a distributor for many reputable kiln and venting manufacturers. We are committed to providing high-quality kilns for use in schools, home ……

#6 Used Kilns For Sale

Domain Est. 1995

Website: surplusrecord.com

Key Highlights: Find new and used Kilns for sale from suppliers near you. Gh Studio, Harrop, L & L and more….

#7 Classroom Kilns For Sale

Domain Est. 1999

Website: glasscraftexpo.com

Key Highlights: Classroom Kilns For Sale. All Kilns being used during Glass Craft & Bead Expo are available to Pre-Purchase at fantastic prices! Kilns will be gently used ……

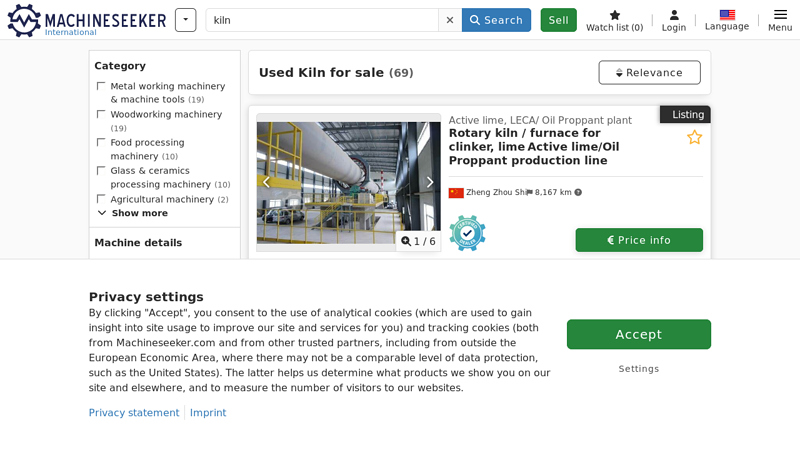

#8 Used Kiln for sale on Machineseeker.com

Domain Est. 1999

Website: machineseeker.com

Key Highlights: Used Kiln for sale on Machineseeker.com ✔️ great brands & offers available now ✔️ buy or sell Kiln on Machineseeker in the USA….

#9 Leading re

Domain Est. 2003

Website: theceramicshop.com

Key Highlights: We are a leading reseller of these kilns simply because we know and love these kilns. Please feel free to call us and learn more about the different sizes….

Expert Sourcing Insights for 2Nd Hand Kilns For Sale

H2: 2026 Market Trends for Second-Hand Kilns for Sale

As the global ceramics, glass, and advanced materials industries continue to evolve, the market for second-hand kilns is expected to experience significant shifts by 2026. Driven by sustainability demands, cost efficiency, and technological advancements, the resale market for industrial and studio kilns is gaining momentum. Below are the key trends shaping the 2026 landscape for second-hand kilns.

-

Growing Demand for Sustainable Manufacturing Solutions

Environmental concerns and corporate sustainability goals are pushing manufacturers and artisans toward energy-efficient and low-carbon production methods. Second-hand kilns offer a sustainable alternative to new equipment by reducing manufacturing waste and conserving raw materials. This eco-conscious shift is increasing demand, particularly among small studios, educational institutions, and startups seeking affordable yet reliable equipment. -

Expansion of Online Marketplaces and Global Trade

Digital platforms such as eBay, specialized industrial equipment exchanges, and regional auction sites are making it easier to buy and sell second-hand kilns globally. By 2026, these platforms are expected to feature enhanced verification systems, condition reporting, and logistics support, boosting buyer confidence. Cross-border trade in used industrial equipment is also expected to rise, especially in emerging markets where access to new kilns remains cost-prohibitive. -

Rising Costs of New Kilns Driving Resale Demand

The increasing price of new kilns—due to inflation, supply chain constraints, and advanced automation features—is prompting buyers to explore refurbished or used models. Many second-hand kilns, especially electric models from reputable brands like Skutt, Paragon, or Noborigama, retain high functionality for years. As a result, the resale value of well-maintained kilns is holding strong, creating a robust secondary market. -

Technological Obsolescence vs. Practical Longevity

While newer kilns come with digital controllers, IoT integration, and improved insulation, many older models remain effective for basic firing needs. Buyers in 2026 are becoming more discerning, prioritizing durability and repairability over cutting-edge features. This trend is fueling demand for mid-tier, older-generation kilns that balance performance with affordability. -

Increased Focus on Refurbishment and Certification

To meet reliability expectations, a growing number of dealers and third-party services now offer certified refurbishment programs. These include heating element replacements, refractory repairs, control system upgrades, and safety testing. By 2026, kilns sold with refurbishment guarantees or performance certifications are expected to command premium prices in the second-hand market. -

Regional Market Divergence

Developed markets such as North America and Western Europe are seeing high supply of used kilns due to studio closures, downsizing, or upgrades to energy-efficient models. In contrast, developing regions in Southeast Asia, Africa, and Latin America are experiencing rising demand as local ceramic industries expand. This imbalance is creating export opportunities for second-hand kiln resellers. -

Impact of Energy Efficiency Standards

Upcoming energy regulations in the EU and North America may affect the resale of older, less efficient kilns. Buyers will increasingly seek models that comply with new standards or are easily modifiable. As a result, kilns with replaceable components or upgrade paths will be more desirable in the 2026 market.

Conclusion

The second-hand kiln market in 2026 will be shaped by sustainability, digital access, and economic pragmatism. With proper maintenance and transparency, used kilns will remain a viable and attractive option across industrial, educational, and artistic sectors. Stakeholders—from sellers to buyers to refurbishers—must adapt to evolving standards and global demand patterns to capitalize on this growing niche.

H2: Common Pitfalls When Sourcing Second-Hand Kilns for Sale (Quality and Intellectual Property Concerns)

Sourcing second-hand kilns can be a cost-effective solution for businesses and artisans, but it comes with several potential pitfalls—particularly regarding equipment quality and intellectual property (IP) considerations. Failing to address these issues can lead to safety hazards, operational inefficiencies, legal complications, and financial losses.

1. Overlooking Mechanical and Structural Integrity

Used kilns may appear functional at first glance, but hidden wear and damage can compromise performance and safety. Common quality issues include cracked refractory linings, warped heating elements, malfunctioning thermocouples, and degraded insulation. These defects can lead to inconsistent firing results, higher energy consumption, or even catastrophic failure during operation.

Pitfall: Assuming visual inspection is sufficient without a thorough technical assessment.

Solution: Engage a qualified technician to inspect the kiln on-site or request detailed maintenance records and diagnostic reports.

2. Inadequate Documentation and Service History

Many second-hand kilns lack complete service logs, manuals, or calibration records. Without this documentation, it becomes difficult to verify maintenance schedules, past repairs, or compliance with safety standards. This lack of traceability increases the risk of unexpected breakdowns and complicates troubleshooting.

Pitfall: Purchasing a kiln without verifying its operational history.

Solution: Request comprehensive documentation from the seller; avoid purchases where records are missing or incomplete.

3. Compatibility with Current Power and Ventilation Systems

Older kilns may require non-standard voltage, phase configurations (e.g., 3-phase power), or specialized ventilation setups. Retrofitting to meet current facility requirements can be costly and time-consuming.

Pitfall: Assuming the kiln will integrate seamlessly with existing infrastructure.

Solution: Confirm electrical, gas, and exhaust specifications before purchase and evaluate compatibility with your facility.

4. Outdated or Proprietary Control Systems

Legacy kilns may use obsolete control panels or software that are no longer supported by manufacturers. Worse, some systems may be protected by proprietary firmware or software licenses.

Pitfall: Acquiring a kiln with outdated or locked-down control systems that cannot be updated or repaired due to IP restrictions.

Solution: Verify that control systems are compatible with modern interfaces and confirm whether firmware/software access or licensing is transferable.

5. Intellectual Property (IP) and Software Licensing Risks

Some industrial kilns include proprietary control software, automation algorithms, or patented features. Reselling or modifying such equipment without proper authorization may infringe on intellectual property rights.

Pitfall: Unknowingly violating software licenses or patents by reprogramming or upgrading the kiln’s control system.

Solution: Investigate whether the kiln includes licensed software and confirm transfer rights with the seller or original manufacturer. Avoid tampering with IP-protected components without legal clearance.

6. Non-Compliance with Safety and Environmental Regulations

Older kilns may not meet current emissions standards, safety codes (e.g., OSHA, CE), or energy efficiency requirements. Using non-compliant equipment can result in fines, operational shutdowns, or liability in case of accidents.

Pitfall: Assuming a working kiln is automatically compliant with regulations.

Solution: Audit the kiln against local and international standards before purchase and budget for necessary upgrades.

Conclusion

While second-hand kilns offer financial advantages, buyers must carefully evaluate quality, safety, and legal factors—especially concerning intellectual property and compliance. Due diligence, technical inspections, and proper documentation are essential to avoid costly mistakes and ensure long-term, reliable operation.

Logistics & Compliance Guide for Second-Hand Kilns For Sale

Understanding Shipping Requirements

Shipping second-hand kilns involves coordinating oversized or heavy equipment transport. Determine the kiln’s dimensions, weight, and disassembly needs. Most kilns require flatbed trucks or specialized freight due to size and fragility. Coordinate with certified heavy equipment movers and verify insurance coverage during transit. Always request lift-gate service if the delivery location lacks a loading dock.

Export and Import Regulations

If selling or shipping internationally, comply with both origin and destination country regulations. Check export controls on industrial equipment, especially if the kiln contains regulated components (e.g., high-temperature insulation materials). Importers must verify customs duties, VAT, or GST requirements. Ensure proper documentation, including a commercial invoice, bill of lading, and packing list with detailed specifications.

Environmental and Safety Compliance

Second-hand kilns may be subject to environmental regulations, particularly if they were used for hazardous materials processing. Confirm that the kiln meets current emissions standards in the destination region (e.g., EPA in the U.S. or EU Ecodesign Directive). Sellers should provide documentation of last maintenance and any decommissioning procedures. Buyers should inspect for residual contaminants or asbestos-containing materials, which are common in older models.

Electrical and Operational Standards

Verify that the kiln’s electrical specifications (voltage, phase, amperage) match the buyer’s facility. Non-compliant systems may require costly modifications or fail safety inspections. Ensure compliance with local electrical codes (e.g., NEC in the U.S., IEC standards internationally). Include all necessary manuals, wiring diagrams, and safety certifications with the sale.

Documentation and Certification Needs

Provide a comprehensive package including proof of ownership, maintenance history, and any prior compliance certifications. For industrial sales, a CE mark (Europe) or UL listing (North America) may be required for reinstallation. If unavailable, consider third-party inspection and recertification to meet local regulatory standards.

Insurance and Liability Considerations

Secure transport insurance covering damage, loss, or delay. Clarify liability terms between buyer and seller—FOB origin vs. FOB destination impacts responsibility during shipping. Sellers should disclose known defects to avoid legal claims post-sale. Buyers are advised to inspect the kiln upon delivery and document any damage immediately.

Installation and Local Permitting

After delivery, buyers may need permits for kiln reinstallation, particularly for gas-fired or high-emission models. Contact local fire, building, and environmental authorities to confirm zoning and operational permits. Professional installation by licensed technicians is strongly recommended to meet safety and code requirements.

In conclusion, sourcing second-hand kilns for sale can be a cost-effective and practical solution for artists, educators, ceramic studios, and small-scale manufacturers seeking reliable high-temperature equipment without the expense of new models. With careful research, buyers can find durable, functional kilns from reputable brands that offer excellent performance and longevity. Key considerations include assessing the kiln’s condition, verifying electrical or gas compatibility, inspecting heating elements and insulation, and ensuring compliance with safety standards. Purchasing from trusted sources—such as ceramic suppliers, educational institutions upgrading equipment, or industrial auctions—can increase the likelihood of a successful transaction. Additionally, factoring in potential refurbishment costs, shipping, and installation is essential for a realistic budget. Overall, with due diligence and clear requirements, acquiring a second-hand kiln can provide significant value and support creative or production needs for years to come.