The global bicycle components market is experiencing steady growth, driven by rising demand for bicycles across commuter, recreational, and e-bike segments. According to Grand View Research, the global bicycle market size was valued at USD 51.4 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.7% from 2023 to 2030, fueled by increasing urbanization, government initiatives promoting cycling, and growing environmental awareness. This surge in bicycle adoption directly impacts the demand for replacement parts, including inner tubes—particularly the widely used 26×1.95 size, common in hybrid, mountain, and comfort bikes. As the need for reliable, high-performance tubes grows, manufacturers are focusing on durability, puncture resistance, and lightweight materials to meet consumer expectations. In this evolving landscape, a select group of global suppliers has emerged as leaders in quality and innovation. Based on production scale, market reach, product specifications, and customer feedback, the following are the top 10 manufacturers of 26×1.95 bicycle tubes.

Top 10 26X1 95 Bicycle Tube Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Bike Tires

Domain Est. 1995

Website: schwalbe.com

Key Highlights: Schwalbe Bike Tires: Large selection ✓ Latest technology ✓ Order Schwalbe Bike Tires now!…

#2 Extra

Domain Est. 1995

Website: slime.com

Key Highlights: These are no ordinary bicycle tubes! Slime’s extra-strong bicycle tubes stop flats for 2 years because there is Slime sealant inside. All sizes available….

#3 Bike tubes & tubeless bike tire accessories

Domain Est. 1995

Website: trekbikes.com

Key Highlights: Find Bontrager bike tubes for road, mountain, and hybrid tires. Upgrade with accessories to go tubeless. | FREE SHIPPING on orders over $49!…

#4 Bicycle Wheels and Tubes

Domain Est. 1995

Website: acehardware.com

Key Highlights: Keep your ride smooth with bike tires and tubes from Ace. Shop inner tubes and wheels in multiple sizes for easy repairs and replacements….

#5 Bike Inner Tubes

Domain Est. 1996

Website: int.vittoria.com

Key Highlights: 6–7 day delivery Free 30-day returnsTubes and rim tape for any bike ride. Technical inner tubes and accessories to connect your rims to Vittoria performance….

#6 Continental Bicycle Tires

Domain Est. 2000

Website: continental-tires.com

Key Highlights: A seven-layer lightweight TPU Inner Tube for performance-focused and space-saving road, gravel and MTB riders. Discover our TPU Tubes. Bicycle Tire Knowledge….

#7 BICYCLE >> MTB tires

Domain Est. 2002

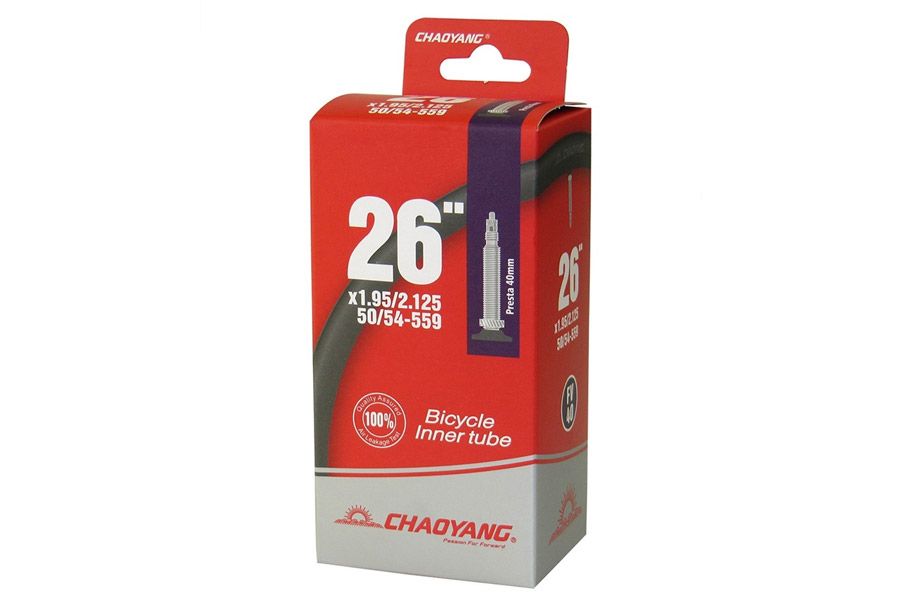

#8 Chaoyang 26×1.95/2.1255 Presta Bike Inner Tube 40mm

Domain Est. 2011

Website: santafixie.com

Key Highlights: In stock 30-day returnsHigh resistance for punctures. Measures: 26×1.95/2.125 (50/54-559). All butyl rubber made, excellent tensile elongation performance; Lightweight and durable …

#9 26 x 1.95 Inner Tube (50

Domain Est. 2018

Website: tubeking.co.uk

Key Highlights: 90-day returnsLooking for a 26 x 1.95 Inner Tube (50-559) ? Well, look no further. Here we have the perfect tube to match and not only that, it’s a premium branded Schwalbe ……

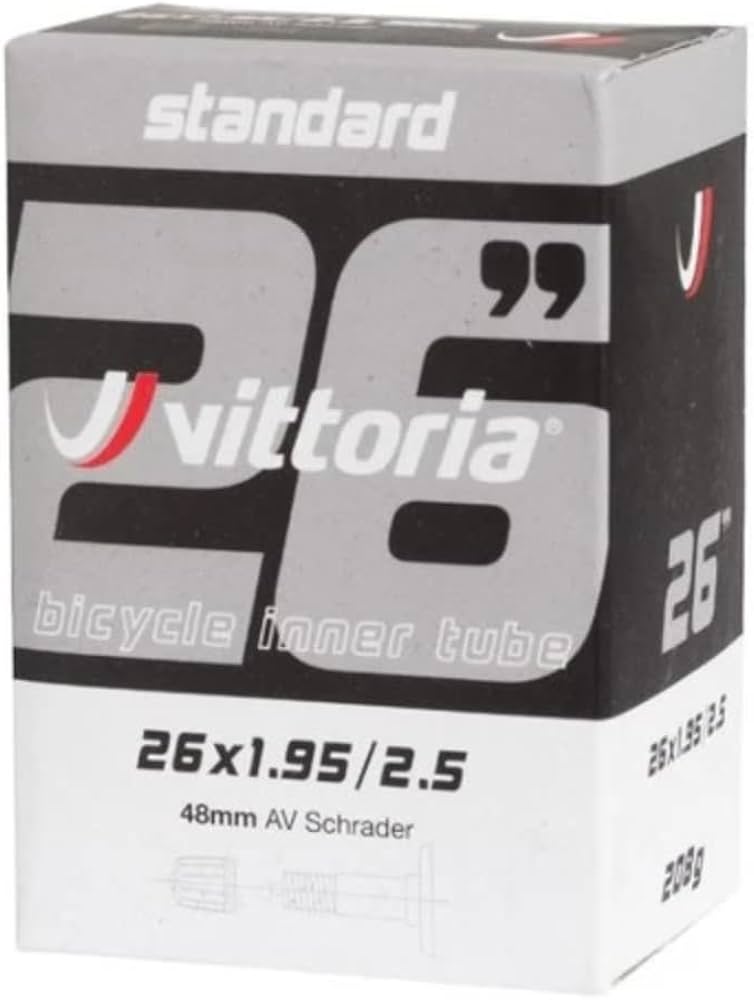

#10 Vittoria Standard 26×1.95/2.50 48mm Schrader Valve Inner Tube in …

Domain Est. 2021

Website: bikewiseandrun.com

Key Highlights: General purpose butyl inner tubes for everyday use. Standard inner tubes are made with high quality synthetic rubber with a wall thickness of 0.9 mm. Features:….

Expert Sourcing Insights for 26X1 95 Bicycle Tube

H2: 2026 Market Trends for 26×1.95 Bicycle Tube

The global market for the 26×1.95 bicycle tube is expected to experience steady but niche growth through 2026, driven by a combination of shifting consumer preferences, regional cycling infrastructure developments, and supply chain dynamics. As electric and urban mobility trends evolve, the demand for this specific tube size—commonly used in hybrid, comfort, and older mountain bikes—reflects broader transformations within the cycling industry.

-

Steady Demand in Mature and Developing Markets

The 26×1.95 tube remains popular in regions where 26-inch wheeled bicycles continue to dominate, such as parts of Asia, Latin America, and Africa. In countries like India, Indonesia, and Nigeria, affordable utility bicycles with 26-inch wheels are widely used for daily commuting and cargo transport. As urbanization and mobility needs grow, replacement tube demand—especially for durable, cost-effective options like the 26×1.95—will sustain market stability through 2026. -

Shift Toward Lightweight and Puncture-Resistant Materials

Manufacturers are increasingly adopting butyl rubber with reinforced liners or hybrid butyl-latex blends to improve air retention and durability. By 2026, expect greater availability of 26×1.95 tubes featuring puncture-resistant technology and reduced rolling resistance, catering to riders seeking reliability without upgrading their entire bike. This innovation helps extend the lifecycle of older 26-inch bikes, aligning with sustainability trends. -

Decline in High-End Adoption, Growth in Replacement Segment

While the 26-inch wheel standard has largely been replaced by 27.5” and 29” in performance mountain biking, the 26×1.95 tube maintains strong relevance in the replacement and repair market. Bicycle owners with legacy models or budget-friendly hybrids continue to depend on this size. The aftermarket segment is projected to account for over 70% of 26×1.95 tube sales by 2026, supported by retail and e-commerce channels. -

E-Bike Compatibility and Reinforcement Trends

As e-bikes grow in popularity—even in comfort and hybrid categories—there is rising demand for reinforced inner tubes capable of handling increased weight and torque. 26×1.95 tubes with thicker walls or higher PSI ratings (up to 85–90 PSI) are being developed to support low-to-mid-speed e-hybrid bikes. This adaptation ensures the tube remains viable in evolving e-mobility ecosystems. -

Sustainability and Environmental Pressures

Environmental regulations are pushing manufacturers to adopt recyclable materials and reduce plastic packaging. By 2026, leading brands are expected to offer eco-conscious 26×1.95 tubes with biodegradable valve caps and reduced carbon footprints. Additionally, the growth of tubeless tire systems may marginally impact demand, but the simplicity and repairability of inner tubes will preserve their relevance, especially in price-sensitive markets. -

Supply Chain and Pricing Outlook

Global rubber pricing and logistics remain volatile due to geopolitical tensions and climate-related disruptions in natural rubber-producing regions. However, efficient manufacturing in Southeast Asia (particularly Thailand and Vietnam) will help stabilize 26×1.95 tube prices. Average retail pricing is expected to increase moderately by 3–5% annually through 2026, mainly due to material and transportation costs.

Conclusion

While the 26×1.95 bicycle tube is no longer at the forefront of innovation, it remains a critical component for millions of cyclists worldwide. Its market through 2026 will be defined by resilience in replacement economies, incremental product improvements, and adaptation to e-bike integration. OEM demand may plateau, but aftermarket and developing-region sales will ensure sustained relevance for this enduring standard.

H2: Common Pitfalls When Sourcing a 26×1.95 Bicycle Tube (Quality and Intellectual Property Concerns)

Sourcing a 26×1.95 bicycle tube may seem straightforward, but several pitfalls—particularly related to quality and intellectual property (IP)—can impact performance, safety, and legal compliance. Being aware of these issues helps ensure you procure reliable, compliant products.

1. Inconsistent Quality Standards

Many suppliers, especially those from regions with less stringent manufacturing regulations, offer tubes that vary significantly in thickness, rubber composition, and valve durability. Low-quality tubes may burst under pressure, develop leaks quickly, or degrade prematurely due to UV exposure or temperature changes. Always verify material specifications (e.g., butyl rubber vs. regrind) and request independent test reports if sourcing in bulk.

2. Mislabeling and Dimensional Inaccuracy

Some tubes advertised as 26×1.95 may not fit true 26×1.95 tires due to poor manufacturing tolerances. This can lead to pinching during installation or uneven inflation. Confirm compatibility with actual tire models and check for standardized sizing labels (e.g., ISO 54-559).

3. Counterfeit or Branded Imitations

Well-known brands like Schrader or Presta valves, or reputable tube manufacturers, are often counterfeited. Suppliers may use logos, packaging, or branding that mimics patented designs or trademarks without authorization. This raises IP infringement risks, especially when importing in large volumes. Always verify authenticity through authorized distributors and request proof of IP clearance.

4. Valve Stem IP and Design Infringement

The design of valve stems (e.g., Schrader, Presta, or proprietary dual-valve systems) may be protected by utility or design patents. Sourcing generic tubes that replicate patented valve mechanisms without a license could expose buyers to legal liability, particularly in markets like the U.S. or EU with strong IP enforcement.

5. Lack of Compliance Documentation

Reputable suppliers should provide certifications (e.g., ISO, REACH, RoHS) confirming material safety and environmental compliance. Absence of such documentation may indicate substandard production processes or use of banned substances, increasing both quality and legal risks.

6. Hidden Costs from Returns and Warranty Claims

Low upfront pricing often correlates with higher failure rates. Tubes that fail shortly after use lead to customer dissatisfaction, returns, and warranty servicing—costs that outweigh initial savings. Evaluate total cost of ownership, not just purchase price.

7. Unverified Supplier Claims

Some suppliers claim “OEM quality” or “brand equivalent” without evidence. These vague terms can mislead buyers into assuming performance parity. Request samples, conduct durability testing, and audit supplier facilities when possible.

To mitigate these risks, work with vetted suppliers, conduct third-party inspections, and consult legal counsel when replicating branded designs. Prioritizing quality and IP compliance ensures safer products and protects your business from avoidable liabilities.

Logistics & Compliance Guide for 26X1.95 Bicycle Tube

Product Overview

The 26X1.95 bicycle tube is an inner tube designed to fit 26-inch diameter wheels with a width of approximately 1.95 inches. It is commonly used in mountain bikes, hybrid bikes, and some commuter bicycles. This guide outlines the logistics and compliance requirements for the safe and legal handling, transport, storage, and sale of this product.

Packaging and Labeling Requirements

Packaging Standards

- Tubes should be individually wrapped in recyclable polybags or cardboard boxes to prevent punctures and exposure to UV light.

- Bulk packaging for distribution should use sturdy corrugated cardboard boxes with internal dividers to minimize movement and damage during transit.

- Each master carton must clearly indicate quantity, SKU, batch number, and manufacturing date.

Labeling Compliance

- Labels must include:

- Product size (26×1.95)

- Valve type (e.g., Schrader or Presta) and length

- Manufacturer or brand name

- Country of origin

- Barcode (UPC or EAN)

- CE or equivalent regional compliance mark, if applicable

- All labels must be durable, legible, and resistant to fading or smudging.

Transportation and Storage

Shipping Conditions

- The tubes must be shipped in dry, temperature-controlled environments. Avoid exposure to extreme heat (>50°C) or cold (<-10°C).

- Do not stack pallets higher than recommended limits (typically 5–6 layers) to prevent crushing.

- Use weatherproof containers when shipping via sea or rail to prevent moisture damage.

Storage Guidelines

- Store in a cool, dry, and well-ventilated warehouse away from direct sunlight and ozone sources (e.g., electric motors).

- Keep away from oils, solvents, and other chemicals that may degrade rubber.

- Rotate stock using FIFO (first-in, first-out) method to minimize aging.

- Maximum recommended storage duration: 3 years from manufacturing date.

Regulatory Compliance

International Regulations

- REACH (EU): Ensure compliance with EU Regulation (EC) No 1907/2006. Confirm absence of restricted substances such as certain phthalates.

- RoHS (EU): Not typically applicable to rubber tubes, but verify if metal valve components comply.

- Proposition 65 (California, USA): Label products if containing chemicals listed by the state (e.g., certain rubber additives).

- TPCH (Toxics in Packaging Clearinghouse): Comply with heavy metal restrictions (lead, cadmium, mercury, hexavalent chromium) in packaging materials.

Import and Customs Documentation

- Provide commercial invoice, packing list, and bill of lading/air waybill.

- Include HS Code: 8714.19.00 (Other parts and accessories of cycles) – verify with local customs authority.

- Certificates of Origin may be required for preferential tariff treatment under trade agreements.

Safety and Environmental Considerations

Handling Precautions

- Train warehouse staff on proper manual handling techniques to avoid strain or injury.

- Avoid using sharp tools near unpacked tubes.

- Ensure fire safety measures are in place, as rubber products are combustible.

End-of-Life and Recycling

- Encourage recycling through rubber reprocessing programs where available.

- Provide information to customers on proper disposal methods.

- Comply with WEEE or local e-waste regulations if packaging includes electronic tracking tags.

Quality Assurance and Traceability

Batch Tracking

- Assign unique batch/lot numbers to each production run.

- Maintain records of raw materials, manufacturing dates, and inspection results for at least 5 years.

- Implement a recall protocol in case of non-compliance or defects.

Testing and Certification

- Conduct periodic burst pressure and air retention tests per ISO 1135 or equivalent standards.

- Validate valve durability and seal integrity.

- Retain test reports for audit purposes.

Conclusion

Proper logistics and compliance management ensures the 26X1.95 bicycle tube reaches customers in optimal condition while meeting global regulatory standards. Adherence to packaging, shipping, safety, and documentation protocols minimizes risk and enhances brand reliability.

In conclusion, sourcing a 26×1.95 bicycle tube requires careful consideration of compatibility, quality, supplier reliability, and cost-effectiveness. Ensuring the tube matches the tire dimensions and valve type (Presta or Schrader) is essential for proper fit and performance. Evaluating suppliers based on product quality, availability, customer reviews, and pricing will help secure a reliable supply. Whether sourcing for retail, repair services, or personal use, choosing durable tubes from reputable brands can reduce maintenance issues and enhance customer satisfaction. Additionally, exploring both local and online suppliers offers flexibility and potential cost savings. With the right sourcing strategy, obtaining 26×1.95 tubes can be efficient, economical, and sustainable in the long term.