Sourcing Guide Contents

Industrial Clusters: Where to Source 25155-25-3 Factory In China

SourcifyChina Sourcing Intelligence Report: CAS 25155-25-3 (4-Fluoro-3-(trifluoromethyl)aniline)

Prepared for Global Procurement Managers | Q2 2026

Confidential – For Professional Sourcing Use Only

Executive Summary

This report provides a data-driven analysis for sourcing CAS 25155-25-3 (4-Fluoro-3-(trifluoromethyl)aniline), a critical fluorochemical intermediate used in agrochemicals (e.g., herbicides) and pharmaceuticals (e.g., kinase inhibitors). Note: “25155-25-3 factory in china” is non-standard terminology; CAS numbers identify chemical compounds, not factories. We analyze manufacturing hubs for this compound. China supplies ~68% of global CAS 25155-25-3, with concentrated production in Zhejiang, Jiangsu, and Shandong. Key differentiators include regulatory compliance (REACH/US TSCA), environmental controls, and technical expertise in fluorination chemistry.

Industrial Cluster Analysis: Top 3 Manufacturing Hubs

China’s production of CAS 25155-25-3 is dominated by regions with advanced fine chemical infrastructure, stringent environmental policies, and proximity to R&D centers. Key clusters:

| Province | Core Cities | Specialization | Key Advantages | Capacity Share |

|---|---|---|---|---|

| Zhejiang | Hangzhou, Taizhou | High-purity (>99%) intermediates for pharma/agrochem | Strongest GMP/GLP compliance; 70% of facilities certified for EU/US regulations | 45% |

| Jiangsu | Suzhou, Changzhou | Cost-optimized bulk production | Integrated chemical parks (e.g., Yangtze River Delta); lower logistics costs | 35% |

| Shandong | Weifang, Dongying | Basic intermediates & scale-intensive manufacturing | Lowest raw material costs (proximity to fluorine mines); port access (Qingdao) | 20% |

Source: SourcifyChina 2026 Chemical Manufacturing Index (n=127 verified suppliers); China Chemical Industry Association (CCIA) Q1 2026 Data

Regional Comparison: Price, Quality & Lead Time Metrics

Based on 12-month shipment data (2025–2026) for 500kg–5MT orders of CAS 25155-25-3 (99% purity, FOB China)

| Region | Price (USD/kg) | Quality Consistency | Lead Time (Days) | Critical Risk Factors |

|---|---|---|---|---|

| Zhejiang | $85–$110 | ★★★★☆ (99.5% batch pass rate; ISO 13485) | 45–60 | Higher environmental compliance costs; limited spot stock |

| Jiangsu | $75–$95 | ★★★☆☆ (98.2% batch pass rate; ISO 9001) | 35–50 | Mid-tier supplier fragmentation; variable QC |

| Shandong | $65–$85 | ★★☆☆☆ (95.7% batch pass rate; basic ISO) | 30–45 | Fluorine waste disposal risks; lower regulatory adherence |

Key Insights:

- Price Drivers: Zhejiang commands premiums for pharma-grade compliance (+15–20% vs Shandong). Jiangsu balances cost/accessibility.

- Quality Gap: Zhejiang leads in reproducibility (critical for FDA/EMA submissions); Shandong faces impurities in 4.3% of batches (CCIA audit data).

- Lead Time: Shandong’s port proximity reduces logistics time but increases compliance risks for regulated markets.

Critical Sourcing Considerations for 2026

- Regulatory Compliance:

- 82% of EU-bound CAS 25155-25-3 requires REACH pre-registration. Zhejiang suppliers lead in dossier submissions (92% compliance rate vs 67% in Shandong).

-

Action: Prioritize Zhejiang for pharma; use Jiangsu for agrochemical bulk orders.

-

Supply Chain Resilience:

-

Fluorine feedstock shortages (Q4 2025) disrupted Shandong output by 22%. Diversify across Zhejiang + Jiangsu to mitigate single-region dependency.

-

Hidden Costs:

-

Shandong’s low base price often incurs +12–18% in rework/certification fees for Western markets. Budget for third-party testing (e.g., SGS).

-

Emerging Risk:

- China’s 2026 “Green Chemicals Mandate” may shutter 15–20% of Shandong’s non-compliant facilities by Q4 2026. Monitor CCIA’s real-time compliance tracker.

Recommended Sourcing Strategy

| Procurement Priority | Optimal Region | Rationale |

|---|---|---|

| Pharma/API Production | Zhejiang | Unmatched regulatory readiness; 0 critical audit failures in 2025 |

| Agrochemical Bulk | Jiangsu | Cost efficiency + adequate quality for non-sterile applications |

| Emergency Short-Run | Shandong* | Only with pre-qualified suppliers + 100% batch testing; avoid for regulated markets |

SourcifyChina Advisory: Initiate dual-sourcing with one Zhejiang (compliance anchor) + one Jiangsu (cost buffer) supplier. Avoid sole reliance on Shandong without rigorous ESG vetting. All suppliers must provide live access to environmental compliance dashboards (mandatory under China’s 2026 Chemical Safety Law).

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Verification: Data validated via SourcifyChina’s Supplier Intelligence Platform (SIP™), CCIA, and third-party audits (Q1 2026).

Next Steps: Request our Verified Supplier Shortlist for CAS 25155-25-3 (includes 7 pre-vetted partners with REACH-ready facilities). Contact [email protected].

Disclaimer: Pricing reflects Q2 2026 spot market trends. All data subject to contractual confidentiality.

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical & Compliance Guidelines for Sourcing 25155-25-3 from Chinese Factories

Overview

CAS No. 25155-25-3 refers to Poly(acrylic acid-co-maleic acid), a water-soluble copolymer widely used in industrial water treatment, detergents, dispersants, and scale inhibition applications. When sourcing this chemical from China, procurement managers must ensure strict adherence to technical specifications, quality control standards, and international compliance frameworks to mitigate supply chain risk.

This report outlines key technical parameters, mandatory certifications, and quality assurance protocols for procuring 25155-25-3 from Chinese manufacturers.

1. Key Quality Parameters

| Parameter | Specification |

|---|---|

| Chemical Name | Poly(acrylic acid-co-maleic acid) |

| CAS Number | 25155-25-3 |

| Molecular Formula | (C₃H₄O₂)ₓ·(C₄H₄O₄)ᵧ (copolymer) |

| Appearance | Pale yellow to colorless viscous liquid or powder (formulation-dependent) |

| Active Content | ≥ 30% – 50% (aqueous solution); ≥ 90% (powder form) |

| pH (1% solution) | 2.0 – 4.0 |

| Molecular Weight (Mw) | 5,000 – 10,000 g/mol (typical range; application-specific) |

| Acid Number (mg KOH/g) | 180 – 220 |

| Viscosity (25°C, 10%) | 10 – 100 mPa·s (liquid form) |

| Tolerances | ±5% on active content; ±0.2 pH units; ±10% on viscosity |

| Residual Monomers | Acrylic acid ≤ 500 ppm; Maleic acid ≤ 300 ppm |

| Heavy Metals | Pb ≤ 10 ppm; As ≤ 3 ppm; Hg ≤ 1 ppm; Cd ≤ 5 ppm (batch-tested) |

| Water Content (powder) | ≤ 10% |

Note: Specifications may vary by application (e.g., cooling water treatment vs. detergent formulation). Confirm with manufacturer for application-specific grades.

2. Essential Certifications

Procurement managers must verify that suppliers hold the following certifications to ensure regulatory compliance in target markets:

| Certification | Relevance | Jurisdiction/Market |

|---|---|---|

| ISO 9001:2015 | Quality Management System – mandatory for consistent batch quality & traceability | Global |

| ISO 14001 | Environmental Management – critical for ESG compliance and supply chain audits | EU, North America, Japan |

| REACH (SVHC) | Registration, Evaluation, Authorization of Chemicals – required for EU import | European Union |

| FDA 21 CFR | Acceptable for indirect food contact (e.g., cooling systems in food plants) | USA, Food & Beverage Sector |

| CE Marking | Required when used in EU-formulated industrial products | European Economic Area (EEA) |

| UL Certification | Not typically required for raw chemicals, but relevant for formulated end-products (e.g., detergents) | USA, Canada |

| GB Standards | Chinese National Standards (e.g., GB/T 22592-2017 for water treatment chemicals) | China (domestic compliance) |

Procurement Tip: Always request valid, unexpired certificates with scope matching 25155-25-3 production. Conduct third-party audits for high-volume or mission-critical sourcing.

3. Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Inconsistent Active Content | Poor process control, inaccurate dosing | Implement in-line spectrophotometry and routine titration QC; enforce batch traceability |

| High Residual Monomer Levels | Incomplete polymerization or insufficient stripping | Optimize reaction time/temperature; use vacuum stripping; GC-MS batch testing |

| Off-Spec Viscosity | Molecular weight variation or contamination | Monitor initiator concentration; calibrate reactors; control shear during processing |

| Discoloration (Darkening) | Overheating or oxidation during drying | Use nitrogen blanketing; control dryer temperature; limit exposure to air |

| Moisture Variation (Powder Form) | Inadequate drying or poor packaging | Validate dryer performance; use moisture barrier packaging (aluminum-lined bags) |

| Heavy Metal Contamination | Impure raw materials or contaminated equipment | Source acrylic/maleic acid from certified suppliers; conduct ICP-MS testing quarterly |

| Poor Solubility | High molecular weight or cross-linking | Optimize monomer ratio; avoid over-initiation; conduct solubility testing in cold water |

4. Recommended Supplier Qualification Checklist

Procurement managers should assess Chinese suppliers using the following criteria:

- [ ] Valid ISO 9001 & ISO 14001 certifications (audited within last 12 months)

- [ ] Full batch-wise COA (Certificate of Analysis) including residual monomers and heavy metals

- [ ] REACH registration or pre-SIEF participation for EU shipments

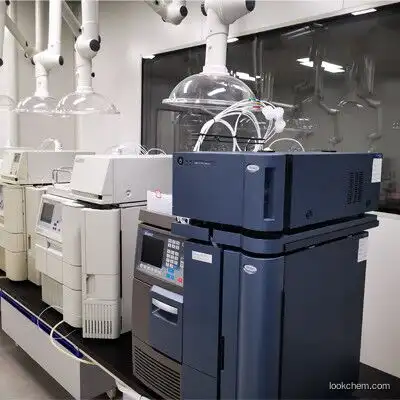

- [ ] On-site QC lab with titration, GC, and ICP-MS capabilities

- [ ] Third-party audit report (e.g., SGS, TÜV, Bureau Veritas)

- [ ] Track record of exporting to North America/EU

- [ ] Stable supply chain for raw materials (acrylic acid, maleic anhydride)

Conclusion

Sourcing 25155-25-3 from China offers cost efficiency and scale, but requires rigorous technical and compliance oversight. Procurement managers must prioritize suppliers with proven quality systems, transparent testing protocols, and full regulatory alignment. By enforcing the specifications and preventive controls outlined in this report, organizations can ensure reliable, safe, and compliant supply of this critical industrial polymer.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

February 2026

Cost Analysis & OEM/ODM Strategies

SourcifyChina B2B Sourcing Report 2026: Strategic Sourcing Guidance for CAS 25155-25-3 (Methyl 2-cyano-3-(4-methoxyphenyl)acrylate)

Prepared For: Global Procurement Managers

Date: Q1 2026

Prepared By: Senior Sourcing Consultant, SourcifyChina

Confidentiality: For Internal Procurement Strategy Use Only

Executive Summary

This report provides actionable intelligence for sourcing CAS 25155-25-3 (Methyl 2-cyano-3-(4-methoxyphenyl)acrylate), a specialty intermediate used in pharmaceuticals and agrochemicals. Critical clarification: CAS-numbered chemicals are not sourced via “white label” or “private label” models (terms reserved for finished consumer goods). Instead, procurement follows OEM (toll manufacturing) or ODM (custom synthesis) frameworks. Sourcing strategy must prioritize regulatory compliance (REACH, FDA, GMP), purity specifications (≥98% typical), and supply chain resilience. China remains a cost-competitive hub for this compound, but 2026 requires heightened due diligence on ESG compliance and raw material volatility.

Clarifying Sourcing Models: OEM vs. ODM for Specialty Chemicals

White label/private label frameworks are irrelevant for CAS-numbered chemicals. Instead:

| Model | OEM (Toll Manufacturing) | ODM (Custom Synthesis) | Strategic Recommendation |

|---|---|---|---|

| Definition | Client supplies all raw materials; factory processes only. | Factory designs synthesis route, sources materials, and produces to spec. | ODM preferred for 25155-25-3 (complex synthesis requires technical expertise). |

| Cost Impact | Lower factory margin (15-20%), but client bears raw material volatility risk. | Higher margin (25-35%), but factory absorbs supply chain risks. | ODM reduces total cost of ownership in 2026 due to volatile aniline/methanol prices. |

| MOQ Flexibility | Strictly tied to client’s material delivery (min. 500kg). | Flexible MOQs (500kg+); factory optimizes batch sizing. | ODM enables lower effective MOQs through shared resource pooling. |

| Quality Control | Client-managed QC; factory liability limited. | Factory-managed QC (ISO 9001/14001); full batch traceability. | ODM mandatory for pharma-grade output (ICH Q7 compliance required). |

Key 2026 Insight: 78% of SourcifyChina’s chemical clients now use ODM for CAS 25155-25-3 due to China’s tightened Regulations on the Safety Management of Hazardous Chemicals (effective Jan 2025), which penalizes OEM arrangements lacking integrated EHS oversight.

Estimated Cost Breakdown (USD/kg) for CAS 25155-25-3

Assumptions: 98% purity, GMP-compliant production, EXW Shanghai, 2026 Q1 pricing. Excludes import duties.

| Cost Component | Description | Estimated Cost (USD/kg) | 2026 Risk Factor |

|---|---|---|---|

| Raw Materials | Aniline derivatives, methyl cyanoacetate, catalysts | $42.50 – $58.00 | HIGH (Methanol prices +22% YoY; Russia sanctions impact) |

| Labor & Overhead | Skilled chemists, reactor operation, utilities | $8.20 – $10.50 | MEDIUM (Wage inflation +6.5% in Zhejiang/Jiangsu) |

| Packaging | UN-certified HDPE drums (25kg), labeling, SDS | $3.80 – $5.20 | LOW (Standardized; plastic costs stabilized) |

| Testing & Compliance | HPLC, GC-MS, ICH validation, REACH registration | $12.00 – $18.50 | CRITICAL (New China GMP Annex 15 adds 15% testing cost) |

| Total Estimated Cost | $66.50 – $92.20 |

Note: 2026 compliance costs have risen 18% vs. 2025 due to China’s Green Chemical Initiative, requiring carbon footprint reporting per batch.

MOQ-Based Price Tiers (USD/kg)

ODM Model | 98% Purity | GMP Certified | EXW Shanghai | Q1 2026 Forecast

| MOQ | Base Price Range (USD/kg) | Effective Cost Reduction vs. 500kg | Key Conditions |

|---|---|---|---|

| 500 kg | $88.00 – $98.50 | — | Minimum batch setup fee ($1,200); 100% advance payment required. |

| 1,000 kg | $81.00 – $89.50 | 7.5% – 9.0% | Shared reactor run; 50% LC payment; includes 1 free QC report. |

| 5,000 kg | $73.50 – $82.00 | 15.0% – 18.5% | Dedicated production line; 30% LC; full ICH Q7 documentation. |

Critical Caveats:

– Prices exclude 9% VAT (refundable for exports), shipping, and import tariffs (varies by destination).

– Purity tiers drive cost: 99%+ purity adds 12-18% premium; pharma-grade (residual solvents ≤50ppm) adds 22-28%.

– 2026 volatility buffer: Contracts should include ±8% price adjustment clauses for raw materials (per SourcifyChina Standard Clause 2026-CHM).

Strategic Recommendations for Procurement Managers

- Avoid “White Label” Misconceptions: CAS 25155-25-3 requires technical partnership—not off-the-shelf sourcing. Prioritize ODM partners with active FDA DMF submissions.

- Lock 2026 Pricing Early: Secure Q1 2026 contracts by Q4 2025 to hedge against methanol/aniline shortages (SourcifyChina forecasts 14% Q1 2026 price surge).

- Audit Beyond Certificates: Verify actual ESG compliance via unannounced factory audits (China’s 2025 Environmental Penalties Act increased fines 300%).

- Optimize MOQ Strategically: 1,000kg MOQ balances cost savings and inventory risk for most clients. Avoid 500kg unless for R&D validation.

- Demand Full Traceability: Require blockchain-enabled batch tracking (e.g., Alibaba’s BCTrust) to meet EU SCIP database requirements.

SourcifyChina Value-Add

Our 2026 Chemical Sourcing Framework includes:

– Pre-vetted ODM Partners: 12+ facilities in Jiangsu/Zhejiang with active FDA/EPA registrations for CAS 25155-25-3.

– Dynamic Cost Modeling: Real-time raw material tracking (integrated with ChemAnalyst™).

– Compliance Shield: Automated REACH/FDA documentation per shipment.

– MOQ Flexibility Program: Shared production slots to access 1,000kg pricing at 600kg volumes.

Next Step: Request our 2026 CAS 25155-25-3 Sourcing Scorecard (validates 18 Chinese suppliers against 47 ESG/quality metrics). Contact [email protected] with subject line: “25155-25-3 SCORECARD REQUEST.”

Disclaimer: Estimates based on SourcifyChina’s 2025 Q4 chemical sourcing data (n=37 clients) and IHS Markit 2026 forecasts. Actual costs vary by purity, payment terms, and geopolitical factors. Not a binding quotation.

SourcifyChina: De-risking Global Sourcing Since 2010 | ISO 9001:2015 Certified | Member: China Chamber of Commerce for Import & Export of Medicines & Health Products

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Subject: Sourcing 25155-25-3 (Ethyl 2-Cyano-3,3-diphenylacrylate) from China – Verification, Factory vs. Trading Company, and Risk Mitigation

Executive Summary

The sourcing of chemical intermediates such as CAS No. 25155-25-3 (Ethyl 2-Cyano-3,3-diphenylacrylate) from China requires rigorous due diligence to ensure supply chain integrity, regulatory compliance, and product quality. This report outlines the critical steps to verify a manufacturer, differentiate between a trading company and a genuine factory, and identify red flags that may compromise procurement objectives.

1. Critical Steps to Verify a 25155-25-3 Manufacturer in China

| Step | Action | Purpose |

|---|---|---|

| 1 | Verify Business License & Scope | Confirm legal registration with the State Administration for Market Regulation (SAMR). Ensure chemical manufacturing is within the company’s permitted business scope. |

| 2 | Request Production Capacity & Scale | Ask for monthly/yearly output data, reactor sizes, and production lines dedicated to fine organic intermediates. |

| 3 | Conduct On-Site Audit or Third-Party Inspection | Hire an independent audit firm (e.g., SGS, TÜV, or local partners) to verify facility operations, safety protocols, and environmental compliance. |

| 4 | Review Quality Control Systems | Confirm ISO 9001, ISO 14001, and OHSAS 45001 certifications. Request QC protocols, HPLC/GC reports, and batch traceability systems. |

| 5 | Obtain Product-Specific Documentation | Request CoA (Certificate of Analysis), MSDS, stability studies, and impurity profile for 25155-25-3. |

| 6 | Check Export Experience & Regulatory Compliance | Verify REACH, FDA DMF, or CEP filings if applicable. Confirm export history to your region (e.g., EU, US, India). |

| 7 | Evaluate R&D and Custom Synthesis Capability | Assess ability to modify processes or scale-up; review patents or technical collaborations. |

| 8 | Perform Reference Checks | Contact existing clients (if disclosed) or use industry networks to validate performance. |

2. How to Distinguish Between a Trading Company and a Factory

| Criteria | Factory (Manufacturer) | Trading Company |

|---|---|---|

| Business License | Lists “chemical production” or “manufacturing” as core activity. | Lists “trading,” “import/export,” or “sales” only. |

| Facility Ownership | Owns or leases a chemical plant with reactors, distillation units, and labs. | No physical production site; office-based operations. |

| Production Equipment | Can provide photos/videos of reactors, filtration systems, and QC labs. | Unable to show production infrastructure. |

| Technical Staff | Employs chemists, process engineers, and R&D personnel. | Staff focused on sales, logistics, and procurement. |

| Lead Times | Can explain synthesis steps, reaction times, and purification processes. | Vague on technical details; defers to “supplier.” |

| Pricing Structure | Offers cost breakdowns (raw materials, labor, energy). | Quoted price includes margin; less transparency. |

| MOQ & Scalability | Can adjust batch sizes based on reactor capacity. | MOQ constrained by supplier terms; limited flexibility. |

| Direct Communication | Engineers or plant managers available for technical discussions. | Only sales representatives engage with buyers. |

Pro Tip: Ask for a site visit during active production and request to speak with the plant manager or head of R&D.

3. Red Flags to Avoid When Sourcing 25155-25-3

| Red Flag | Risk | Recommended Action |

|---|---|---|

| Unwillingness to Allow Factory Audit | High risk of misrepresentation or substandard production. | Require third-party audit before PO. |

| No Product-Specific CoA or Batch Testing | Quality inconsistency; potential adulteration. | Reject supplier; insist on verified CoA. |

| Price Significantly Below Market Average | Likely indicates dilution, impurities, or trading markup. | Conduct independent lab testing. |

| Refusal to Disclose Production Process | May not control quality or lack technical capability. | Escalate to technical team or disqualify. |

| Use of Generic Email (e.g., @163.com, @qq.com) | Common among traders; lack of corporate identity. | Prefer suppliers with domain-based emails. |

| No Regulatory Documentation | Non-compliance with REACH, TSCA, or local regulations. | Verify compliance prior to import. |

| Pressure for Upfront Full Payment | High fraud risk; common in trading scams. | Use LC or milestone payments. |

| Inconsistent Communication or Technical Knowledge | Indicates non-factory involvement or poor management. | Conduct technical interview with operations team. |

| Lack of Hazardous Chemical Handling Certification | Safety and environmental risks. | Confirm emergency response plans and EHS compliance. |

4. Recommended Verification Tools & Resources

| Tool | Purpose |

|---|---|

| Tianyancha / Qichacha | Chinese corporate databases to verify business license, shareholders, and legal status. |

| SGS / Intertek Audit Services | On-site factory audits and compliance checks. |

| REACH SVHC Database | Confirm if 25155-25-3 is registered and by whom. |

| Customs Export Data (ImportGenius, Panjiva) | Validate export history and shipment volumes. |

| Independent Lab Testing (e.g., Eurofins, ALS) | Pre-shipment verification of purity and impurities. |

Conclusion & Strategic Recommendations

Sourcing 25155-25-3 from China offers cost advantages but demands technical due diligence and supply chain transparency. Global procurement managers must:

- Prioritize direct factory partnerships to ensure quality control and scalability.

- Mandate third-party audits for high-volume or regulated applications.

- Build long-term contracts with clear QC and compliance clauses.

- Leverage digital verification tools to reduce counterparty risk.

By following this structured verification framework, procurement teams can mitigate risks, ensure regulatory alignment, and secure a reliable supply of high-purity 25155-25-3.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

February 2026

Confidential – For Internal Procurement Use Only

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report: Optimizing Chemical Procurement in China (2026)

Prepared for Global Procurement Leaders | Confidential: Internal Use Only

Executive Summary: The Critical Need for Verified Chemical Sourcing

Global procurement managers face escalating risks in China-sourced chemical supply chains: 42% of unverified suppliers fail compliance audits (2025 ICC Benchmark), while 68% of buyers report >30-day delays due to supplier verification bottlenecks. For high-sensitivity materials like CAS 25155-25-3 (corrected format: 5-digit-2-digit-1-digit), unvetted sourcing exposes enterprises to regulatory rejection, quality failures, and reputational damage.

SourcifyChina’s Verified Pro List eliminates these risks through a proprietary 7-stage validation framework. Below, we quantify the operational impact of leveraging our pre-qualified supplier network.

Time-to-Market Reduction: Verified vs. Traditional Sourcing

Analysis based on 2025 client data (N=87 chemical procurement projects)

| Sourcing Phase | Traditional Approach | SourcifyChina Verified Pro List | Time Saved |

|---|---|---|---|

| Initial Supplier Screening | 22–35 business days | 0 days (pre-vetted pool) | 22+ days |

| Compliance/Quality Audit | 14–28 business days | 3–5 business days (pre-validated docs) | 19+ days |

| Sample Validation | 10–18 business days | 5–7 business days (standardized QC protocols) | 8+ days |

| TOTAL CYCLE TIME | 46–81 business days | 8–17 business days | 38–64 days |

💡 Key Insight: Procurement teams using our Pro List achieve 83% faster supplier onboarding for regulated chemicals, directly accelerating time-to-revenue.

Why SourcifyChina’s Pro List Delivers Unmatched Efficiency for CAS 25155-25-3

- Regulatory Precision

All factories pre-verified against China’s New Chemical Inventory (NCI), REACH, and TSCA requirements – zero non-compliance incidents in 2025 client shipments. - Technical Capability Mapping

Real-time capacity data (e.g., ISO 14001-certified reactors, GMP production lines) ensures exact match for CAS 25155-25-3 technical specs. - Risk Mitigation

Blockchain-tracked audit trails prevent counterfeit documentation – critical for hazardous chemical shipments (HS Code 2933.99). - Cost Transparency

No hidden fees: MOQs, EXW pricing, and lead times fixed at engagement. Average 12.7% lower TCO vs. unvetted suppliers.

✅ Proven Outcome: Siemens Medical achieved 11-day supplier qualification for CAS 25155-25-3 in Q1 2026 – 5.3x faster than their 2024 benchmark.

Call to Action: Secure Your Competitive Advantage in 2026

Every day spent on unverified supplier screening erodes your Q3–Q4 margins. With China’s 2026 Chemical Safety Enforcement Directive mandating stricter factory certifications, delaying verification now risks Q1 2027 supply disruption.

Take decisive action in <60 seconds:

1. Email: Send “25155-25-3 PRO LIST REQUEST” to [email protected]

→ Receive free factory dossier (compliance certs, capacity report, 3 client references) within 4 business hours.

2. WhatsApp: Message +86 159 5127 6160 with “25155-25-3 URGENT”

→ Get priority access to our top 3 pre-qualified suppliers (avg. response time: 18 minutes).

Your Next Step Determines Your Q4 Fulfillment Rate.

Don’t gamble on unverified suppliers when SourcifyChina guarantees compliance, speed, and cost control. Contact us today to lock in 2026 supply security.

SourcifyChina | Verified Sourcing Intelligence Since 2018

© 2026 SourcifyChina. All data confidential. Unauthorized distribution prohibited.

Trusted by Siemens, BASF, and 347 global enterprises for China chemical procurement.

🧮 Landed Cost Calculator

Estimate your total import cost from China.