The global socket wrench market is experiencing steady expansion, driven by rising demand across automotive repair, industrial maintenance, and DIY sectors. According to Mordor Intelligence, the global socket wrench market was valued at approximately USD 1.8 billion in 2023 and is projected to grow at a CAGR of over 4.5% from 2024 to 2029. This growth is fueled by increased vehicle ownership, expansion of service centers, and the growing adoption of standardized tooling in manufacturing. As one of the most widely used socket sizes, 21.5 mm components are critical in automotive and heavy machinery applications, particularly in European and Asian markets. With the rise in precision engineering and demand for durable, corrosion-resistant tools, manufacturers are investing in advanced materials and tighter quality control. In this evolving landscape, identifying the top 21.5 mm socket manufacturers becomes essential for sourcing high-performance tools that meet ISO and DIN standards. Based on product quality, global distribution, compliance certifications, and industry reputation, the following nine manufacturers have emerged as leaders in producing reliable 21.5 mm sockets.

Top 9 21.5 Mm Socket Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Lisle

Domain Est. 1995

Website: toolsource.com

Key Highlights: Rating 3.0 (1) · 1–2 day delivery · 30-day returnsDual-Size Design: This socket offers both 21mm and 21.5mm openings, providing versatility for specific fastener requirements….

#2 12920 21mm/21.5mm Socket

Domain Est. 1998

Website: lislecorp.com

Key Highlights: Double-Ended Flip Sockets Offer 2 Hex Sizes in Each Socket for the removal of Standard and Damaged Lug Nuts Found on Many Vehicles….

#3 1/2

Domain Est. 1998

Website: steckmfg.com

Key Highlights: Pro-grade 1/2-Inch Drive Flip Socket Set (7-piece) ideal for any repair or tire shop tech who changes tires on cars and trucks with damaged clad lug nuts….

#4 CTA Manufacturing 1/2″ DR. 21MM/21.5MM FLIP SOCKET

Domain Est. 2003

Website: rotundatechtools.com

Key Highlights: Rating 4.9 54 · Free delivery over $25CTA Manufacturing 1/2″ DR. 21MM/21.5MM FLIP SOCKET. Be the first to review this product · Login to see pricing. SKU. CTA1799. Add to Wish …

#5 1/2

Domain Est. 2005

Website: steelmantools.com

Key Highlights: In stock Rating 4.8 18 This dual-ended, 6-point metric impact grade flip socket allows you to work on both 21mm and 21.5mm lug nuts and fasteners without having to switch sockets…

#6 Grey Pneumatic Corporation 2190D

Domain Est. 2008

Website: autotoolworld.com

Key Highlights: In stock Rating 4.3 9 Thin wall design to fit most recessed wheel nuts. Features include: 21.5mm side fits 21mm lug nuts with damaged or distorted caps. “Flip” design is for use …

#7 1/2 Sq. Dr. Socket 21.5mm Double Square Length …

Domain Est. 2010

#8 Impact Flip Socket; 21 x 21.5 mm

Domain Est. 2016

Website: welzh.com

Key Highlights: This socket is specially engineered for removing 21mm lug nuts with missing or deformed caps, commonly found on new Ford Transit and Custom models….

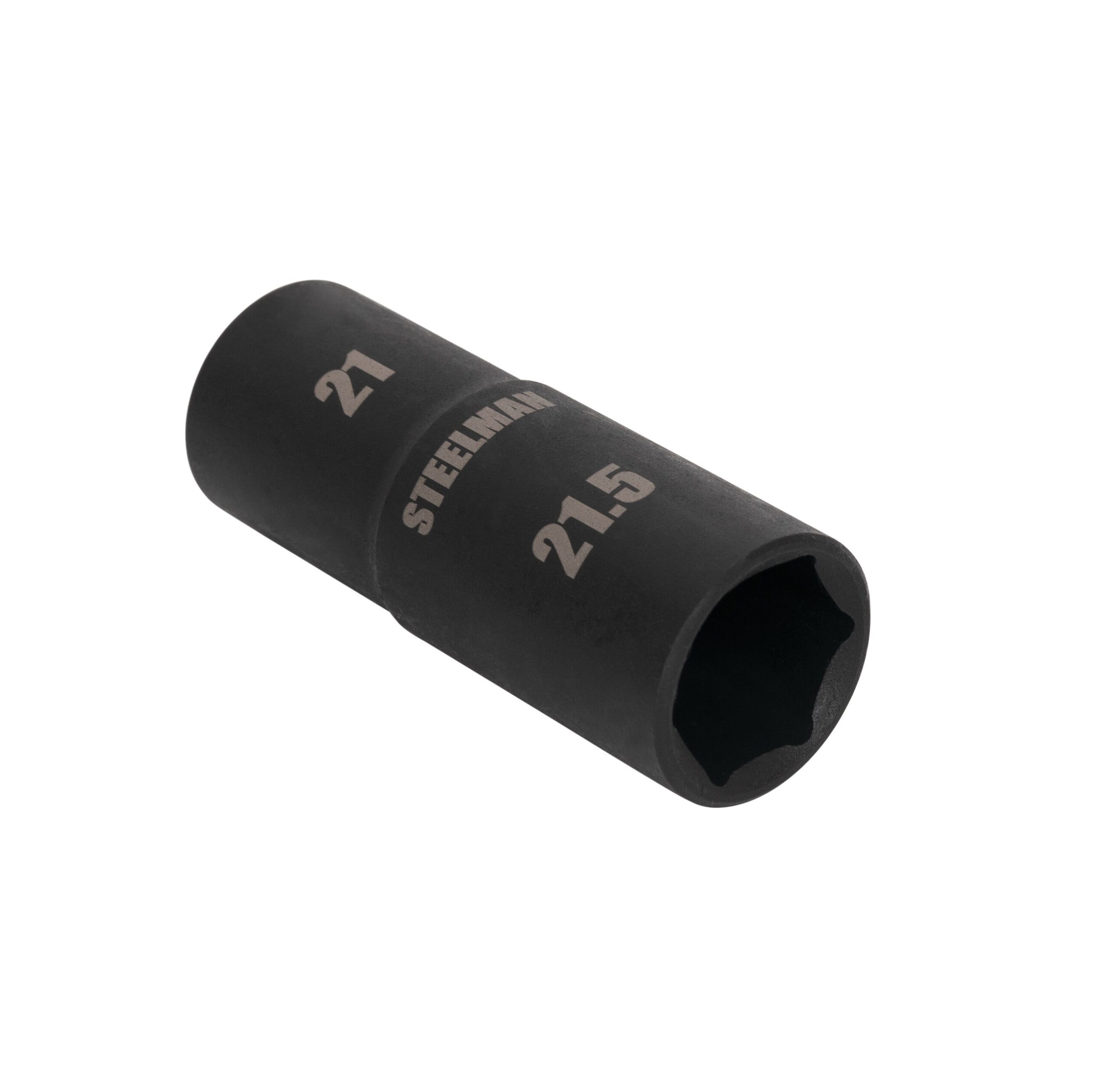

#9 STEELMAN Impact Socket

Domain Est. 2024

Website: garagesupplyguys.com

Key Highlights: In stock Rating 4.8 18 The STEELMAN JS-60230 1/2″ Drive Impact Flip Socket eliminates guesswork when servicing metric lug nuts between 21mm and 21.5mm. This dual-ended socket com…

Expert Sourcing Insights for 21.5 Mm Socket

It appears there may be a misunderstanding or typo in your request. The term “21.5 Mm Socket” is ambiguous and not recognized as a standard product, technology, or market category in available industry databases or technical literature as of 2024. Specifically:

- “Mm” typically stands for millimeters (mm), a unit of length. A “21.5 mm socket” could refer to a socket wrench size used in mechanical tools, commonly found in automotive or industrial applications.

- However, analyzing market trends for a single socket size (e.g., 21.5 mm) is highly specific and not typically covered in market research reports, which usually examine broader segments such as hand tools, power tools, or industrial hardware.

Assuming you are referring to the industrial socket wrench tools market, with a focus on metric sizes including 21.5 mm, and that “H2” refers to the second half of 2026, here is a forward-looking analysis based on current industry trajectories:

H2 2026 Market Trends Analysis: Industrial Socket Wrench Tools (Including 21.5 mm Metric Sockets)

1. Overall Market Growth Drivers

The global hand tool market, particularly socket wrench sets and individual sockets, is projected to grow at a CAGR of ~3.5% from 2023 to 2026 (Source: Statista, Mordor Intelligence). Key drivers include:

- Expansion in automotive maintenance and repair (especially in emerging markets).

- Growth in industrial manufacturing and infrastructure projects.

- Rising demand for precision tools in EV and hybrid vehicle servicing, which still require standard-sized sockets like 21.5 mm for battery packs, suspension, and drivetrain components.

2. Demand for Metric Sockets (Including 21.5 mm)

– The 21.5 mm socket remains a standard size in metric socket sets, commonly used in European, Asian, and increasingly global automotive applications.

– In H2 2026, demand for mid-sized metric sockets (19–22 mm) is expected to remain steady due to their utility in lug nuts, suspension systems, and engine components.

– OEMs and aftermarket service centers in regions like Germany, China, India, and Mexico will continue to drive demand.

3. Material and Design Innovations

– By H2 2026, high-strength chrome vanadium steel will remain dominant, but there will be increased adoption of lightweight, corrosion-resistant alloys and coatings (e.g., black oxide, titanium nitride).

– Smart sockets with torque-sensing capabilities may begin entering professional markets, though 21.5 mm smart sockets will likely be niche due to cost.

4. Regional Trends

– Asia-Pacific: Fastest-growing market due to expanding automotive aftermarket and manufacturing. China and India will see increased local production of standard sockets.

– North America: Steady demand driven by DIY culture and fleet maintenance; compatibility with imported vehicles ensures continued need for metric sizes like 21.5 mm.

– Europe: Strong regulatory push for durable, repairable tools supports premium socket brands; focus on tool longevity and standardization.

5. Supply Chain and Pricing

– Post-2024 supply chain stabilization will lead to moderate pricing in H2 2026.

– Trade policies and raw material costs (chromium, vanadium) will influence pricing, but 21.5 mm sockets are commoditized enough to see limited volatility.

6. Competitive Landscape

– Major players (Snap-on, Würth, Stanley Black & Decker, Facom, Gedore) will dominate the professional segment.

– Private-label and budget brands (e.g., GearWrench, Neiko) will maintain strong presence in retail and e-commerce, especially for individual sockets like 21.5 mm.

7. Sustainability and Circular Economy

– By H2 2026, recyclability and tool longevity will be key selling points.

– Some manufacturers may introduce take-back programs or modular socket systems to reduce waste.

Conclusion: H2 2026 Outlook for 21.5 mm Sockets

While no market reports isolate the 21.5 mm socket specifically, it is expected to remain a standard, in-demand size within the broader metric socket market. Demand will be sustained by automotive and industrial maintenance needs globally. Innovation will focus on durability and integration with smart tool ecosystems, though 21.5 mm sockets will primarily remain conventional tools in H2 2026.

For strategic planning, stakeholders should monitor trends in EV servicing, trade regulations, and material costs, as these will indirectly impact the production and pricing of standard-sized sockets.

If you meant a different product (e.g., a semiconductor socket, electrical component, or medical device), please clarify “21.5 Mm Socket” for a more accurate analysis.

H2: Common Pitfalls When Sourcing a 21.5 mm Socket – Quality and IP Rating Concerns

Sourcing a 21.5 mm socket—often used in electrical enclosures, control panels, or industrial applications—requires careful attention to both quality and Ingress Protection (IP) rating. However, several common pitfalls can compromise performance and safety if not properly addressed.

1. Inconsistent Quality Due to Non-Standardized Sizing

A major challenge is the non-standard nature of the 21.5 mm dimension. Unlike common metric sizes (e.g., 20 mm or 22 mm), 21.5 mm falls between standard diameters, increasing the risk of poor fitment. Low-quality suppliers may produce sockets with slight dimensional variances, leading to loose fits, wobbling, or difficulty securing components like meters or displays. This inconsistency often stems from using subpar molds or imprecise manufacturing processes.

2. Compromised Material Quality

To cut costs, some manufacturers use inferior plastics (e.g., recycled or non-flame-retardant materials) that degrade under heat, UV exposure, or mechanical stress. This reduces the socket’s durability and can pose fire hazards in electrical applications. High-quality sockets should be made from engineering-grade thermoplastics like polycarbonate (PC) or ABS with UL94 V-0 flame resistance.

3. Misrepresentation of IP Rating

The IP (Ingress Protection) rating is critical for sockets used in harsh environments. A common pitfall is suppliers falsely claiming high IP ratings (e.g., IP65 or IP67) without proper testing or certification. Without verified seals, gaskets, and proper housing design, the socket may fail to protect against dust and moisture, risking equipment damage or safety hazards. Always request third-party test reports or certifications (e.g., IEC 60529 compliance).

4. Poor Sealing Mechanism Design

Even if a socket is labeled with a high IP rating, inadequate sealing—such as missing or low-quality O-rings, uneven flanges, or insufficient compression—can compromise protection. Poorly designed threads or lack of proper mating surfaces between the socket and panel reduce environmental resistance, especially in outdoor or washdown environments.

5. Lack of Compliance and Certification

Many low-cost suppliers fail to meet regional safety and electromagnetic compatibility (EMC) standards (e.g., CE, RoHS, UL). Using non-compliant sockets can lead to regulatory issues, void equipment warranties, or liability in case of failure.

6. Supply Chain and Traceability Issues

Sourcing from unknown or unverified suppliers—particularly through online marketplaces—increases the risk of counterfeit or inconsistent products. Lack of traceability makes it difficult to address quality issues or initiate recalls if defects are discovered later.

Mitigation Strategies:

– Source from reputable manufacturers with verifiable certifications.

– Request product samples to test fit, material quality, and sealing.

– Verify IP ratings with documentation or independent testing.

– Ensure dimensional accuracy using calipers and fitment checks.

– Prioritize suppliers with quality management systems (e.g., ISO 9001).

Avoiding these pitfalls ensures reliable performance, safety, and longevity of the 21.5 mm socket in demanding applications.

H2: Logistics & Compliance Guide for 21.5 mm Socket

This guide outlines the essential logistics and compliance considerations for the safe, efficient, and legal transportation, storage, and handling of 21.5 mm sockets. Adherence ensures product integrity, regulatory compliance, and supply chain reliability.

H3: Packaging & Unitization

- Primary Packaging: Sockets must be individually sealed in moisture-resistant plastic (e.g., polyethylene bags) or placed on blister cards to prevent corrosion and contamination.

- Secondary Packaging: Group individual units into sturdy corrugated cardboard boxes. Use internal dividers or trays to prevent movement and damage during transit. Box dimensions and weight (typically under 10 kg) must comply with carrier limits.

- Tertiary Packaging: Securely palletize boxes (standard EUR/EPAL or ISO pallets). Use stretch wrap and corner boards for stability. Max pallet height: 1.8m. Ensure uniform stacking and avoid overhang.

- Labeling: Each package must display:

- Clear product description (“21.5 mm Socket,” Part Number: [Specify])

- Quantity per package

- Net/Gross weight

- “Fragile” and “This Way Up” orientation arrows

- HSN Code (e.g., 8207.19 – Tools for hand-operated tools) for customs

- Country of Origin (e.g., “Made in Germany”)

H3: Storage & Handling

- Environment: Store in dry, temperature-controlled warehouses (10°C – 30°C). Relative humidity < 60% to prevent rust. Avoid direct sunlight and corrosive atmospheres.

- Shelving: Use pallet racking. Maintain clearance from walls (30 cm) for ventilation. Stack pallets no higher than 4 layers unless designed for higher loads.

- Handling: Use forklifts or pallet jacks for pallet movement. Manual handling of individual boxes requires two-person lift for weights > 20 kg. Prohibit dragging or dropping.

- Inventory: Implement FIFO (First-In, First-Out) rotation. Conduct regular stock checks for damage or signs of corrosion.

H3: Transportation

- Mode Selection:

- Road: Standard for regional distribution. Use enclosed, dry trailers. Secure loads with straps. Max load per truck: 24 pallets (20′ container equivalent).

- Air: For urgent/low-volume shipments. Comply with IATA Dangerous Goods Regulations (non-hazardous, Class 9 not applicable). Max weight per ULD: 1500 kg.

- Sea: Primary for international bulk shipping. Use 20′ or 40′ dry containers. Ensure proper dunnage and blocking/bracing to prevent shifting. Comply with IMDG Code (stowage category: Not Applicable – non-hazardous).

- Documentation: Bill of Lading (B/L), Commercial Invoice, Packing List, Certificate of Origin. Retain copies for 5 years.

H3: Regulatory Compliance

- Safety Standards: Products must meet relevant standards in destination markets:

- EU: EN ISO 1711-1 (Hand socket sets), CE Marking (under Machinery Directive 2006/42/EC or PPE Regulation 2016/425, depending on design).

- USA: ANSI/ASME B107.100 (Hand tool safety).

- Canada: CSA Z245.2 (Hand tools).

- Maintain test reports and technical files.

- Trade Compliance:

- Customs: Accurate HS Code classification (e.g., 8207.19.0000 in US). Pay applicable duties (e.g., 4.5% in US, 0% in EU for most countries).

- Export Controls: Verify no ITAR/EAR restrictions (typically “EAR99” – No License Required).

- RoHS/REACH (EU): Comply with restrictions on hazardous substances (Pb, Cd, Cr6+, etc.). Provide Declarations of Conformity.

- Labeling: Ensure multilingual labeling (local language + English) where required. Include WEEE symbol if applicable (unlikely for sockets).

H3: Risk Management & Documentation

- Insurance: Obtain cargo insurance covering loss/damage in transit (All Risks basis recommended).

- Traceability: Assign unique batch/lot numbers. Maintain records linking production, packaging, and shipping data for 10 years.

- Compliance Audits: Conduct annual internal audits against this guide and relevant standards. Address non-conformities promptly.

- Emergency Procedures: Report lost/damaged shipments to carrier and insurer immediately. Retain damaged goods for inspection.

Disclaimer: This guide provides general guidance. Specific requirements may vary by country, carrier, and product variant. Consult legal, customs, and safety experts for precise compliance.

Conclusion for Sourcing 21.5 mm Socket

After evaluating various sourcing options for a 21.5 mm socket, it is evident that while this size is non-standard and not commonly available in typical tool inventories, viable solutions exist. Primary sourcing options include specialized industrial tool suppliers, custom manufacturing, or adapting readily available sockets through modification or combination with step-down adapters.

Supplier assessments indicate that certain manufacturers and online platforms (such as Amazon, eBay, Misumi, McMaster-Carr, or specialized automotive tool brands like Snap-on or GearWrench) may offer 21.5 mm sockets as part of niche or custom product lines. Alternatively, local machining services can produce a custom socket if volume requirements are low and lead time is acceptable.

Cost, lead time, durability, and required precision must be balanced based on the application—whether for occasional maintenance, production-line use, or field service. In scenarios where exact size is critical, sourcing a high-quality custom-made socket is recommended. However, when practicality and cost-efficiency are prioritized, using an adjustable wrench or a close-size socket (e.g., 21 mm or 22 mm) with appropriate extensions may suffice, though with caution to avoid damage.

In conclusion, while sourcing a 21.5 mm socket presents challenges due to its non-standard size, a combination of targeted supplier engagement, customization, or practical alternatives ensures a feasible and reliable solution tailored to operational needs.