The global small engine components market, which includes critical parts such as carburetors for utility and industrial applications, is experiencing steady growth driven by rising demand in outdoor power equipment, agricultural machinery, and generator sets. According to Grand View Research, the global small gasoline engine market size was valued at USD 13.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. A key segment within this market is the 212cc engine category, particularly those based on the widely adopted Predator engine platform—a popular choice among go-kart builders, DIY enthusiasts, and small equipment manufacturers. Due to their reliability and aftermarket adaptability, 212cc Predator engines have spurred growing demand for compatible performance parts, especially high-efficiency carburetors. This has led to an influx of manufacturers specializing in carburetor solutions tailored to this engine variant. Driven by e-commerce expansion, the global aftermarket for engine components is projected to gain further momentum, creating a competitive landscape of suppliers focused on durability, fuel efficiency, and ease of integration. The following list highlights the top eight manufacturers leading innovation and market penetration in the 212cc Predator engine carburetor space.

Top 8 212Cc Predator Engine Carburetor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Carburetors

Domain Est. 1998

Website: arcracing.com

Key Highlights: $30 delivery · 30-day returnsBSP/Clone RuiXing Carburetor. This is the stock OEM carb for the BSP/Dupor 196cc Clone engines. Nothing has been altered or changed on these carbs….

#2 Predator 212cc OEM Parts

Domain Est. 1999

Website: dynocams.com

Key Highlights: 5.0 23 Shop for original OEM parts for Predator 212cc engines at DynoCams. Keep your engine running smoothly with our reliable components….

#3 Predator 212 Non

Domain Est. 1998

Website: eccarburetors.com

Key Highlights: 4.7 470 EC is the leader in small engine carburation. We have blueprinted and design carburetor solutions for the Wildcat to increase power and torque for your ……

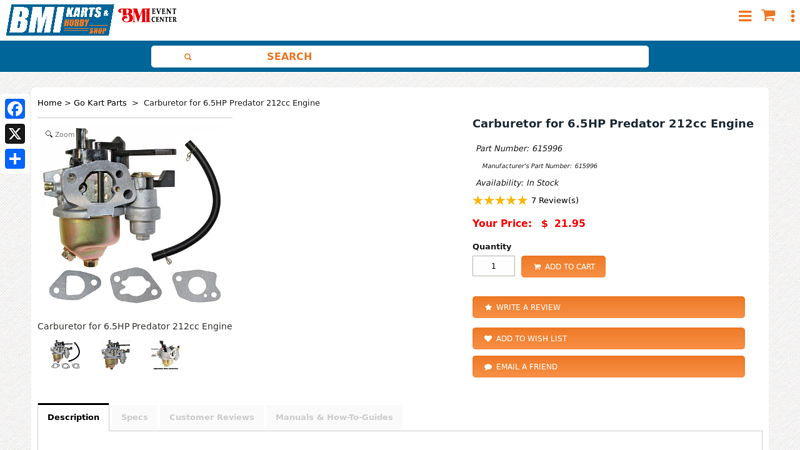

#4 Carburetor for 6.5HP Predator 212cc Engine

Domain Est. 2000

Website: bmikarts.com

Key Highlights: In stock Rating 5.0 (7) Carburetor with On/Off Switch for 6.5HP Predator 212cc Engine (Hemi and Non-Hemi); Includes manual choke lever, fuel hose, and 3 gaskets. Customer Reviews…

#5 Mikuni Carbs and Parts

Domain Est. 2010

Website: ombwarehouse.com

Key Highlights: Free delivery over $200 · 60-day returnsOur Mini Bike Predator 212cc Mikuni Carbs and Parts promise high performance and reliability. The package includes 1 pcs carburetor,1 pc ai…

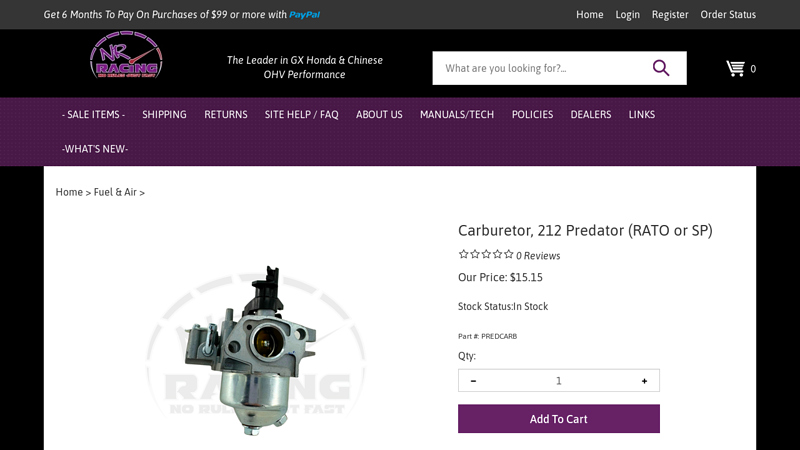

#6 Carburetor, 212 Predator (RATO or SP)

Domain Est. 2010

Website: nrracing.com

Key Highlights: In stockStock replacement for all 212 Predators. Fits both new and old-style. *New take-off carb. May be either “Rato” or “SP” ……

#7 Predator 212cc harbor freight engine Carburetor with gaskets

Domain Est. 2010

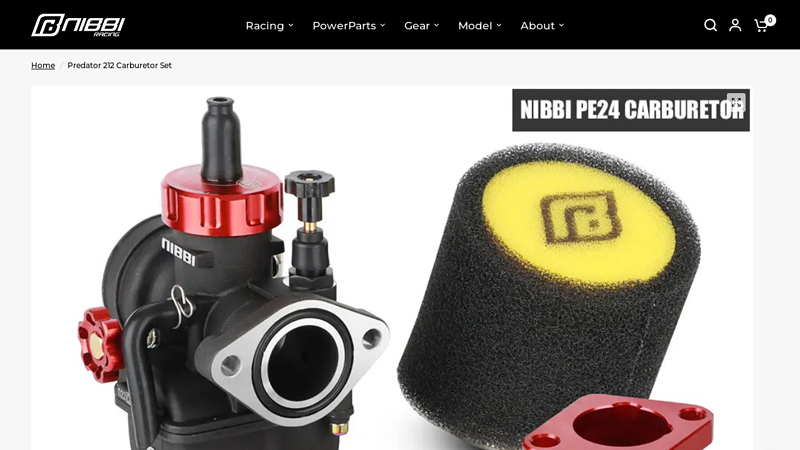

#8 Predator 212 Carburetor Set

Domain Est. 2012

Website: nibbiracing.com

Key Highlights: In stock Rating 5.0 (4) The kit includes brand-new NIBBI PE 24 Flange Carburetor, 48mm Air Filter and black CNC Inlet Pipe Manifold, gaskets, oilter filter and a set of mounting …

Expert Sourcing Insights for 212Cc Predator Engine Carburetor

H2: 2026 Market Trends for 212cc Predator Engine Carburetor

The market for the 212cc Predator engine carburetor is expected to undergo notable shifts by 2026, influenced by evolving consumer demands, regulatory standards, and technological advancements in small internal combustion engines. As a widely used component in outdoor power equipment such as go-karts, mini bikes, pressure washers, and custom utility vehicles, the 212cc Predator engine—originally modeled after the Honda GX210—remains popular in the aftermarket and DIY sectors. Below are the key market trends anticipated for its carburetor segment in 2026:

-

Increased Demand in DIY and Racing Communities

The 212cc Predator engine continues to be a staple in hobbyist and performance modification circles. By 2026, the carburetor market will likely see sustained demand from DIY enthusiasts seeking performance upgrades, such as high-flow carburetors, adjustable jets, and billet components. Online marketplaces and specialty retailers are expected to expand their inventory to cater to custom builds requiring enhanced fuel delivery systems. -

Shift Toward Fuel Efficiency and Emissions Compliance

With tightening EPA and CARB regulations on small off-road engines (SORE), manufacturers and aftermarket suppliers are developing carburetors designed for cleaner combustion and reduced emissions. By 2026, we anticipate a rise in carburetor models featuring optimized air-fuel mixing, improved idle stability, and compatibility with ethanol-blended fuels. Retrofit kits and EPA-compliant carburetor replacements will become more prevalent. -

Growth of Aftermarket Performance Parts Ecosystem

The 212cc Predator engine’s modular design fosters a robust aftermarket. Carburetor manufacturers are increasingly offering bolt-on performance kits—including dual carb setups, velocity stacks, and CV (constant vacuum) carburetor conversions—aimed at boosting horsepower and throttle response. This trend will likely accelerate through 2026 as consumer interest in engine tuning grows. -

Competition from Fuel-Injected Alternatives

While carbureted engines remain dominant in budget and entry-level applications, the gradual adoption of electronic fuel injection (EFI) in small engines may pressure the carburetor market. However, due to cost, simplicity, and ease of repair, carburetors will retain strong market presence—especially in developing markets and rural applications—through 2026. -

Expansion of E-Commerce and Global Supply Chains

Online platforms such as Amazon, eBay, and specialized engine parts websites will continue to dominate carburetor distribution. By 2026, global suppliers—particularly from Asia—are expected to offer high-quality, low-cost carburetor alternatives, increasing competition and driving innovation in materials (e.g., die-cast aluminum, anti-corrosion coatings). -

Focus on Reliability and Maintenance Simplicity

End users prioritize durability and ease of maintenance. Carburetor designs with accessible adjustment screws, tool-less cleaning features, and improved float bowl seals will gain market share. Brands emphasizing ruggedness and compatibility with low-grade fuels will appeal to industrial and agricultural users.

In summary, the 2026 market for the 212cc Predator engine carburetor will be shaped by a blend of performance-driven customization, regulatory adaptation, and digital retail expansion. While facing long-term challenges from electrification and fuel injection, carburetors will remain a vital component in the small engine ecosystem, particularly for affordable, serviceable, and modifiable platforms like the Predator 212cc.

Common Pitfalls Sourcing a 212cc Predator Engine Carburetor (Quality & IP Concerns)

When sourcing a replacement carburetor for a 212cc Predator engine—commonly found in go-karts, mini bikes, pressure washers, and other small equipment—buyers often encounter significant challenges related to quality and intellectual property (IP). Being aware of these pitfalls can help avoid poor performance, safety hazards, and legal risks.

Low-Quality Aftermarket Carburetors

Many replacement carburetors marketed for the 212cc Predator engine are low-cost, mass-produced units from third-party manufacturers. These often suffer from:

- Poor Material Quality: Use of inferior aluminum alloys or plastic components that degrade quickly under heat and vibration.

- Inconsistent Manufacturing Tolerances: Leads to air/fuel mixture imbalances, resulting in hard starting, rough idling, or poor engine performance.

- Faulty or Missing Components: Gaskets, jets, or adjustment screws may be poorly machined or omitted, requiring additional purchases or modifications.

- Short Lifespan: These carburetors may fail within weeks due to internal corrosion or clogging from substandard fuel bowl materials.

Impact: Users often experience reduced engine efficiency, increased fuel consumption, and frequent replacements—negating any initial cost savings.

Intellectual Property (IP) and Design Infringement

The Predator engine is based on the Honda GX200 design, and while the engine itself is often sold under a different brand, the carburetor design closely mirrors OEM specifications.

- Patent and Trademark Concerns: Many aftermarket carburetors are direct clones of OEM designs (e.g., Walbro or Tillotson carburetors used in Honda engines). These clones may infringe on intellectual property rights, even if sold openly online.

- “Compatible With” Labeling Loopholes: Vendors often label products as “compatible with” Predator or Honda engines to avoid direct IP liability, but the physical design may still be a replica.

- Legal and Ethical Risks: While enforcement against individual consumers is rare, purchasing counterfeit or IP-infringing parts supports illegal manufacturing practices and may void equipment warranties.

Impact: Supporting IP violations can harm innovation and lead to supply chain instability. In commercial applications, businesses may face liability or reputational damage.

Lack of Standardization and Compatibility Issues

Not all 212cc Predator engines are identical—differences in model years, emissions standards, or aftermarket modifications can affect carburetor fit.

- Misleading Product Listings: Sellers may list carburetors as “fits all 212cc Predator engines” when subtle differences in throttle linkages, fuel inlet orientation, or mounting flanges make them incompatible.

- No OEM Specifications: Aftermarket carburetors rarely provide detailed technical specs (e.g., jetting sizes, venturi diameter), making tuning difficult.

Impact: Buyers risk receiving a carburetor that doesn’t fit or perform properly, leading to return hassles or unsafe engine operation.

Recommendations to Avoid Pitfalls

- Buy from Reputable Suppliers: Choose vendors with verified reviews and clear return policies.

- Look for Brand-Named Aftermarket Parts: Consider reputable brands like Tillotson, Walbro, or Aisan—even if more expensive, they offer better reliability and compliance.

- Verify Compatibility: Double-check carburetor model numbers, mounting dimensions, and fuel inlet type before purchasing.

- Avoid Suspiciously Low Prices: Extremely cheap carburetors are often poor quality or counterfeit.

- Check for Compliance and Certification: Where applicable, ensure parts meet EPA or CARB emissions standards, especially for equipment used in regulated environments.

By understanding these common pitfalls, buyers can make informed decisions that balance cost, performance, and legal compliance when sourcing a 212cc Predator engine carburetor.

H2: Logistics & Compliance Guide for 212cc Predator Engine Carburetor

This guide provides essential logistics and compliance information for the safe, legal, and efficient handling, transportation, storage, and use of the carburetor for the 212cc Predator engine (typically found on engines like the Harbor Freight 67072 / 6.5HP model). Adherence is critical for safety, regulatory compliance, and product performance.

H2: 1. Handling & Storage

- Pre-Handling Inspection:

- Visually inspect packaging for damage (dents, punctures, moisture) upon receipt. Document and report any damage immediately to the carrier and supplier.

- Verify part number (e.g., 691751, 692131, or equivalent) matches the order and engine model.

- Safe Handling:

- Wear cut-resistant gloves when handling sharp edges of brackets or linkages.

- Avoid dropping or impacting the carburetor – internal components (float, needle valve, jets) are sensitive.

- Keep the carburetor upright (bowl down) during handling and transport to prevent fuel leakage and float damage.

- Protect the throttle shaft and choke lever from forceful twisting or bending.

- Storage Conditions:

- Environment: Store in a clean, dry, well-ventilated area with stable temperature (ideally 10°C – 30°C / 50°F – 86°F) and low humidity (<60%).

- Position: Store upright (bowl down) in original packaging or on a clean, non-abrasive surface. Never store inverted.

- Contamination: Keep sealed from dust, dirt, moisture, and corrosive vapors (e.g., solvents, fuels, acids). Cover if necessary.

- Separation: Store away from fuels, oils, solvents, and strong oxidizing agents. Do not store near open flames or ignition sources.

- Duration: Avoid long-term storage (>12 months) without protective measures (e.g., fogging oil in fuel passages if pre-assembled). Check manufacturer recommendations.

- Inventory: Practice First-In, First-Out (FIFO) inventory rotation.

H2: 2. Transportation

- Packaging:

- Use the original manufacturer’s packaging whenever possible. It is designed for protection.

- If repackaging is necessary, use rigid, crush-resistant boxes with ample internal cushioning (bubble wrap, foam inserts) to immobilize the carburetor and prevent movement. Seal securely.

- Securing Loads:

- Ensure boxes are properly stacked and secured within vehicles (trucks, containers) to prevent shifting, crushing, or falling during transit.

- Use straps, load bars, or dunnage to block and brace pallets or loose boxes.

- Environmental Protection:

- Protect from exposure to rain, snow, direct sunlight (UV degradation), and extreme temperatures during loading, unloading, and transit. Use tarps or climate-controlled transport if necessary.

- Avoid transporting with hazardous chemicals that could leak or off-gas.

- Documentation: Ensure shipping manifests accurately list the contents (e.g., “Engine Carburetor – Non-Hazardous”). Retain records.

H2: 3. Regulatory Compliance

- Material Safety Data Sheet (MSDS/SDS):

- Obtain: Acquire the SDS from the carburetor manufacturer/supplier. This is mandatory.

- Review: Understand contents regarding potential hazards (e.g., small residual fuel/priming oil, cleaning solvents used in manufacturing, zinc/aluminum alloys). Focus on Section 3 (Composition), Section 7 (Handling), and Section 13 (Disposal).

- Availability: Keep the SDS readily accessible to personnel involved in handling, storage, or maintenance (e.g., in a safety binder, digital system).

- Hazardous Materials (HazMat) Classification:

- General Rule: A new, empty carburetor is typically NOT classified as a hazardous material for transport under major regulations (DOT 49 CFR, IATA DGR, IMDG Code) because it contains no significant quantity of hazardous substances.

- Critical Exception: If the carburetor contains residual fuel, oil, or cleaning solvent (e.g., improperly drained, used, or damaged), it MAY become classified as hazardous waste (e.g., ORM-D, Class 3 Flammable Liquid). Never ship a carburetor known to contain fuel.

- Used/Contaminated Units: Handle used carburetors (especially those removed from engines) as potential hazardous waste due to fuel, oil, and leaded solder content. Follow local RCRA (US) or equivalent regulations for collection, labeling, storage, and disposal. Consult your Environmental Health & Safety (EHS) department.

- Emissions & Air Quality Compliance (End-Use):

- CARB (California Air Resources Board): The 212cc Predator engine and its carburetor are typically NOT CARB-compliant for sale or use in California or areas adopting California emissions standards. Using a non-compliant engine/carburetor in these areas violates regulations. Verify local requirements.

- EPA (US): While small engines have EPA standards, the Predator 212cc is often sold for “recreational” or “off-highway” use, bypassing stricter on-road standards. Ensure end-use application aligns with the engine’s certification.

- Other Jurisdictions: Check local environmental regulations (e.g., EU Stage V, Canadian EPA) if exporting or operating internationally. Non-compliance can lead to fines and equipment seizure.

- RoHS/REACH (Materials): While primarily impacting electronics, be aware that the carburetor may contain restricted substances (e.g., lead in solder, certain alloys). Suppliers should provide compliance declarations. Manage end-of-life disposal responsibly.

H2: 4. Installation & Use (Compliance Aspects)

- Fuel Compatibility: Use only the fuel type specified for the engine (typically unleaded gasoline with ≤10% ethanol (E10)). Higher ethanol blends (E15, E85) can damage carburetor components (rubber seals, plastic parts, zinc alloys).

- Maintenance:

- Clean using only carburetor cleaner compatible with its materials (avoid harsh chlorinated solvents unless specified). Follow safety precautions on the cleaner’s SDS.

- Dispose of cleaning waste and rags according to local hazardous waste regulations.

- Tampering: Never modify the carburetor (e.g., drilling jets, removing air bleed restrictions) to increase power or alter fuel mixture. This violates emissions regulations (EPA, CARB), voids warranties, creates safety hazards (overheating, fire), and may be illegal.

H2: 5. Disposal

- New/Unused Carburetors: If defective or obsolete, dispose of as general industrial waste unless contaminated. Recycle metals (aluminum, brass, steel) if possible.

- Used Carburetors:

- Treat as Hazardous Waste: Due to potential residual fuel, oil, and lead.

- Drain: Drain any residual fuel/oil into approved containers (following fuel storage regulations).

- Clean: If possible and safe, clean to remove gross contamination (using appropriate methods/SDS).

- Recycle: Separate and recycle metals through certified recyclers.

- Hazardous Waste Stream: Dispose of the entire unit or contaminated parts (e.g., gaskets, diaphragms) through licensed hazardous waste disposal contractors. Document disposal.

- Comply: Follow all applicable federal (RCRA), state, provincial, and local waste disposal regulations.

Disclaimer: This guide provides general information. Specific regulations (especially emissions like CARB) and best practices evolve. Always consult:

* The carburetor manufacturer’s specifications and SDS.

* Your organization’s EHS policies.

* Local, state/provincial, and national regulatory authorities (EPA, CARB, DOT, Transport Canada, etc.).

* Licensed hazardous waste disposal providers.

In conclusion, sourcing a carburetor for a 212cc Predator engine requires careful consideration of compatibility, quality, and reliability. The most effective approach is to identify the correct carburetor model—typically the CV-style or Walbro-type carburetor used in the Predator 212cc engines—and ensure that replacements or upgrades match the engine’s specifications. Aftermarket carburetors are widely available from online retailers, automotive parts suppliers, and specialized engine performance shops, often offering improved adjustability and durability. It is essential to verify fitment, read customer reviews, and choose reputable suppliers to avoid compatibility issues or subpar performance. Whether restoring, repairing, or enhancing the engine, selecting the right carburetor contributes significantly to optimal fuel delivery, smooth operation, and overall engine efficiency. With proper research and due diligence, sourcing a suitable carburetor for the 212cc Predator engine is a straightforward and cost-effective process.