The global laser cleaning machine market is experiencing robust expansion, driven by increasing demand for eco-friendly, precision-based surface treatment solutions across industries such as automotive, aerospace, and heavy manufacturing. According to a 2023 report by Grand View Research, the global laser cleaning market size was valued at USD 729.3 million in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 17.8% from 2023 to 2030. This growth is fueled by the rising adoption of Industry 4.0 technologies, stringent environmental regulations limiting chemical cleaning methods, and the superior efficiency of high-power systems like 2000-watt laser cleaners.

As businesses prioritize automation and sustainability, the demand for high-performance laser cleaning machines has surged, leading to increased competition and innovation among manufacturers. In particular, 2000-watt lasers have emerged as a preferred choice, offering optimal balance between cleaning speed, depth, and operational cost for industrial-scale applications. Based on market presence, technological innovation, customer reviews, and global distribution reach, the following nine companies represent the leaders in manufacturing 2000-watt laser cleaning machines in 2024.

Top 9 2000 Watt Laser Cleaning Machine Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Industrial 1500W 2000W CW Laser Cleaning Machine Rusty Remove

Website: xinglaser.com

Key Highlights: XING Laser (6am Life LLC, DBA XING Laser) specializes in the development and manufacture of high-performance handheld laser cleaning and rust removal equipment….

#2 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: we engineer and manufacture the most advanced—and most powerful—pulsed industrial laser cleaning systems on the market, built for both manual and automated ……

#3 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#4 Laser Cleaning Machine Manufacturers

Website: fortunelaser.com

Key Highlights: Fortune Laser CW 1000W/1500W/2000W cleaning width 650mm large format cleaning machine · Fortune Laser Pulses 500W Water Cooling Laser Cleaning Machine ……

#5 Argento Lux

Website: argentolux.com

Key Highlights: The A-LUX 2000W laser has been a total game-changer for our shop. It eliminated the need for our chemical wash bay, saving us space, cutting waste disposal ……

#6 BK

Website: baikeopto.com

Key Highlights: In stock1. Laser Cleaning Head. Lightweight Design; Can work for a long time · 2. Humanized Design. Easily move anywhere; Simple operation · 3. Laser Cleaning System….

#7 2000W Continuous Wave Laser Cleaning Machine

Website: nuwavelaser.com

Key Highlights: Check out our 2000w Continuous Wave Laser Cleaning Machine. Perfect for removing rust, paint, and other contaminants. Shop this machine now!…

#8 2000W SUP Fiber Laser Cleaning Rust Removal Machine

Website: lasersonly.com

Key Highlights: 2000 Fiber Laser Rust Removing / Cleaning Machine can remove rust, paint, oil, and oxide film on all metal and some non-metal surfaces, as well as the ……

#9 Handheld Laser Cleaning Machines

Website: ipgphotonics.com

Key Highlights: With up to 2000 watts of power, these mobile laser cleaning systems are designed for handling large areas fast and efficiently. These self sufficient units ……

Expert Sourcing Insights for 2000 Watt Laser Cleaning Machine

H2: 2026 Market Trends for 2000 Watt Laser Cleaning Machines

The global market for 2000-watt laser cleaning machines is poised for significant transformation by 2026, driven by technological advancements, expanding industrial applications, and growing environmental regulations. As industries shift toward sustainable and precision-based solutions, high-power laser cleaning systems—particularly those operating at 2000 watts—are emerging as a preferred alternative to traditional surface cleaning methods such as sandblasting, chemical treatments, and dry ice blasting. Below are the key market trends expected to shape the 2000-watt laser cleaning machine sector by 2026.

-

Increased Industrial Adoption Across Manufacturing Sectors

By 2026, sectors such as automotive, aerospace, shipbuilding, and heavy machinery are projected to significantly increase their adoption of 2000-watt laser cleaning systems. These high-power units offer faster cleaning speeds and deeper rust and coating removal, making them ideal for large-scale industrial maintenance and surface preparation. Automotive OEMs, in particular, are integrating laser cleaning into pre-welding processes to improve weld quality and reduce defects, a trend expected to accelerate demand. -

Growing Emphasis on Eco-Friendly and Non-Abrasive Technologies

Environmental sustainability is a major driver. Unlike chemical or abrasive methods, 2000-watt laser cleaners generate no secondary waste or harmful emissions, aligning with global green manufacturing initiatives and tightening environmental regulations (e.g., EU’s Green Deal and U.S. EPA guidelines). This eco-friendly profile is incentivizing companies to invest in laser cleaning, especially in regions with strict industrial emission norms. -

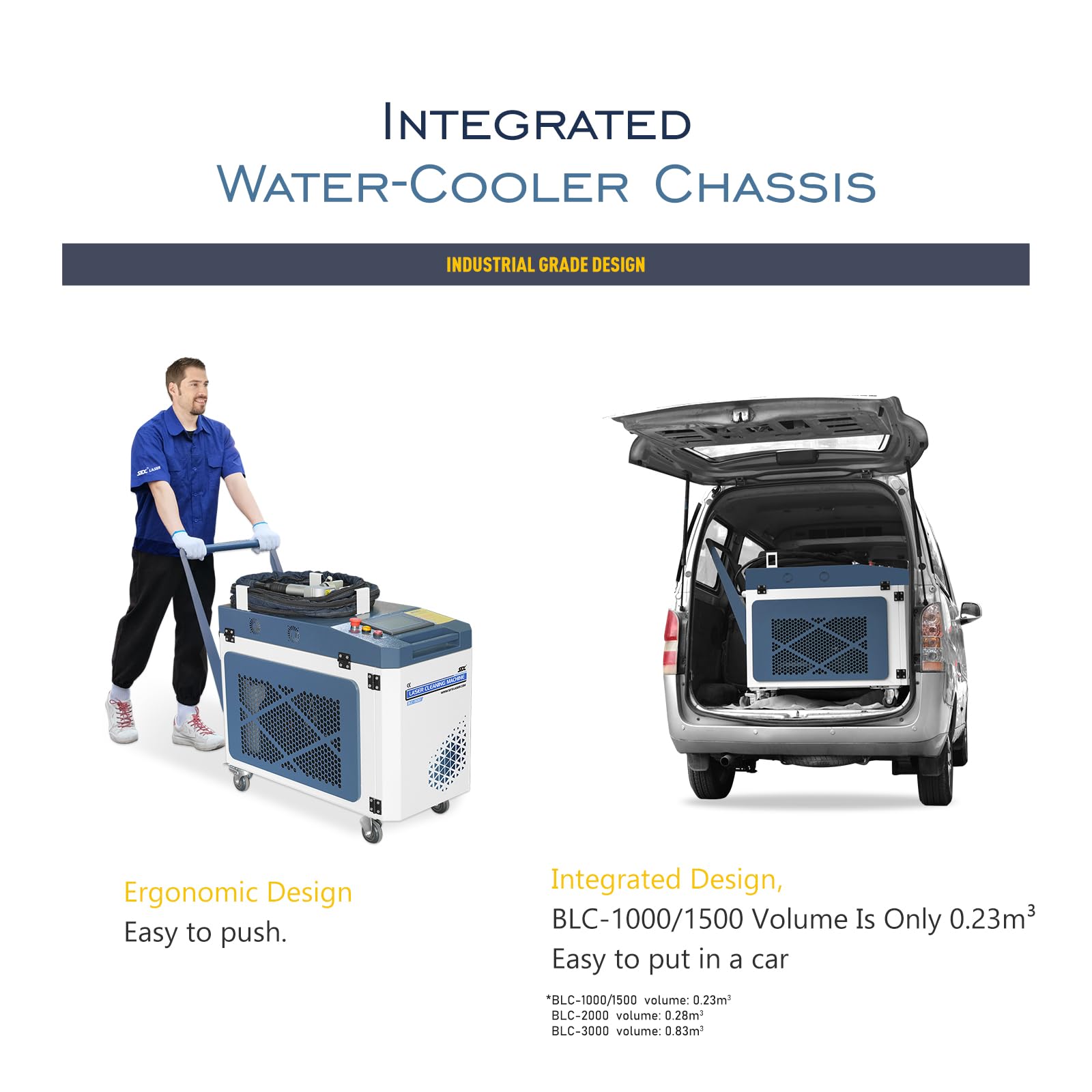

Advancements in Laser Efficiency and Portability

Technological improvements are enhancing the efficiency, reliability, and portability of 2000-watt systems. By 2026, expect next-generation models with improved beam quality, intelligent control systems, and integrated IoT capabilities for real-time monitoring and predictive maintenance. Compact and mobile designs will also gain traction, enabling on-site cleaning in remote or confined industrial environments. -

Cost Reduction and Improved ROI

Although initial investment remains high, the total cost of ownership for 2000-watt laser cleaners is decreasing due to falling component costs (e.g., fiber lasers) and longer system lifespans. As operational efficiency improves, the return on investment (ROI) is becoming more attractive, encouraging mid-sized enterprises to enter the market. Rental and leasing models are also emerging, further lowering entry barriers. -

Expansion in Emerging Markets

Asia-Pacific, particularly China, India, and Southeast Asia, is expected to be a high-growth region by 2026. Rapid industrialization, government support for smart manufacturing (e.g., China’s “Made in China 2025” initiative), and rising awareness of laser technology are fueling demand. Local manufacturers are also entering the market with competitively priced 2000-watt systems, increasing accessibility. -

Integration with Automation and Robotics

The trend toward Industry 4.0 is pushing integration of 2000-watt laser cleaning machines with robotic arms and automated production lines. This allows for consistent, high-precision cleaning in repetitive tasks, improving throughput and reducing labor costs. Fully automated laser cleaning cells are expected to become standard in advanced manufacturing facilities by 2026. -

Rising Focus on Safety and Standards

As adoption grows, so does the need for standardized safety protocols and certifications. By 2026, stricter international safety standards (e.g., IEC 60825) and mandatory training programs for operators are expected to be implemented, promoting responsible use and minimizing workplace hazards.

In conclusion, the 2000-watt laser cleaning machine market in 2026 will be characterized by broader industrial integration, technological innovation, and strong growth driven by sustainability and automation. Companies that invest in R&D, expand into emerging markets, and align with environmental regulations will be well-positioned to lead in this evolving landscape.

Common Pitfalls When Sourcing a 2000 Watt Laser Cleaning Machine (Quality & IP)

Purchasing a 2000W laser cleaning machine is a significant investment. While the high power promises fast and effective cleaning, sourcing the wrong machine can lead to poor performance, safety hazards, high operating costs, and even intellectual property (IP) infringement. Avoid these critical pitfalls:

H2: Overlooking Build Quality and Component Reliability

- Pitfall: Focusing solely on price and power rating while ignoring the quality of core components and overall construction. Cheap machines often use:

- Low-Grade Optics: Inexpensive lenses and mirrors degrade quickly under 2000W power, leading to beam distortion, reduced cleaning efficiency, and frequent, costly replacements.

- Under-Spec’d Cooling Systems: Inadequate chillers or poor heat dissipation cause thermal lensing (beam focus shifts), unstable output, and premature laser source failure.

- Flimsy Mechanics: Poorly built motion systems (gantries, manipulators) or handheld units result in imprecise scanning, inconsistent cleaning, vibration, and reduced lifespan.

- Substandard Electrical Components: Cheap power supplies, wiring, and connectors increase fire risk and cause frequent downtime.

- Consequence: Rapid performance degradation, high maintenance costs, frequent breakdowns, shortened machine life, potential safety incidents, and failure to meet cleaning requirements.

- Mitigation: Demand detailed specifications on laser source (brand/model), optics (material, coatings), cooling capacity, and structural materials. Request proof of component quality (e.g., Raycus/Max brand laser source certificates). Prioritize manufacturers with proven engineering and robust build standards.

H2: Ignoring Critical Safety Features and Certification

- Pitfall: Assuming all machines meet safety standards or downplaying the extreme hazards of a 2000W laser (Class 4). Key omissions include:

- Lack of Proper IP Rating: An “IP54” claim without verification is common. True IP54 requires effective enclosures preventing dust ingress and water splashes from any direction – crucial in industrial environments. Lower IP ratings risk internal contamination and failure.

- Inadequate Interlocks: Missing or faulty safety interlocks on doors, covers, or emergency stops.

- Insufficient Fume Extraction Integration: Poorly designed or undersized extraction ports lead to hazardous fume buildup and contaminate optics.

- Missing Safety Labels & Documentation: Absence of proper warning labels, operation manuals, and safety procedures.

- Lack of Compliance Certificates: Missing CE, FDA (if applicable), or other regional safety certifications (e.g., UKCA).

- Consequence: Severe eye/skin injury risk, fire hazard, operator exposure to toxic fumes, machine damage, non-compliance with regulations leading to shutdowns or fines, and liability issues.

- Mitigation: Verify the actual IP rating through independent testing reports or rigorous on-site inspection. Demand full safety documentation and valid certification copies. Inspect the machine’s physical safety features (interlocks, emergency stops, beam shrouds, extraction ports) thoroughly before purchase.

H2: Falling for IP (Intellectual Property) Infringement and “Copycat” Designs

- Pitfall: Purchasing machines that are blatant copies of leading brands, often sold at lower prices. These infringe on patents and trademarks.

- Counterfeit Components: Use of fake laser sources or controllers masquerading as reputable brands (e.g., Raycus, JPT).

- Copied Software & Interfaces: Illegally replicated control software with bugs, instability, and no support.

- Stolen Design Elements: Mimicking the look, feel, and specific engineering solutions of protected machines.

- Consequence: No access to genuine manufacturer software updates, technical support, or spare parts. High risk of software failures, poor performance, and rapid obsolescence. Potential legal liability for using infringing equipment. Voided warranties. Damage to your company’s reputation.

- Mitigation: Buy directly from the OEM or authorized distributors of reputable brands. Verify the manufacturer’s legitimacy, patents, and software licensing. Be wary of prices significantly below market average. Check for unique branding and original software interfaces. Request proof of IP ownership or licensing agreements for key components.

H2: Neglecting Service, Support, and Technical Expertise

- Pitfall: Focusing only on the initial purchase price and ignoring long-term support.

- Unresponsive or Incompetent Support: Vendors located overseas with poor communication, slow response times, and lack of technical expertise for complex 2000W systems.

- Unavailability of Spare Parts: Long lead times or inability to source critical components (lenses, laser diodes, scanners).

- Lack of Training: Inadequate or non-existent operator and maintenance training.

- No Local Service Network: Requirement for factory returns for repairs, leading to extended downtime.

- Consequence: Prolonged machine downtime during critical operations, difficulty resolving technical issues, inability to perform basic maintenance, increased total cost of ownership, and frustration.

- Mitigation: Prioritize suppliers with proven, responsive technical support (check references). Ensure clear SLAs for support response and repair times. Confirm the availability and cost of critical spare parts. Verify comprehensive training is included. Assess the presence of local service engineers or partners.

By meticulously addressing these H2-level pitfalls – Build Quality, Safety & IP Rating, IP Infringement, and Support – you significantly increase the chances of acquiring a reliable, safe, high-performing, and legally compliant 2000W laser cleaning machine that delivers a strong return on investment.

H2: Logistics & Compliance Guide for 2000 Watt Laser Cleaning Machine

Transporting and operating a 2000-watt laser cleaning machine requires strict adherence to international and local regulations due to its high-powered laser source, electrical components, and potential safety hazards. This guide outlines the key logistics and compliance considerations to ensure safe, legal, and efficient handling of the equipment from shipment to operation.

H2: Export & Import Regulations

-

Export Classification:

The 2000-watt laser cleaning machine typically falls under the Export Control Classification Number (ECCN) 6A003.b.4 (lasers with specific power and wavelength characteristics) under the U.S. Commerce Control List (CCL). This may require an export license from the U.S. Department of Commerce, Bureau of Industry and Security (BIS), especially for destinations subject to sanctions or export restrictions. -

Import Compliance (Destination Country):

Verify import regulations in the destination country. Many countries (e.g., EU, Canada, Australia) require: - A conformity certificate (e.g., CE marking in the EU).

- Laser safety certification (e.g., IEC 60825-1).

- Electrical safety standards (e.g., IEC 61010).

-

Customs documentation including commercial invoice, packing list, bill of lading, and certificate of origin.

-

Restricted Destinations:

Avoid shipping to embargoed or sanctioned countries (e.g., Iran, North Korea, Crimea region) without proper authorization.

H2: Packaging & Transportation

- Crating and Protection:

- Use a custom wooden export crate with internal foam or shock-absorbing materials to protect sensitive optical and electronic components.

- Seal components against moisture and dust; include desiccant packs if shipping overseas or in humid climates.

-

Clearly label the crate with: “Fragile,” “This Side Up,” “Protect from Moisture,” and “Laser Equipment – Do Not Invert.”

-

Shipping Mode:

- Air Freight: Suitable for urgent deliveries; requires IATA-compliant packaging and documentation. Lasers may be subject to additional screening.

- Sea Freight: Cost-effective for heavy machinery. Ensure compliance with IMDG Code if transporting by sea.

-

Ground Transport: Use padded, climate-controlled trucks for domestic or regional delivery.

-

Hazardous Materials:

While the laser itself is not classified as hazardous, batteries (if included) or cooling systems with refrigerants may require special handling under UN/DOT/IATA regulations.

H2: Laser Safety & Regulatory Compliance

-

Laser Classification:

A 2000-watt laser is classified as a Class 4 laser—the highest risk category—capable of causing severe eye and skin injuries, fire hazards, and generating hazardous fumes during operation. -

Safety Standards:

Ensure compliance with: - IEC 60825-1: Safety of laser products.

- ANSI Z136.1 (U.S.): Safe use of lasers.

- Directive 2014/35/EU (Low Voltage Directive) and 2014/30/EU (EMC Directive) in the EU.

-

FDA/CDRH Regulations (U.S.): 21 CFR 1040.10 and 1040.11 for laser products.

-

Required Safety Features:

- Emergency stop button.

- Interlock systems on access panels.

- Beam shutter and key-controlled power switch.

- Protective enclosures or interlocks in automated systems.

- Warning labels (laser radiation, high voltage, hot surfaces).

H2: Operational Compliance & Training

- User Training & Certification:

Operators must receive formal training on: - Laser safety protocols.

- Proper use of personal protective equipment (PPE), including laser safety goggles (OD 5+ for wavelengths used).

- Emergency procedures (e.g., fire, exposure incidents).

-

Fume extraction and ventilation requirements.

-

Workplace Safety:

- Establish a controlled access laser area with warning signs.

- Install beam barriers and interlocks.

-

Use fume extraction systems to capture particulates and volatile compounds generated during cleaning.

-

Documentation:

Maintain records of: - Laser safety officer (LSO) designation (required in many jurisdictions).

- Equipment maintenance logs.

- Operator training certifications.

H2: After-Sales & Technical Support Compliance

-

Warranty & Service:

Ensure service technicians are trained and certified to handle high-power laser systems. Remote diagnosis tools should comply with data privacy laws (e.g., GDPR). -

Spare Parts & Repairs:

Replacement optical components (e.g., lenses, mirrors) may be subject to export controls. Maintain proper documentation for all part shipments.

H2: Environmental & Disposal Regulations

- End-of-Life Disposal:

- Lasers contain hazardous materials (e.g., optical coatings, electronic waste). Follow WEEE (EU) or EPA (U.S.) guidelines for disposal.

- Return or recycle optical and electronic components through certified e-waste handlers.

Conclusion

Shipping and operating a 2000-watt laser cleaning machine demands rigorous compliance with export controls, transportation standards, laser safety regulations, and environmental laws. Partner with certified logistics providers and legal experts to ensure full regulatory adherence across all stages of the machine’s lifecycle.

Conclusion for Sourcing a 2000 Watt Laser Cleaning Machine:

After a thorough evaluation of technical requirements, market options, and supplier capabilities, sourcing a 2000-watt laser cleaning machine represents a strategic investment for enhancing industrial cleaning efficiency, reducing operational downtime, and minimizing environmental impact. The high power output ensures superior performance in removing rust, paint, coatings, and contaminants from heavy-duty surfaces such as metal, concrete, and machinery, particularly in demanding environments like shipbuilding, automotive restoration, and large-scale manufacturing.

Key considerations—such as beam quality, cooling system, portability, automation compatibility, and safety certifications—must be carefully assessed to ensure reliability and long-term cost-effectiveness. Additionally, vendor support, warranty terms, training, and after-sales service play a crucial role in maximizing return on investment.

Preliminary supplier comparisons indicate competitive pricing and technological advancements from manufacturers in China and Europe, with reliable brands offering robust performance and scalable solutions. It is recommended to conduct on-site demonstrations, request customer references, and verify compliance with international safety standards (e.g., CE, FDA) before finalizing procurement.

In conclusion, acquiring a 2000-watt laser cleaning machine aligns with modern, sustainable industrial practices. With proper due diligence in vendor selection and integration planning, this technology will significantly improve cleaning precision, operational efficiency, and workplace safety across targeted applications.