The global laser market is experiencing robust expansion, driven by rising demand across industrial, medical, and automotive sectors. According to Grand View Research, the global laser market size was valued at USD 16.7 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. This growth is fueled by the increasing adoption of high-power laser systems—particularly in metal cutting, welding, and additive manufacturing—where precision and efficiency are paramount. As a result, 200-watt lasers have become a preferred choice for mid-to-high intensity industrial applications, striking an optimal balance between performance and operational cost. With this surge in demand, several manufacturers have emerged as key players in producing reliable, high-quality 200-watt laser systems. The following list highlights the top eight manufacturers that lead in innovation, market presence, and technical capabilities, based on performance metrics, customer adoption, and technological advancement.

Top 8 200 Watt Laser Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

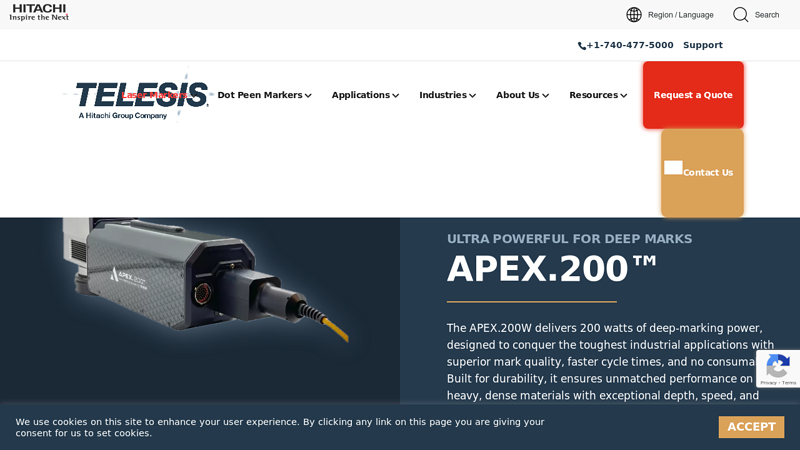

#1 Apex.200

Website: telesis.com

Key Highlights: The APEX.200W delivers 200 watts of deep-marking power, designed to conquer the toughest industrial applications with superior mark quality, faster cycle times, ……

#2 Wuhan Raycus Fiber Laser Technologies Co., Ltd.

Website: en.raycuslaser.com

Key Highlights: High efficiency of electro-optic conversion · Resistance to high resistance · Efficient sheet cutting · Output fiber length can be customized · Maintenance free ……

#3 JPT Laser

Website: en.jptoe.com

Key Highlights: As a leading laser manufacturer in China, JPT offers a full range of lasers, including MOPA laser, CW laser, DPSS laser, and diode lasers. JPT delivers ……

#4 Full Spectrum Laser

Website: fslaser.com

Key Highlights: 7–15 day delivery 30-day returnsFull Spectrum Laser is a US based company that designs, manufactures, and sells powerful and affordable laser cutting & laser engraving products….

#5 200 watt Option for Fusion Pro 36 and 48 Now Available

Website: epiloglaser.com

Key Highlights: Discover the power of the 200 watt laser option from Epilog Laser. Cut through up to ¾” of acrylic and more with ease and precision….

#6 IPG Photonics

Website: ipgphotonics.com

Key Highlights: IPG Photonics manufactures high-performance fiber lasers, amplifiers, and laser systems for diverse applications and industries. Discover your solution….

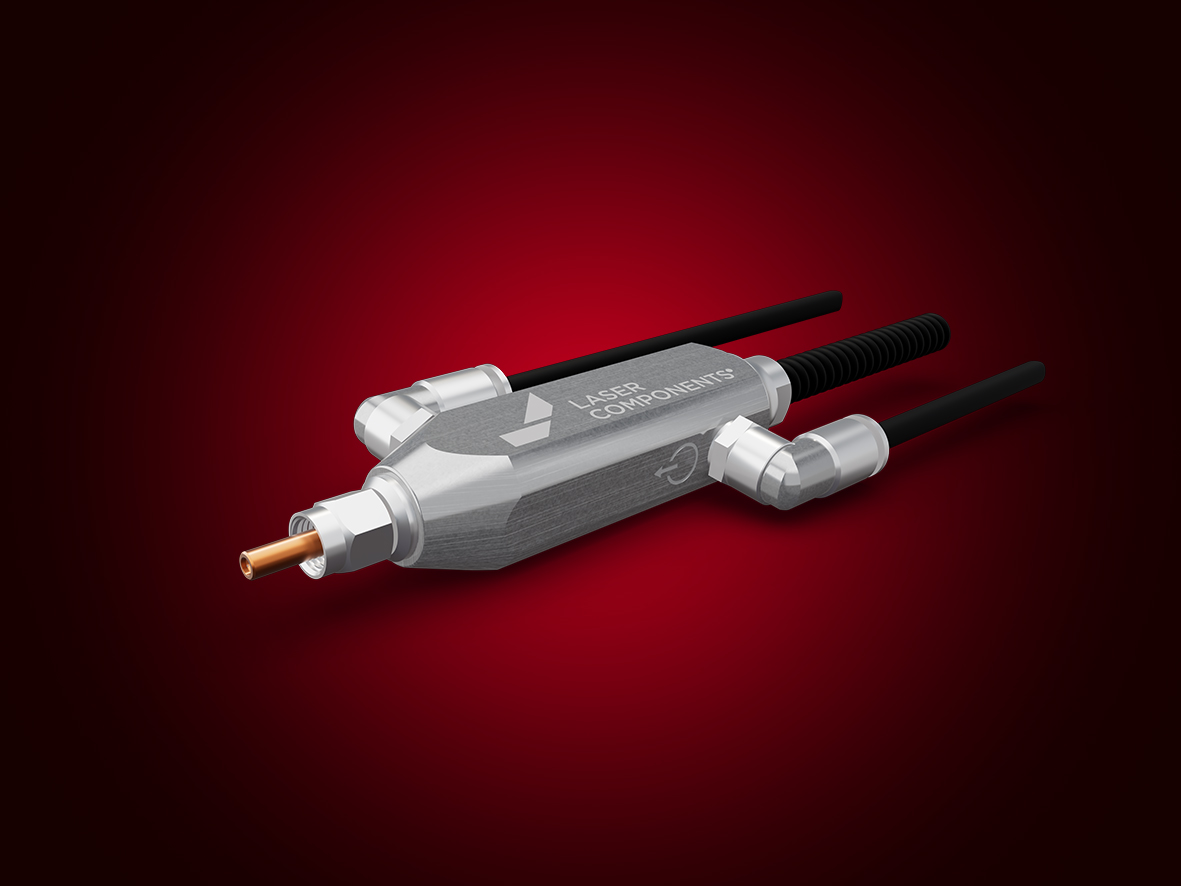

#7 Laser Components

Website: lasercomponents.com

Key Highlights: We manufacture our components for the photonics industry at various locations in Germany, Canada, and the US. Laser optics; Pulsed laser diodes; Avalanche ……

#8 Best 200W Laser Cleaner Factory and Manufacturers, Direct Price

Website: fortunelaser.com

Key Highlights: 200W laser cleaner – Factory, Suppliers, Manufacturers from China. We’ve been committed to offering easy,time-saving and money-saving one-stop purchasing ……

Expert Sourcing Insights for 200 Watt Laser

2026 Market Trends for 200 Watt Lasers

The 200-watt laser market is poised for significant evolution by 2026, driven by advancements in laser technology, increasing industrial automation, and expanding applications across multiple sectors. This analysis explores key trends shaping the demand, innovation, and competitive landscape for 200-watt lasers in the coming years.

Growing Demand in Industrial Manufacturing

By 2026, the industrial manufacturing sector is expected to remain the primary driver of demand for 200-watt lasers. These mid-power lasers are increasingly being adopted for precision cutting, welding, and surface treatment of materials such as thin to medium-gauge metals, plastics, and composites. The rise of smart factories and Industry 4.0 initiatives is accelerating the integration of fiber lasers—particularly 200-watt models—into automated production lines due to their reliability, energy efficiency, and low maintenance requirements.

Small and medium enterprises (SMEs) are also adopting 200-watt systems as entry-level solutions for metal fabrication, benefiting from declining costs and modular designs that allow scalability.

Expansion in Non-Traditional Applications

Beyond traditional manufacturing, 200-watt lasers are finding new applications in emerging industries. These include:

- Electronics and Semiconductor Packaging: Used for precise marking, trimming, and micro-welding.

- Battery Manufacturing: Critical in electric vehicle (EV) production for welding battery tabs and foils.

- Medical Device Fabrication: Enabling high-precision cutting of stents and surgical tools.

- Additive Manufacturing (3D Printing): Some hybrid systems use 200-watt lasers for metal sintering and cladding.

The versatility and balance between power and precision make 200-watt lasers ideal for these high-accuracy applications, contributing to market growth.

Technological Advancements and Efficiency Improvements

Innovation in laser diodes, beam delivery systems, and cooling mechanisms is expected to enhance the performance of 200-watt lasers by 2026. Key developments include:

- Improved Beam Quality: Higher brightness and focusability enable finer processing and faster cycle times.

- Increased Electrical Efficiency: Newer fiber laser architectures reduce power consumption and heat generation.

- Smart Controls and IoT Integration: Real-time monitoring and predictive maintenance via cloud-connected systems.

These improvements will lower the total cost of ownership and expand the operational envelope of 200-watt lasers, making them more attractive across industries.

Regional Market Dynamics

Asia-Pacific, particularly China and India, will continue to dominate the 200-watt laser market due to robust industrial growth, government support for manufacturing, and a growing domestic laser manufacturing base. North America and Europe are expected to see steady growth, driven by aerospace, defense, and high-tech manufacturing sectors.

Local production of laser components in regions like Southeast Asia and Eastern Europe will help reduce dependency on imports and lower system costs.

Competitive Landscape and Pricing Trends

The market is becoming increasingly competitive, with both established players (e.g., IPG Photonics, TRUMPF, nLIGHT) and emerging Chinese manufacturers (e.g., Raycus, Max Photonics) offering cost-effective 200-watt laser solutions. This competition is driving down prices and accelerating innovation.

By 2026, we anticipate a commoditization trend for standard 200-watt fiber lasers, pushing manufacturers to differentiate through software integration, service offerings, and application-specific configurations.

Sustainability and Regulatory Influences

Environmental regulations and corporate sustainability goals are influencing laser adoption. 200-watt fiber lasers are favored for their lower energy consumption and reduced waste compared to traditional machining methods. Additionally, regulations around workplace safety and emissions are prompting upgrades to enclosed, automated laser systems—further boosting demand.

Conclusion

By 2026, the 200-watt laser market will be characterized by broader adoption across industries, enhanced performance through technological innovation, and intensified competition. As a balanced solution offering sufficient power for a wide range of industrial tasks without excessive energy use, the 200-watt laser will remain a cornerstone of modern manufacturing and advanced processing applications.

Common Pitfalls When Sourcing a 200 Watt Laser: Quality and Intellectual Property (IP) Concerns

Sourcing a 200-watt laser, particularly from unfamiliar or offshore suppliers, involves significant risks related to both the actual performance quality of the equipment and potential intellectual property (IP) violations. Being aware of these pitfalls is crucial to avoid costly mistakes, operational downtime, and legal exposure.

Overstated Power Output and Performance

One of the most common issues is the misrepresentation of actual laser power. Many suppliers, especially those in competitive or less-regulated markets, advertise “200W” lasers that deliver significantly less power in real-world conditions. This can result in slower processing speeds, incomplete cuts, or the inability to handle intended materials. Always demand independent, third-party power verification (e.g., via a calibrated laser power meter) and real-world cutting/engraving test results under your specific operating parameters.

Poor Beam Quality and Stability

Even if a laser achieves 200W output, beam quality (measured by M² factor) and stability are critical for precision applications. Low-cost lasers often use substandard optics and diodes, leading to inconsistent beam focus, reduced cutting accuracy, and shorter component lifespans. Poor thermal management can cause power fluctuations and premature failure. Verify beam specifications and request data on long-term stability and thermal performance.

Use of Counterfeit or Reverse-Engineered Components

Many budget 200W lasers incorporate counterfeit or illegally reverse-engineered components, especially laser diodes and control electronics. These components may mimic branded products (e.g., falsely labeled “Laser Components GmbH” or “nLIGHT” diodes) but fail to meet specifications or safety standards. Using such parts not only compromises reliability but also exposes the buyer to IP infringement liability if the equipment is used commercially.

Lack of Genuine IP Licensing

Reputable laser manufacturers invest heavily in R&D and hold patents on critical technologies—beam delivery systems, cooling mechanisms, driver electronics, and software. Some low-cost suppliers copy these designs without licensing, distributing equipment that infringes on protected IP. Purchasing such systems can make your business complicit in IP theft, potentially leading to legal action, shipment seizures, or reputational damage.

Inadequate Documentation and Support

Low-cost suppliers often provide incomplete technical documentation, non-compliant safety certifications (e.g., fake CE or FDA marks), and minimal customer support. This creates risks during installation, maintenance, and regulatory compliance. Without genuine manuals, firmware updates, or trained technical support, resolving issues becomes difficult and downtime increases.

Hidden Costs and Short Lifespan

While upfront pricing may seem attractive, poor-quality 200W lasers often incur high total cost of ownership due to frequent part replacements, energy inefficiency, and unplanned downtime. Components like lenses, cooling pumps, and diodes may fail within months, especially under continuous operation. This undermines productivity and negates any initial savings.

Mitigation Strategies

To avoid these pitfalls:

– Source from reputable, established manufacturers with verifiable track records.

– Request third-party test reports for power output and beam quality.

– Audit component provenance—ask for datasheets and supplier certifications.

– Verify IP compliance; inquire whether the manufacturer holds or licenses relevant patents.

– Prioritize suppliers offering comprehensive warranties, technical support, and genuine spare parts.

Ignoring quality and IP concerns when sourcing a 200W laser may lead to operational failures and legal risks that far outweigh initial cost savings. Due diligence is essential for a reliable, compliant, and efficient laser system.

H2: Logistics & Compliance Guide for 200-Watt Laser Systems

Transporting and operating a 200-watt laser requires strict adherence to international, national, and local regulations due to its classification as a high-power Class 4 laser. This guide outlines key logistical and compliance considerations.

H3: 1. Regulatory Classification

- Laser Safety (IEC 60825-1 / FDA 21 CFR 1040.10): A 200-watt laser is Class 4 – the highest hazard class. It poses severe risks:

- Eye Hazard: Instant permanent eye damage from direct or scattered beam exposure (including reflections).

- Skin Hazard: Severe burns from direct beam contact.

- Fire Hazard: Can ignite combustible materials.

- Transportation (UN Recommendations): Laser products are typically UN 3499, LASER, CLASS 3B OR CLASS 4.

- Proper Shipping Name: “Laser, Class 3B or Class 4”

- UN Number: UN 3499

- Hazard Class: 9 (Miscellaneous Dangerous Goods)

- Packing Group: III (Generally Low Hazard relative to other Class 9 goods, but not low risk for lasers).

- Special Provisions: SP 274 applies (Laser must be secured to prevent accidental operation; aperture must be protected; warnings visible).

H3: 2. Packaging & Labeling for Transport

- Robust Packaging: Use a rigid, crush-resistant outer container (e.g., double-wall cardboard, wooden crate). Inner packaging must immobilize the laser and prevent contact with controls.

- Beam Aperture Protection: Securely cap, tape, or shield the beam aperture to prevent accidental exposure. Use non-combustible materials.

- Prevent Accidental Activation:

- Remove power cords/batteries.

- Securely tape power switches in the “OFF” position.

- Use tamper-evident seals on access panels.

- Mandatory Labels:

- Class 9 Hazard Label: “Miscellaneous Dangerous Goods” diamond label.

- UN 3499 / Proper Shipping Name: Clearly displayed.

- Class 4 Laser Warning Label: Standard “DANGER” or “WARNING” label with laser symbol, wavelength, max output (200W), and hazard statements. Must be visible on both the inner packaging and outer container.

- Shipper/Consignee Information: Full names, addresses, and contact details.

- Orientation Arrows: If required by orientation.

- Documentation: Include a Transport Document (e.g., Air Waybill, Bill of Lading) declaring UN 3499, Class 9, PG III. A Dangerous Goods Declaration is mandatory for air freight (IATA) and often required for sea/road.

H3: 3. Key Transportation Regulations

- Air Freight (IATA DGR): Strictest rules. Requires:

- Trained, certified personnel (DG Shipper).

- Detailed Dangerous Goods Declaration.

- Specific packaging testing (drop, stack, vibration).

- Quantity limitations per package and per aircraft.

- Notification to the airline before tendering.

- Ocean Freight (IMDG Code): Similar principles to IATA, but with different packaging and documentation nuances. Requires a Dangerous Goods Note (DGN).

- Road Freight (ADR – Europe / National Regs): Requires driver training, vehicle labeling (“Class 9”), and emergency procedures. ADR applies in Europe; check national regulations elsewhere.

- Rail Freight (RID): Similar to ADR for Europe.

H3: 4. Import/Export Compliance

- Export Controls:

- Dual-Use Items: High-power lasers may fall under export control regimes (e.g., Wassenaar Arrangement, EAR (US)).

- Licensing: An export license may be required, especially to certain countries or end-users (military, sensitive industries). Check the Harmonized System (HS) code (e.g., 8543.10.00 for lasers) and national control lists.

- Import Regulations:

- Duties & Taxes: Standard import duties and VAT/GST apply. HS code determines rates.

- Product Safety Standards: The laser must comply with the destination country’s safety standards (e.g., CE marking in EU, FCC in US for RF emissions, local laser safety regulations). Conformity assessment may be needed.

- Customs Declaration: Accurate description, HS code, value, and origin are critical.

H3: 5. On-Site Handling & Receiving

- Trained Personnel: Only personnel trained in laser safety (e.g., Laser Safety Officer – LSO) and dangerous goods handling should receive and unpack.

- Inspection: Check packaging for damage before opening. Verify contents against documentation.

- Safe Unpacking: Perform in a designated, controlled area. Keep aperture protected until installation. Dispose of packaging safely.

H3: 6. Installation & Operational Compliance

- Designated Laser Controlled Area (LCA): Establish a clearly marked, access-controlled area.

- Engineering Controls:

- Enclosure: Fully enclose the beam path where possible (interlocked).

- Beam Path Enclosure: Use beam tubes or barriers for open paths.

- Interlocks: On access doors, panels, and safety curtains.

- Emergency Stop (E-Stop): Easily accessible, hardwired.

- Ventilation/Fume Extraction: Required for cutting/engraving processes.

- Administrative Controls:

- Laser Safety Officer (LSO): Appoint a qualified LSO.

- Standard Operating Procedures (SOPs): Develop and enforce.

- Training: Mandatory for all users and personnel in the area.

- Permit-to-Work: For maintenance or non-routine tasks.

- Personal Protective Equipment (PPE):

- Laser Safety Eyewear: Wavelength-specific (OD 6+ for 200W), certified (e.g., EN 207, ANSI Z136.1). Essential for alignment tasks.

- Protective Clothing: Flame-resistant lab coat/apron, gloves (non-reflective, non-melting).

- Warning Signs: “DANGER – Class 4 Laser – Avoid Eye or Skin Exposure to Direct or Scattered Radiation” at all entrances.

H3: 7. Key Standards & Authorities

- Safety: IEC 60825-1, ANSI Z136.1, EN 60825-1

- Transport: IATA DGR, IMDG Code, ADR, 49 CFR (US)

- Export: Wassenaar Arrangement, EAR (US), national export control agencies.

- Product Compliance: CE Marking (EU), FCC (US), RCM (AU), KC (KR), etc.

H2: Critical Next Steps

1. Identify Specific Model & Location: Regulations vary by country and laser specifics (wavelength, pulsed/CW).

2. Consult Experts: Engage a Laser Safety Officer (LSO) and a Certified Dangerous Goods Consultant.

3. Verify Export/Import Licenses: Contact relevant national authorities early.

4. Use Certified Carriers: Partner with freight forwarders experienced in Class 4 lasers and dangerous goods.

5. Document Everything: Maintain records of training, inspections, maintenance, and compliance.

Disclaimer: This guide provides general information. Regulations are complex and subject to change. Always consult the latest official regulations and qualified experts for your specific shipment and operational context.

Conclusion for Sourcing a 200-Watt Laser:

After evaluating technical requirements, supplier capabilities, cost considerations, and long-term operational needs, sourcing a 200-watt laser represents a strategic investment for high-precision cutting, engraving, or welding applications. This power level offers an optimal balance between processing speed and energy efficiency, suitable for a range of materials including metals, plastics, and composites.

Key factors in the sourcing decision include laser type (fiber vs. CO₂), beam quality, cooling requirements, integration compatibility with existing systems, and after-sales support. Suppliers should be assessed not only on price but also on reliability, warranty terms, service availability, and compliance with safety standards.

Ultimately, selecting a reputable manufacturer or distributor with proven experience in 200-watt laser systems ensures performance consistency, scalability, and reduced downtime. With proper maintenance and operator training, a 200-watt laser can significantly enhance production capabilities, improve product quality, and deliver a strong return on investment over time.