The global dump truck market is experiencing robust growth, driven by rising infrastructure development, urbanization, and increased mining activities. According to a report by Mordor Intelligence, the dump truck market was valued at USD 18.3 billion in 2023 and is projected to grow at a CAGR of over 5.8% from 2024 to 2029. This growth is particularly pronounced in emerging economies across Asia-Pacific, Latin America, and Africa, where demand for heavy-duty construction and haulage equipment continues to climb. Among the various payload capacities, 20-ton dump trucks occupy a strategic sweet spot—offering optimal load efficiency, maneuverability, and compliance with road regulations—making them a preferred choice for medium-scale construction, quarrying, and municipal projects. As demand intensifies, a select group of manufacturers have emerged as leaders in engineering, durability, and after-sales support. Below are the top 10 manufacturers of 20-ton dump trucks, recognized for their innovation, market presence, and performance metrics across diverse operating environments.

Top 10 20 Ton Dump Truck Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 High

Domain Est. 2024

Website: chenglongtrucks.com

Key Highlights: As a trusted exporter, Dongfeng Liuzhou Motor Co., Ltd. offers high-quality 20 ton dump trucks, ensuring exceptional service tailored for your business ……

#2 T880

Domain Est. 1994

Website: kenworth.com

Key Highlights: Advanced technology and street-smart design — sloped hood, fuel-efficient drivetrain, aerodynamic and job-specific options, unconventional maneuverability ……

#3 Rugby Manufacturing

Domain Est. 1997

Website: rugbymfg.com

Key Highlights: Rugby is North America’s leading designer and manufacturer of Class 3 – 7 dump truck bodies, landscape bodies, platform bodies, truck and trailer hoists….

#4 Articulated Dump Trucks

Domain Est. 1990

Website: deere.com

Key Highlights: Whether it’s 26 ton, 31 ton, 41 ton, or 46 ton, our ADTs deliver impressive power and torque for exceptional power-to-weight ratios and fast cycles….

#5 Off-Highway Trucks

Domain Est. 1993

Website: cat.com

Key Highlights: Caterpillar builds Off-Highway Trucks specifically for work in mines, construction and quarries….

#6 Trucks

Domain Est. 1995

Website: komatsu.com

Key Highlights: We offer an extensive line of 30- to 400-ton capacity trucks for construction and mining. We want you to meet your productivity targets….

#7 Peterbilt Model 567

Domain Est. 1996

Website: peterbilt.com

Key Highlights: Class: 8 · Used for: Dump Trucks, Heavy Haul, Construction, Oil Field, Other Demanding Jobs · GVWR: Up to 100k lbs. · Horsepower: 320 – 605 hp · Torque: 1,000 – ……

#8 Dump Trucks

Domain Est. 1998

Website: international.com

Key Highlights: Browse medium, heavy, and severe-duty trucks equipped with the features and capabilities to get the job done….

#9 Articulated Dump Trucks & Haul Trucks

Domain Est. 2000

Website: volvoce.com

Key Highlights: Volvo articulated dump trucks are engineered for continuous production and incredible fuel efficiency, reducing downtime and boosting your bottom line….

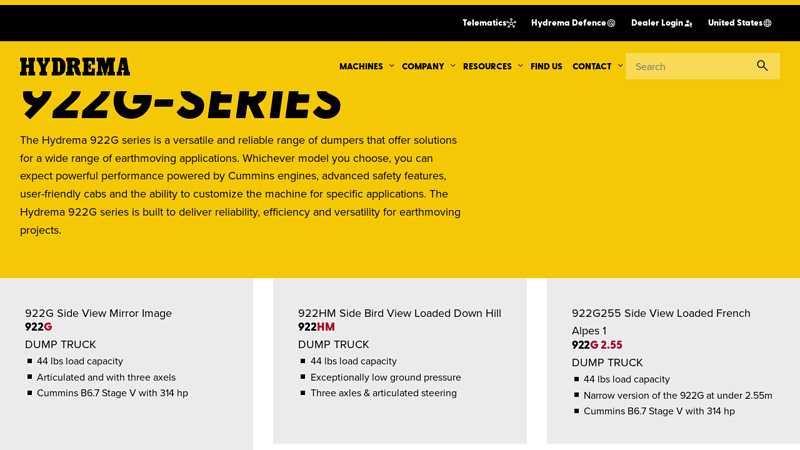

#10 922G

Domain Est. 2009

Website: hydrema.us

Key Highlights: Welcome to Hydrema’s impressive 922G Series, a collection of state-of-the-art 18 ton and 20 ton dump trucks that are built to dominate the earthmoving world….

Expert Sourcing Insights for 20 Ton Dump Truck

H2: 2026 Market Trends for 20-Ton Dump Trucks

The global market for 20-ton dump trucks is poised for significant transformation by 2026, driven by technological innovation, environmental regulations, regional infrastructure development, and shifts in construction and mining demand. As urbanization accelerates and governments invest in large-scale infrastructure projects, the demand for medium-duty dump trucks—particularly the 20-ton segment—will grow, especially in emerging markets. Below are the key market trends expected to shape the 20-ton dump truck industry by 2026.

1. Electrification and Alternative Powertrains

A major trend shaping the 20-ton dump truck market is the shift toward electrification. By 2026, electric-powered 20-ton dump trucks are expected to gain traction, particularly in urban construction zones and mining operations aiming to reduce emissions. Manufacturers such as Volvo, Scania, and BYD are already testing and deploying electric dump truck models with improved battery life and charging infrastructure. In regions with stringent emission norms—such as the European Union and parts of North America—fleet operators are increasingly adopting battery-electric and hybrid variants to comply with environmental regulations.

2. Regional Infrastructure Investment Driving Demand

Asia-Pacific, especially India, Southeast Asia, and China, will remain a high-growth region for 20-ton dump trucks due to ongoing infrastructure development and smart city projects. Similarly, government spending on transportation networks in Africa and the Middle East will fuel demand for cost-effective, durable dump trucks. In contrast, mature markets like North America and Western Europe will see steady but slower growth, focused more on fleet modernization and replacement cycles.

3. Adoption of Smart and Connected Technologies

By 2026, connectivity and telematics will be standard features in new 20-ton dump trucks. Advanced driver assistance systems (ADAS), GPS tracking, remote diagnostics, and predictive maintenance tools will enhance operational efficiency and reduce downtime. Fleets are increasingly leveraging data analytics to optimize fuel consumption, route planning, and driver performance—key factors in improving profitability.

4. Focus on Fuel Efficiency and Total Cost of Ownership (TCO)

With rising fuel prices and pressure to reduce operating costs, manufacturers are designing 20-ton dump trucks with improved aerodynamics, lightweight materials, and more efficient diesel engines. Customers are evaluating purchases based on TCO rather than upfront cost, leading to increased demand for reliable, low-maintenance models with longer service intervals.

5. Growth in Rental and Fleet-as-a-Service Models

The construction sector is witnessing a rise in equipment rental and pay-per-use models. By 2026, more companies are expected to opt for leasing or rental services for 20-ton dump trucks rather than outright purchases, especially for short-term or seasonal projects. This trend supports flexibility and reduces capital expenditure for small and medium-sized contractors.

6. Supply Chain Localization and Resilience

Post-pandemic supply chain disruptions have prompted manufacturers to localize production and component sourcing. By 2026, regional manufacturing hubs in India, Mexico, and Eastern Europe are expected to play a larger role in supplying 20-ton dump trucks, reducing lead times and dependency on global logistics.

7. Sustainability and Circular Economy Initiatives

End-of-life vehicle recycling, remanufacturing of components, and use of sustainable materials are gaining attention. Leading OEMs are launching programs to refurbish and resell used 20-ton dump trucks, appealing to budget-conscious buyers while promoting environmental responsibility.

In conclusion, the 2026 market for 20-ton dump trucks will be characterized by technological advancement, regulatory pressure, and evolving customer preferences. Companies that innovate in electrification, digitalization, and sustainable practices will be best positioned to capture market share in this dynamic segment.

Common Pitfalls When Sourcing a 20 Ton Dump Truck (Quality & IP Concerns)

Sourcing a 20-ton dump truck, especially from international suppliers or new manufacturers, involves significant risks related to both quality and intellectual property (IP). Avoiding these pitfalls is crucial for ensuring performance, safety, longevity, and legal compliance.

Quality-Related Pitfalls

1. Inadequate Material Specifications and Construction

One of the most common issues is receiving a truck built with substandard materials. Suppliers may use lower-grade steel for the chassis, body, or critical components to cut costs. This compromises structural integrity, increases susceptibility to corrosion, and reduces load capacity and lifespan. Always verify material certifications (e.g., ASTM or ISO standards) and conduct third-party inspections during production.

2. Poor Welding and Assembly Practices

Improper welding techniques or inconsistent assembly processes can lead to premature fatigue, cracking, or catastrophic failures under load. Insufficient penetration, lack of weld inspection, or untrained personnel contribute to this risk. Require evidence of welding certifications (e.g., ISO 3834) and request detailed photos or videos of the manufacturing process.

3. Subpar Component Sourcing (Engines, Hydraulics, Axles)

Many manufacturers source engines, hydraulic systems, or axles from third parties. Hidden quality issues arise when these components are counterfeit, reconditioned, or from unreliable brands. Confirm the OEM specifications of key parts and verify authenticity through serial number checks or direct validation with original component manufacturers.

4. Inadequate Testing and Quality Control Protocols

Some suppliers skip rigorous testing procedures such as load testing, stress analysis, or durability runs. Without proper factory acceptance testing (FAT), defects may go unnoticed until the truck is in operation. Insist on documented test reports and consider hiring an independent inspector to oversee final quality checks.

5. Misrepresentation of Payload Capacity and Performance

Suppliers may overstate the effective payload or durability of the dump truck. A “20-ton” rating might not account for body weight, fuel, or accessories, leading to underperformance or overloading risks. Clarify whether the rating is gross vehicle weight (GVWR) or payload only, and verify with detailed technical specifications.

Intellectual Property (IP) Pitfalls

1. Use of Counterfeit or Unlicensed Designs

Some manufacturers replicate designs from well-known brands (e.g., Caterpillar, Komatsu, Sinotruk) without authorization. This includes copying body styles, cab designs, or proprietary hydraulic systems. Using such trucks exposes the buyer to legal risks, especially if imported into jurisdictions with strict IP enforcement.

2. Lack of Documentation for Genuine Components

When key parts (e.g., engines, transmissions) are sourced illegally or rebranded, proper licensing documentation is often missing. This can lead to voided warranties, service challenges, and potential legal liability. Always demand OEM documentation and verify component authenticity through manufacturer databases.

3. Ambiguous or Missing IP Ownership in Contracts

Supplier contracts may fail to clarify IP rights, particularly if custom modifications are made. Without clear agreements, disputes may arise over design ownership, especially in cases of joint development or customization. Ensure contracts explicitly state that no third-party IP is infringed and define ownership of any bespoke features.

4. Risk of Import Seizures or Legal Action

Importing trucks with suspected IP violations can result in customs seizures, fines, or litigation, particularly in regions like the EU or North America. Conduct due diligence on the manufacturer’s reputation and consider IP screening services before finalizing procurement.

5. Limited After-Sales Support Due to IP Restrictions

If the truck uses cloned or unauthorized technology, spare parts and technical support may be unavailable or unreliable. This undermines maintenance efforts and increases downtime. Prioritize suppliers who use licensed, traceable components with established service networks.

Mitigation Strategies

To avoid these pitfalls, conduct thorough supplier vetting, request detailed technical and compliance documentation, perform on-site audits or third-party inspections, and include clear quality and IP clauses in procurement contracts. Engaging legal and technical experts during the sourcing process significantly reduces exposure to both quality and IP risks.

Logistics & Compliance Guide for 20 Ton Dump Truck

This guide outlines essential logistics considerations and regulatory compliance requirements for operating a 20-ton dump truck. Adhering to these standards ensures operational efficiency, safety, and legal compliance.

Vehicle Specifications and Classification

A 20-ton dump truck typically refers to a vehicle with a Gross Vehicle Weight Rating (GVWR) of approximately 20 tons (40,000 lbs or 18,144 kg). Accurate classification is critical for regulatory purposes. Such trucks usually fall under Class 7 or Class 8 commercial motor vehicles according to the U.S. Federal Highway Administration (FHWA) vehicle classification system, depending on exact weight and configuration.

Weight Limits and Axle Configurations

Compliance with weight regulations is mandatory. Key considerations include:

- Federal Bridge Formula: Governs maximum weight allowable on groups of axles to prevent road damage. Exceeding limits results in fines and penalties.

- State and Local Limits: Vary significantly—always verify limits for each jurisdiction traveled. Some states allow higher gross weights with permits.

- Axle Load Distribution: Proper load distribution across axles is essential. Overloading any single axle can lead to violations, mechanical failure, and safety hazards.

- Tare and Payload Weighing: Know the truck’s empty (tare) weight and calculate payload accordingly to stay within legal GVWR.

Licensing and Driver Requirements

Operators must meet stringent licensing and qualification standards:

- Commercial Driver’s License (CDL): A Class A or B CDL is required, depending on the truck’s GVWR and trailer configuration.

- Endorsements: A “T” (double/triple trailers) or “N” (tank vehicle) endorsement is typically not required for standard dump trucks, but a “P” (passenger) endorsement is unnecessary unless carrying workers.

- Medical Certification: Drivers must hold a valid Department of Transportation (DOT) medical examiner’s certificate.

- Hours of Service (HOS): Compliance with FMCSA HOS rules, including 11-hour driving limit, 14-hour duty window, and mandatory rest periods, is required.

Safety and Maintenance Compliance

Regular maintenance and safety protocols are vital for reliability and legal compliance:

- Pre-Trip and Post-Trip Inspections: Required by FMCSA; drivers must document vehicle condition using DVIRs (Driver Vehicle Inspection Reports).

- Scheduled Maintenance: Follow manufacturer guidelines for engine, brake, suspension, and hydraulic system servicing.

- Brake Performance: Ensure brakes meet stopping distance requirements under loaded and unloaded conditions.

- Lights, Reflectors, and Signals: All must be operational and compliant with FMVSS (Federal Motor Vehicle Safety Standards).

Cargo Securement and Load Management

Proper load handling prevents spills and accidents:

- Covering Loads: Use tarps or automated covers to prevent debris from falling onto roadways, especially when transporting loose materials like gravel or sand.

- Securement Standards: Adhere to FMCSA cargo securement rules (49 CFR Part 393, Subpart I) to prevent shifting or loss during transit.

- Load Height and Width: Ensure cargo does not exceed legal dimensions (typically 8.5 ft wide and 13.5 ft high in the U.S. without a permit).

Environmental and Emissions Regulations

Modern dump trucks must comply with environmental standards:

- EPA Emissions Standards: Ensure engine meets current EPA regulations (e.g., Tier 4 Final for newer diesel engines).

- Diesel Exhaust Fluid (DEF): For Selective Catalytic Reduction (SCR) systems, maintain adequate DEF levels.

- Spill Prevention: Implement measures to prevent fuel, oil, or hydraulic fluid leaks; carry spill kits on board.

Permits and Road Access

Special permits may be required for certain operations:

- Oversize/Overweight Permits: Needed if exceeding standard weight or dimension limits—obtain from state DOTs.

- Local Access Restrictions: Some urban areas, bridges, or tunnels restrict heavy vehicle access; verify routes in advance.

- Temporary Hauling Permits: May be required for construction-related hauling in residential zones or during off-hours.

Insurance and Liability Coverage

Adequate insurance is mandatory:

- Minimum Liability Coverage: Typically $750,000 for trucks over 10,000 lbs used in interstate commerce.

- Cargo and Physical Damage Insurance: Protects against damage to the truck and load.

- Workers’ Compensation: Required if transporting employees.

Documentation and Recordkeeping

Maintain accurate records for audits and inspections:

- Bill of Lading (BOL): Document each load transported.

- IFTA Records: For fuel tax reporting across jurisdictions (if operating in multiple states).

- ELD Logs: Electronic Logging Devices automatically record HOS data; required for most CDL drivers.

- Registration and Inspection Stickers: Keep up to date and visibly displayed.

Conclusion

Operating a 20-ton dump truck requires strict adherence to logistics planning and regulatory standards. Proactive compliance with weight limits, licensing, maintenance, and safety rules ensures efficient operations, reduces liability, and supports long-term business success. Always consult local, state, and federal regulations as they may vary by region.

Conclusion for Sourcing a 20-Ton Dump Truck:

After a thorough evaluation of available options, specifications, supplier capabilities, and total cost of ownership, sourcing a 20-ton dump truck requires a balanced approach that considers performance, durability, operational efficiency, and after-sales support. It is recommended to prioritize suppliers with a proven track record, comprehensive warranty coverage, and accessible service networks to ensure long-term reliability and minimal downtime.

Key factors such as engine efficiency, payload capacity, fuel consumption, safety features, and compliance with environmental regulations should guide the final selection. Additionally, considering the total cost of ownership—including maintenance, spare parts availability, and resale value—will contribute to a more sustainable investment.

For optimal results, it is advisable to solicit competitive bids from reputable manufacturers or authorized dealers, conduct site visits or equipment demonstrations where possible, and involve technical and operational stakeholders in the decision-making process. By aligning the procurement strategy with operational needs and long-term goals, the acquisition of a 20-ton dump truck will effectively enhance productivity and support project success.