The market for circuit protection devices, including 20 amp single pole breakers, is experiencing steady growth driven by rising infrastructure investments, increased residential and commercial construction, and the expansion of smart grid technologies. According to Grand View Research, the global circuit breakers market was valued at USD 13.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.2% from 2023 to 2030. This growth is fueled by the growing demand for reliable electrical distribution systems and stringent safety regulations across key regions. As the need for efficient load management and overcurrent protection escalates, manufacturers of single pole breakers—particularly in the widely used 20 amp category—are advancing product innovation, durability, and compliance with industry standards such as UL 489 and NEC codes. In this competitive landscape, several leading companies have emerged as dominant suppliers, combining technological expertise with scalable manufacturing to meet global demand.

Top 5 20 Amp Single Pole Breaker Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

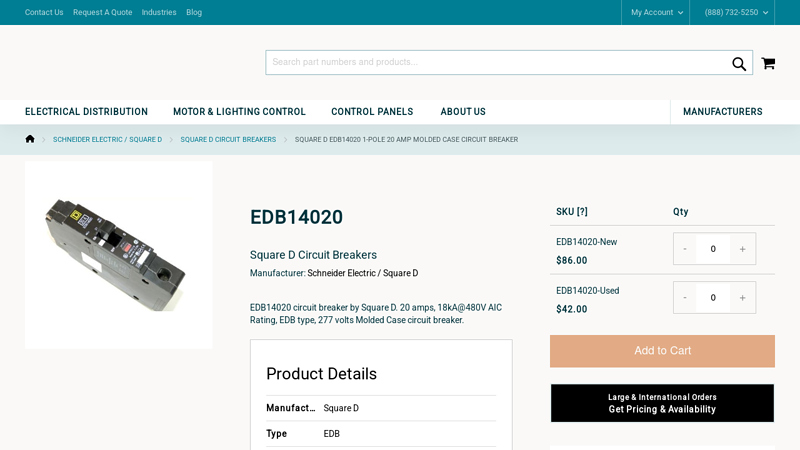

#1 Square D EDB14020 1

Domain Est. 1999

Website: baypower.com

Key Highlights: In stock 5-day deliveryManufacturer: Schneider Electric / Square D. EDB14020 circuit breaker by Square D. 20 amps, 18kA@480V AIC Rating, EDB type, 277 volts Molded Case circuit ……

#2 Circuit Breaker, 1 Pole, 20 Amps

Domain Est. 1995

#3 Electrical circuit breakers

Domain Est. 1996

Website: eaton.com

Key Highlights: Eaton’s low and medium-voltage circuit breakers provide premium protection for overheating wires, overloads and short circuits….

#4 Square D by Schneider Electric FJA140205 Molded Case Circuit …

Domain Est. 1998

Website: omnicable.com

Key Highlights: Square D by Schneider Electric FJA140205 Molded Case Circuit Breaker; 277V, 20 Amp, 1 Pole #FJA140205 | OmniCable….

#5 20 Amp Breaker Single Pole

Domain Est. 2005

Website: cncele.com

Key Highlights: Our 20 Amp Single Pole Circuit Breaker shields residential and small commercial systems from overloads and short circuits—ideal for lighting ……

Expert Sourcing Insights for 20 Amp Single Pole Breaker

H2: 2026 Market Trends for 20 Amp Single Pole Breakers

The market for 20 Amp single pole circuit breakers is poised for steady growth and transformation by 2026, driven by evolving construction practices, regulatory updates, and increased demand for energy-efficient and smart electrical systems. As a foundational component in residential and light commercial electrical panels, the 20 Amp single pole breaker remains essential for branch circuit protection. Key trends shaping its market landscape include:

-

Growth in Residential Construction and Renovations

The ongoing expansion of housing developments—particularly in North America and parts of Asia-Pacific—is fueling demand for standard electrical components, including 20 Amp breakers. Additionally, aging infrastructure in developed markets is prompting widespread electrical panel upgrades and rewiring projects, further boosting replacement demand. -

Adoption of Smart and AFCI/GFCI-Enhanced Breakers

Regulatory mandates, such as those from the National Electrical Code (NEC), continue to expand requirements for arc-fault (AFCI) and ground-fault (GFCI) protection in living areas, kitchens, and bathrooms. As a result, traditional thermal-magnetic breakers are being increasingly replaced by 20 Amp single pole breakers with integrated AFCI/GFCI functionality. The trend toward smart homes is also encouraging adoption of Wi-Fi-enabled or app-monitored breakers, allowing remote control and real-time diagnostics. -

Emphasis on Safety and Code Compliance

Electrical safety standards are becoming more stringent globally. The 2026 market will see a preference for breakers that meet the latest UL 489 and NEC 2023 (and upcoming 2026) requirements. Manufacturers are responding by enhancing trip reliability, reducing nuisance tripping, and improving compatibility with modern electrical loads like EV chargers and heat pumps. -

Supply Chain Resilience and Localization

Post-pandemic supply chain disruptions have prompted manufacturers to diversify sourcing and increase regional production. By 2026, more 20 Amp breakers are expected to be produced closer to end markets (e.g., U.S., Germany, India) to reduce lead times and logistics costs. This shift supports faster deployment in construction cycles and reduces dependency on single-source suppliers. -

Sustainability and Material Efficiency

Environmental regulations and corporate ESG goals are driving innovation in breaker design. Manufacturers are exploring lighter-weight materials, recyclable components, and energy-efficient production methods. While the core function remains unchanged, the environmental footprint of these units is gaining attention among large contractors and institutional buyers. -

Consolidation and Brand Competition

The market remains dominated by key players such as Eaton, Square D (Schneider Electric), Siemens, and Leviton. However, increased competition from mid-tier and emerging brands—especially from Asia—is putting pressure on pricing and driving innovation. By 2026, differentiation through smart features, warranties, and integration with energy management systems will be critical.

In summary, the 2026 market for 20 Amp single pole breakers will be characterized by a shift from basic protection devices to smarter, safer, and code-compliant solutions. While the core design remains stable, advancements in technology, regulatory requirements, and construction dynamics will shape demand, distribution, and product evolution across global markets.

Common Pitfalls Sourcing a 20 Amp Single Pole Breaker (Quality, IP)

Sourcing a reliable and code-compliant 20 Amp single pole circuit breaker is critical for electrical safety and system performance. Overlooking key factors related to quality and intellectual property (IP) can lead to significant risks, including fire hazards, equipment damage, and liability issues. Here are the most common pitfalls to avoid:

Selecting Counterfeit or Non-Listed Breakers

One of the most dangerous pitfalls is purchasing counterfeit or unlisted breakers. These products often mimic reputable brands but lack proper safety certifications (like UL, ETL, or CSA). They may use substandard materials, fail under load, or not trip correctly during overcurrent or short-circuit events. Always verify the breaker is listed with a recognized testing laboratory and purchase only from authorized distributors to avoid life-threatening risks.

Ignoring Brand and Panel Compatibility

Using a breaker not approved for your specific electrical panel (e.g., installing a generic or off-brand breaker in a Siemens, Square D, or GE panel) can void warranties and create dangerous arc faults or improper tripping. Breakers are precisely engineered for the busbar configuration and trip characteristics of their designated panels. Always confirm compatibility using the panel manufacturer’s listing or labeling.

Overlooking Intellectual Property (IP) Infringement

Sourcing breakers that infringe on patented designs or trademarks—such as exact replicas of branded breakers with altered logos—exposes buyers and contractors to legal liability. These knock-offs not only violate IP laws but are often produced without quality control, increasing the risk of failure. Choose reputable suppliers who respect IP and offer genuine or properly licensed products.

Prioritizing Cost Over Safety and Certification

While budget constraints are real, choosing the cheapest available breaker often leads to compromised safety. Low-cost breakers may skip critical testing or use inferior internal components (e.g., weaker bimetallic strips or contacts). Investing in certified, high-quality breakers from trusted manufacturers ensures long-term reliability and compliance with electrical codes (NEC, CEC, etc.).

Failing to Verify Sourcing Channel Authenticity

Purchasing breakers from unauthorized online marketplaces, third-party sellers, or unclear supply chains increases the risk of receiving counterfeit or repackaged products. Always buy from authorized distributors or directly from the manufacturer. Check packaging integrity, serial numbers, and certification marks upon receipt.

Neglecting Environmental and Application Requirements

Some installations—such as damp locations, outdoor enclosures, or industrial settings—require breakers with appropriate Ingress Protection (IP) ratings or environmental durability. Standard indoor breakers may corrode or fail prematurely if exposed to moisture or contaminants. Ensure the breaker is rated for the intended environment to maintain performance and safety.

By recognizing and avoiding these common pitfalls, you ensure the electrical system remains safe, compliant, and reliable. Always prioritize certified, compatible, and legally sourced components when installing or replacing a 20 Amp single pole breaker.

Logistics & Compliance Guide for 20 Amp Single Pole Breaker

Product Overview

A 20 Amp Single Pole Circuit Breaker is a protective electrical device designed to interrupt current flow in a single energized wire when overloads or short circuits occur. It is commonly used in residential and light commercial applications to protect 120-volt branch circuits with a maximum load of 20 amps. Proper logistics handling and compliance are essential for safety, regulatory adherence, and reliable performance.

Regulatory Compliance Requirements

National Electrical Code (NEC)

The 20 Amp Single Pole Breaker must comply with the National Electrical Code (NEC), specifically Article 240 – Overcurrent Protection. Key requirements include:

– Rated for 20 amps and 120/240V AC.

– Listed for use with specific panelboards (e.g., compatible with common brands like Square D, Siemens, Eaton).

– Must meet interrupting rating (AIC) requirements based on the installation environment.

UL Certification

All breakers must be certified by Underwriters Laboratories (UL) under standard UL 489 – Molded-Case Circuit Breakers. Look for the UL Listed mark on packaging and product. UL certification ensures the breaker has been tested for safety, performance, and durability under fault conditions.

RoHS and REACH Compliance

For environmental and material safety, ensure the breaker complies with:

– RoHS (Restriction of Hazardous Substances): Limits the use of lead, mercury, cadmium, and other hazardous materials.

– REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals): Applies to products sold in the EU; requires disclosure of Substances of Very High Concern (SVHC).

Packaging and Labeling Standards

Packaging Requirements

- Breakers must be shipped in manufacturer-sealed, anti-static packaging to prevent damage.

- Inner packaging should prevent movement and contact with conductive materials.

- Outer shipping containers must be sturdy, moisture-resistant, and labeled for electrical equipment.

Labeling Requirements

Each unit and its packaging must include:

– Manufacturer name and model number

– Ampere rating (20A), voltage rating (120/240V)

– Short-circuit current interrupting rating (e.g., 10kA, 22kA)

– UL Listing mark and file number

– Date of manufacture and lot/batch code

– Warning labels: “Do Not Install in Panel Without Proper Training” or similar

Shipping and Handling Guidelines

Transportation

- Use temperature-controlled vehicles; avoid exposure to extreme heat (>55°C) or cold (<-25°C).

- Prevent exposure to moisture, dust, and corrosive atmospheres.

- Stack cartons securely; do not exceed maximum stacking height indicated on packaging.

Handling

- Use clean, dry hands or gloves when handling to avoid contamination.

- Avoid dropping or applying mechanical stress to the breaker.

- Store in original packaging until installation.

Storage Conditions

Environment

- Store in a dry, indoor environment with temperatures between 10°C and 40°C.

- Relative humidity should be maintained below 80% non-condensing.

- Keep away from direct sunlight, chemicals, and electromagnetic interference sources.

Shelf Life

- Most breakers have a recommended shelf life of 5–10 years if stored properly.

- Inspect older inventory for signs of corrosion or packaging degradation before distribution.

Import/Export Considerations

Customs Documentation

For international shipments, ensure compliance with:

– Harmonized System (HS) Code: Typically 8536.30 (circuit breakers, voltage ≤1000V).

– Commercial invoice, packing list, and certificate of origin.

– UL certification documentation and RoHS/REACH declarations.

Country-Specific Approvals

- Canada: Must meet CSA C22.2 No. 234 or be certified by CSA Group.

- European Union: Requires CE marking and compliance with Low Voltage Directive (LVD) and EMC Directive.

- Other regions: Verify local standards (e.g., CCC in China, PSE in Japan).

Installation and Safety Compliance

Qualified Personnel Only

Installation must be performed by licensed electricians in accordance with local codes and manufacturer instructions.

Improper installation voids warranties and creates fire or shock hazards.

Panel Compatibility

Verify breaker compatibility with the load center (panelboard) model. Mixing brands may violate NEC 110.3(B) and create safety risks.

Post-Installation Testing

After installation, perform continuity and trip testing to ensure proper function. Document testing for compliance records.

Warranty and Recalls

Manufacturer Warranty

Typical warranty: 10 years limited. Retain proof of purchase and installation records.

Recall Monitoring

Register products with the manufacturer to receive safety alerts. Monitor CPSC (U.S. Consumer Product Safety Commission) and manufacturer websites for recall notices.

Disposal and Recycling

End-of-Life Handling

- Do not dispose of in regular trash. Circuit breakers contain electronic components and metals.

- Follow local e-waste regulations. Many manufacturers offer take-back or recycling programs.

- If damaged or recalled, follow specific disposal instructions from the manufacturer or regulatory body.

Summary

Proper logistics and compliance for 20 Amp Single Pole Breakers ensure safety, reliability, and legal adherence. From UL certification and proper storage to correct installation and end-of-life recycling, every step must follow established standards. Always consult the manufacturer’s documentation and local regulatory authorities to remain compliant.

Conclusion for Sourcing a 20 Amp Single-Pole Breaker:

Sourcing a 20 amp single-pole circuit breaker requires careful consideration of compatibility, safety standards, and application requirements. It is essential to verify that the breaker is compatible with the specific brand and model of the electrical panel (e.g., Siemens, Square D, GE, or Eaton), as using a non-listed or incompatible breaker can pose serious safety hazards and may violate electrical codes.

When selecting a breaker, ensure it is certified by a recognized testing laboratory (such as UL or ETL) and meets current National Electrical Code (NEC) standards. While many 20 amp single-pole breakers are interchangeable within the same manufacturer’s load center line, universal breakers should be avoided unless explicitly approved for use in the panel.

Purchasing from reputable suppliers or authorized distributors helps ensure authenticity and reliability. Additionally, consulting a licensed electrician is recommended to confirm proper installation and compliance with local codes. In summary, sourcing the correct 20 amp single-pole breaker involves prioritizing safety, compatibility, and code adherence to ensure the electrical system operates efficiently and safely.