The global fertilizer market is experiencing robust growth, driven by rising agricultural demand to support an expanding population and increasing focus on crop yield optimization. According to Grand View Research, the global fertilizer market size was valued at USD 207.0 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 5.7% from 2024 to 2030. This expansion is further fueled by advancements in precision farming and government initiatives promoting food security. Among the various NPK formulations, 20-5-10—known for its balanced nitrogen content and suitability for vegetative growth—has become a preferred choice for a wide range of crops. As demand for high-efficiency, balanced fertilizers rises, manufacturers specializing in this formulation are scaling production and innovating delivery methods. Based on market presence, production capacity, and product quality, we examine the top 8 manufacturers leading the 20-5-10 fertilizer segment in this evolving landscape.

Top 8 20-5-10 Fertilizer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 LESCO 20

Domain Est. 1995

Website: siteone.com

Key Highlights: This 20-5-10 Professional Turf Fertilizer incorporates PolyPlus® OPTI™ Polymer Coated Urea, a controlled-release technology that steadily feeds nitrogen to turf ……

#2 20 5 10 fertilizer manufacturer

Domain Est. 2014

Website: hhfertilizer.com

Key Highlights: The numbers in the fertilizer ratio 20-5-10 represent the percentage by weight of three key macronutrients that are essential for plant growth nitrogen (N), ……

#3 Eckroat Seed Co Products

Domain Est. 1998

Website: eckroatseed.com

Key Highlights: Seeds, fertilizers, chemicals, pest control, and more. Everything you need for your exterior project. Call us today….

#4 Milorganite Fertilizer

Domain Est. 1999

Website: milorganite.com

Key Highlights: Milorganite can be used with confidence for all of your fertilizing needs, including lawns, trees, shrubs, flowers, and vegetables when used as directed….

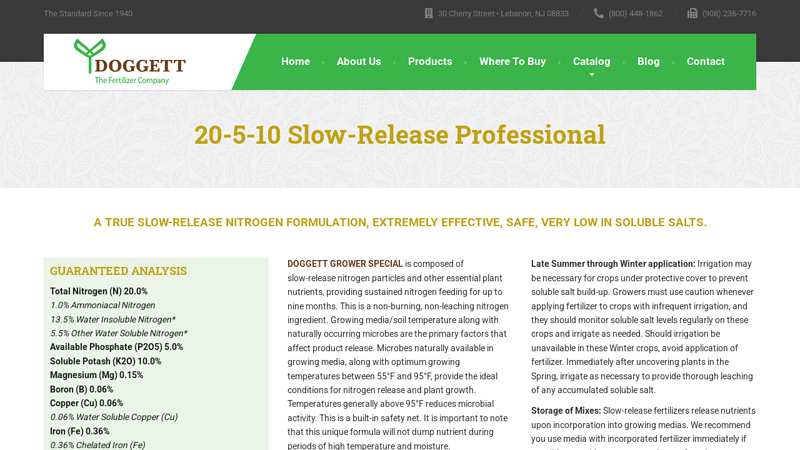

#5 20

Domain Est. 2001

Website: doggettcorp.com

Key Highlights: A true slow-release nitrogen formulation, extremely effective, safe, very low in soluble salts. Guaranteed analysis….

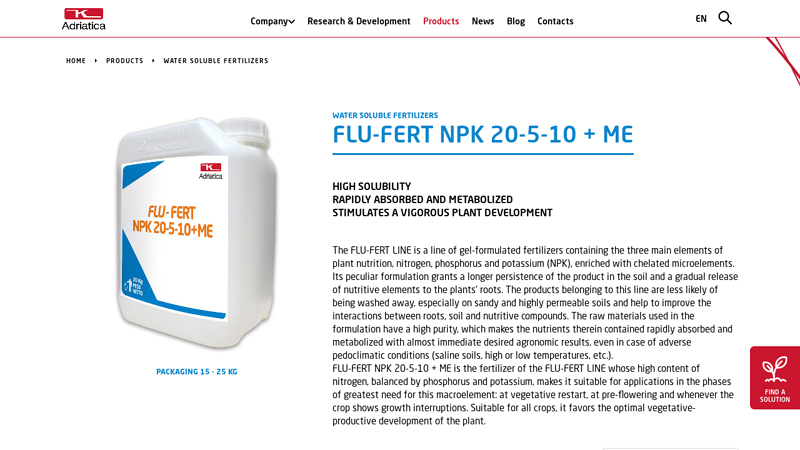

#6 FLU

Domain Est. 2014

Website: k-adriatica.it

Key Highlights: The FLU-FERT LINE is a line of gel-formulated fertilizers containing the three main elements of plant nutrition, nitrogen, phosphorus and potassium (NPK), ……

#7 High

Domain Est. 2023

Website: king-boron.com

Key Highlights: The 20-5-10 slow release fertilizer composition means that your plants receive nitrogen, phosphorus, and potassium in the optimal ratio for sustained growth….

#8 Doggett 20

Website: tipco.green

Key Highlights: In stock Free deliveryDOGGETT GROWER SPECIAL is composed of slow-release nitrogen particles and other essential plant nutrients, providing sustained nitrogen feeding for up to nine…

Expert Sourcing Insights for 20-5-10 Fertilizer

H2: Market Trends for 20-5-10 Fertilizer in 2026

The 2026 market for 20-5-10 fertilizer—a balanced NPK (Nitrogen-Phosphorus-Potassium) formulation widely used in agriculture for crops requiring strong vegetative growth and root development—is expected to be shaped by macroeconomic conditions, technological advancements, sustainability initiatives, and evolving agricultural practices. Below is an analysis of key trends anticipated to influence the 20-5-10 fertilizer market in 2026:

-

Increased Demand from Sustainable and Precision Farming

By 2026, precision agriculture is projected to gain wider adoption globally, especially in North America and Europe. This trend drives demand for targeted fertilizer applications, with 20-5-10 formulations being optimized through variable-rate technology (VRT) and soil testing. Farmers are increasingly using data analytics to apply fertilizers more efficiently, reducing waste and environmental impact while maintaining crop yields. -

Rising Focus on Soil Health and Nutrient Management

Regulatory and environmental pressures are pushing farmers to adopt best nutrient management practices. The 20-5-10 blend, with its higher nitrogen content, supports leafy and vegetative growth in crops like corn, sugarcane, and turfgrass. In 2026, its use is expected to grow in integrated nutrient management (INM) systems that combine synthetic fertilizers with organic inputs to improve long-term soil fertility and reduce nitrogen leaching. -

Regional Demand Variations

- Asia-Pacific: Countries like India, China, and Indonesia are expected to remain key markets due to large agricultural sectors and government subsidies on fertilizers. The 20-5-10 formulation is popular in rice and vegetable cultivation, driving steady demand.

- Sub-Saharan Africa: As agricultural productivity initiatives expand, demand for balanced NPK fertilizers like 20-5-10 is likely to rise, supported by development programs and improved distribution networks.

-

North America and Europe: Demand may grow moderately, with a shift toward enhanced-efficiency fertilizers (EEFs) and controlled-release versions of 20-5-10 to comply with environmental regulations.

-

Volatility in Raw Material Prices

The production cost of 20-5-10 fertilizer is sensitive to fluctuations in nitrogen (from natural gas), phosphate rock, and potash prices. In 2026, geopolitical stability, energy markets, and trade policies—particularly involving major potash exporters like Canada, Russia, and Belarus—will continue to influence pricing and availability. Manufacturers may increasingly hedge inputs or explore alternative nutrient sources. -

Growth of Blended and Custom Fertilizers

The trend toward custom-blended fertilizers tailored to specific soil and crop needs is expected to accelerate. The 20-5-10 ratio serves as a base in many blended products, often modified with micronutrients (e.g., zinc, boron) or soil conditioners. In 2026, agri-service providers and cooperatives are likely to offer more customized 20-5-10-based solutions, enhancing its market relevance. -

Regulatory and Environmental Pressures

Stricter regulations on nitrogen runoff and greenhouse gas emissions (particularly nitrous oxide) may affect the application rates and timing of 20-5-10 fertilizer use. In response, manufacturers may reformulate products with nitrification inhibitors or promote split-application techniques to minimize environmental impact. -

Innovation in Fertilizer Delivery Systems

Advances in fertilizer technology, such as polymer-coated or stabilized nitrogen formulations, are expected to improve the efficiency of 20-5-10 blends. These innovations reduce volatilization and leaching, making the fertilizer more attractive under sustainability certification programs. -

Impact of Climate Change

Changing weather patterns—including increased droughts and erratic rainfall—may influence fertilizer application strategies. In 2026, the resilience of crops treated with balanced NPK fertilizers like 20-5-10 could bolster their use, especially when combined with drought-tolerant seed varieties and conservation tillage.

Conclusion:

In 2026, the 20-5-10 fertilizer market will be characterized by a blend of traditional demand drivers and emerging sustainability imperatives. While global food security concerns sustain baseline demand, innovations in precision agriculture, environmental regulations, and customized nutrient solutions will redefine how and where this balanced fertilizer is used. Producers who adapt to these trends—through product innovation, supply chain resilience, and farmer education—are likely to capture growing market opportunities.

H2: Common Pitfalls When Sourcing 20-5-10 Fertilizer (Quality and Intellectual Property Concerns)

Sourcing 20-5-10 fertilizer—containing 20% nitrogen (N), 5% phosphorus (P₂O₅), and 10% potassium (K₂O)—can be efficient for crop nutrition, but several pitfalls related to quality and intellectual property (IP) must be carefully managed to avoid inefficiencies, legal issues, or reduced agricultural performance.

1. Inconsistent Nutrient Content and Quality Control

A major pitfall is receiving substandard or inconsistent fertilizer batches. Some suppliers, particularly lesser-known or unregulated manufacturers, may not adhere to strict quality control standards, resulting in actual nutrient levels that fall below the labeled 20-5-10 ratio. This can lead to under-fertilization, reduced crop yields, or the need for corrective applications. Always verify third-party lab testing and request Certificates of Analysis (CoA) to confirm nutrient content and absence of contaminants like heavy metals.

2. Use of Inferior or Non-Standard Raw Materials

The source of raw materials significantly affects fertilizer performance. Some low-cost producers use lower-grade or non-standard chemical inputs that may reduce solubility, nutrient availability, or cause soil buildup of impurities. For example, using technical-grade rather than agricultural-grade potassium sources can introduce unwanted compounds. Ensure your supplier discloses raw material sources and complies with international quality benchmarks (e.g., ISO, OMRI for organic systems).

3. Lack of Traceability and Transparency

Opaque supply chains increase the risk of counterfeit or misrepresented products. Without clear traceability, it’s difficult to verify the origin, manufacturing process, or consistency of the fertilizer. This is especially critical when sourcing from international markets where regulatory oversight varies. Demand full supply chain transparency, including manufacturing location and batch tracking.

4. Intellectual Property Infringement Risks

Branded or patented fertilizer formulations may be protected under intellectual property laws. Some generic or private-label suppliers may produce knock-offs that mimic popular 20-5-10 formulations, potentially infringing on proprietary blends or trademarks. Sourcing such products—especially in regulated markets—can expose buyers to legal liability. Conduct due diligence to ensure the product does not violate existing patents or registered formulations.

5. Mislabeling and Regulatory Non-Compliance

Improper labeling (e.g., inaccurate N-P-K values, missing micronutrients, or false claims) is a common issue, particularly with imported fertilizers. Regulatory bodies like the EPA (U.S.) or EFSA (EU) enforce strict labeling standards. Using mislabeled fertilizer can lead to compliance penalties, environmental harm, or voided crop insurance. Confirm that products meet local regulatory requirements and carry proper registration numbers.

6. Inadequate Packaging and Storage Conditions

Poor packaging (e.g., non-moisture-resistant bags) or improper storage during transit can degrade fertilizer quality through caking, nutrient loss, or contamination. This is often overlooked when sourcing from distant suppliers. Specify packaging standards in procurement contracts and verify storage conditions throughout the supply chain.

7. Overreliance on Unverified Supplier Claims

Some suppliers may exaggerate product efficacy, sustainability credentials, or compatibility with certain crops. Claims such as “slow-release” or “organic-compliant” must be validated through independent certification (e.g., OMRI, CDFA). Avoid sourcing based solely on marketing materials—request trial data or field performance records.

Mitigation Strategies:

– Partner with reputable, certified suppliers with verifiable quality systems.

– Include quality specifications and IP compliance clauses in contracts.

– Conduct periodic audits and product testing.

– Work with legal counsel to assess IP risks when adopting new formulations.

By proactively addressing these pitfalls, agricultural operations can ensure reliable access to effective, legally compliant 20-5-10 fertilizer that supports optimal crop production and long-term soil health.

H2: Logistics & Compliance Guide for 20-5-10 Fertilizer

This guide outlines key logistics and compliance considerations for handling, transporting, storing, and using 20-5-10 fertilizer (20% Nitrogen, 5% Phosphorus as P₂O₅, 10% Potassium as K₂O). Adherence to these guidelines ensures safety, regulatory compliance, and product efficacy.

H3: Regulatory Classification & Compliance

- GHS/OSHA Hazard Communication (HazCom):

- Classification: Typically classified as Not classified under GHS for physical or health hazards. However, it may carry specific hazard statements depending on form and impurities.

- Hazard Statements (May Include):

- H228: Flammable solid (if dusty and fines are present, though uncommon for standard granular forms).

- H319: Causes serious eye irritation.

- H412: Harmful to aquatic life with long-lasting effects.

- Safety Data Sheet (SDS): MANDATORY. Obtain and maintain the current SDS from your supplier. Review Section 2 (Hazard Identification), Section 4 (First Aid Measures), Section 7 (Handling and Storage), Section 8 (Exposure Controls/Personal Protection), Section 9 (Physical and Chemical Properties), and Section 13 (Disposal Considerations). Ensure SDS is accessible to all handlers.

- EPA Regulations (USA):

- FIFRA: Fertilizers are generally exempt from FIFRA registration as they are not pesticidal. However, labeling must comply with state and federal fertilizer laws.

- Nutrient Management: Subject to State Fertilizer Laws and potentially Nutrient Management Plans (NMPs) or Nutrient Management Regulations (especially in sensitive watersheds like Chesapeake Bay, Great Lakes). These regulate application rates, timing, setbacks from water bodies, and recordkeeping to prevent nutrient runoff (eutrophication). Know and comply with local/state regulations.

- SPCC Plan: Facilities storing large quantities of oil (e.g., for equipment) may need an SPCC plan, but the fertilizer itself doesn’t trigger this. However, storage practices should prevent contamination of stormwater.

- DOT (USA) / Transport Canada (TDG):

- Classification: Generally Not regulated as a hazardous material for transport under 49 CFR (DOT) or TDG regulations when in solid form (granular, prilled) due to its low hazard profile.

- Packaging: Must be in sturdy, non-leaking containers (bags, totes, bulk) suitable for the mode of transport. Ensure bags are securely closed and pallets are stable.

- Documentation: Standard Bill of Lading (BOL) sufficient. SDS must accompany shipment if requested or if specific hazards are indicated on the label/SDS.

- Segregation: No special segregation required from most goods, but avoid direct contact with strong oxidizers, acids, or foodstuffs. Keep separate from incompatible materials.

- International Transport (IMDG, IATA): Similar to DOT/TDG, 20-5-10 fertilizer is typically not regulated as dangerous goods for air or sea freight when in solid form. Verify specific UN number/Proper Shipping Name (e.g., UN 2067, FERTILIZER, SOLID, N.O.S. (contains ammonium nitrate)) only if it contains significant quantities of regulated components like ammonium nitrate (>45% in some cases) – rare for standard 20-5-10 blends. Check the SDS and consult regulations.

- State & Local Regulations: CRITICAL. Compliance with state departments of agriculture (labeling, registration, quality standards) and local ordinances (noise, dust control, operating hours near residences) is paramount. Permits may be required for large storage facilities.

H3: Handling & Personal Protection (PPE)

- Minimize Dust: Handle gently to avoid generating dust. Use enclosed transfer systems where possible.

- Personal Protective Equipment (PPE):

- Mandatory: Safety glasses or chemical splash goggles. Dust mask (N95 or equivalent) if significant dust is generated during handling (loading, emptying, spreading).

- Recommended: Long sleeves, long pants, chemical-resistant gloves (e.g., nitrile) to prevent skin irritation, sturdy footwear.

- Hygiene: Wash hands and exposed skin thoroughly with soap and water after handling, before eating, drinking, or using the restroom. Do not eat, drink, or smoke in handling areas.

- Spills: Sweep up solid spills promptly. Avoid creating dust. Collect material in a suitable, dry, covered container for disposal or reuse. Prevent entry into drains, sewers, or waterways. Report significant spills per site procedures.

H3: Storage Requirements

- Location: Store in a cool, dry, well-ventilated area. Protect from direct sunlight, heat sources, and moisture.

- Containers: Keep in original, tightly closed containers. If decanted, use clean, dry, non-reactive containers clearly labeled.

- Palletizing: Store bags on pallets to prevent moisture absorption from the floor. Stack neatly and securely to prevent collapse. Follow manufacturer’s stacking height recommendations.

- Segregation: Store away from strong oxidizing agents (e.g., chlorine, peroxides), strong acids, bases, and food/feedstuffs. Maintain separation from combustible materials if significant dust is present.

- Environmental Protection: Store on an impervious surface (concrete). Implement measures (e.g., berms, secondary containment) to prevent leaching into soil or runoff into storm drains, especially for bulk storage. Cover bulk piles if stored outdoors.

- Inventory & Rotation: Practice First-In, First-Out (FIFO) inventory management to prevent product degradation over time. Monitor for caking or moisture absorption.

- Security: Secure storage area against unauthorized access, especially from children.

H3: Transportation Logistics

- Mode Selection: Choose appropriate transport (truck, rail, container ship) based on volume, distance, and destination.

- Loading/Unloading:

- Use appropriate equipment (forklifts, conveyors) rated for the load.

- Handle bags carefully to avoid tearing. Do not drag or drop.

- Secure loads on trucks/trailers to prevent shifting during transit (e.g., straps, load bars, dunnage).

- Documentation: Ensure BOL, delivery notes, and SDS (if required) are complete and accompany the shipment. Confirm recipient information and delivery instructions.

- Carrier Requirements: Communicate any specific handling instructions to the carrier. Ensure the carrier is aware of the product nature (non-hazardous fertilizer).

- Temperature: Avoid prolonged exposure to extreme heat during transit, which can increase caking potential.

H3: Application & Environmental Stewardship

- Calibration: Calibrate spreaders (broadcast, drop) accurately according to the recommended application rate on the product label or your nutrient management plan.

- Weather Conditions: Avoid application immediately before heavy rain or on saturated/compact soils to minimize runoff. Avoid application on frozen ground if runoff risk is high.

- Setbacks: Adhere strictly to required buffer zones (setbacks) from surface water bodies (rivers, lakes, streams, ditches), wells, and drains as mandated by regulations or best management practices (BMPs).

- Recordkeeping: Maintain detailed records of application: Date, location (field/area), product used (name, lot #), application rate, total amount applied, weather conditions, applicator name. This is crucial for regulatory compliance (NMPs), traceability, and environmental protection.

- Spill Prevention: Use care during filling spreaders to prevent spills. Have a containment plan (e.g., shovel, bucket) readily available.

H3: Disposal

- Unused Product: If unused product is sound, consider using it according to label directions. Contact the supplier or manufacturer for potential take-back programs.

- Contaminated Material/Spills: Collect contaminated soil or sweepings. Dispose of as non-hazardous solid waste in accordance with local, state, and federal regulations. Consult your local waste authority.

- Empty Containers:

- Triple Rinse: Puncture or crush rinsed containers to prevent reuse. Follow triple-rinse procedure if required by label/SDS.

- Recycling: Participate in agricultural container recycling programs (e.g., PLASTIC FARM, Ag Container Recycling Council – ACRC in USA) if available. Check local options.

- Landfill: If recycling is not available and rinsed, dispose of in a permitted sanitary landfill as non-hazardous waste. Never burn plastic fertilizer bags.

- SDS Guidance: Always refer to Section 13 (Disposal Considerations) of the SDS for specific disposal recommendations.

Disclaimer: This guide provides general information. Regulations vary significantly by country, state, and locality. Always consult the product’s Safety Data Sheet (SDS), the product label, and all applicable federal, state, provincial, and local regulations for the most accurate and legally binding requirements. Engage with your supplier, regulatory agencies (e.g., State Dept of Ag, EPA regional office), and environmental consultants as needed.

In conclusion, sourcing a 20-5-10 fertilizer provides an effective solution for promoting strong plant growth, particularly in scenarios requiring a balanced yet nitrogen-rich nutrient profile. This NPK ratio supports vigorous leaf development, moderate root and flower growth, and overall plant health, making it suitable for lawns, leafy vegetables, and general landscape use. When sourcing this fertilizer, it is important to consider factors such as product quality, cost-effectiveness, availability, and environmental impact. Whether choosing organic or synthetic variants, reliable suppliers, proper storage, and adherence to local regulations ensure optimal performance and sustainability. By selecting a reputable source and applying the fertilizer according to recommended guidelines, growers can maximize yields, improve soil fertility, and achieve long-term agricultural or horticultural success.