The global wheelbarrow market is experiencing steady growth, driven by rising demand across construction, agriculture, and landscaping sectors. According to Grand View Research, the global hand truck and wheelbarrow market size was valued at USD 1.2 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.8% from 2023 to 2030. This growth is fueled by increased infrastructure development, particularly in emerging economies, and a growing emphasis on labor-saving equipment in both professional and residential applications. Among product segments, two-wheel metal wheelbarrows are gaining preference for their stability, durability, and load-bearing capacity—making them ideal for rugged worksite conditions. As demand rises, several manufacturers have distinguished themselves through innovation, material quality, and scalable production. Based on market presence, product performance, and industry reputation, the following are seven leading manufacturers at the forefront of the two-wheel metal wheelbarrow market.

Top 7 2 Wheel Metal Wheelbarrow Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 2

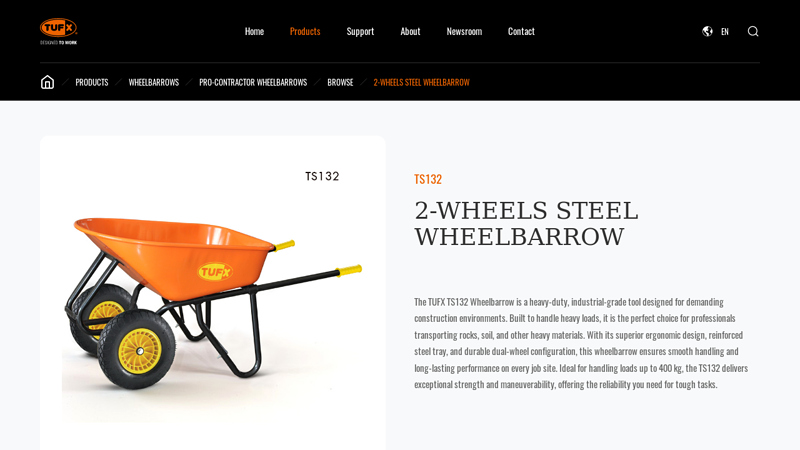

Domain Est. 2005

Website: tufx.com

Key Highlights: The TUFX TS132 Wheelbarrow is a heavy-duty, industrial-grade tool designed for demanding construction environments. Built to handle heavy loads, ……

#2 RACE 2

Domain Est. 2000

Website: bigrocksupply.com

Key Highlights: In stock Free deliveryRACE 2-Wheel Wheelbarrow (RACE-2WWFF) with 6 cu ft capacity, heavy tubular steel frame, skid plate protection, dual flat-free tires, and durable tray tip….

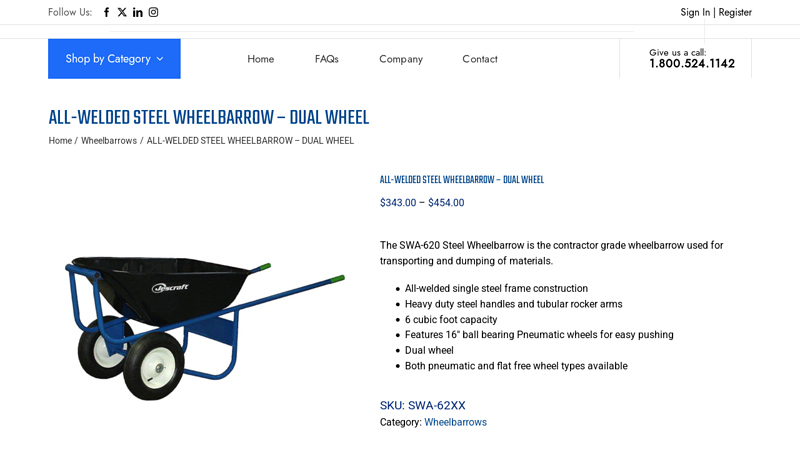

#3 ALL

Domain Est. 2005

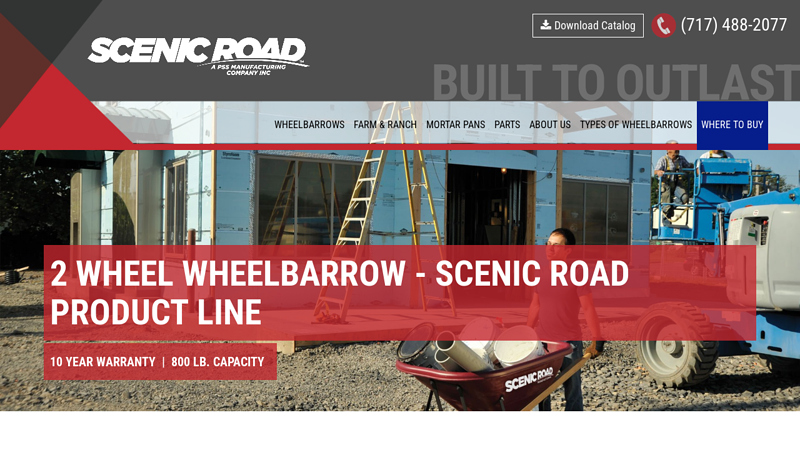

#4 2 Wheel Wheelbarrow

Domain Est. 2009

Website: scenicroadmfg.com

Key Highlights: 2 wheeled wheelbarrows by Scenic Road. Extra thick high-density polyethylene Tray with UV stabilizers, heavy duty bearing wheel assembly….

#5 Wheelbarrows & Carts

Domain Est. 2021

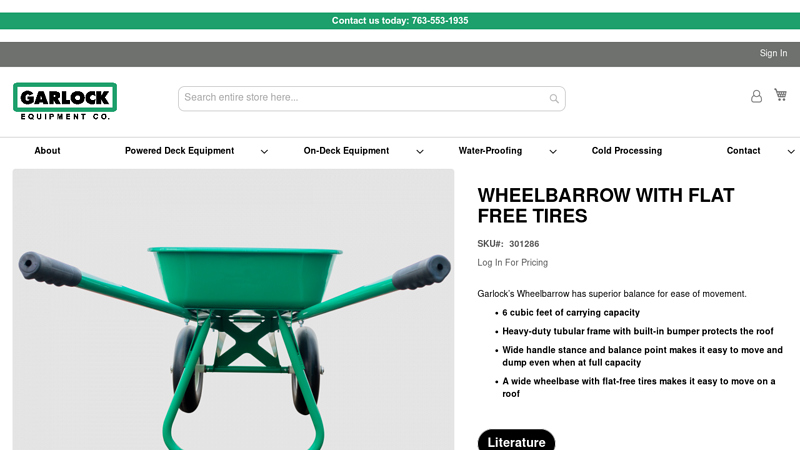

#6 Wheelbarrow with Flat Free Tires

Domain Est. 2021

#7 Jackson

Website: jacksonwheelbarrow.com

Key Highlights: Crafted with heavy-duty steel trays, solid hardwood handles, and innovative stabilizers, these wheelbarrows are built to handle the toughest jobs without …Missing: 2 metal…

Expert Sourcing Insights for 2 Wheel Metal Wheelbarrow

H2: 2026 Market Trends for 2-Wheel Metal Wheelbarrow

The global market for 2-wheel metal wheelbarrows is poised for steady growth and transformation by 2026, driven by advancements in materials, evolving consumer demands, and increasing infrastructure and landscaping activities worldwide. This analysis examines key trends shaping the 2-wheel metal wheelbarrow segment across industrial, commercial, and residential applications.

-

Rising Demand in Construction and Landscaping Sectors

The continued expansion of construction, agriculture, and urban landscaping projects—particularly in emerging economies—will fuel demand for durable, high-capacity transport tools. The 2-wheel metal wheelbarrow, known for enhanced stability and heavier load capacity compared to single-wheel models, is increasingly preferred on job sites. By 2026, growing investments in infrastructure development in regions such as Asia-Pacific, the Middle East, and Africa are expected to significantly boost market demand. -

Shift Toward Durable, Corrosion-Resistant Materials

Manufacturers are responding to customer demands for longevity and low maintenance by upgrading from traditional steel to powder-coated steel, galvanized metal, and stainless-steel variants. These materials offer improved resistance to rust and wear, especially in humid or outdoor environments. By 2026, wheelbarrows made with advanced metal composites are expected to dominate premium market segments. -

Emphasis on Ergonomic Design and User Comfort

With increasing awareness of workplace safety and ergonomics, manufacturers are integrating design improvements such as padded handles, balanced weight distribution, and pneumatic or solid rubber tires. These features reduce user fatigue and injury risk, making 2-wheel metal wheelbarrows more attractive to professional landscapers and construction workers. The trend toward user-centric design will be a key differentiator in competitive markets. -

Growth in DIY and Home Improvement Markets

The surge in home improvement and gardening activities—accelerated by post-pandemic lifestyle changes—continues to support demand in the consumer segment. Homeowners favor 2-wheel models for their stability when transporting soil, mulch, or stones. Retailers and e-commerce platforms are expected to expand product offerings tailored to DIY users, including lightweight metal designs and easy-assembly options. -

Sustainability and Circular Manufacturing Practices

By 2026, environmental considerations will play a larger role in manufacturing decisions. Brands are adopting sustainable practices such as using recycled metals, minimizing waste in production, and designing for durability and recyclability. Eco-conscious consumers and business buyers are increasingly favoring brands with transparent, sustainable supply chains. -

Regional Market Dynamics

North America and Europe will remain significant markets due to high construction activity and stringent safety standards. However, the fastest growth is anticipated in Asia-Pacific, led by countries like India and Vietnam, where urbanization and government-funded infrastructure projects are on the rise. Localized production and distribution networks will be critical for market penetration. -

Competitive Landscape and Innovation

The market will see increased competition between established manufacturers and new entrants offering innovative features such as foldable frames, modular trays, or integrated tool storage. Digital marketing and direct-to-consumer sales models will enable smaller brands to compete with traditional industry leaders.

Conclusion

By 2026, the 2-wheel metal wheelbarrow market will be characterized by innovation in materials, design, and sustainability, supported by strong demand from both professional and consumer sectors. Companies that prioritize durability, user experience, and environmental responsibility are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls When Sourcing a 2-Wheel Metal Wheelbarrow: Quality and Intellectual Property Concerns

Sourcing a 2-wheel metal wheelbarrow—especially for bulk procurement or private labeling—can present several challenges, particularly in ensuring product quality and avoiding intellectual property (IP) issues. Being aware of these pitfalls helps mitigate risks and ensures a reliable, legally compliant supply chain.

Overlooking Material Quality and Durability

One of the most frequent mistakes is failing to verify the quality of materials used in construction. Many low-cost suppliers use thin-gauge steel or substandard coatings that lead to rust, warping, or structural failure under load. Buyers may be attracted by low prices but end up with wheelbarrows that degrade quickly, especially in outdoor or high-moisture environments. Always request material specifications (e.g., steel gauge, powder coating type) and conduct third-party testing when possible.

Inadequate Load Capacity Testing

Some suppliers exaggerate load ratings without proper testing. A wheelbarrow advertised as capable of carrying 200 kg may fail under half that weight due to weak welds, poor wheel attachment, or inadequate frame design. Insist on performance test reports or on-site load testing during factory audits to validate claims.

Poor Welding and Assembly Standards

Inconsistent or poorly executed welding compromises structural integrity. Look for signs of incomplete welds, burn-throughs, or misaligned joints. These defects can lead to premature failure, especially at stress points like the tray-to-frame connection. Factory audits and sample inspections (e.g., AQL checks) are essential to assess build quality.

Substandard Wheel and Bearing Components

While the tray gets the most attention, the wheels are critical for functionality. Low-quality pneumatic tires, plastic hubs, or non-sealed bearings wear out quickly and increase maintenance. Ensure wheels are rated for the intended terrain and load. Consider requesting greaseable or sealed bearings for longevity.

Ignoring Design and Ergonomics

A poorly balanced or awkwardly designed wheelbarrow can cause user fatigue and safety issues. The center of gravity, handle angle, and tray depth all impact usability. Avoid copying designs without understanding ergonomic principles—this not only affects customer satisfaction but can also lead to safety liabilities.

Intellectual Property Infringement Risks

Copying popular wheelbarrow designs—especially those with patented shapes, folding mechanisms, or unique axle systems—can result in legal action. Even minor design similarities may trigger IP disputes, particularly in markets like the U.S. or EU. Always conduct a design freedom-to-operate (FTO) search and consider custom engineering to differentiate your product legally.

Relying on Unverified Suppliers

Sourcing from suppliers without proper due diligence increases the risk of counterfeit goods, delayed shipments, or non-compliance with safety standards. Verify certifications (e.g., ISO, CE if applicable), conduct factory audits, and start with small trial orders before scaling.

Lack of Compliance with Regional Safety Standards

Different markets have varying requirements for hand tools and outdoor equipment. For example, the EU may require CE marking with mechanical safety directives, while North America may look for compliance with ANSI or CSA standards. Failing to meet these can result in shipment rejections or fines.

By addressing these pitfalls proactively—through supplier vetting, quality control protocols, and IP due diligence—businesses can source reliable, compliant 2-wheel metal wheelbarrows that meet customer expectations and avoid costly setbacks.

Logistics & Compliance Guide for 2-Wheel Metal Wheelbarrow

Conclusion for Sourcing a Two-Wheel Metal Wheelbarrow:

After a thorough evaluation of product quality, durability, cost, supplier reliability, and market demand, sourcing a two-wheel metal wheelbarrow proves to be a sound investment for both commercial and residential applications. The two-wheel design offers enhanced stability and load capacity compared to single-wheel models, while the metal construction ensures long-term durability in demanding environments such as construction sites, landscaping projects, and agricultural settings.

Sourcing from reputable manufacturers, particularly those offering galvanized or powder-coated steel options, ensures resistance to rust and wear, thereby reducing maintenance costs and extending product lifespan. Additionally, competitive pricing and the potential for bulk purchasing further improve cost-efficiency. Reliable suppliers with certifications, favorable lead times, and strong logistical support contribute to a sustainable supply chain.

In conclusion, the two-wheel metal wheelbarrow is a practical, durable, and cost-effective solution that meets the needs of professional users and DIY consumers alike. Strategic sourcing from qualified suppliers will ensure consistent quality, timely delivery, and strong return on investment, making it a recommended addition to any procurement portfolio in the tools and equipment sector.