The global fire protection equipment market is experiencing steady growth, driven by increasing industrialization, stricter safety regulations, and urban development. According to Mordor Intelligence, the Fire Protection Equipment Market was valued at USD 74.2 billion in 2023 and is projected to reach USD 101.3 billion by 2029, growing at a CAGR of 5.3% during the forecast period. A critical component within this ecosystem is the 2-inch fire hose—a standard size widely used in municipal fire brigades, industrial facilities, and commercial buildings for its balance of maneuverability and water delivery capacity. With rising demand across both developed and emerging economies, manufacturers of 2-inch fire hoses are scaling production, enhancing durability with advanced materials, and focusing on compliance with international standards such as NFPA, BS, and IS. As procurement teams and safety officers seek reliable suppliers, identifying leading manufacturers becomes essential for ensuring quality, performance, and supply chain resilience. Below is a data-informed overview of the top nine 2-inch fire hose manufacturers shaping the industry’s competitive landscape.

Top 9 2 Inch Fire Hose Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Hart Industries, Inc.

Domain Est. 1995

Website: hose.com

Key Highlights: Hart Industries, Inc. is a Hose Supplier founded in Middletown, Ohio in 1967. We also sell products such as hose fittings, hose connectors, and valves….

#2 Mercedes Textiles

Domain Est. 1999

Website: mercedestextiles.com

Key Highlights: For more than 40 years we’ve offered a full line of hoses, pumps, couplings and accessories all with one unrelenting goal – keep people safe….

#3 North American Fire Hose

Domain Est. 2000

Website: nafhc.com

Key Highlights: North American Fire Hose is the industry’s most experienced manufacturer of innovative fire hose products. Our top priority is the safety of firefighters.Missing: 2 inch…

#4 ZYfire Hose Corporation

Domain Est. 2003 | Founded: 2000

Website: zyfire.com

Key Highlights: ZYfire Hose Corporation, founded in 2000, is the leader in research and production of Lay flat frac hoses, fire hose, rack hose, industrial hose, forestry hose….

#5 Snap

Domain Est. 2019 | Founded: 1969

Website: snaptitehose.com

Key Highlights: Snap-tite Hose – NFPA-certified, Made in USA lay-flat hoses for firefighting, industrial, and agricultural needs. Trusted since 1969 for quality….

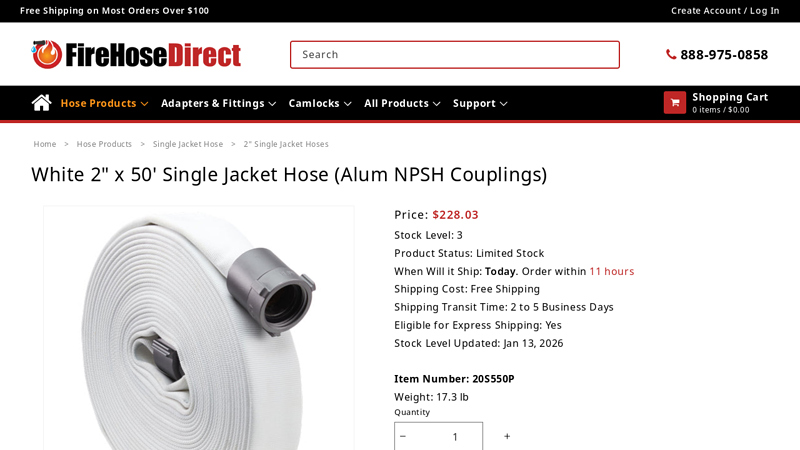

#6 White 2″ x 50′ Single Jacket Hose (20S550P)

Domain Est. 2011

Website: firehosedirect.com

Key Highlights: In stock Free deliveryMade In USA · Hose Size: 2 inches (Inside Diameter) · Hose Length : 50 feet (Approximately) · Male Coupling: Aluminum 2 inch NPSH · Swivel Female Coupling: …

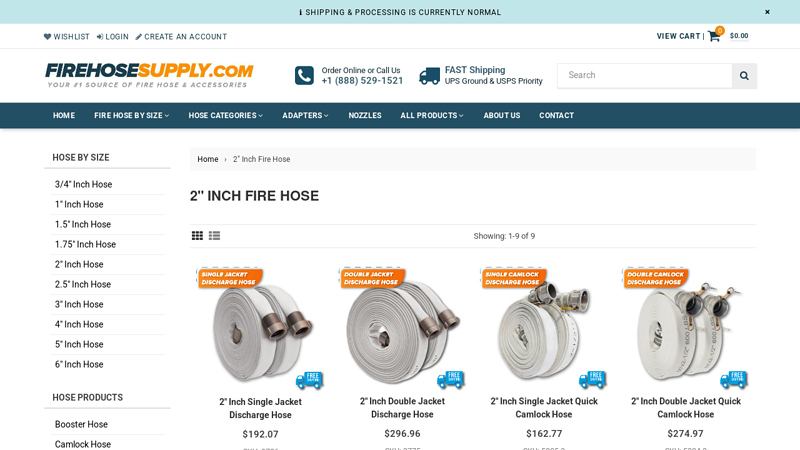

#7 2″ Inch Fire Hose

Domain Est. 2012

#8 Key Hose

Domain Est. 2012

Website: keyhose.com

Key Highlights: At Key, we are dedicated to design and manufacture of the highest quality fire hose products, combining the best in raw materials with expert craftsmanship….

#9 Austin Hose

Domain Est. 2016

Website: austinhose.com

Key Highlights: Austin Hose is a premier hose, fittings, and accessories supplier with locations from coast to coast that service the entire country….

Expert Sourcing Insights for 2 Inch Fire Hose

H2: 2026 Market Trends for 2-Inch Fire Hose

The global market for 2-inch fire hoses is projected to experience steady growth through 2026, driven by increasing emphasis on fire safety infrastructure, urbanization, and regulatory compliance across commercial, industrial, and municipal sectors. As a standard size for firefighting operations due to its balance of portability and water delivery capacity, the 2-inch fire hose remains a critical component in emergency response systems.

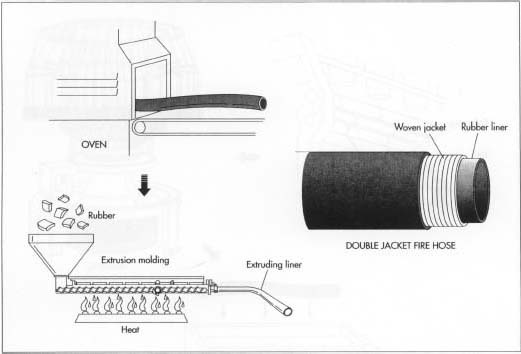

One key trend shaping the 2026 landscape is the rising adoption of advanced materials. Manufacturers are increasingly utilizing lightweight, high-tenacity synthetic fibers such as polyester and high-performance polyethylene, combined with durable rubber or thermoplastic linings. These innovations enhance hose durability, reduce weight for improved firefighter mobility, and extend service life—factors that are gaining importance amid growing operational efficiency demands.

Another significant trend is the integration of smart technologies. By 2026, some 2-inch fire hoses are expected to incorporate embedded sensors to monitor pressure, flow rate, and structural integrity in real time. These “smart hoses” support data-driven firefighting strategies and improve safety, particularly in complex urban or industrial fire scenarios.

Regional dynamics also play a crucial role. North America and Europe are seeing market growth driven by stringent fire safety regulations and the modernization of aging firefighting equipment. In contrast, the Asia-Pacific region is expected to register the highest compound annual growth rate (CAGR), fueled by rapid urban development, expanding industrial zones, and increased government investment in public safety infrastructure in countries like India and China.

Moreover, sustainability is becoming a competitive differentiator. Fire hose manufacturers are responding to environmental concerns by developing recyclable materials and eco-friendly production processes. Regulatory pressures and corporate sustainability goals are expected to accelerate this shift by 2026.

In conclusion, the 2-inch fire hose market in 2026 will be shaped by innovation in materials, digital integration, regional infrastructure development, and sustainability initiatives. These trends collectively point toward a more resilient, efficient, and technologically advanced firefighting ecosystem.

Common Pitfalls When Sourcing 2-Inch Fire Hose (Quality & IP)

Sourcing 2-inch fire hose involves critical considerations beyond simple price comparison. Overlooking quality and Ingress Protection (IP) ratings can compromise safety, performance, and compliance. Here are key pitfalls to avoid:

1. Prioritizing Low Cost Over Certified Quality

- Pitfall: Choosing the cheapest option without verifying compliance with recognized standards (e.g., NFPA 1961, EN 14540, BS 639).

- Risk: Substandard materials (weak jacket weave, poor liner adhesion, inferior couplings) lead to rapid deterioration, leaks, bursts under pressure, and catastrophic failure during firefighting.

- Solution: Insist on documentation proving certification to relevant standards. Verify test reports for burst pressure, coupling retention strength, and abrasion resistance.

2. Ignoring Ingress Protection (IP) Rating for Couplings

- Pitfall: Assuming all couplings are equally resistant to dust and moisture ingress, especially critical for threaded or non-quick-connect types.

- Risk: Dust, dirt, sand, or water entering coupling threads or mechanisms causes corrosion, seizing, difficult mating, or failure to seal properly. This delays deployment and creates hazardous leaks.

- Solution: Specify couplings (especially storage caps/dust covers and the coupling mechanisms themselves) with appropriate IP ratings (e.g., IP54 or higher for significant dust and water splashing resistance). Verify the IP rating applies to the mated connection.

3. Overlooking Jacket Material and Construction

- Pitfall: Not scrutinizing the jacket weave (e.g., single/double jacket), material (e.g., polyester, nylon, PBI, aramid blends), and coatings.

- Risk: Poor weave density leads to excessive water permeation (“weeping”). Low-quality materials degrade rapidly from UV exposure, chemicals, abrasion, or heat, reducing lifespan and reliability.

- Solution: Specify double-jacket construction for durability. Choose materials suited to the environment (e.g., UV-resistant coatings, chemical resistance). Demand test data on abrasion resistance and permeability.

4. Neglecting Liner Material and Bonding

- Pitfall: Focusing only on the outer jacket and ignoring the inner liner (e.g., rubber, thermoplastic) and its bond to the jacket.

- Risk: Poor liner bonding causes delamination, drastically reducing flow rate and pressure. Incompatible liner materials can degrade with certain chemicals or water additives (foams).

- Solution: Specify liner material compatible with intended use (e.g., oil-resistant liners if using Class B foams). Require proof of strong jacket-to-liner adhesion tests.

5. Inadequate Coupling Quality and Compatibility

- Pitfall: Accepting couplings made from substandard brass (prone to dezincification), aluminum (weaker), or with poor thread quality/finish.

- Risk: Couplings can crack, strip threads, or fail under pressure. Incompatible threads (even if “standard” nominal size) prevent connection with existing equipment.

- Solution: Specify high-quality, dezincification-resistant brass (DZR) couplings. Verify thread type and pitch (e.g., NST, Storz, BSP) match existing infrastructure exactly. Inspect for smooth thread finish and proper gland nuts/gaskets.

6. Insufficient Testing and Documentation

- Pitfall: Relying solely on supplier claims without demanding independent test reports.

- Risk: No verification of actual performance against standards. Potential for counterfeit or misrepresented products.

- Solution: Require recent, valid test certificates from accredited laboratories for the specific hose and coupling model being purchased, covering NFPA/EN/BS requirements (e.g., hydrostatic proof pressure, coupling retention, kink resistance).

7. Disregarding Environmental and Storage Conditions

- Pitfall: Selecting hose without considering exposure to UV, extreme temperatures, ozone, or chemicals at the point of use or storage.

- Risk: Accelerated degradation of jacket and liner, leading to premature failure.

- Solution: Choose hose specifically rated for the expected environment (e.g., enhanced UV protection, ozone resistance, wider temperature range). Ensure storage practices (dark, dry, cool, properly rolled) are followed.

By proactively addressing these pitfalls—focusing on certified quality, verifying IP ratings for critical components like couplings, and demanding thorough documentation—organizations can source reliable, safe, and compliant 2-inch fire hose that performs when lives depend on it.

Logistics & Compliance Guide for 2-Inch Fire Hose

Overview

The 2-inch fire hose is a critical component in firefighting operations, designed to deliver large volumes of water under high pressure. Proper logistics management and adherence to compliance standards ensure operational readiness, firefighter safety, and legal conformity. This guide outlines key considerations for the storage, transportation, inspection, maintenance, and regulatory compliance of 2-inch fire hose.

Regulatory Standards and Certifications

Fire hoses must comply with national and international standards to ensure performance and safety. The primary standards applicable to 2-inch fire hose include:

- NFPA 1962: Standard for the Inspection, Care, and Use of Fire Hose, Couplings, Nozzles, and Fire Hose Appliances. This standard mandates regular inspection, testing, and maintenance schedules.

- ULC-S553 (Canada): Standard for Fire Hose, published by Underwriters Laboratories of Canada.

- EN 671-1 (Europe): Specification for semi-rigid fire hose.

- FM Global Approval: Often required by industrial and commercial facilities for loss prevention.

Ensure all 2-inch fire hoses are certified to the appropriate standard for your region and application. Documentation of certification should accompany each hose or batch upon delivery.

Procurement and Sourcing

When sourcing 2-inch fire hose:

- Verify manufacturer compliance with NFPA 1961 (Standard on Fire Hose) or equivalent.

- Confirm hose length, liner material (e.g., thermoplastic, rubber), jacket type (e.g., polyester, nylon), and coupling compatibility.

- Obtain Material Safety Data Sheets (MSDS) or Safety Data Sheets (SDS) for any hose components, particularly if used in hazardous environments.

- Source from reputable suppliers with traceability and batch tracking capabilities.

Storage Requirements

Proper storage extends hose life and prevents damage:

- Store in a clean, dry, well-ventilated area away from direct sunlight, ozone sources (e.g., motors), and extreme temperatures.

- Use hose racks or reels to prevent kinking, crushing, or twisting.

- Keep hoses elevated off concrete floors to avoid moisture absorption and chemical exposure.

- Avoid contact with oils, grease, solvents, and corrosive substances.

- Maintain organized inventory with clear labeling (size, length, date of service, inspection status).

Transportation Guidelines

During transit:

- Pack hoses on pallets or in crates to prevent abrasion and impact damage.

- Secure loads to avoid shifting, which can cause kinks or coupling damage.

- Protect from weather exposure—use waterproof coverings if shipped outdoors.

- Avoid stacking heavy items on top of hose bundles.

- For international shipments, comply with IATA/IMDG regulations if transporting hazardous components (e.g., coated hoses with chemical treatments).

Inspection and Testing Schedule

Regular inspection and testing are required by NFPA 1962:

- Daily/Pre-Use Inspection: Check for leaks, abrasions, weakened areas, and coupling integrity.

- Monthly Visual Inspection: Examine entire length; check for mildew, stiffness, or UV degradation.

- Annual Service Testing: Perform hydrostatic test at 400 psi (27.6 bar) for five minutes. Hoses must show no leakage, weeping, or coupling slippage.

- After-Use Inspection: Inspect and clean after every use. Dry completely before storage.

- Maintain detailed logs of all inspections, tests, repairs, and retirements.

Maintenance and Repair

- Clean hoses with mild soap and water after exposure to contaminants.

- Dry thoroughly using a hose dryer or by hanging in a ventilated area—never store wet.

- Only certified personnel should repair hoses using manufacturer-approved kits.

- Retire and replace hoses that fail testing, show significant wear, or exceed service life (typically 10 years, per NFPA).

Compliance Documentation

Maintain the following records for audit and inspection readiness:

- Purchase orders and certification documents

- Incoming inspection reports

- Inventory logs with serial or ID tracking

- Inspection and test records (including dates, personnel, results)

- Repair and retirement records

- Training records for personnel handling hose maintenance

Disposal and Environmental Considerations

- Retired fire hoses may contain materials subject to environmental regulations.

- Consult local waste management authorities for proper disposal or recycling options.

- Some manufacturers offer hose recycling programs.

- Avoid open burning or landfill disposal without regulatory clearance.

Training and Personnel

Ensure all personnel involved in handling, deploying, or maintaining 2-inch fire hoses are trained in:

- Proper deployment and coupling techniques

- Inspection procedures per NFPA 1962

- Safety protocols during testing and maintenance

- Documentation requirements

Training records should be maintained and updated regularly.

Conclusion

Effective logistics and compliance management of 2-inch fire hose ensures reliability during emergencies and adherence to safety regulations. By following established standards, implementing rigorous inspection schedules, and maintaining accurate records, organizations can safeguard their firefighting assets and personnel. Regular review of this guide ensures alignment with evolving codes and best practices.

Conclusion for Sourcing 2-Inch Fire Hose

After a thorough evaluation of suppliers, product specifications, certifications, pricing, and lead times, sourcing a 2-inch fire hose requires a balanced approach that prioritizes safety, durability, and compliance with industry standards such as NFPA 1961 and UL/FM listings. While cost-effectiveness is an important factor, it should not compromise the quality and performance of the hose, especially given its critical role in firefighting operations.

Key considerations in the sourcing decision include material construction (e.g., polyester jacket with rubber lining), burst pressure ratings, abrasion resistance, weight, ease of handling, and warranty support. Domestic suppliers may offer faster delivery and better customer service, while international options could provide cost savings but may involve longer lead times and logistical challenges.

Ultimately, the recommended course of action is to select a reputable supplier offering a 2-inch fire hose that meets or exceeds all required safety standards, provides strong warranty and after-sales support, and aligns with the department’s operational needs and budget. Establishing a long-term relationship with a reliable vendor will ensure consistent quality, timely replenishment, and readiness for emergency response.