The global epoxy resin market is experiencing robust growth, driven by rising demand across industries such as automotive, aerospace, wind energy, and electronics. According to a report by Mordor Intelligence, the market was valued at USD 9.87 billion in 2023 and is projected to grow at a CAGR of over 5.8% from 2024 to 2029. This expansion is fueled by the increasing adoption of lightweight and durable materials, particularly in composite applications where epoxy resins play a critical role. As demand for high-performance resins scales, 2-gallon kits have emerged as a popular format for both industrial users and artisans, offering a balance between usability, shelf life, and cost-efficiency. With North America and Asia-Pacific leading in production and consumption, manufacturers are focusing on advanced formulations that enhance curing speed, UV resistance, and mechanical strength. This growing market dynamic has intensified competition, prompting innovation and quality differentiation among key players. Below is a data-driven look at the top 10 manufacturers leading the 2-gallon epoxy resin segment, selected based on product performance, customer reviews, availability, and market presence.

Top 10 2 Gallon Epoxy Resin Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Ice Epoxy Crystal Casting Resin

Domain Est. 2019

Website: iceepoxy.com

Key Highlights: Ice Epoxy offer high performance architectural, craft and casting resin. We are a leading North American manufacturer of high-quality casting epoxy used to make ……

#2 WiseBond Deep Pour Epoxy Table Top Countertop Epoxy Art …

Domain Est. 2003

Website: wisebond.com

Key Highlights: Free delivery over $200 30-day returnsOur WiseBond® Deep Pour 2:1 Ratio, 2-Part Epoxy is a premium commercial grade live-edge wood slab river table and thick casting epoxy resin….

#3 2 Part Epoxy Resin for Coating & Laminating

Domain Est. 2003

Website: aeromarineproducts.com

Key Highlights: 6–12 day delivery · 30-day returns…

#4 Magic Resin USA: Clear Epoxy Resin Kits with FREE 1

Domain Est. 2010

Website: magicresin.com

Key Highlights: Discover top-quality clear epoxy resin at Magic Resin, perfect for coating and casting applications such as table tops, bar tops, counter tops, river tables….

#5 Bar Top and Table Top Clear Epoxy Resin 2 Gallons

Domain Est. 2012

Website: bestbartopepoxy.com

Key Highlights: UltraClear epoxy resin is hyper durable with a crystal-clear finish. Waterproof, scratch-resistant, and proudly made in the USA! Get yours today….

#6 Bar & Table Top Epoxy Resin

Domain Est. 2017

Website: primaloc.com

Key Highlights: In stock Rating 4.8 (654) Primaloc Epoxy specializes in crystal-clear epoxy solutions for bar tops, table tops, and countertops. Made 100% in the USA, our epoxy is designed to re…

#7 EPE EasyPour Epoxy 2 Gallon Kit

Domain Est. 2019

Website: easypourepoxy.com

Key Highlights: START RIGHT AWAY – This Liquid Epoxy Resin Kit Comes With A 64oz Bottle Of Resin And Hardener (Totaling 2 Gallons Of Epoxy Resin When Mixed) ……

#8 Craft Resin

Domain Est. 2019

Website: craft-resin.com

Key Highlights: Craft Resin is a crystal clear epoxy resin and premium mica powder for artists. We supply epoxy resin pro kits online for moulding, arts, and crafts….

#9 Frontpage

Domain Est. 2022

Website: westlakeepoxy.com

Key Highlights: Coatings & Composites. We have been enabling progress through development of innovative epoxy resin systems for more than 75 years….

#10 Resin Kits With The Best Online Price

Domain Est. 2014

Website: eastcoastresin.com

Key Highlights: Whether you need epoxy resin for a small project, or you need to order bulk epoxy resin for something larger, we will help you!…

Expert Sourcing Insights for 2 Gallon Epoxy Resin

2026 Market Trends for 2 Gallon Epoxy Resin

The 2-gallon epoxy resin market in 2026 is poised for significant evolution, driven by shifting consumer preferences, technological advancements, and broader economic and environmental forces. This analysis examines the key trends shaping demand, competition, and innovation within this specific product segment.

Rising Demand in DIY and Craft Sectors Fuels Growth

The 2-gallon epoxy resin format is experiencing robust demand, primarily fueled by the sustained popularity of the DIY (Do-It-Yourself) and artisanal crafts movement. Consumers increasingly seek high-quality materials for home improvement projects, furniture restoration, and decorative art, including river tables, countertops, jewelry, and geode art. The 2-gallon size offers an optimal balance between value (lower cost per ounce than smaller kits) and manageability for serious hobbyists and small-scale artisans, making it a preferred choice over bulk 5-gallon pails. E-commerce platforms, social media inspiration (especially YouTube and Instagram), and accessible online tutorials continue to lower entry barriers, expanding the user base and driving consistent sales of 2-gallon kits through both specialty retailers and major online marketplaces like Amazon.

Sustainability and Low-VOC Formulations Become Key Differentiators

Environmental consciousness is a major trend impacting the 2026 market. Consumers and regulators are demanding more sustainable and safer products. This translates into a significant shift towards low-VOC (Volatile Organic Compounds) and zero-VOC epoxy formulations in the 2-gallon segment. Resins marketed as “eco-friendly,” “non-toxic” (once cured), or made with bio-based components (e.g., partially derived from plant oils) are gaining substantial traction. Brands emphasizing minimal fumes, reduced environmental impact, and safer handling without sacrificing performance (clarity, hardness, UV resistance) will hold a competitive advantage. Transparency in sourcing and manufacturing processes, including recyclable packaging (e.g., recyclable plastic pails or cardboard overwrap), will be increasingly important for brand reputation and consumer trust.

Performance Enhancement and Specialized Formulations Drive Innovation

Beyond basic clear casting, the market is seeing a surge in specialized 2-gallon epoxy formulations tailored to specific applications. Key innovations include:

* Enhanced UV Resistance: Formulations with superior UV stabilizers to combat yellowing, crucial for furniture and art intended for sunlit areas or outdoor use (e.g., outdoor tables with epoxy finishes).

* Improved Heat Resistance: Resins designed to withstand higher temperatures, appealing for countertops near stoves or in warmer climates.

* Faster Cure Times: Options offering quicker demolding or handling times cater to users wanting faster project turnaround.

* Self-Deairing/Reduced Bubbles: Formulations engineered to minimize bubble formation, reducing the need for pressure potting, a significant pain point for users.

* High-Clarity & Water-Like Feel: Premium resins emphasizing exceptional optical clarity and a glass-like, smooth surface are in high demand for decorative applications. These performance-driven innovations allow brands to command premium pricing and cater to discerning users.

Competitive Landscape Intensifies with Brand Consolidation and Direct-to-Consumer Shifts

The 2-gallon epoxy market is highly competitive, featuring established chemical companies, specialized resin brands, and numerous private-label offerings. In 2026, expect further market consolidation as larger players acquire successful niche brands to capture market share and leverage distribution networks. Simultaneously, Direct-to-Consumer (D2C) sales models are strengthening. Brands with strong digital marketing, engaging content (tutorials, project ideas), and excellent customer support are building loyal communities and bypassing traditional retail markups. This D2C focus allows for better control over pricing, branding, and customer data, putting pressure on traditional distributors and retailers. Success will depend on building brand trust through consistent quality, reliable customer service, and community engagement.

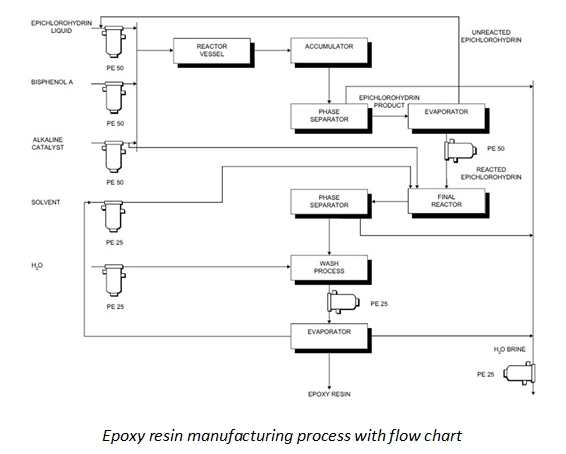

Supply Chain Resilience and Raw Material Costs Remain Critical

The epoxy resin industry remains sensitive to fluctuations in raw material prices (primarily epichlorohydrin and bisphenol-A) and global supply chain dynamics. Geopolitical tensions, energy costs, and logistical disruptions can impact availability and pricing. In 2026, suppliers offering 2-gallon kits will need robust supply chain strategies, potentially involving regional manufacturing, diversified sourcing, and strategic inventory management to ensure consistent supply and mitigate cost volatility. Transparency regarding potential price adjustments due to raw material costs will be crucial for maintaining customer relationships. Brands investing in supply chain resilience will have a significant operational advantage.

Common Pitfalls Sourcing 2 Gallon Epoxy Resin (Quality, IP)

Sourcing a 2-gallon epoxy resin kit can seem straightforward, but significant pitfalls exist, particularly concerning quality consistency and intellectual property (IP) protection. Overlooking these can lead to project failures, safety hazards, and legal exposure.

Quality-Related Pitfalls

- Inconsistent Formulation & Performance: Many bulk suppliers, especially generic manufacturers or resellers, may alter resin/hardener ratios, filler content, or use different base chemicals between batches to cut costs. This results in unpredictable pot life, cure times, strength, clarity, and adhesion. A batch that cured perfectly last month might remain tacky or crack this time.

- Substandard Raw Materials: To offer lower prices, suppliers might use lower-purity epoxy resins (e.g., higher chlorinated content) or inferior hardeners. This compromises key properties:

- Reduced mechanical strength and impact resistance.

- Poor UV stability (leading to rapid yellowing, even for “non-yellowing” claims).

- Increased shrinkage during cure, causing stress cracks.

- Higher VOC emissions and potential health hazards.

- Inadequate or Missing Technical Data: Generic kits often lack comprehensive, batch-specific Technical Data Sheets (TDS) and Safety Data Sheets (SDS). Without precise mix ratios, temperature requirements, pot life, cure profiles, and safety handling information, achieving reliable results is guesswork.

- Poor Quality Control & Contamination: Bulk manufacturing or repackaging facilities may lack rigorous QC protocols. Moisture ingress, dust, or cross-contamination between batches can ruin the resin or prevent proper curing.

- Exaggerated Claims & Misleading Marketing: Terms like “professional-grade,” “crystal clear,” or “marine-grade” are often used loosely without certification or testing data. Kits may claim suitability for specific applications (e.g., deep pours, food contact) without meeting relevant standards (e.g., FDA, ASTM).

Intellectual Property (IP)-Related Pitfalls

- Sourcing Counterfeit or Knock-Off Products: Unverified suppliers may sell resin kits falsely branded as premium manufacturers (e.g., System Three, West System, MAS). These counterfeits use inferior formulations, void warranties, and offer no technical support, damaging the reputation of the genuine brand.

- Reverse Engineering & Formula Theft: Sharing detailed requirements or samples with unvetted suppliers, especially overseas manufacturers, risks your proprietary formulations or unique application specifications being copied without recourse. Standard NDAs may be unenforceable internationally.

- Lack of Licensing for Proprietary Formulas: If your project relies on a specific patented epoxy chemistry (e.g., for high-temperature resistance, specific adhesion properties), sourcing a generic 2-gallon kit won’t provide the same performance and could inadvertently infringe on patents if the supplier’s formula is too similar.

- Unclear IP Ownership in Custom Blends: If you commission a custom formulation, contracts must explicitly state that all IP (formula, process, improvements) developed belongs to you. Without this, the supplier may retain rights or reuse the formula for competitors.

- Supply Chain Transparency Gaps: It can be difficult to trace the origin of raw materials (resins, hardeners, additives) in a generic 2-gallon kit. This lack of transparency increases the risk of inadvertently using materials covered by patents or subject to trade restrictions.

Mitigation: Prioritize reputable suppliers with verifiable quality certifications (ISO 9001), provide full TDS/SDS, offer batch traceability, and have enforceable IP agreements. For critical applications, consider smaller batches from proven brands or invest in custom formulation with clear IP clauses. Always test samples rigorously before committing to large 2-gallon purchases.

Logistics & Compliance Guide for 2-Gallon Epoxy Resin (Hazard Class 2)

Version: 1.0

Applicable to: Two-gallon (approximately 7.57 liters) container of epoxy resin classified under UN number and hazard class as per H2 guidance

1. Product Overview

- Product Name: Epoxy Resin (2-Gallon Kit – Resin & Hardener, typically sold as a set)

- Packaging: 2 x 1-gallon high-density polyethylene (HDPE) containers or composite packaging (plastic jugs in fiberboard outer)

- Total Volume: ~7.57 liters (2 US gallons)

- Hazard Classification: May fall under Hazard Class 3 (Flammable Liquids) or Hazard Class 8 (Corrosive Substances) depending on formulation, but for this guide, we assume H2 refers to health hazard statement H226 (Flammable liquid and vapor) per GHS.

Note: “H2” in this context refers to GHS Hazard Statement H226: “Flammable liquid and vapor.”

2. Hazard Classification & Regulatory Basis

| Parameter | Detail |

|——–|——–|

| GHS Classification | H226: Flammable liquid and vapor |

| UN Number | UN 1866 (if flammable; resin solutions in flammable solvent) or UN 3082 (if environmentally hazardous) – verify SDS |

| Proper Shipping Name | “Flammable liquid, n.o.s. (Epoxy Resin)” or “Organic peroxide, liquid, n.o.s.” (if applicable) |

| Packing Group | II (Medium Danger) – typical for flammable epoxy resins |

| Hazard Class (DOT/IMDG/IATA) | Class 3 – Flammable Liquids |

| GHS Pictograms | Flame (for H226) |

Critical Step: Always refer to the Safety Data Sheet (SDS), Section 14, for exact UN number, hazard class, and shipping name.

3. Packaging Requirements

- Use UN-certified packaging rated for Packing Group II liquids.

- Inner containers (1-gallon HDPE jugs) must be:

- Leak-proof

- Chemically resistant to epoxy resin

- Secured with tamper-evident seals

- Outer packaging:

- Double-wall corrugated fiberboard box

- Cushioning material to prevent movement (e.g., foam inserts)

- Absorbent material (e.g., spill pad) in case of leakage

- Markings:

- UN specification mark (e.g., 1H2/Yxx/S)

- Proper shipping name and UN number

- Class 3 hazard label (flame symbol)

- Orientation arrows (↑)

- “This Way Up” markings

4. Labeling & Marking

All packages must display:

– Hazard Class 3 Label (red and white diamond with flame)

– Proper Shipping Name: “FLAMMABLE LIQUID, N.O.S. (Epoxy Resin)” – UN 1866

– UN Number: UN 1866 (top and bottom corners of label)

– Shipper/Consignee Information

– GHS Labels (for workplace/OSHA compliance): Includes H226 statement, pictogram, signal word (“Danger”)

5. Documentation

- Safety Data Sheet (SDS): Must accompany shipment (electronically or physically)

- Shipper’s Declaration for Dangerous Goods (required for air transport under IATA)

- Bill of Lading / Commercial Invoice:

- Clearly state hazardous nature

- Include UN number, PSN, class, and packing group

- Regulatory Compliance Statement: Confirm adherence to 49 CFR (US), ADR (Europe), IMDG (sea), or IATA (air)

6. Transport Regulations by Mode

A. Ground Transport (US – 49 CFR)

- Quantity: 2 gallons (~7.57 L) → within Limited Quantity (LQ) exemption if criteria met

- Limited Quantity Eligibility:

- Max 1 L per inner container (if using 1-gallon jugs = 3.78 L → exceeds LQ limit)

- Therefore, NOT eligible for LQ exemption → full hazmat rules apply

- Requirements:

- Hazmat employee training (49 CFR 172.704)

- Placarding not required for < 1,001 lbs total aggregate weight of Class 3

- Vehicle not required to be placarded for small quantities

- Carrier must be hazmat-certified

B. Air Transport (IATA DGR)

- 2 gallons = ~7.57 kg (depending on density)

- Not eligible for Excepted Quantity or Limited Quantity due to volume

- Requires:

- Fully regulated shipment

- IATA-compliant packaging (tested, certified)

- Shipper’s Declaration for Dangerous Goods

- Training for personnel (IATA certification)

- Class 3 label + orientation arrows

- Notify airline in advance

C. Ocean Freight (IMDG Code)

- Use IMDG-compliant packaging and documentation

- Stowage: Away from heat sources and oxidizers

- Segregation: As per IMDG segregation table (typically away from Class 8 and Class 5)

- Container: Ventilated if large quantities; secure to prevent shifting

7. Storage & Handling

- Storage Conditions:

- Cool, dry, well-ventilated area

- Temperature: 60–80°F (15–27°C); avoid freezing or >120°F

- Away from ignition sources (no smoking, sparks, open flames)

- Segregated from oxidizers, acids, amines

- Handling:

- Use PPE: Nitrile gloves, safety goggles, ventilation

- Avoid skin contact and inhalation of vapors

- Use grounded containers to prevent static discharge

8. Emergency Response

- Spill Response:

- Contain with absorbent pads (vermiculite, spill pillows)

- Do NOT use sawdust (may be combustible)

- Collect and dispose as hazardous waste

- Ventilate area

- Fire Response:

- Use alcohol-resistant foam, CO₂, or dry chemical extinguishers

- Water may be ineffective; cool containers exposed to fire

- First Aid:

- Skin contact: Wash with soap and water

- Eye contact: Flush with water for 15 minutes; seek medical help

- Inhalation: Move to fresh air

9. Disposal

- Dispose of in compliance with EPA, RCRA, and local regulations

- Unused resin/hardener: May be hazardous waste (check D001 for ignitability)

- Empty containers: Triple-rinsed and managed as non-hazardous, or treat as hazardous

- Use licensed hazardous waste disposal vendor

10. Compliance Checklist

✅ SDS available and up to date

✅ UN-certified packaging used

✅ Proper hazard labels and markings applied

✅ Transport documents complete (BOL, SDS, DGD if required)

✅ Personnel hazmat-trained (if required)

✅ Storage compliant with fire codes (NFPA 30)

✅ Emergency procedures in place

Disclaimer

This guide assumes the epoxy resin is classified under GHS H226 (Flammable). Always verify classification using the manufacturer’s SDS. Regulations vary by country and transport mode. Consult a certified dangerous goods safety advisor (DGSA) when in doubt.

Prepared by: [Your Company Name] – EHS/Logistics Department

Date: [Insert Date]

Reference Standards: 49 CFR, IATA DGR 2024, IMDG Code 2024, GHS Rev. 9, OSHA HCS 2012

In conclusion, sourcing a 2-gallon epoxy resin requires careful consideration of quality, intended application, and supplier reliability. It is essential to select a product with the right mix ratio, working time, and durability—whether for casting, coating, or adhesive purposes. Comparing prices, reading customer reviews, and verifying technical specifications help ensure you obtain a high-performance resin that meets your project requirements. Additionally, purchasing from reputable suppliers guarantees authenticity, consistent quality, and access to proper safety data and customer support. By evaluating these factors, you can make an informed decision that balances cost-effectiveness with optimal results in your epoxy application.