The global brass nipples market is experiencing steady growth, driven by rising demand across plumbing, HVAC, and industrial manufacturing sectors. According to Grand View Research, the global brass fittings market was valued at USD 16.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030, fueled by infrastructure development and increasing construction activities, particularly in Asia-Pacific and Latin America. Mordor Intelligence further highlights the sustained demand for corrosion-resistant and durable piping components, with brass nipples remaining a critical element in secure and leak-proof connections. As industries prioritize reliability and compliance with international standards, manufacturers specializing in precision brass components are well-positioned to meet evolving market needs. This data-backed growth trajectory underscores the importance of identifying top-tier brass nipple manufacturers known for quality, scalability, and innovation.

Top 5 2 1 2 Brass Nipple Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Quality Pipe Nipple Manufacturer

Domain Est. 1997

Website: meritbrass.com

Key Highlights: Find reliable pipe nipples for your plumbing and industrial needs at Merit Brass. We prioritize quality and offer strong inventories and timely deliveries….

#2 2

Domain Est. 1999

#3 SCH 40 Lead Free Brass Pipe Nipple

Domain Est. 1999

#4 1/2″ x 2-1/2″ Brass Pipe Nipple

Domain Est. 2009

Website: pexuniverse.com

Key Highlights: In stock Rating 4.9 (57) 1/2″ Male NPT Threaded, 2-1/2″ long Brass Pipe Nipple. Manufactured from Lead-Free Red Brass. Meets or exceeds all applicable ANSI standards….

#5 Midland Industries

Domain Est. 2011

Website: midlandindustries.com

Key Highlights: NOW IN STOCK · Lead-Free Brass Forged Bodies · Full Port 3/4″ Drain Outlets · Ready to ship from Midland….

Expert Sourcing Insights for 2 1 2 Brass Nipple

2026 Market Trends for 2 1/2″ Brass Nipple

The market for 2 1/2″ brass nipples—threaded pipe fittings used extensively in plumbing, HVAC, industrial, and gas distribution systems—is poised for moderate growth through 2026, driven by infrastructure development, material reliability, and regulatory standards. This analysis explores key trends shaping demand, supply, pricing, and application areas for this specific plumbing component.

Rising Infrastructure and Construction Activity

Global investment in residential, commercial, and public infrastructure is a primary driver for brass nipple demand. With urbanization accelerating in regions like Asia-Pacific, the Middle East, and Africa, new building projects require durable plumbing components. The 2 1/2″ size is commonly used in large-scale water and gas line installations, making it essential for municipal and industrial applications. Government-led water conservation and sanitation programs will further boost demand for reliable fittings such as brass nipples, which offer corrosion resistance and long service life.

Preference for Corrosion-Resistant and Sustainable Materials

Brass remains a preferred material in plumbing due to its durability, resistance to corrosion, and compatibility with potable water systems. As sustainability concerns grow, manufacturers are focusing on lead-free or low-lead brass (e.g.,遵守 NSF/ANSI 61 standards) to meet environmental and health regulations. This shift is particularly evident in North America and the EU, where compliance with safe drinking water laws is mandatory. The 2 1/2″ brass nipple market will benefit from this trend, as end-users prioritize compliant, long-lasting components.

Impact of Raw Material and Manufacturing Costs

Copper and zinc—key constituents of brass—are subject to global commodity price fluctuations. Rising metal prices in 2024–2025 could pressure manufacturers’ margins and influence 2026 pricing. However, advancements in manufacturing efficiency, such as automated threading and CNC machining, may offset some cost increases. Regional production hubs in China, India, and Mexico will continue to dominate supply, offering cost-effective alternatives while maintaining quality standards.

Growth in Industrial and Commercial Applications

Beyond residential plumbing, the 2 1/2″ brass nipple sees increasing use in industrial automation, compressed air systems, and renewable energy infrastructure (e.g., biogas and hydrogen distribution). As industries expand their process piping networks, demand for standardized, high-pressure fittings will rise. Additionally, retrofitting older systems to improve efficiency will create replacement demand, supporting steady market growth.

E-Commerce and Distribution Channel Evolution

Online B2B marketplaces and industrial supply platforms are transforming how brass nipples are procured. By 2026, digital channels will play a larger role in distribution, enabling faster delivery, price transparency, and access to technical specifications. This shift benefits smaller contractors and maintenance teams who require reliable components without long lead times.

Regional Market Dynamics

North America and Europe will remain stable markets due to ongoing building code enforcement and infrastructure upgrades. However, the fastest growth is expected in emerging economies—particularly India, Southeast Asia, and the Gulf Cooperation Council (GCC) countries—where construction and industrialization are accelerating. Local manufacturing and favorable trade policies will enhance regional availability of 2 1/2″ brass nipples.

In conclusion, the 2026 market for 2 1/2″ brass nipples will be shaped by infrastructure expansion, regulatory compliance, material sustainability, and digital procurement. While subject to raw material volatility, the product’s reliability and versatility ensure continued relevance across multiple sectors.

H2: Common Pitfalls When Sourcing 2″ x 1/2″ Brass Nipples (Quality and IP Compliance)

Sourcing a 2″ x 1/2″ brass nipple may seem straightforward, but several pitfalls can compromise quality, performance, and regulatory compliance—especially when considering Industrial Pipe (IP) standards. Being aware of these issues ensures reliability and avoids costly failures.

1. Substandard Material Composition

One of the most frequent issues is receiving brass nipples made from inferior alloys. Authentic brass should primarily consist of copper and zinc (typically C37700 or C83600 for plumbing). Substandard products may use high-lead brass or non-compliant alloys, increasing the risk of corrosion, leaks, or contamination—especially in potable water systems.

2. Lack of IP (Industrial Pipe) Certification

Many suppliers claim IP compliance without providing documentation. True IP-grade brass nipples must meet specific dimensional, pressure, and material standards (e.g., ASTM B43, ASME B16.18). Without proper certification, the nipple may not fit properly into existing systems or withstand required pressure ratings, leading to system failure.

3. Poor Thread Quality and Dimensional Inaccuracy

Inaccurate threading (e.g., mismatched NPT sizes, stripped threads, or incorrect taper) is a common defect. A poorly threaded 1/2″ end may not seal properly, causing leaks. Dimensional inconsistencies in the 2″ length can also lead to misalignment or stress on connected fittings.

4. Inadequate Corrosion Resistance

Low-quality brass nipples may lack proper dezincification-resistant (DZR) treatment, which is critical in water applications. Non-DZR brass can deteriorate over time, especially in soft or acidic water, leading to internal blockages or failures.

5. Mislabeling and Counterfeit Products

Some suppliers misrepresent product specifications or sell counterfeit items labeled as “lead-free” or “IP-certified” without verification. Always request mill test reports (MTRs) and verify compliance with standards like NSF/ANSI 61 or NSF/ANSI 372 for potable water use.

6. Inconsistent Manufacturing Processes

Inconsistent casting or machining processes can result in weak spots, porosity, or internal cracks. These defects are not always visible but can fail under pressure or temperature fluctuations.

7. Inadequate Supplier Vetting

Relying on unverified suppliers, especially from online marketplaces, increases the risk of receiving non-compliant or subpar products. Always source from reputable suppliers with proven track records and request samples before bulk ordering.

Conclusion

To avoid these pitfalls, prioritize suppliers who provide full material traceability, certification to IP standards, and compliance with applicable health and safety regulations. Inspecting samples, verifying thread accuracy, and confirming material composition can prevent costly mistakes in critical applications.

Logistics & Compliance Guide for 2 1/2″ Brass Nipple

This guide outlines the key logistics considerations and compliance requirements for the handling, transportation, import/export, and use of 2 1/2″ brass nipples — a common threaded pipe fitting used in plumbing, HVAC, and industrial applications.

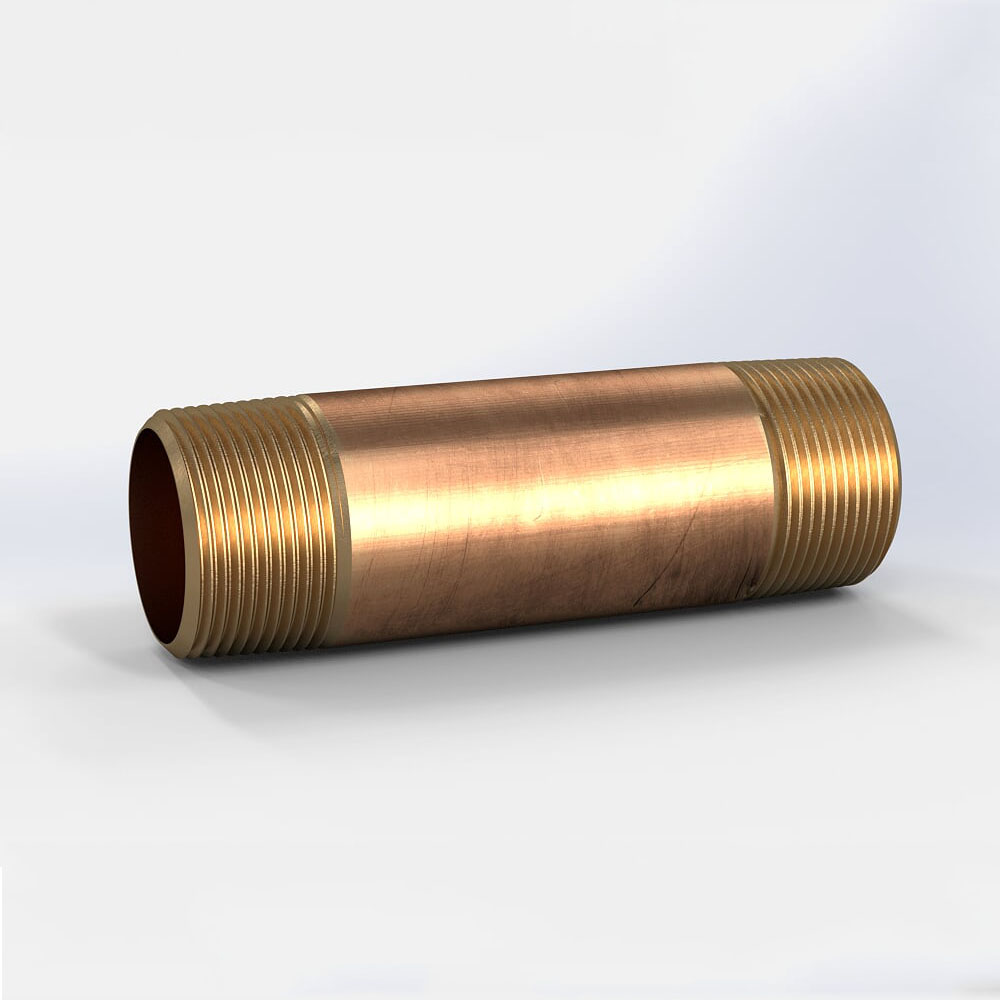

Product Overview

A 2 1/2″ brass nipple is a short length of threaded brass pipe used to connect two female-threaded fittings or fixtures. Typically made from dezincification-resistant (DZR) brass or C36000 free-machining brass, these fittings must meet industry standards for pressure, temperature, and material composition.

Packaging & Handling

- Packaging: Brass nipples are usually packed in sealed plastic bags or wrapped in moisture-resistant paper, then boxed in sturdy corrugated cardboard. Bulk quantities may be palletized with edge protection.

- Labeling: Each package should include product specifications (size: 2 1/2″, material, thread type—typically NPT), batch/lot number, manufacturer name, and compliance markings.

- Handling: Store in a dry, indoor environment to prevent corrosion. Avoid exposure to moisture, salt air, or corrosive chemicals. Use appropriate lifting equipment for palletized loads.

Transportation & Shipping

- Mode of Transport: Suitable for road, rail, air, and sea freight. Choose based on urgency, cost, and destination.

- Weight & Dimensions: A single 2 1/2″ brass nipple weighs approximately 0.75–1.2 lbs (0.34–0.54 kg). Palletized shipments typically follow standard dimensions (e.g., 48″ x 40″) with a max load height of 72″.

- Hazard Classification: Non-hazardous under DOT, IATA, and IMDG regulations. No special handling required.

- Documentation: Include commercial invoice, packing list, and bill of lading. For international shipments, a certificate of origin may be required.

Regulatory Compliance

- Drinking Water Safety (USA): Must comply with NSF/ANSI 61 and Safe Drinking Water Act (SDWA) lead content limits (<0.25% weighted average lead). Look for NSF-pw or NSF-61 certification.

- RoHS (EU): Complies if lead content is within permitted levels. Most modern brass fittings meet RoHS requirements for restricted substances.

- REACH (EU): Ensure no SVHCs (Substances of Very High Concern) are present above thresholds. Standard DZR brass typically complies.

- CAD Standards (Canada): Must meet NSF/ANSI 61 and CAN/CSA-B125.1 for plumbing fittings.

- UKCA Marking: Required for sale in Great Britain; ensure conformity with relevant UK construction product regulations.

Import/Export Requirements

- HS Code: Typically classified under 7412.10 (Copper pipes and tubes, of brass) or 7412.20 (Fittings for pipes/tubes, of copper). Confirm with local customs authority.

- Import Duties: Vary by country. Check with destination customs for applicable tariffs. Preferential rates may apply under trade agreements (e.g., USMCA, EU free trade pacts).

- Certification Requirements: Some countries require third-party inspection or certification (e.g., SONCAP for Nigeria, BIS for India). Verify destination-specific rules.

Environmental & Sustainability Considerations

- Recyclability: Brass is 100% recyclable. Scrap brass has high market value; ensure proper recycling at end-of-life.

- Packaging Waste: Use recyclable materials and minimize excess packaging to support sustainability goals.

- Carbon Footprint: Optimize logistics routes and consolidate shipments to reduce emissions.

Quality Assurance & Traceability

- Standards Compliance: Ensure products meet ASME B16.22, ASTM B43, or MSS SP-83 for dimensional and performance specifications.

- Traceability: Maintain lot traceability for quality control and recall purposes. Keep records of material certifications and test reports.

- Supplier Verification: Source from reputable manufacturers with ISO 9001 certification and documented quality management systems.

Storage & Shelf Life

- Storage Conditions: Keep in a clean, dry, temperature-controlled environment (10–30°C / 50–86°F). Avoid condensation.

- Shelf Life: Indefinite if stored properly. Inspect for tarnish or corrosion before use; light oxidation can often be cleaned without affecting performance.

Safety & Worker Protection

- Handling: Wear gloves to prevent skin oils from accelerating corrosion. Use eye protection when cutting or threading.

- Ventilation: Ensure adequate ventilation when working with cutting oils or during machining operations.

- MSDS/SDS: Although brass is not hazardous, an SDS may be available per manufacturer and should be retained for workplace safety compliance.

By adhering to this logistics and compliance guide, businesses can ensure the safe, legal, and efficient handling of 2 1/2″ brass nipples across the supply chain.

Conclusion for Sourcing 2.5-inch Brass Nipple:

After evaluating potential suppliers, material specifications, pricing, and availability, sourcing a 2.5-inch brass nipple can be successfully achieved by selecting a reputable plumbing or hardware supplier that offers ASTM or ANSI-compliant brass fittings. It is essential to confirm the thread type (typically NPT), material grade (such as ASTM B43 for red brass or ASTM B68 for free-cutting brass), and compliance with relevant industry standards to ensure compatibility and durability in the intended application.

Purchasing from certified suppliers—whether through local distributors or trusted online platforms like Grainger, McMaster-Carr, or Ferguson—ensures product quality and traceability. Bulk ordering may provide cost advantages, but lead time and minimum order requirements should be considered. Additionally, verifying corrosion resistance and suitability for use with specific fluids (e.g., water, air, or fuel) is recommended based on the operational environment.

In conclusion, with proper specification alignment and supplier vetting, sourcing a 2.5-inch brass nipple is both feasible and reliable for plumbing, HVAC, or industrial applications.