The global stainless steel water bottle market is experiencing robust growth, driven by increasing consumer awareness around health, sustainability, and plastic reduction. According to Grand View Research, the global reusable water bottle market size was valued at USD 11.3 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. A key contributor to this trend is the rising preference for 18/8 (Type 304) stainless steel—a corrosion-resistant, food-safe alloy known for its durability and non-leaching properties. Mordor Intelligence further highlights that the Asia-Pacific region is emerging as a manufacturing and export hub, with countries like China and India seeing increased production capacity and quality improvements in stainless steel consumer goods. As demand surges in North America and Europe for eco-conscious, BPA-free alternatives, sourcing from reliable 18/8 stainless steel water bottle manufacturers has become critical for brands aiming to capture market share. Based on production scale, certifications, export history, and material quality, we’ve identified the top 8 manufacturers leading innovation and supply in this growing industry.

Top 8 18 8 Stainless Steel Water Bottle Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 25 Years+ Stainless Steel Water Bottle Manufacturer

Domain Est. 2002

Website: haers.com

Key Highlights: For over 25 years, Haers has led the industry in designing and manufacturing high-quality stainless steel water bottles….

#2 All Reusable Water & Shaker Bottles

Domain Est. 2005

Website: gocontigo.com

Key Highlights: Free delivery over $35View our entire collection of BPA-free water bottles that are with you on the move, at home, or while working out. Smarter technology that works….

#3 GOX China OEM Dual

Domain Est. 2022

Website: goxbottles.com

Key Highlights: The insulated water bottle is made from food grade 18/8 stainless steel materials, free of BPA, chemical toxins or metallic aftertaste transfer. 100% Leakproof….

#4 Stainless steel water bottle: Reusable & sustainable

Domain Est. 1998

Website: waterdrop.com

Key Highlights: 30-day returnsStainless steel drinking bottles from waterdrop®: Keeps 24h cold & 12h hot ✓ Various sizes ✓ BPA & toxin-free ✓ Buy online now!…

#5 SIGG Water Bottles

Domain Est. 2003

Website: sigg.com

Key Highlights: SIGG is the brand for high-quality, modern and sustainable drinking bottles for every situation. Drinking bottles made of aluminum, stainless steel and plastic ……

#6 bottleworx

Domain Est. 2009

Website: bottleworx.com

Key Highlights: 18/8 food-grade stainless steel protects the inside of our insulated water bottles from any bad taste, mold, or staining. Nothing sticks, so your bottle stays ……

#7 Stainless Steel

Domain Est. 2020

#8 Stainless Steel Water Bottle

Website: discoversharks.shop

Key Highlights: HIGH-QUALITY STAINLESS STEEL: Made from premium 18/8 food-grade stainless steel, this water bottle is BPA-free, odor-resistant, and non-toxic, ensuring safe and ……

Expert Sourcing Insights for 18 8 Stainless Steel Water Bottle

H2: Projected Market Trends for 18/8 Stainless Steel Water Bottles in 2026

In 2026, the global market for 18/8 stainless steel water bottles is expected to witness sustained growth, driven by heightened consumer awareness around health, sustainability, and product performance. The 18/8 (also known as 304-grade) stainless steel—comprising 18% chromium and 8% nickel—is favored for its corrosion resistance, durability, and non-reactive properties, making it ideal for reusable water bottles. Several key trends are shaping the trajectory of this market:

-

Increased Demand for Sustainable Products

Environmental concerns continue to influence consumer purchasing behavior. With global plastic reduction initiatives and single-use plastic bans gaining momentum, reusable alternatives like 18/8 stainless steel bottles are becoming mainstream. Consumers are prioritizing products with low environmental impact, and stainless steel—being 100% recyclable and free from microplastic leaching—aligns with eco-conscious values. -

Premiumization and Brand Differentiation

Brands are focusing on premium designs, enhanced insulation (double-wall vacuum technology), and customizable features (engraving, color finishes, smart integrations). In 2026, the market will see a rise in high-end stainless steel bottles with added functionalities such as temperature tracking, hydration reminders, and modular lids. This premiumization strategy supports higher price points and brand loyalty. -

Expansion in Emerging Markets

While North America and Europe remain dominant markets, Asia-Pacific, Latin America, and parts of Africa are experiencing rapid growth. Rising middle-class populations, urbanization, and increased health awareness are driving demand in countries like India, Indonesia, and Brazil. Localized marketing and affordable product tiers are enabling broader market penetration. -

E-commerce and Direct-to-Consumer (DTC) Growth

Online sales channels continue to expand, with DTC brands leveraging social media and influencer marketing to reach environmentally conscious millennials and Gen Z consumers. Subscription models, bundling offers, and carbon-neutral shipping options enhance customer retention and brand appeal in the digital space. -

Regulatory and Safety Standards

Stricter regulations around food-grade materials and lead-free certifications (e.g., FDA, LFGB, REACH) are reinforcing consumer trust in 18/8 stainless steel. Unlike aluminum bottles that may require liners, 18/8 steel is inherently safe, providing a competitive advantage in health-focused markets. -

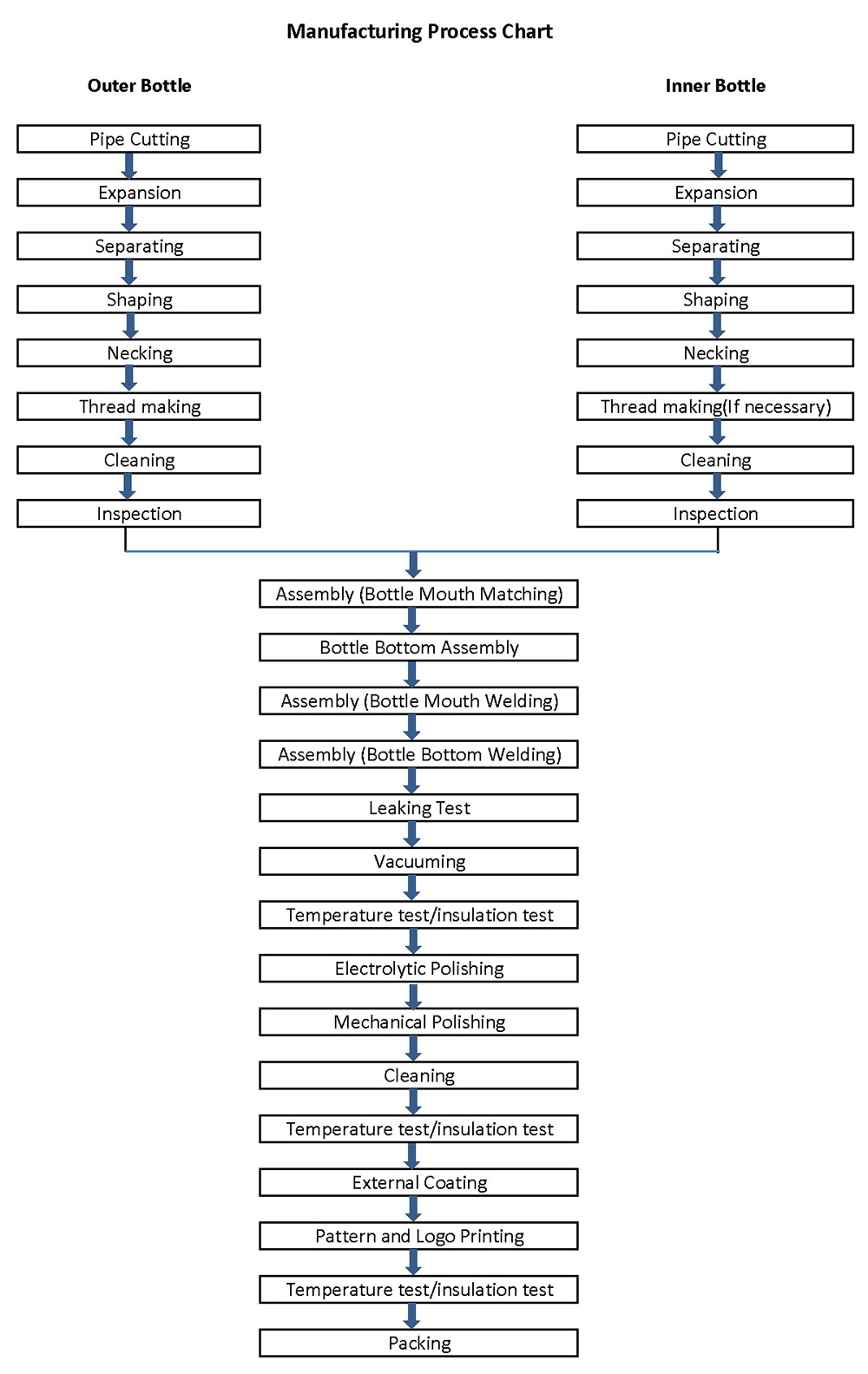

Innovation in Manufacturing and Supply Chain

To meet rising demand and reduce environmental footprints, manufacturers are investing in energy-efficient production, recycled stainless steel sourcing, and localized supply chains to mitigate geopolitical and logistical risks. These efforts support sustainability claims and improve operational resilience.

In summary, the 18/8 stainless steel water bottle market in 2026 is poised for robust growth, underpinned by sustainability trends, technological innovation, and shifting consumer preferences toward health and environmental responsibility. Companies that emphasize transparency, quality, and circular economy principles are likely to lead the market.

Common Pitfalls When Sourcing 18/8 Stainless Steel Water Bottles (Quality & IP)

Sourcing 18/8 (commonly known as 304) stainless steel water bottles can be cost-effective, but several critical pitfalls related to quality and intellectual property (IP) must be carefully navigated to avoid reputational damage, legal issues, and customer dissatisfaction.

Quality Pitfalls

Misrepresentation of Stainless Steel Grade

Suppliers may claim bottles are made from 18/8 (304) stainless steel, but deliver lower-grade materials like 201 or 430. These alternatives have less nickel and chromium, making them more prone to corrosion, rust, and metal leaching—especially when exposed to acidic beverages. Always demand mill test certificates (MTCs) and conduct independent material verification through third-party labs.

Inconsistent Wall Thickness and Construction

Poorly manufactured bottles may have uneven wall thickness, leading to structural weakness, dents, or compromised insulation (in double-wall variants). Thin walls also reduce thermal performance and durability. Insist on precise engineering drawings and conduct on-site factory inspections to verify manufacturing consistency.

Substandard Welding and Sealing

Low-quality welding on seams or base caps can result in leaks, compromised vacuum insulation, or bacterial accumulation. Look for smooth, continuous welds and consider requiring helium leak testing for vacuum-sealed bottles to ensure long-term performance.

Poor Lid and Component Quality

Often overlooked, lids made from inferior plastics or non-food-grade silicone can degrade, leach chemicals, or cause odors. Ensure all components comply with food safety standards (e.g., FDA, LFGB) and are BPA-free. Test closures for leak resistance and ease of use.

Inadequate Surface Finish and Coating

Scratches, rough seams, or inconsistent powder coating not only affect aesthetics but can harbor bacteria and accelerate wear. Verify the finish meets specified standards (e.g., brushed, matte, polished) and performs well in abrasion and salt spray tests.

Intellectual Property (IP) Pitfalls

Copying Branded Designs

Many suppliers offer counterfeit versions of popular water bottle designs (e.g., resembling Hydro Flask, Yeti, etc.). Sourcing such products exposes your brand to trademark and design patent infringement lawsuits. Always verify originality and request proof of design freedom-to-operate (FTO).

Unauthorized Use of Logos and Branding

Even if the bottle shape is generic, applying logos or emblems without proper licensing infringes on trademarks. Ensure all branding elements are either original or properly licensed, and conduct thorough IP clearance before production.

Patent Infringement on Functional Features

Innovative features like leak-proof mechanisms, ergonomic grips, or smart lid technologies may be protected by utility patents. Sourcing bottles with these features without due diligence can lead to legal action. Perform patent searches or consult an IP attorney to assess risk.

Lack of IP Ownership in Custom Designs

When commissioning custom designs, failure to secure written agreements transferring IP rights to your company means the supplier may retain ownership or resell the design to competitors. Use clear contracts specifying full IP assignment upon payment.

By proactively addressing these quality and IP pitfalls through due diligence, third-party testing, and legal safeguards, businesses can source reliable, compliant 18/8 stainless steel water bottles that protect both consumer safety and brand integrity.

H2: Logistics & Compliance Guide for 18/8 Stainless Steel Water Bottles

This guide outlines the critical logistics and regulatory compliance considerations for the safe, legal, and efficient movement of 18/8 (AISI 304) stainless steel water bottles through the global supply chain.

H2.1: Regulatory & Safety Compliance

- Food Contact Material Regulations:

- USA (FDA): Comply with 21 CFR 178.3297 (Stainless Steel) and 21 CFR 177.1520 (Rubber articles). Ensure no lead or cadmium leaching. Documentation: Certificate of Conformance (CoC) for material.

- European Union (EU): Comply with Regulation (EC) No 1935/2004 and Regulation (EU) No 10/2011 (Plastics in contact with food – relevant for lids/seals). Material must meet specific migration limits. Documentation: EU Declaration of Conformity (DoC).

- Canada (CFIA): Comply with the Food and Drug Regulations (B.23.001 – B.23.008). Follow specific migration limits for metals. Documentation: Product Safety Declaration.

- Other Markets: Check specific national regulations (e.g., UK FSA, Australia FSANZ, Japan MHLW, China GB 4806.9-2016). Key Focus: Verify low levels of chromium, nickel, and manganese migration.

- Heavy Metal Restrictions:

- Proposition 65 (California, USA): Requires warning labels if products expose consumers to chemicals above safe harbor levels (e.g., lead, cadmium). Critical: Test for and ensure levels of these metals are below Proposition 65 thresholds.

- RoHS (EU/China/Global): Primarily for electronics, but applicable if the bottle contains electronic components (e.g., temperature displays). Restricts lead, cadmium, mercury, etc.

- Product Safety & Labeling:

- Country of Origin Marking: Clearly label “Made in [Country]” (e.g., Made in Vietnam) as per destination country rules (e.g., 19 U.S.C. § 1304).

- Capacity Marking: Accurately state capacity (e.g., 500ml, 17oz) per measurement standards.

- Care Instructions: Include washing instructions (e.g., “Hand wash recommended,” “Do not microwave”).

- Child Safety (if applicable): If packaging poses choking hazards, comply with relevant standards (e.g., CPSIA in USA).

- Environmental Regulations:

- WEEE (EU): May apply if electronic components are present (require recycling markings).

- Packaging Waste: Comply with national packaging waste directives (e.g., Germany’s VerpackG – Green Dot system).

H2.2: Packaging & Preparation for Shipment

- Inner Packaging:

- Use food-safe, non-abrasive materials (e.g., polypropylene bags, tissue paper) to protect surfaces and prevent scratching.

- Ensure individual packaging prevents movement within the outer box.

- Outer Packaging (Cartons):

- Use sturdy, double-wall corrugated cardboard boxes rated for the shipment weight (Gross Weight).

- Clearly label with: Product Description, Quantity, Net/Gross Weight, Dimensions (LxWxH), Fragile/Handle with Care, “This Way Up,” and destination address.

- Include compliance labels (e.g., Prop 65 warning if required, country of origin) on the shipping carton if mandated.

- Palletization:

- Stack cartons securely on standard pallets (e.g., 48″x40″ in North America, EUR-pallet in Europe).

- Use stretch wrap (food-safe film) to secure cartons. Avoid excessive force that could damage bottles.

- Label pallets with: Pallet ID, Total Weight, Total Quantity, Shipping Marks (matching Bill of Lading), and handling instructions.

- Unit Load Stability: Ensure the load is stable and won’t collapse during transit. Use corner boards or dunnage if needed.

H2.3: Transportation & Logistics

- Mode Selection:

- Ocean Freight (FCL/LCL): Most cost-effective for large volumes. Use standard dry containers (20ft, 40ft). Ensure proper container sealing and ventilation if necessary.

- Air Freight: For urgent, high-value, or low-volume shipments. Faster but significantly more expensive.

- Land Freight (Truck/Rail): For regional distribution or final mile delivery.

- Incoterms® 2020: Clearly define responsibilities (costs, risks) using standard terms (e.g., FOB [Port], EXW [Factory], DDP [Destination]):

- FOB: Supplier responsible until goods loaded on vessel; Buyer responsible for main carriage & import.

- EXW: Buyer responsible for all logistics from supplier’s warehouse.

- CIF/DDP: Supplier handles more logistics/costs (CIF: Cost, Insurance, Freight to port; DDP: Delivered Duty Paid to final address).

- Customs Clearance:

- Accurate Documentation: Prepare a Commercial Invoice, Packing List, Bill of Lading/Air Waybill, and Certificate of Origin.

- HS Code: Use the correct Harmonized System code (e.g., 7323.93.00 – Table, kitchen or other household articles and parts thereof, of stainless steel). Verify with local customs broker.

- Tariffs & Duties: Research applicable import tariffs and VAT/GST rates in the destination country. Factor into pricing.

- Customs Broker: Engage a licensed broker in the destination country to handle clearance efficiently.

- Insurance: Obtain adequate cargo insurance (e.g., All Risk) covering loss or damage during transit.

H2.4: Quality Control & Testing

- Pre-Shipment Inspection (PSI): Conduct third-party inspections (e.g., SGS, Bureau Veritas) based on AQL (Acceptable Quality Level) standards (e.g., AQL 2.5/4.0) to check:

- Material verification (18/8 SS)

- Dimensional accuracy

- Surface finish (scratches, dents)

- Lid/seal functionality

- Packaging integrity

- Labeling accuracy

- Laboratory Testing:

- Migration Testing: Essential for food contact compliance (e.g., testing for Cr, Ni, Mn, Pb, Cd migration into food simulants).

- Material Certification: Obtain mill test reports (MTRs) from the stainless steel supplier confirming 18/8 (304) composition.

- Prop 65 Testing: Specifically test for lead and cadmium content if selling in California.

H2.5: Key Documentation Checklist

- Certificate of Conformance (Material – 18/8 Stainless Steel)

- Certificate of Origin

- Commercial Invoice

- Packing List

- Bill of Lading (Ocean) / Air Waybill (Air)

- Test Reports (Migration, Prop 65, Material)

- EU Declaration of Conformity (for EU)

- Product Safety Declaration (for Canada)

- Incoterms® Agreement

H2.6: Critical Considerations

- Supplier Vetting: Ensure manufacturing partners have robust QMS (e.g., ISO 9001) and understand compliance requirements.

- Labeling Variations: Requirements differ significantly by country. Adapt labels (language, warnings, symbols) for each market.

- Lead Times: Factor in production, testing, customs clearance, and transportation times.

- Sustainability: Consider recyclable packaging materials and communicate the bottle’s recyclability (Stainless Steel is highly recyclable).

- Consult Experts: Engage customs brokers, freight forwarders, and regulatory consultants familiar with the destination markets and product type.

Adherence to this guide ensures your 18/8 stainless steel water bottles meet safety standards, clear customs efficiently, reach customers undamaged, and avoid costly delays or penalties.

In conclusion, sourcing 18/8 stainless steel water bottles offers a reliable balance of quality, durability, and safety for both consumers and businesses. The 18/8 (also known as 304) stainless steel composition provides excellent corrosion resistance, ensures food-grade safety, and maintains hygiene over long-term use. When evaluating suppliers, it is essential to verify material authenticity, manufacturing standards, and compliance with certifications such as FDA, LFGB, or ISO. Factors such as MOQs, pricing, production lead times, and customization options should also be carefully assessed to align with business goals. By selecting reputable manufacturers—whether domestic or overseas—companies can secure high-performing, eco-friendly products that meet consumer demands for sustainable and non-toxic hydration solutions. Ultimately, a well-informed sourcing strategy for 18/8 stainless steel water bottles supports long-term brand credibility, customer satisfaction, and environmental responsibility.