The global laser welding machine market is experiencing robust growth, driven by increasing demand for precision welding in the automotive, aerospace, electronics, and heavy manufacturing sectors. According to Grand View Research, the global laser welding market was valued at USD 1.98 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 7.3% from 2023 to 2030. This growth is further amplified by advancements in fiber laser technology and the rising adoption of automation in production lines. As manufacturing standards evolve, 1500W laser welding machines have emerged as a sweet spot—offering high efficiency, deeper penetration, and faster welding speeds ideal for medium to thick materials. With industrial digitization accelerating worldwide, the demand for reliable, high-performance laser systems has never been greater. This has led to a surge in capable manufacturers delivering advanced 1500W solutions. Based on technological innovation, global reach, customer reviews, and market presence, here are the top 9 manufacturers leading the charge in the 1500W laser welding machine segment.

Top 9 1500W Laser Welding Machine Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 1500W Handheld Laser Welding Machine

Website: laserdmk.com

Key Highlights: 1500W Handheld Laser Welding Machine Manufacturer & Supplier in China – Demark (Wuhan) Technology Co., Ltd….

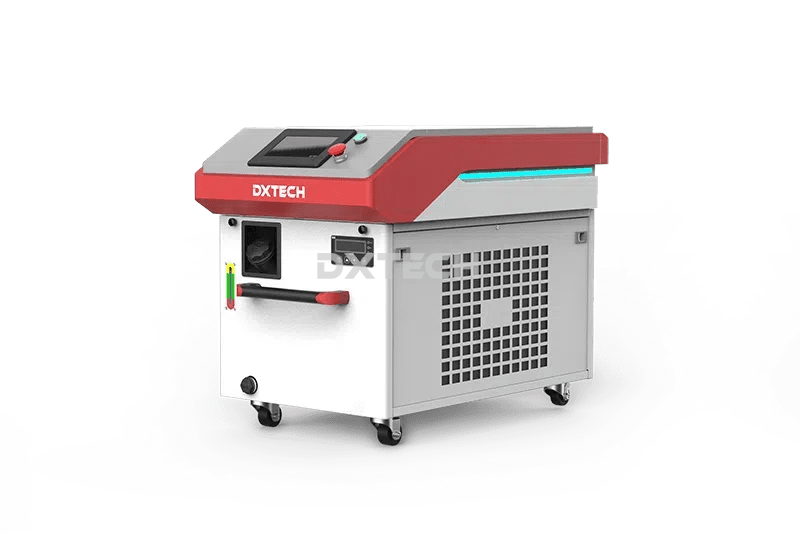

#2 DXTECH Official

Website: dxtech.com

Key Highlights: DXTECH, as the advanced CNC laser machine manufacturer, mainly manufactures and supplies the laser cutting machines, laser welding machines, laser engraving ……

#3 IPG Photonics

Website: ipgphotonics.com

Key Highlights: IPG Photonics manufactures high-performance fiber lasers, amplifiers, and laser systems for diverse applications and industries. Discover your solution….

#4 Handheld Fiber Laser Welding Machine

Website: omtech.com

Key Highlights: In stock Free delivery1500W Laser Power: Tackle both thick and thin metals with ease using OMTech’s 1500W fiber laser welder. Enjoy fast, precise welding with minimal material ……

#5 Laser Welder 1500W Handheld Laser Welding Equipment HT …

Website: heltec-energy.com

Key Highlights: This is a Lithium Battery Special Handheld Galvanometer-Type Laser Welding Machine, supporting welding 0.3mm-2.5mm copper/aluminum….

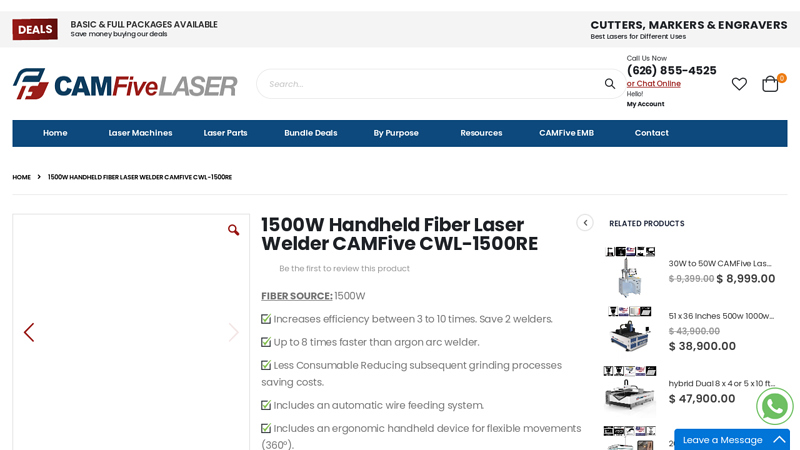

#6 1500W Handheld Fiber Laser Welder CAMFive CWL

Website: camfivelaser.com

Key Highlights: In stock 30-day returnsFIBER SOURCE: 1500W. ☑️ Increases efficiency between 3 to 10 times. Save 2 welders. ☑️ Up to 8 times faster than argon arc welder….

#7 1500w Laser Welding Machine For Stainless Steel

Website: igoldencnc.com

Key Highlights: Rating 5.0 (87) The 1500w laser welding machine employs high-octane laser pulse to heat one particular area of tiny areas on a work material….

#8 Best 1500W 4

Website: bcamcnc.com

Key Highlights: 1500W 4-in-1 portable laser welding machine for metal: weld, cut, clean, and polish seams. Ideal for industrial, furniture, automotive, ……

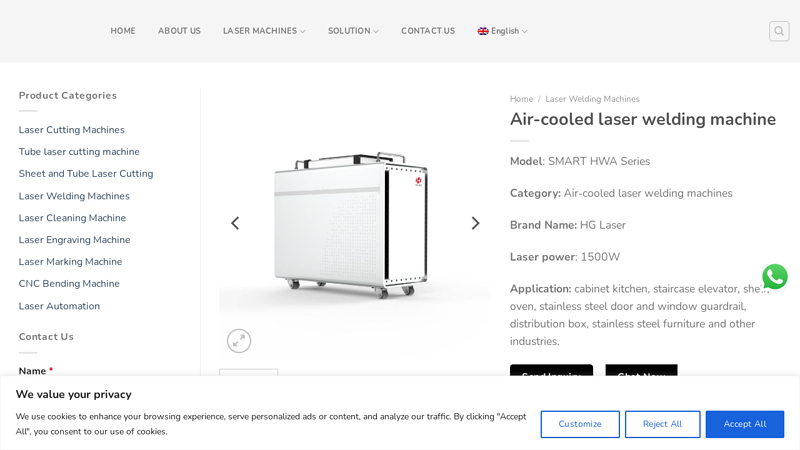

#9 HWA Series Best Air

Website: hg-star.com

Key Highlights: The air-cooled laser welding machines has the best fibre optic laser beam for fast welding speed, high quality welds and no consumables….

Expert Sourcing Insights for 1500W Laser Welding Machine

H2: 2026 Market Trends for 1500W Laser Welding Machines

The global market for 1500W laser welding machines is poised for substantial growth and transformation by 2026, driven by advancements in manufacturing technologies, rising automation, and increasing demand for high-precision welding across key industries. This analysis explores critical market trends expected to shape the landscape of 1500W laser welding systems in the coming years.

1. Rising Adoption in Automotive and EV Manufacturing

The electric vehicle (EV) revolution continues to accelerate demand for lightweight, durable, and energy-efficient components. The 1500W laser welding machine, offering an optimal balance between power, precision, and cost-efficiency, is becoming a preferred solution for battery tab welding, structural component joining, and powertrain assembly. By 2026, an increasing number of EV manufacturers are expected to integrate 1500W fiber laser systems into their production lines due to their reliability and compatibility with robotic automation.

2. Growth in Metal Fabrication and General Manufacturing

Small-to-medium enterprises (SMEs) in the metal fabrication sector are increasingly investing in affordable, high-performance laser systems. With prices for fiber laser technology declining and operational efficiency improving, 1500W machines are gaining traction as a cost-effective alternative to higher-wattage systems. Their versatility in welding stainless steel, aluminum, and carbon steel makes them ideal for applications in construction, aerospace, and consumer goods manufacturing.

3. Technological Advancements and Smart Integration

By 2026, 1500W laser welding machines are expected to feature enhanced intelligence through IoT connectivity, real-time monitoring, and AI-driven process optimization. Manufacturers are integrating predictive maintenance, remote diagnostics, and adaptive control systems to reduce downtime and improve weld consistency. These smart features enhance user-friendliness and appeal to industries seeking Industry 4.0 compliance.

4. Regional Market Expansion

Asia-Pacific—particularly China, India, and Southeast Asia—will remain the largest market for 1500W laser welding machines, fueled by booming industrialization and government support for advanced manufacturing. Europe and North America will see steady growth, driven by reshoring of manufacturing and increased investments in automation. Localized service and support networks are expected to expand to meet after-sales demands.

5. Competitive Landscape and Price Pressure

The market is becoming increasingly competitive with a growing number of Chinese and European manufacturers offering high-quality 1500W systems at competitive prices. This competition is driving innovation and putting downward pressure on costs, making these machines more accessible to a broader range of users. Differentiation is increasingly based on software capabilities, beam quality, and integration with automation systems.

6. Sustainability and Energy Efficiency Focus

As industries prioritize sustainability, the energy-efficient operation of 1500W fiber lasers—offering high wall-plug efficiency and low maintenance—will enhance their appeal. Their minimal heat input and reduced material waste align with green manufacturing goals, further supporting adoption in eco-conscious supply chains.

Conclusion

By 2026, the 1500W laser welding machine market will be defined by technological sophistication, broader industry adoption, and strong regional growth. Positioned as a versatile and economical solution, the 1500W system is expected to occupy a sweet spot in the mid-power laser welding segment, serving as a cornerstone in modern, automated manufacturing environments across diverse sectors.

Common Pitfalls When Sourcing a 1500W Laser Welding Machine (Quality & IP Risks)

Sourcing a 1500W laser welding machine involves significant investment and technical complexity. Buyers often encounter critical pitfalls related to quality assurance and intellectual property (IP) protection, especially when dealing with less-established suppliers. Avoiding these risks is essential for long-term operational success and legal compliance.

Overlooking Build Quality and Component Sourcing

A major pitfall is assuming all 1500W machines deliver equivalent performance. Many low-cost suppliers use substandard components to reduce prices, leading to premature failures. Key concerns include:

- Inferior Laser Sources: Some manufacturers rebrand or clone fiber lasers without proper calibration or quality control. These units often suffer from unstable output, shortened lifespans, and inconsistent beam quality.

- Poor Cooling Systems: Inadequate chiller design or undersized components can cause overheating, reducing laser efficiency and damaging internal parts.

- Low-Grade Mechanical Parts: Linear guides, motors, and frames made from subpar materials increase wear and reduce welding precision over time.

Always request documentation on core component specifications (e.g., IPG or Raycus laser source) and conduct factory audits or third-party inspections before purchase.

Ignoring Intellectual Property (IP) Infringement Risks

Purchasing machines from suppliers with questionable IP practices can expose buyers to legal liability. Common issues include:

- Cloned Control Systems: Some machines use pirated software or reverse-engineered control boards, violating copyright and potentially exposing users to malware or lack of updates.

- Counterfeit Branding: Suppliers may falsely claim affiliation with reputable brands (e.g., “compatible with Trumpf” or “designed in Germany”) without authorization.

- Patent Violations: Machine designs or optical configurations may infringe on existing patents, leading to customs seizures or litigation, particularly in regulated markets like the EU or U.S.

To mitigate IP risks, verify supplier credentials, request proof of licensing for critical technologies, and ensure contracts include IP indemnification clauses.

Relying Solely on Specifications Without Verification

Suppliers often exaggerate technical specs—such as actual output power, beam parameter product (BPP), or duty cycle—to appear competitive. A machine advertised as 1500W may deliver only 1300W under sustained load due to poor thermal management.

Always:

- Request independent test reports or conduct on-site power output verification.

- Ask for sample welds under real-world conditions.

- Clarify warranty terms and availability of genuine spare parts.

Underestimating After-Sales Support and Serviceability

Even high-quality machines require maintenance. Sourcing from suppliers without local technical support or transparent service networks can result in extended downtime. Ensure the supplier offers:

- Access to firmware updates and technical documentation.

- Training for operators and maintenance staff.

- Clear channels for repair and replacement of IP-sensitive components.

Failing to address these quality and IP-related pitfalls can result in costly downtime, legal exposure, and compromised product integrity. Due diligence in supplier selection is not optional—it’s a strategic necessity.

Logistics & Compliance Guide for 1500W Laser Welding Machine

Overview

This guide outlines the essential logistics and compliance considerations for the safe, legal, and efficient transportation, importation, and operation of a 1500W laser welding machine. Due to its high power, electrical requirements, and laser classification, strict adherence to international, national, and local regulations is required.

1. International Shipping & Transport Logistics

Packaging Requirements

– Use shock-resistant, moisture-proof, and anti-static packaging.

– Secure all optical components with protective caps and internal bracing.

– Include desiccants and humidity indicators in the packaging.

– Clearly label packaging: “Fragile,” “This Side Up,” “Optical Equipment,” and “Do Not Stack.”

Freight Mode Selection

– Air freight: Use only if urgently needed; ensure compliance with IATA Dangerous Goods Regulations (Class 9 for lithium batteries if included).

– Sea freight: Preferred for cost-efficiency; use containerized shipping with climate control if possible.

– Overland transport: Use padded, climate-controlled vehicles; secure machine to prevent movement.

Documentation

– Commercial Invoice (with declared value, HS code, and technical specs).

– Packing List.

– Bill of Lading (B/L) or Air Waybill (AWB).

– Certificate of Origin.

– Technical Datasheet (highlighting laser class, power, and safety features).

2. Import & Customs Compliance

HS Code Classification

– Typical HS Code: 8515.31 (Resistance welding machines) or 8515.80 (Other welding equipment).

– Confirm exact code with local customs broker, as misclassification can delay clearance.

Import Duties & Taxes

– Research applicable tariffs, VAT/GST, and import licensing requirements in destination country.

– Some countries offer exemptions for industrial or R&D equipment—verify eligibility.

Regulatory Approvals

– Obtain necessary import permits for high-power electronic and laser equipment.

– Check if the machine requires pre-shipment inspection or conformity assessment (e.g., SONCAP for Nigeria, SABER for Saudi Arabia).

3. Laser Safety & Regulatory Compliance

Laser Classification

– A 1500W laser welding machine typically falls under Class 4 (IEC 60825-1 / ANSI Z136.1).

– Class 4 lasers pose severe eye and skin hazards and can ignite flammable materials.

Required Safety Features

– Interlock systems on access panels.

– Emergency stop buttons.

– Beam shutters and key-controlled operation.

– Warning labels (laser radiation symbol, power, wavelength).

– Fume extraction interface.

Compliance Certifications

– CE Marking (EU): Comply with Machinery Directive 2006/42/EC, EMC Directive 2014/30/EU, and LVD 2014/35/EU.

– FDA Registration (USA): Comply with 21 CFR 1040.10 and 1040.11; register with CDRH.

– Other Regions: KC (Korea), CCC (China), RCM (Australia/NZ), etc.

4. Electrical & Installation Compliance

Power Supply Requirements

– Verify voltage (e.g., 208V, 230V, 400V), phase (3-phase), and frequency (50/60 Hz) match local standards.

– Ensure grounding and circuit protection (e.g., 32A breaker) are in place.

Electrical Certification

– Equipment must meet local electrical safety standards:

– UL/CSA (North America)

– CE / UKCA (Europe/UK)

– PSE (Japan)

Installation Environment

– Provide adequate ventilation and temperature control (15–30°C typical).

– Ensure clean, dry installation area with ESD protection.

– Maintain minimum clearance around machine for maintenance and cooling.

5. Workplace Safety & Operational Compliance

Workplace Controls (OSHA, EU-OSHA, etc.)

– Establish a Laser Controlled Area with warning signs and interlocks.

– Use Laser Protective Eyewear (wavelength- and power-rated).

– Implement a Laser Safety Officer (LSO) program if required.

Training & Procedures

– Train operators on laser safety, emergency procedures, and machine operation.

– Maintain operating manuals and safety documentation onsite.

Ventilation & Fume Extraction

– Connect to an industrial fume extraction system compliant with local air quality regulations (e.g., OSHA PELs, EU Directive 2004/37/EC).

6. Environmental & Disposal Compliance

Hazardous Components

– Identify and manage batteries, capacitors, or cooling fluids per local hazardous waste laws.

– Do not dispose of in general waste.

End-of-Life Disposal

– Follow WEEE Directive (EU) or equivalent for electronic waste recycling.

– Partner with certified e-waste recyclers for component recovery.

7. Documentation & Record Keeping

Required Records

– Import and customs clearance documents (retain for 5–7 years).

– Safety certifications (CE, FDA, etc.).

– Maintenance logs and safety inspections.

– Operator training records.

– Laser safety program documentation (if applicable).

Summary

Transporting and operating a 1500W laser welding machine requires careful planning across multiple compliance domains. Ensure all logistics partners and end-users are aware of regulatory and safety requirements. Proactive compliance minimizes delays, ensures safety, and avoids penalties. Consult with local regulatory bodies and certified experts when in doubt.

Conclusion on Sourcing a 1500W Laser Welding Machine

After a thorough evaluation of available options, technical specifications, supplier reliability, and cost-effectiveness, sourcing a 1500W fiber laser welding machine presents a strategic investment for enhancing manufacturing productivity and weld quality. The 1500W power capacity strikes an optimal balance between performance and operational efficiency, suitable for a wide range of industrial applications—including automotive components, metal fabrication, and precision manufacturing—offering excellent weld penetration, speed, and minimal heat distortion.

Key considerations such as beam quality, duty cycle, cooling requirements, automation compatibility, and after-sales support emphasize the importance of selecting a reputable supplier with proven technology and service networks. While initial costs may vary between domestic and international manufacturers, prioritizing reliability, warranty terms, and long-term maintenance can significantly reduce downtime and total cost of ownership.

In conclusion, procuring a 1500W laser welding machine aligns with modern manufacturing demands for precision, efficiency, and scalability. With proper integration into existing production workflows and operator training, this equipment will drive improved product quality, faster throughput, and a strong return on investment. Recommended next steps include finalizing supplier negotiations, conducting on-site demonstrations, and initiating staff training programs to ensure seamless implementation.