The industrial laser welding market is experiencing robust expansion, driven by increasing demand for precision manufacturing across automotive, aerospace, and electronics sectors. According to Grand View Research, the global laser welding market was valued at USD 2.3 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 7.8% from 2023 to 2030. This growth is further fueled by the rising adoption of high-power laser systems, particularly 1500-watt and higher models, which offer enhanced welding speed, penetration depth, and operational efficiency. As manufacturers seek to optimize production throughput and weld quality, 1500-watt laser welders have emerged as a sweet spot between performance and cost-effectiveness. With Asia Pacific leading in deployment due to rapid industrialization and government initiatives in advanced manufacturing, the competitive landscape is becoming increasingly concentrated among innovative technology providers. Based on market presence, technological capability, and global reach, the following nine companies represent the leading manufacturers of 1500-watt laser welders shaping the future of industrial joining solutions.

Top 9 1500 Watt Laser Welder Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 1500 watt laser welding machine Manufacturer & Supplier in China

Website: laserdmk.com

Key Highlights: The DMK 1500 watt laser welder device is made in order to make a laser beam that are extremely concentrated and that can be employed to fuse steel components ……

#2 IPG Photonics

Website: ipgphotonics.com

Key Highlights: IPG Photonics manufactures high-performance fiber lasers, amplifiers, and laser systems for diverse applications and industries. Discover your solution….

#3 Handheld Fiber Laser Welding Machine

Website: omtech.com

Key Highlights: In stock Free delivery1500W Laser Power: Tackle both thick and thin metals with ease using OMTech’s 1500W fiber laser welder. Enjoy fast, precise welding with minimal material ……

#4 BK

Website: baikeopto.com

Key Highlights: In stockBK-WD1500N 1500W Automatic Energy-Saving Fiber Laser Welder Machine for Mold & Sheet Metal Applications ; Laser power, 1200W, 1500W ; Laser wavelength, 1064~ ……

#5 Laser Welder 1500W Handheld Laser Welding Equipment HT …

Website: heltec-energy.com

Key Highlights: This is a Lithium Battery Special Handheld Galvanometer-Type Laser Welding Machine, supporting welding 0.3mm-2.5mm copper/aluminum….

#6 LightWELD 1500 XC Handheld Laser Welding System

Website: themakerschest.com

Key Highlights: Free delivery 75-day returnsThe 1500 XC Laser Welder Machine comes with adjustable wobble welding, pulsed laser modes, dual wire feed options, and precise focal controls. With 100+…

#7 1500watt Portable Fiber Laser Welder

Website: peslaser.com

Key Highlights: Handheld laser welding machine has the advantages of simple operation, beautiful weld seam, fast welding speed, and no consumables….

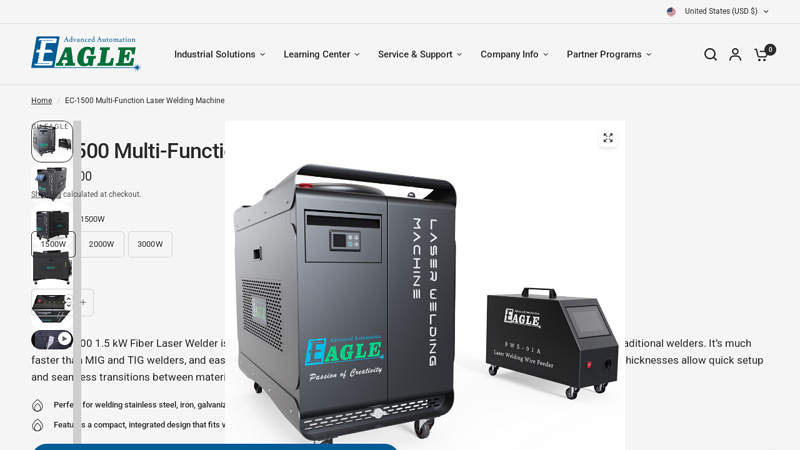

#8 EC

Website: gueagle.com

Key Highlights: In stockThe EC-1500 1.5 kW Fiber Laser Welder is a favorite among custom metal fabricators, offering significant cost savings over traditional welders….

#9 HWA Series Best Air

Website: hg-star.com

Key Highlights: The air-cooled laser welding machines has the best fibre optic laser beam for fast welding speed, high quality welds and no consumables….

Expert Sourcing Insights for 1500 Watt Laser Welder

2026 Market Trends for 1500 Watt Laser Welder

The global market for industrial laser systems is undergoing rapid transformation, and the 1500 watt (W) laser welder segment is poised for significant growth and technological advancement by 2026. This power class sits at a strategic intersection—offering high processing speed, deep penetration, and versatility across multiple industries—making it a focal point for innovation and adoption in manufacturing.

Rising Demand Across Key Industries

By 2026, the demand for 1500W laser welders is expected to surge, driven primarily by the automotive, aerospace, and clean energy sectors. In the automotive industry, the shift toward electric vehicles (EVs) has increased the need for precision welding of battery components, power electronics, and lightweight structures. The 1500W laser provides an optimal balance between speed and control, enabling high-throughput production lines without sacrificing weld quality.

In renewable energy, particularly in solar panel and battery manufacturing, 1500W lasers are being adopted for their ability to weld dissimilar and highly reflective materials such as copper and aluminum—common in energy storage systems. Aerospace manufacturers are also leveraging these systems for lightweight structural components, where precision and minimal heat distortion are critical.

Advancements in Fiber Laser Technology

Technological improvements in fiber laser efficiency, beam quality, and reliability are a key driver of 1500W laser welder adoption. By 2026, next-generation fiber lasers are expected to offer wall-plug efficiencies exceeding 45%, significantly reducing operational costs and cooling requirements. Enhanced beam shaping and modularity allow dynamic control over weld profiles, enabling tailored solutions for specific applications such as seam welding, spot welding, and 3D contouring.

Integrated monitoring systems using AI and real-time process feedback are becoming standard, ensuring consistent weld quality and predictive maintenance. These smart features are expected to become differentiators in competitive markets, where uptime and repeatability are paramount.

Regional Market Expansion

Asia-Pacific, particularly China, Japan, and South Korea, will remain the dominant region for 1500W laser welder demand in 2026. Domestic manufacturing growth, government support for advanced manufacturing, and widespread adoption of automation in electronics and EV supply chains are fueling investment in laser welding technology.

Europe and North America are also seeing steady growth, driven by reshoring initiatives, stringent quality standards, and investments in Industry 4.0 infrastructure. In these regions, the focus is shifting toward flexible, modular laser systems that integrate seamlessly with robotic cells and digital factory ecosystems.

Competitive Landscape and Pricing Trends

The competitive landscape is intensifying, with both established players (e.g., IPG Photonics, TRUMPF, Coherent) and emerging Chinese manufacturers (e.g., Raycus, Max Photonics) offering increasingly capable 1500W systems at competitive price points. This has led to a downward pressure on prices while performance continues to improve.

By 2026, the average price for a standalone 1500W fiber laser source is projected to decrease by 15–20% compared to 2023 levels, making the technology more accessible to small and medium-sized enterprises (SMEs). Bundled solutions that include welding heads, motion systems, and software are gaining traction, offering turnkey automation capabilities.

Sustainability and Energy Efficiency

Sustainability is becoming a key consideration in industrial procurement decisions. The 1500W laser welder’s high energy efficiency and reduced material waste compared to traditional welding methods align with corporate ESG (Environmental, Social, and Governance) goals. Manufacturers are increasingly highlighting low power consumption, recyclable components, and longer service life as selling points.

Additionally, the integration of energy recovery systems and hybrid welding techniques—combining laser with arc processes—could further improve sustainability metrics by reducing overall energy use and consumables.

Conclusion

By 2026, the 1500W laser welder market will be characterized by increased adoption, smarter technology, and broader accessibility. Driven by industrial digitization, demand for high-precision manufacturing, and sustainability imperatives, this power class will remain a cornerstone of modern welding solutions. Companies that invest in integrated, intelligent, and energy-efficient systems will be best positioned to capitalize on these evolving market dynamics.

Common Pitfalls When Sourcing a 1500 Watt Laser Welder: Quality and Intellectual Property (IP) Concerns

Sourcing a 1500-watt laser welder can be a strategic decision for manufacturers seeking precision, speed, and efficiency. However, businesses often encounter significant challenges related to product quality and intellectual property (IP) protection—especially when procuring from low-cost or overseas suppliers. Understanding these pitfalls is crucial to ensuring long-term operational success and legal compliance.

1. Compromised Build Quality and Component Sourcing

One of the most common issues with lower-cost 1500-watt laser welders is inconsistent build quality. Many suppliers, particularly in competitive price-driven markets, use substandard materials or non-industrial-grade components to reduce costs. This can result in:

- Overheating or premature failure of the laser source

- Poor beam quality affecting weld consistency

- Inadequate cooling systems leading to downtime

- Shortened service life and increased maintenance costs

Tip: Always verify the laser source manufacturer (e.g., IPG, Raycus, nLight) and request documentation on component specifications. Avoid suppliers who are vague about OEM partnerships.

2. Misrepresentation of Power Output and Performance

Some vendors advertise “1500-watt” lasers that fail to deliver true continuous output. This misrepresentation occurs through:

- Peak power vs. sustained power labeling

- Use of underperforming diodes or outdated technology

- Lack of third-party performance validation

Consequence: The machine may not achieve required weld penetration or throughput, impacting production quality.

Tip: Request independent test reports or conduct on-site performance trials before finalizing a purchase.

3. Lack of Compliance with International Safety and Certification Standards

Many budget laser welders lack essential certifications such as CE, FDA (for U.S. import), or IEC 60825 (laser safety). Operating non-compliant equipment can lead to:

- Workplace safety hazards

- Legal liability or regulatory fines

- Inability to pass quality audits in regulated industries

Tip: Insist on full compliance documentation and verify certification authenticity through official databases.

4. Intellectual Property (IP) Infringement Risks

A major but often overlooked risk is purchasing equipment that infringes on patented technologies. Some manufacturers replicate designs or software from established brands without licensing, particularly in regions with lax IP enforcement.

Risks include:

- Legal liability for using or reselling infringing equipment

- Seizure of machines at customs during import

- Damage to brand reputation

For example, copying beam delivery systems, control software algorithms, or cooling mechanisms may violate patents held by companies like TRUMPF, IPG Photonics, or Coherent.

Tip: Conduct due diligence on the manufacturer’s IP history. Ask for proof of licensing for critical technologies and consider legal consultation before large-scale procurement.

5. Inadequate Technical Support and Spare Parts Availability

Even if the initial purchase price is low, poor after-sales support can lead to extended downtime. Common issues include:

- Unavailability of replacement parts

- Language or time-zone barriers in support

- Lack of trained local technicians

This is especially problematic with IP-protected components that require authorized service.

Tip: Choose suppliers with established service networks or partnerships with recognized component OEMs.

6. Hidden Software Limitations and Licensing

Some laser welders use proprietary control software that may be:

- Reverse-engineered or pirated

- Limited in functionality (e.g., disabled features)

- Subject to remote deactivation

Using such software can expose buyers to cybersecurity risks and legal action.

Tip: Verify software authenticity and ensure licenses are transferable and legally obtained.

Conclusion

Sourcing a 1500-watt laser welder requires more than comparing price tags. Prioritizing verified quality, regulatory compliance, and IP integrity protects your investment and avoids costly legal and operational setbacks. Always conduct thorough due diligence, including factory audits, reference checks, and technical validation, to mitigate these common pitfalls.

H2: Logistics & Compliance Guide for 1500 Watt Laser Welder

Handling, transporting, and operating a 1500-watt fiber or CO₂ laser welder requires strict adherence to logistics protocols and regulatory compliance to ensure safety, legal conformity, and operational efficiency. This guide outlines key considerations across international, national, and regional standards relevant to the movement, installation, and use of high-power industrial laser equipment.

1. Classification & Regulatory Framework

1.1 Laser Safety Classification

- A 1500-watt laser system is classified as a Class 4 laser under IEC 60825-1 and ANSI Z136.1 standards.

- Class 4 lasers pose severe risks including skin burns, eye damage, fire hazards, and potential generation of hazardous fumes.

- Requirement: Full engineering and administrative controls must be in place prior to operation.

1.2 Equipment Standards Compliance

Ensure the laser welder meets:

– IEC 60825-1: Safety of laser products – Equipment classification and requirements.

– IEC 61400-11 (if applicable to integration with automation).

– ISO 13849-1: Safety of machinery – Safety-related parts of control systems.

– CE Marking (for EU): Indicates conformity with health, safety, and environmental protection standards.

– FDA/CDRH Regulations (21 CFR 1040.10 & 1040.11) (for U.S. market): Mandatory for laser products, including reporting and certification.

2. Transportation & Logistics

2.1 Packaging & Handling

- Use manufacturer-approved packaging with shock-absorbing materials to protect optical components and electronics.

- Clearly label crates with:

- “Fragile – Handle with Care”

- “This Side Up”

- “Optical Equipment – Do Not Invert”

- “Laser Radiation – Do Not Open” (Class 4 symbol required)

- Secure all moving parts and optics to prevent displacement during transit.

2.2 International Shipping

- UN/DOT Classification: Laser systems are generally not classified as hazardous materials if lasers are powered off and safety interlocks engaged. However:

- Batteries (if included) may fall under UN 3480 (lithium-ion) or UN 2800 (non-spillable).

- Power supplies with capacitors may require special discharge procedures.

- Documentation Required:

- Commercial Invoice

- Packing List

- Bill of Lading / Air Waybill

- Certificate of Conformity (CE, FCC, etc.)

- FDA Accession Number (for U.S. entry)

- Import licenses (if required by destination country)

2.3 Customs Clearance

- HS Code Guidance: Typically classified under:

- 8515.21 – Resistance welding machines

- 8515.31 – Laser welding machines

- Confirm with local customs for precise classification.

- Provide technical specifications:

- Laser type (fiber, CO₂, etc.)

- Output power (1500 W)

- Intended industrial use

- Be prepared for potential duty rates and import taxes depending on country of destination.

3. Import & Installation Compliance

3.1 Import Regulations by Region

| Region | Key Requirements |

|——-|——————|

| European Union | CE certification, Declaration of Conformity, notified body involvement if needed. Compliance with Machinery Directive (2006/42/EC) and EMC Directive (2014/30/EU). |

| United States | FDA/CDRH product report, variance (if applicable), compliance with 21 CFR 1040.10. FCC Part 18 for electromagnetic interference. |

| Canada | Compliance with Health Canada’s Radiation Emitting Devices Act (REDA). Registration via the Laser Registry. |

| China | CCC Marking may be required depending on configuration. China RoHS compliance. |

| Australia/NZ | Compliance with AS/NZS IEC 60825.1. Notification to the Australian Radiation Protection and Nuclear Safety Agency (ARPANSA). |

3.2 Installation & Site Preparation

- Electrical Requirements:

- Confirm voltage (e.g., 3-phase 400V or 480V), frequency, and grounding.

- Install dedicated circuit with surge protection.

- Ventilation & Fume Extraction:

- Mandatory for laser welding due to metal fume generation (e.g., zinc, chromium, or manganese oxides).

- Use HEPA or ULPA filtration systems compliant with OSHA (U.S.) or COSHH (UK) standards.

- Laser Controlled Area:

- Designate a Class 1 enclosed workspace or install interlocked barriers.

- Post warning signs per ANSI Z535 or ISO 7010 (e.g., “Laser Radiation – Avoid Eye or Skin Exposure”).

- Emergency Stop & Interlocks:

- Ensure beam shutter, door interlocks, and E-stop functions are operational.

4. Operational & Workplace Safety Compliance

4.1 Personal Protective Equipment (PPE)

- Laser safety eyewear with appropriate Optical Density (OD) for the laser wavelength (e.g., OD 5+ for 1070 nm fiber lasers).

- Flame-resistant clothing, face shields, and gloves.

- Hearing protection if auxiliary equipment (e.g., chiller, fume extractor) exceeds 85 dB.

4.2 Training & Certification

- Operators must be trained per:

- ANSI Z136.1 (U.S.)

- EN 60825-14 (EU)

- Appoint a Laser Safety Officer (LSO) if required by local regulations (mandatory in many jurisdictions for Class 4 lasers).

4.3 Maintenance & Documentation

- Keep a laser safety logbook with:

- Maintenance records

- Safety inspections

- Personnel training records

- Follow manufacturer’s service schedule; only qualified technicians should access internal components.

5. Environmental & Waste Compliance

- Coolant & Lubricants: Handle and dispose of per EPA (U.S.) or REACH/CLP (EU) regulations.

- Metal Fumes & Particulates: Filtered waste must be tested for hazardous content (e.g., hexavalent chromium) and disposed of as hazardous waste if required.

- End-of-Life Equipment: Recycle via WEEE (EU) or state e-waste programs (U.S.).

6. Summary Checklist

| Task | Status |

|——|——–|

| Verify CE/FCC/FDA compliance | ☐ |

| Confirm correct HS Code for customs | ☐ |

| Prepare shipping documentation | ☐ |

| Ensure proper packaging & labeling | ☐ |

| Validate site power & ventilation | ☐ |

| Install interlocks & warning signs | ☐ |

| Train operators & appoint LSO | ☐ |

| Conduct initial safety audit | ☐ |

Conclusion

The 1500-watt laser welder is a powerful industrial tool requiring rigorous logistics planning and compliance with international safety and trade regulations. Proactive adherence to transportation, import, installation, and operational standards ensures legal operation, personnel safety, and equipment longevity. Always consult local regulatory authorities and the manufacturer for model-specific requirements.

Last Updated: April 2024

Prepared by: [Your Company] Safety & Compliance Team

Conclusion for Sourcing a 1500-Watt Laser Welder

After a thorough evaluation of technical requirements, market options, supplier capabilities, and total cost of ownership, sourcing a 1500-watt fiber laser welder is a strategic investment that aligns well with our operational goals of improving welding precision, increasing production efficiency, and enhancing product quality. The 1500-watt power output offers an optimal balance between performance and energy consumption, enabling reliable welding of a wide range of materials and thicknesses commonly used in our applications.

Key suppliers evaluated offer competitive technologies with advanced features such as integrated real-time monitoring, automated control systems, and strong after-sales support. The selected solution not only meets current production demands but also provides scalability for future expansion. Additionally, the long-term cost benefits—such as reduced maintenance, lower consumable usage, and higher throughput—justify the initial capital expenditure.

In conclusion, procuring a 1500-watt laser welder from a reputable supplier with proven performance and service support will significantly enhance our manufacturing capabilities, improve weld consistency, and contribute to overall operational excellence. The next steps include finalizing vendor selection, finalizing technical specifications, and planning for installation, training, and integration into existing production workflows.