The global laser welding machine market is experiencing robust growth, driven by increasing demand for high-precision joining solutions across industries such as automotive, electronics, and medical devices. According to a 2023 report by Mordor Intelligence, the global laser welding market was valued at USD 3.98 billion in 2022 and is projected to reach USD 6.47 billion by 2028, growing at a CAGR of 8.3% during the forecast period. This expansion is fueled by the adoption of fiber laser technology, rising automation in manufacturing, and the need for energy-efficient, high-speed welding processes. At the forefront of this trend are 1500 W laser welding machines, which offer an optimal balance of power, precision, and cost-efficiency for mid-to-heavy-duty industrial applications. As demand surges, numerous manufacturers have emerged to meet evolving technological requirements. Based on market presence, innovation, product reliability, and global reach, the following nine companies represent leading players in the 1500 W laser welding machine space.

Top 9 1500 W Laser Welding Machine Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 1500W Handheld Laser Welding Machine

Website: laserdmk.com

Key Highlights: 1500W Handheld Laser Welding Machine Manufacturer & Supplier in China – Demark (Wuhan) Technology Co., Ltd….

#2 LaserStar Technologies

Website: laserstar.net

Key Highlights: LaserStar Technologies designs and manufactures high-performance laser welding, marking, and cutting systems for industrial, jewelry, ……

#3 Handheld Fiber Laser Welding Machine

Website: omtech.com

Key Highlights: In stock Free delivery1500W Laser Power: Tackle both thick and thin metals with ease using OMTech’s 1500W fiber laser welder. Enjoy fast, precise welding with minimal material ……

#4 Fanuci & Falcon

Website: fanuci-falcon.com

Key Highlights: FANUCI & FALCON is an innovative high-tech enterprise specializing in the manufacturing of advanced fiber laser machines for metal processing applications ……

#5 IPG Photonics

Website: ipgphotonics.com

Key Highlights: IPG Photonics manufactures high-performance fiber lasers, amplifiers, and laser systems for diverse applications and industries. Discover your solution….

#6 Laser Welder 1500W Handheld Laser Welding Equipment HT …

Website: heltec-energy.com

Key Highlights: This is a Lithium Battery Special Handheld Galvanometer-Type Laser Welding Machine, supporting welding 0.3mm-2.5mm copper/aluminum….

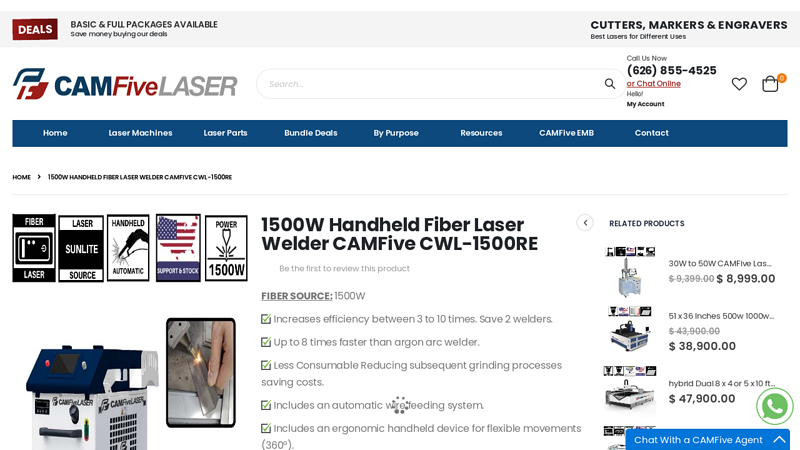

#7 1500W Handheld Fiber Laser Welder CAMFive CWL

Website: camfivelaser.com

Key Highlights: In stock 30-day returnsFIBER SOURCE: 1500W. ☑️ Increases efficiency between 3 to 10 times. Save 2 welders. ☑️ Up to 8 times faster than argon arc welder….

#8 Mini handheld laser welding machine, 1500W laser welder

Website: triumphlaser.com

Key Highlights: Mini laser welding machine is designed to be lightweight and compact, making them easy to carry to different job sites or within a workshop….

#9 HWA Series Best Air

Website: hg-star.com

Key Highlights: Model: SMART HWA Series. Category: Air-cooled laser welding machines. Brand Name: HG Laser. Laser power: 1500W. Application: cabinet kitchen, staircase ……

Expert Sourcing Insights for 1500 W Laser Welding Machine

H2: 2026 Market Trends for 1500 W Laser Welding Machines

The global market for 1500 W laser welding machines is poised for significant transformation by 2026, driven by advancements in laser technology, rising industrial automation, and growing demand across key manufacturing sectors. This analysis explores the key trends shaping the adoption, innovation, and competitive landscape of 1500 W laser welding systems in the coming years.

-

Increased Adoption in Electric Vehicle (EV) Manufacturing

By 2026, the electric vehicle industry will remain a major growth driver for mid-power (1000–2000 W) laser welding systems. The 1500 W laser welding machine offers an optimal balance of precision, speed, and penetration depth for battery pack assembly, motor components, and lightweight body structures. As EV production scales globally, manufacturers are increasingly investing in reliable, high-throughput welding solutions. Fiber laser systems at 1500 W are favored for their efficiency, low maintenance, and compatibility with robotic integration. -

Growth in Precision Manufacturing and Consumer Electronics

The demand for miniaturization and high-precision joining in consumer electronics, medical devices, and aerospace components is boosting the use of 1500 W lasers. These systems enable clean, low-heat-input welds on thin metals and dissimilar materials, meeting stringent quality standards. By 2026, expect increased integration of 1500 W lasers in automated production lines for smart devices, wearables, and IoT hardware. -

Technological Advancements: Smart Lasers and Automation

Laser welding machines are becoming smarter, with embedded sensors, real-time monitoring, and AI-driven process optimization. By 2026, 1500 W systems will increasingly feature adaptive control systems that adjust parameters dynamically for consistent weld quality. Integration with Industry 4.0 platforms allows remote monitoring, predictive maintenance, and seamless data exchange—enhancing productivity and reducing downtime. -

Cost Optimization and Market Accessibility

The cost of fiber laser sources has steadily declined, making 1500 W systems more accessible to small and medium-sized enterprises (SMEs). Chinese manufacturers have played a key role in driving down prices through localized production and innovation. By 2026, competitive pricing and modular designs will expand the market beyond traditional heavy industries into niche and emerging applications. -

Regional Market Shifts

Asia-Pacific, particularly China, India, and Southeast Asia, will dominate demand due to booming manufacturing sectors and government support for advanced manufacturing. North America and Europe will see steady growth, driven by reshoring initiatives and sustainability goals. Localized production and service networks will become critical for vendors aiming to capture market share. -

Sustainability and Energy Efficiency

As industries focus on reducing carbon footprints, the energy efficiency of 1500 W fiber lasers—offering high wall-plug efficiency and minimal consumables—will make them a preferred choice over traditional welding methods. By 2026, eco-friendly manufacturing practices will further accelerate the transition to laser-based solutions. -

Competitive Landscape and Vendor Innovation

Leading players such as IPG Photonics, Raycus, Max Photonics, and TRUMPF are expected to intensify R&D efforts in beam shaping, multi-kilowatt modular systems, and hybrid welding solutions. While higher-power lasers (3 kW+) dominate heavy fabrication, the 1500 W segment will thrive in applications requiring precision, flexibility, and cost-effectiveness.

Conclusion

By 2026, the 1500 W laser welding machine market will be characterized by technological sophistication, broader industrial adoption, and global expansion. Driven by EV production, automation, and cost efficiency, this power class will occupy a strategic niche in the laser processing ecosystem—bridging the gap between low-power precision tasks and high-power industrial welding. Companies that invest in smart integration, regional support, and application-specific solutions will be best positioned to capitalize on these trends.

Common Pitfalls When Sourcing a 1500 W Laser Welding Machine (Quality & IP)

Sourcing a 1500 W laser welding machine involves significant investment and technical complexity. Overlooking key quality and intellectual property (IP) aspects can lead to operational failures, legal risks, and financial losses. Here are the most common pitfalls to avoid:

1. Overlooking Build Quality and Component Reliability

Many suppliers, especially lower-cost or new market entrants, cut corners on critical components. A 1500 W system demands robust engineering, but buyers often focus only on laser power while ignoring:

– Inferior laser sources: Using rebranded or counterfeit fiber lasers lacking proper certifications or lifespan guarantees.

– Poor cooling systems: Inadequate chillers or heat dissipation leading to thermal instability, power fluctuations, and premature component failure.

– Low-grade motion systems: Weak linear guides, motors, or frames that compromise weld precision and repeatability.

– Substandard electrical components: Cheap wiring, connectors, or control boards increase downtime and safety risks.

Risk: Reduced machine lifespan, inconsistent weld quality, frequent maintenance, and safety hazards.

2. Insufficient Verification of Laser Source Authenticity

The laser source is the core of the system. Counterfeit or misrepresented modules are common. Pitfalls include:

– Accepting supplier claims without independent verification of brand (e.g., IPG, Raycus, nLight).

– Failing to request proof of origin, warranty documentation, or serial number validation.

– Ignoring discrepancies in beam quality (M²), stability, and power output under load.

Risk: Purchasing underperforming or unreliable lasers, voided warranties, and lack of technical support.

3. Underestimating Software and Control System Limitations

Advanced welding demands intelligent software. Buyers often assume all controllers are equal, leading to:

– Proprietary software with limited functionality, poor user interface, or no API for integration.

– Lack of real-time monitoring, adaptive control, or process feedback (e.g., seam tracking, melt pool monitoring).

– Inadequate data logging or traceability features critical for quality assurance.

Risk: Inflexible operation, difficulty meeting production standards, and inability to scale or integrate into smart manufacturing systems.

4. Neglecting Intellectual Property (IP) Protection

When customizing or integrating a laser system, IP ownership can become a major issue:

– Signing contracts that transfer IP rights of custom software, fixtures, or process parameters to the supplier.

– Using systems with embedded third-party software lacking proper licensing.

– Failing to secure documentation and source code necessary for future maintenance or modifications.

Risk: Loss of proprietary processes, legal disputes, and dependency on the supplier for updates or repairs.

5. Inadequate After-Sales Support and Service Infrastructure

High-power lasers require ongoing maintenance and technical expertise. Common oversights:

– Choosing suppliers without local service engineers or long response times.

– Unclear warranty terms, especially regarding consumables or laser source degradation.

– Lack of training programs or spare parts availability.

Risk: Extended downtime, increased total cost of ownership, and operational bottlenecks.

6. Ignoring Compliance and Safety Certification

Laser systems must meet stringent safety standards. Pitfalls include:

– Accepting machines without proper CE, FDA, or IEC 60825 certification.

– Inadequate safety interlocks, enclosures, or emergency stops.

– Missing documentation for laser safety officer (LSO) requirements.

Risk: Regulatory non-compliance, workplace safety incidents, and liability exposure.

7. Falling for Misleading Specifications

Suppliers may exaggerate performance:

– Claiming “1500 W” without specifying whether it’s peak, average, or sustained power.

– Omitting duty cycle, beam quality, or focus spot size—critical for actual welding performance.

– Providing lab-condition results not replicable in real-world environments.

Risk: Machine underperforming in production, failure to achieve required weld penetration or speed.

Mitigation Strategy: Always conduct factory audits, demand third-party test reports, verify component authenticity, negotiate clear IP clauses, and prioritize suppliers with proven track records and comprehensive support. Due diligence is essential to avoid costly pitfalls in both quality and IP when investing in a 1500 W laser welding system.

Logistics & Compliance Guide for 1500 W Laser Welding Machine

This guide outlines essential logistics and compliance considerations for the international shipment, import, and operation of a 1500 W Laser Welding Machine. Adhering to these guidelines ensures smooth transit, customs clearance, and safe, legal deployment.

Shipping & Packaging Requirements

- Robust Crating: The machine must be secured in a custom wooden export crate with internal bracing and shock-absorbing materials (e.g., foam inserts) to prevent movement during transit.

- Moisture Protection: Include desiccant packs and use moisture-barrier wrap (e.g., VCI paper) to protect sensitive electronics in humid environments.

- Labeling: Clearly label the crate with:

- “Fragile”

- “This Side Up”

- “Do Not Stack”

- Machine model, serial number, and weight

- Carrier-provided tracking and handling labels

- Weight and Dimensions: Confirm total gross weight and dimensions (L x W x H) for accurate freight classification and transport mode selection (air, sea, or land).

Export Compliance & Documentation

- Export Classification: Determine the correct Export Control Classification Number (ECCN). Laser welding machines above 500 W often fall under ECCN 2B201 (Lasers) on the Commerce Control List (CCL), requiring a license for certain destinations.

- License Requirements: Verify if export to the destination country requires an export license from the U.S. Department of Commerce (BIS) or equivalent national authority. High-power lasers may be restricted in embargoed or high-risk countries.

- Required Documents:

- Commercial Invoice (with full technical specs, value, and Incoterms)

- Packing List

- Bill of Lading (B/L) or Air Waybill (AWB)

- Export Declaration (e.g., AES filing in the U.S.)

- Certificate of Origin (if required for preferential tariffs)

- Technical Datasheet (for customs and safety verification)

Import Regulations & Duties

- HS Code Classification: Classify the machine using the Harmonized System (HS) code. Likely classifications include:

- 8515.21 (Laser welding machines)

- 8456.90 (Other machine tools)

Confirm the exact code with local customs or a customs broker. - Import Duties & Taxes: Calculate applicable import tariffs, VAT, or GST based on the destination country’s tariff schedule. Rates vary significantly by country.

- Local Certification: Verify if the destination country requires:

- CE Marking (for EU)

- UKCA Marking (for UK)

- CCC Certification (for China)

- PSE Mark (for Japan)

- EAC Certification (for Russia/CIS)

- Registration: Some countries require industrial lasers to be registered with national safety or radiation protection authorities.

Safety & Regulatory Compliance

- Laser Safety Standards: Ensure compliance with IEC 60825-1 (Safety of laser products) and IEC 60204-1 (Safety of machinery – Electrical equipment). The 1500 W laser is Class 4 – high risk of eye/skin injury and fire hazard.

- Protective Measures:

- Install interlocks, emergency stop systems, and beam enclosures.

- Provide laser safety eyewear (OD 5+ for 1070 nm wavelength typical in fiber lasers).

- Implement warning labels and area signage (“Laser Radiation When Open”).

- EMC Compliance: Meet electromagnetic compatibility standards (e.g., IEC/EN 61326) to avoid interference with other equipment.

Installation & Operational Compliance

- Facility Requirements:

- Adequate ventilation or fume extraction system to manage welding byproducts.

- Stable power supply with correct voltage and grounding.

- Controlled access to the laser operation area.

- Training: Provide certified operator training on laser safety, machine operation, and emergency procedures per ANSI Z136.1 or equivalent standards.

- Maintenance Logs: Maintain records of service, safety checks, and calibration for audits and compliance verification.

Environmental & Disposal Regulations

- Hazardous Materials: Identify and document any hazardous components (e.g., batteries, capacitors) for proper handling.

- End-of-Life Disposal: Follow WEEE (Waste Electrical and Electronic Equipment) directives or local e-waste regulations for decommissioning and recycling.

Summary

Shipping and deploying a 1500 W Laser Welding Machine requires careful attention to export controls, import regulations, safety standards, and proper logistics handling. Partner with experienced freight forwarders, customs brokers, and safety consultants to ensure full compliance across all jurisdictions involved.

Conclusion for Sourcing a 1500 W Laser Welding Machine

After a thorough evaluation of technical specifications, supplier capabilities, cost considerations, and long-term operational needs, sourcing a 1500 W fiber laser welding machine is a strategic and viable decision for enhancing manufacturing efficiency and weld quality. The 1500 W power output offers an optimal balance between precision and productivity, enabling high-speed, deep-penetration welding across a range of materials including steel, stainless steel, and aluminum—common in automotive, aerospace, and industrial fabrication applications.

The integration of advanced features such as real-time monitoring, automated control systems, and compatibility with robotic arms supports Industry 4.0 initiatives, ensuring improved process repeatability and reduced operational downtime. Additionally, the energy efficiency and low maintenance requirements of modern fiber laser systems contribute to a favorable total cost of ownership over time.

Careful selection of a reputable supplier with proven technical support, warranty coverage, and training services is essential to maximize uptime and ensure smooth integration into existing production lines. With proper operator training and safety protocols in place, the 1500 W laser welding machine will significantly improve weld strength, reduce distortion, and elevate overall product quality.

In conclusion, investing in a 1500 W laser welding machine aligns with long-term goals of automation, precision manufacturing, and competitiveness in high-demand industrial sectors. It is a well-justified capital expenditure that delivers both technical and economic benefits.