The septic tank market has experienced steady growth in recent years, driven by increased infrastructure development, urbanization, and a growing emphasis on sanitation in both developed and emerging economies. According to Grand View Research, the global septic tank market was valued at USD 7.9 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is further propelled by rising residential construction and stricter environmental regulations requiring efficient wastewater management systems. Among the various capacities available, 1500-gallon cement septic tanks are particularly popular for mid- to large-sized households and light commercial applications due to their durability, long service life, and suitability for high-water-use environments. As demand for reliable and scalable wastewater solutions increases, manufacturers of 1500-gallon concrete septic tanks are playing a critical role in meeting these needs. The following list highlights the top seven manufacturers known for their quality, innovation, and market presence in this segment.

Top 7 1500 Gallon Cement Septic Tank Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Pedestrian Rated Septic Tank

Domain Est. 1996

Website: jensenprecast.com

Key Highlights: Septic tanks are buried, watertight container that collects wastewater and separates solids from liquids. Jensen offers concrete and fiberglass tanks.Missing: cement manufacturer…

#2 CXT Precast Concrete Septic Tanks Texas

Domain Est. 1996

Website: lbfoster.com

Key Highlights: CXT precast concrete wastewater products are a durable and long-lasting option. Our precast products wastewater products are manufactured in Hillsboro, Texas….

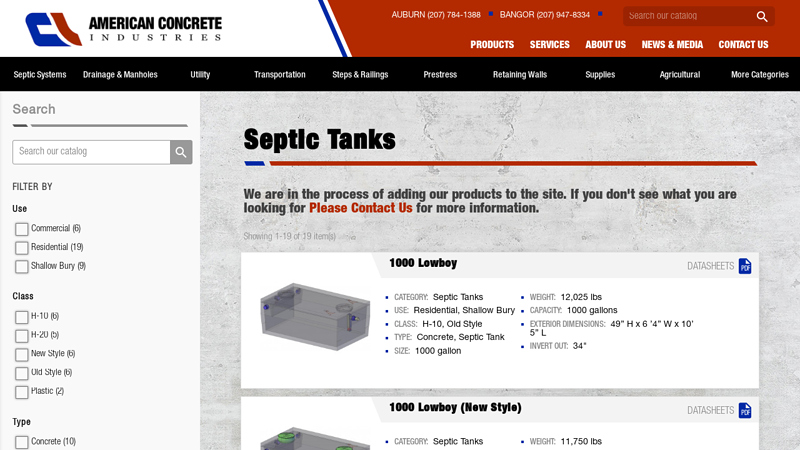

#3 Septic Tanks

Domain Est. 1998

Website: americanconcrete.com

Key Highlights: Weight:23,750 lbs; Capacity:1,500 gallons; Interior Dimensions:46″ H x 6′-0″ W x 12′-0″ L; Exterior Dimensions:61.5″ H x 6′-10″ W x 12′-10″ ……

#4 Precast Concrete Residential Septic Tanks

Domain Est. 1999

Website: sheaconcrete.com

Key Highlights: Precast concrete septic tanks from Shea are strong, watertight, environmentally friendly, and ideal for any residential waste management system….

#5 Concrete Septic Tanks

Domain Est. 2000

Website: procastproducts.com

Key Highlights: Our concrete septic tanks and septic systems are non-toxic and durable, preserving ground water and surface water throughout application and use….

#6 Septic Tanks

Domain Est. 2002

Website: monarchprecast.com

Key Highlights: 1250 Gal Two Compartment Tank. Download PDF File. 1500 Gal Single Compartment Septic Tank Traffic Duty. Download PDF File. 1500 Gal Single Compartment Septic ……

#7 1500 Gallon Septic Tank

Domain Est. 2008

Website: briggsconcrete.com

Key Highlights: Septic tank includes a regular lid. Available Options: water testing, traffic top lid, 6″ or 12″ risers, flat lids or dome lids. Free local delivery….

Expert Sourcing Insights for 1500 Gallon Cement Septic Tank

H2: 2026 Market Trends for 1500-Gallon Cement Septic Tanks

The market for 1500-gallon cement septic tanks in 2026 is poised for moderate growth, driven by a combination of regulatory developments, housing trends, environmental concerns, and material competition. As decentralized wastewater treatment remains essential in rural and suburban areas, cement septic tanks continue to play a critical role—particularly the 1500-gallon size, which is standard for mid-sized households and small commercial applications.

-

Steady Demand in Residential Construction

Ongoing growth in single-family home construction, especially in rural and exurban regions of North America and parts of Europe, supports consistent demand. With stricter building codes requiring larger-capacity systems for homes exceeding three bedrooms, the 1500-gallon cement tank remains a go-to solution due to its durability and compliance with local regulations. -

Environmental and Regulatory Pressures

Environmental regulations are increasingly focused on groundwater protection and long-term system performance. Cement tanks, when properly installed and maintained, offer excellent leak resistance and longevity (50+ years), aligning with sustainability goals. In 2026, several U.S. states and Canadian provinces are expected to update septic system standards, potentially favoring pre-cast concrete over plastic alternatives due to structural integrity and reduced environmental impact. -

Competition from Alternative Materials

Despite their durability, cement tanks face growing competition from fiberglass and polyethylene models, which are lighter, easier to install, and resistant to cracking in freeze-thaw climates. However, cement tanks maintain an edge in markets where soil conditions are unstable or where local codes mandate concrete for structural load-bearing requirements. -

Supply Chain and Cost Considerations

Rising costs of raw materials such as Portland cement and steel rebar may increase manufacturing prices. However, localized production and a mature supply chain help mitigate disruptions. In 2026, producers are expected to adopt more efficient pre-casting techniques and green cement technologies to reduce carbon footprints and production costs. -

Regional Market Variations

In the U.S., the South and Midwest remain strong markets due to low sewer infrastructure penetration. In contrast, Europe shows slower growth, with many regions shifting toward centralized treatment. Emerging markets in Latin America and Southeast Asia are beginning to adopt cement septic systems, though smaller tank sizes dominate. -

Focus on Maintenance and Retrofitting

An aging inventory of existing septic systems in developed markets is driving demand for replacements and upgrades. The 1500-gallon cement tank is a common choice for retrofits due to availability and code compatibility. Service providers are increasingly bundling tank sales with inspection and maintenance contracts, enhancing customer retention. -

Technological Integration

While the tank itself is a passive component, smart monitoring systems (e.g., IoT-based level and pump sensors) are being integrated into new installations. Though not built into the tank, these add-ons are influencing purchasing decisions—especially for new construction where homeowners seek low-maintenance, high-efficiency systems.

In summary, the 2026 market for 1500-gallon cement septic tanks remains stable, supported by regulatory frameworks, durability, and ongoing demand in residential development. While facing material competition and cost pressures, cement tanks are likely to retain a significant share—particularly in regions prioritizing long-term performance and environmental safety.

Common Pitfalls When Sourcing a 1500-Gallon Cement Septic Tank (Quality & Intellectual Property)

Sourcing a 1500-gallon cement septic tank requires careful attention to avoid significant issues related to structural integrity, longevity, and legal compliance. Overlooking key aspects can lead to costly failures, safety hazards, and potential legal disputes. Below are the most common pitfalls to watch for:

Inadequate Material Quality and Construction Standards

One of the primary risks in sourcing cement septic tanks is compromising on material quality. Substandard concrete, improper reinforcement, or poor curing processes can drastically reduce the tank’s lifespan and performance. Tanks may crack under soil pressure or fail during backfilling if not manufactured to meet ASTM or local building codes (e.g., ASTM C913 for precast concrete septic tanks). Buyers should verify compressive strength (typically 4,000+ psi), proper steel rebar placement, and watertight seals.

Lack of Third-Party Certification and Testing

Many suppliers offer tanks without providing evidence of independent testing or agency approval. Without certification from recognized bodies such as ICC-ES or NSF/ANSI Standard 245, there is no assurance that the tank meets structural, hydraulic, and environmental safety standards. Relying solely on manufacturer claims without documentation increases the risk of installing non-compliant or unsafe systems.

Poor Design and Engineering for Site-Specific Conditions

A 1500-gallon tank must be engineered to handle local soil types, groundwater levels, and traffic loads (e.g., vehicular access). Generic designs that don’t account for these variables can lead to buoyancy issues, wall collapse, or shifting. Ensure the supplier provides stamped engineering plans and offers customization based on site conditions and local permitting requirements.

Intellectual Property Infringement Risks

Using or sourcing septic tank designs protected by patents, trademarks, or proprietary engineering can expose buyers and contractors to intellectual property (IP) violations. Some manufacturers invest heavily in innovative features—such as baffle designs, inlet/outlet configurations, or lifting systems—protected by IP rights. Sourcing from unauthorized producers who replicate these designs may result in legal action, project delays, or forced system removal.

Insufficient Warranty and After-Sales Support

Low-cost suppliers may offer limited or vague warranty terms, excluding critical failures like cracking or leakage. A reputable provider should offer a comprehensive warranty (e.g., 10+ years) covering both materials and workmanship. Lack of technical support during installation or troubleshooting can lead to improper setup and system failure.

Inadequate Supplier Vetting and Due Diligence

Failing to conduct due diligence on the manufacturer or distributor increases exposure to all the above risks. Buyers should assess supplier reputation, review project references, inspect manufacturing facilities if possible, and confirm compliance with environmental and labor regulations. Sourcing from unknown or offshore producers without local support channels adds logistical and quality control challenges.

Avoiding these pitfalls requires thorough vetting, insistence on certifications, and legal awareness of IP considerations. Prioritizing quality and compliance ensures long-term performance and regulatory acceptance of the septic system.

H2: Logistics & Compliance Guide for 1500-Gallon Cement Septic Tank Installation

Installing a 1500-gallon cement septic tank requires careful planning, adherence to strict regulations, and coordination of heavy logistics. This guide outlines key steps and considerations to ensure a safe, compliant, and successful project.

H2: Pre-Installation Planning & Permits

- Site Assessment & Design:

- Conduct a thorough site evaluation, including soil percolation (perk) testing, groundwater table assessment, and topographic survey.

- Hire a licensed septic system designer or engineer to create plans meeting local code requirements for tank size, placement, drainfield design, and setbacks.

- Obtain Permits:

- Submit design plans and application to the local health department or environmental regulatory agency.

- Secure necessary permits before any excavation or delivery occurs. Permit requirements vary significantly by county/state.

- Utility Locates:

- Contact 811 (or local equivalent) at least 48-72 hours before digging to mark underground utilities (gas, electric, water, telecom, sewer).

- Delivery Planning:

- Access Route: Ensure a clear, unobstructed path from the road to the installation site. Consider driveway width, turning radius, overhead clearance (wires, trees), and ground strength.

- Delivery Window: Coordinate a specific delivery time with the supplier. Cement tanks are heavy and require specialized equipment.

- Site Preparation: Clear the tank location and access path of debris, vegetation, and obstructions. Mark the exact placement location.

H2: Logistics & Delivery

- Transportation:

- Tanks are typically delivered by flatbed truck or specialized low-boy trailer.

- Weight: A 1500-gallon reinforced concrete tank weighs 12,000 – 18,000+ lbs (6-9+ tons) empty.

- Dimensions: Approx. 6-7 ft diameter x 8-10 ft long (varies by manufacturer). Confirm exact specs.

- Equipment Requirements:

- Crane or Heavy Duty Excavator: Essential for offloading and placing the tank. A crane (mobile or truck-mounted) with sufficient reach and lift capacity (min. 20-ton capacity recommended) is standard. A large excavator with a lifting attachment can sometimes be used.

- Rigging: Use certified slings, chains, or lifting straps rated for the tank’s weight. Never lift by manhole covers or inlet/outlet pipes.

- Safety During Delivery/Placement:

- Only trained, qualified personnel should operate lifting equipment.

- Establish a clear exclusion zone around the lifting area.

- Use clear hand signals or radios for communication between ground crew and crane operator.

- Inspect the tank immediately upon delivery for cracks or damage before placement.

H2: Installation & Backfilling

- Excavation:

- Dig the hole to the depth and dimensions specified in the approved plans, including space for a level bedding layer (typically 4-6 inches of sand or fine gravel).

- Ensure stable, undisturbed soil at the bottom. Slope sides if necessary for safety.

- Placement:

- Carefully lower the tank onto the prepared bedding using the crane/excavator. Ensure it is perfectly level.

- Connect inlet and outlet pipes (T-fittings) according to code and design, using appropriate sealants and gaskets. Protect pipe ends during backfill.

- Install risers and manhole covers securely.

- Backfilling:

- Critical Step: Backfill in stages (6-8 inch layers) with approved material (usually native soil free of rocks >2″, or specific sand/gravel mix as per code).

- Simultaneous Filling: As backfilling proceeds around the tank, fill the tank with water simultaneously at approximately the same rate to prevent buoyant forces from lifting or shifting the empty tank. Use a garden hose.

- Compact backfill material thoroughly on all sides after each layer. Avoid over-compacting directly against the tank walls.

- Do not use large equipment (backhoe bucket) to backfill within 2 feet of the tank; use hand tools or small plates.

H2: Compliance & Inspections

- Local Health Department/Building Code Official Inspections:

- Pre-Installation Check: Verify excavation depth, bedding, and tank placement.

- During Installation: Check pipe connections and alignment.

- Final Inspection: Required before final backfill covers the tank top or before backfilling the drainfield. Inspector checks tank level, pipe seals, inlet/outlet elevations, and overall compliance with the permit.

- Key Compliance Areas:

- Setbacks: Strict adherence to minimum distances from property lines, wells, water bodies, buildings, and driveways (typically 10-50+ feet, varies locally).

- Tank Specifications: Use a tank meeting ASTM C913 or CSA A23.4 standards for precast concrete septic tanks. Verify manufacturer certification.

- Watertightness: Tank must be structurally sound and watertight. Some jurisdictions require a hydrostatic test (filling tank with water and monitoring for leaks) after installation but before final backfill.

- Drainfield Compliance: The leach field/tile field must also be installed per approved plans and inspected.

- Record Keeping:

- Keep copies of all permits, approved plans, inspection reports, and manufacturer documentation (tank specs, warranty).

- Obtain the final “Certificate of Compliance” or “Letter of Approval” from the health department.

H2: Post-Installation & Maintenance

- System Commissioning: After final inspection approval, connect the home’s plumbing waste lines to the tank inlet.

- Initial Use: Avoid excessive water use initially. The bacterial ecosystem needs time to establish.

- Ongoing Maintenance:

- Pumping: Schedule professional pumping every 3-5 years (or as recommended by inspector based on household size/usage).

- Inspection: Have the tank inspected (including baffles and tees) during pumping.

- Protect: Avoid driving or heavy equipment over the tank or drainfield area. Do not plant deep-rooted trees nearby.

- Record: Maintain a maintenance log.

Disclaimer: This guide provides general information. ALWAYS consult your local health department, building codes, and a licensed septic professional for the specific, legally binding requirements in your jurisdiction. Regulations are stringent and failure to comply can result in fines, system failure, and environmental contamination.

In conclusion, sourcing a 1,500-gallon cement septic tank requires careful consideration of several key factors, including local regulations, soil conditions, site accessibility, and long-term maintenance requirements. Cement tanks offer durability and strength, making them a reliable option for residential or light commercial applications when properly installed and maintained. It is essential to work with licensed professionals and certified suppliers to ensure compliance with environmental and health standards. Additionally, comparing quotes from multiple vendors, evaluating delivery and installation logistics, and verifying warranties can help secure a cost-effective and high-quality solution. With the right planning and due diligence, a 1,500-gallon cement septic tank can provide an efficient and long-lasting wastewater management system.