The global plywood market is experiencing steady expansion, driven by rising demand from the construction, furniture, and interior design sectors. According to Grand View Research, the global plywood market size was valued at USD 43.9 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This growth is further fueled by increasing infrastructure development and urbanization, particularly in emerging economies across Asia-Pacific and Latin America. As demand for high-quality, dimensionally stable plywood persists, the 1.5-inch thickness segment has gained prominence for use in heavy-duty flooring, formwork, and structural applications. With quality and consistency becoming critical differentiators, identifying reliable manufacturers has become essential for contractors, builders, and retailers. Based on production capacity, geographic reach, certifications, and market reputation, here are the top 9 manufacturers leading innovation and supply in the 1.5-inch plywood segment worldwide.

Top 9 1.5 Inch Plywood Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Mr. Plywood: Tools

Domain Est. 2005

Website: mrplywoodinc.com

Key Highlights: At Mr. Plywood in Portland, OR, we provide top-notch plywood, lumber, and tools to meet all your construction needs.Missing: 1.5 inch manufacturer…

#2 Shop Plywood & Sheetgoods

Domain Est. 1996

#3

Domain Est. 1997

Website: dixieply.com

Key Highlights: Dixie Plywood and Lumber Company, the preferred wholesale distributor of plywood, lumber, building materials and specialty products to lumber dealers.Missing: 1.5 inch…

#4 All America Plywood

Domain Est. 1999

Website: allamericaplywood.com

Key Highlights: A DETROIT AREA BUSINESS. Hardwood Plywoods are our specialty! In addition to our extensive stocking inventory, we can handle your special order requirements.Missing: 1.5 inch…

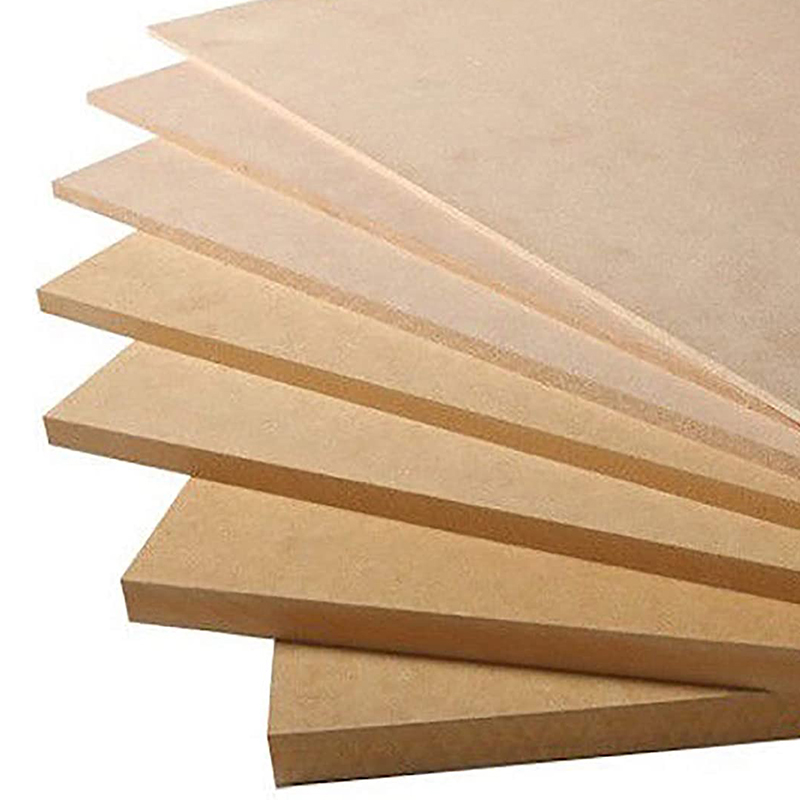

#5 MDF 1-1/2-inch 5×10 – MDF Board & Panels

Domain Est. 1999

Website: plywoodcompany.com

Key Highlights: 30-day returnsMEDIUM DENSITY FIBERBOARD – 1-1/2″ MDF · Thickness: 1-1/2″ · Size: 61″ x 121″ · Uses include moulding, trim, millwork. · TSCA Title VI Compliant….

#6 Plywood

Domain Est. 2000

Website: houstonhardwoods.com

Key Highlights: Houston Hardwoods Company is located in Houston, Texas. We offer one of the largest selections of mouldings in Texas. Marine grade plywood is our specialty….

#7 Mendham Plywood

Domain Est. 2009

Website: mendhamplywood.com

Key Highlights: We’re a family-owned lumberyard and building supply company in the heart of Morris County, serving professional contractors and homeowners alike.Missing: 1.5 inch…

#8 Baltic Birch Plywood

Domain Est. 2015

Website: ply-supply.com

Key Highlights: We carefully source Baltic birch, form plywood, construction-grade pine plywood, and other specialty panels from top suppliers and deliver them across Canada ……

#9 plywood

Domain Est. 2022

Website: keimcompany.com

Key Highlights: At Keim, we offer plywood sheets in 4 x 8 feet or 5 x 5 foot panels. The thickness of the boards vary from ⅛-inch to ¾ inch. Smaller, pre-cut ……

Expert Sourcing Insights for 1.5 Inch Plywood

H2: 2026 Market Trends for 1.5 Inch Plywood

The global market for 1.5-inch plywood is poised for notable evolution by 2026, driven by shifts in construction dynamics, material innovation, regional demand patterns, and sustainability imperatives. As a thicker-grade plywood, 1.5-inch boards are primarily used in heavy-duty structural applications such as formwork, industrial flooring, heavy furniture, and specialized construction projects. The following trends are expected to shape the 1.5-inch plywood market in 2026:

-

Growing Demand in Infrastructure and Industrial Construction

By 2026, increased government and private-sector investments in infrastructure—particularly in emerging economies across Asia-Pacific, Africa, and Latin America—are expected to drive demand for durable construction materials. The 1.5-inch plywood, known for its strength and load-bearing capacity, will be increasingly utilized in concrete formwork systems, bridge construction, and industrial platforms. Countries like India, Vietnam, and Nigeria are anticipated to lead regional growth due to large-scale urbanization projects. -

Shift Toward Engineered and High-Performance Plywood

Manufacturers are responding to market needs by enhancing the performance of 1.5-inch plywood through better adhesives (e.g., phenol-formaldehyde and melamine-urea-formaldehyde resins) and engineered wood technologies. These improvements enhance moisture resistance, dimensional stability, and longevity—making the product more suitable for outdoor and semi-permanent structures. By 2026, high-performance variants are expected to capture a growing share of the market, especially in humid or high-stress environments. -

Sustainability and Certification Influence

Environmental regulations and green building certifications (e.g., LEED, BREEAM) are pushing construction firms toward sustainably sourced materials. As a result, demand for 1.5-inch plywood from certified sustainable forests (FSC or PEFC) is projected to rise steadily. Manufacturers investing in eco-friendly production processes and recycled content will gain a competitive advantage in environmentally conscious markets such as Europe and North America. -

Rising Competition from Alternative Materials

Despite its strengths, 1.5-inch plywood faces competition from alternatives such as oriented strand board (OSB), fiber cement boards, and steel-reinforced composites. These materials may offer cost or durability benefits in certain applications. However, plywood retains an edge in workability, surface finish, and compatibility with traditional construction techniques. Market players are likely to emphasize these advantages through targeted marketing and technical support. -

Regional Market Divergence

Asia-Pacific will remain the largest consumer and producer of 1.5-inch plywood in 2026, led by China, India, and Southeast Asian nations. In contrast, North America and Europe may see slower growth due to saturated construction markets, but demand will persist in renovation and industrial sectors. Meanwhile, Africa and the Middle East are emerging as high-potential regions due to infrastructure expansion and limited local production, creating import opportunities. -

Supply Chain Resilience and Price Volatility

Raw material availability—particularly tropical hardwoods and adhesives—will influence pricing and supply stability. Geopolitical factors, trade policies, and transportation costs may contribute to price fluctuations. Leading producers are expected to adopt vertical integration strategies and diversify fiber sources to mitigate risks and ensure consistent supply chains. -

Digitalization and Smart Manufacturing

By 2026, digital tools such as AI-driven production optimization, IoT-enabled quality control, and blockchain for supply chain transparency are expected to become more widespread in the plywood industry. These technologies will enhance productivity, reduce waste, and improve traceability—key factors for large-scale buyers and export-oriented manufacturers.

In conclusion, the 1.5-inch plywood market in 2026 will be shaped by structural demand from construction, technological improvements, and sustainability trends. While challenges such as material substitution and price volatility persist, strategic innovation and regional expansion will enable key players to maintain growth and meet evolving industry needs.

Common Pitfalls When Sourcing 1.5 Inch Plywood (Quality & IP)

Sourcing 1.5 inch plywood presents unique challenges due to its thickness, structural demands, and specialized applications. Avoiding these common pitfalls is crucial for ensuring material performance and protecting intellectual property (IP).

Quality-Related Pitfalls

Inconsistent Core Bonding and Delamination Risk

Thick plywood like 1.5-inch stock relies heavily on strong, uniform adhesive bonds between each core layer. Poor-quality manufacturers may use insufficient or low-grade glue, leading to internal delamination under stress, moisture exposure, or temperature changes. This compromises structural integrity, especially in load-bearing applications such as marine construction or heavy-duty formwork.

Poor Dimensional Accuracy and Warping

Due to its mass, 1.5-inch plywood is prone to warping, cupping, or bowing if not properly dried and balanced during manufacturing. Sourcing from suppliers without strict moisture control (ideal MC: 6–12%) or symmetrical veneer layering can result in unusable material, leading to installation issues and increased waste.

Inadequate Veneer Quality and Core Gaps

Thick plywood often uses lower-grade inner plies. However, excessive core voids, knotholes, or mismatched grain orientation can weaken the panel. Buyers may unknowingly receive material with internal defects not visible on the surface, reducing strength and making it unsuitable for structural or precision applications.

Misrepresentation of Species and Grade

Suppliers may label plywood with premium species (e.g., Douglas Fir, Birch) or grades (e.g., A-B, APA Rated) without certification. Without proper documentation or third-party testing, buyers risk receiving inferior or mixed-species material that fails to meet project specifications or building codes.

Intellectual Property (IP) and Compliance Pitfalls

Unauthorized Use of Patented Manufacturing Processes

Some engineered 1.5-inch plywood products use proprietary lamination techniques, resins, or core configurations protected by patents. Sourcing from unauthorized manufacturers—especially overseas—risks infringing on IP rights, potentially leading to legal liability, shipment seizures, or project delays.

Counterfeit or Misbranded Certified Products

Reputable plywood often carries certifications like APA (Engineered Wood Association), CARB2, or PEFC. Unscrupulous suppliers may falsify stamps or documentation, selling non-compliant material as certified. This exposes buyers to regulatory penalties and voids warranties, particularly in commercial or export projects.

Lack of Traceability and Documentation

Without proper mill certifications, batch numbers, or chain-of-custody records, it’s difficult to verify material origin, compliance, or authenticity. This opacity increases IP risk and complicates quality disputes or recalls, especially in industries like aerospace, defense, or high-end architectural work.

Failure to Secure Custom Design Rights

When sourcing custom-profiled or treated 1.5-inch plywood (e.g., for proprietary furniture or industrial tooling), buyers may overlook contractual IP protections. Suppliers could replicate designs or sell them to competitors unless clear ownership, non-disclosure, and non-compete clauses are established upfront.

Logistics & Compliance Guide for 1.5 Inch Plywood

Overview of 1.5 Inch Plywood

1.5 inch (approximately 38 mm) plywood is a heavy-duty engineered wood product commonly used in industrial, construction, and marine applications. Due to its thickness and weight, logistics and compliance considerations are critical for safe, legal, and efficient transportation and handling.

Material Specifications

- Thickness: 1.5 inches (38.1 mm)

- Common Sizes: 4’ x 8’ (1.22 m x 2.44 m), 4’ x 10’ (1.22 m x 3.05 m), or custom dimensions

- Core Types: Softwood, hardwood, marine-grade, or specialty composites

- Grades: Vary by application (e.g., A-D for appearance, Exposure 1 or Exterior for durability)

- Weight: Approximately 70–100 lbs (32–45 kg) per 4’ x 8’ sheet, depending on species and density

Packaging & Handling Requirements

- Unit Load: Sheets are typically bundled with steel or plastic banding and placed on wooden or composite pallets.

- Stacking: Max recommended stacking height is 5–6 feet (1.5–1.8 m) to prevent warping and ensure safety.

- Protection: Use edge protectors and moisture-resistant wrapping (e.g., plastic film) to prevent damage during transit.

- Handling Equipment: Forklifts, pallet jacks, or crane lifts are required due to weight. Manual handling is not recommended.

Transportation & Shipping Logistics

- Load Securing:

- Use ratchet straps or load locks to secure bundles on flatbeds, dry vans, or containers.

- Prevent shifting during transit by blocking and bracing.

- Truck Type:

- Flatbed trailers for oversized loads (if exceeding standard container dimensions).

- Dry van trailers for standard 4’ x 8’ sheets.

- Container Shipping:

- Limited space efficiency; typically only 1–2 layers fit in a standard 20’ or 40’ container due to thickness.

- Max container weight must not be exceeded (~20–28 metric tons depending on container).

- Weight Considerations:

- 1.5 inch plywood is significantly heavier than thinner variants—verify axle weight limits and bridge laws for over-the-road transport.

International Trade & Compliance

- HS Code:

- Typically classified under 4412.31 or 4412.32 (Plywood consisting solely of sheets of wood, whether or not spliced).

- Confirm local tariff classification; may vary by country and wood species.

- Import/Export Regulations:

- Phytosanitary Certificate: Required for most countries to prevent pest infestation; must be issued by the exporting country’s agricultural authority.

- ISPM 15 Compliance: Wooden packaging (pallets, dunnage) must be heat-treated and marked with the IPPC stamp.

- Lacey Act (USA):

- Requires documentation proving legal harvest and chain of custody for wood products imported into the U.S.

- Declaration forms (e.g., PPQ Form 505) may be required at entry.

- EPA TSCA Title VI Compliance (USA):

- Ensures formaldehyde emissions from composite wood products meet safety standards.

- Suppliers must certify compliance with EPA regulations.

Environmental & Sustainability Standards

- FSC® or PEFC Certification:

- Required by many buyers and public projects; ensures sustainable forest management.

- Maintain chain-of-custody documentation if certified material is claimed.

- CARB Phase 2 (California):

- Applies to formaldehyde emissions; relevant even for non-California shipments if product is sold in U.S. markets.

Storage & Inventory Management

- Indoor Storage: Recommended to avoid moisture absorption, warping, or delamination.

- Ventilation: Store on level, elevated pallets with air circulation underneath and between stacks.

- Shelf Life: Limited exposure to humidity; use within 6–12 months for optimal performance, especially for non-treated grades.

Safety & Regulatory Compliance

- OSHA (USA) & Equivalent (Other Regions):

- Training required for heavy lifting and equipment operation.

- Use PPE (gloves, safety glasses, steel-toe boots) during handling.

- MSDS/SDS:

- Provide Safety Data Sheets if adhesives or treatments contain hazardous substances.

- Fire Codes:

- Store away from ignition sources; some treated plywood may be classified as combustible.

Documentation Checklist

- Bill of Lading (BOL)

- Packing List (with dimensions, weight, quantity)

- Phytosanitary Certificate (international shipments)

- FSC/PEFC Chain-of-Custody Certificate (if applicable)

- Lacey Act Declaration (for U.S. imports)

- EPA TSCA Title VI Compliance Certificate

- ISPM 15 Marking on Pallets

Summary

Transporting and managing 1.5 inch plywood demands careful attention to weight, packaging, regulatory compliance, and environmental conditions. Adhering to international standards, securing loads properly, and maintaining accurate documentation are essential for smooth logistics and legal compliance across supply chains. Always verify region-specific regulations and work with certified suppliers to ensure product integrity and regulatory alignment.

Conclusion for Sourcing 1.5-Inch Plywood:

Sourcing 1.5-inch plywood presents a unique challenge due to its non-standard thickness, as plywood is typically manufactured in more common dimensions such as 1/4″, 1/2″, or 3/4″. This thickness is not readily available in most markets, suggesting that custom fabrication or lamination of multiple standard plywood sheets may be necessary to achieve the desired dimension. When selecting a supplier, it is essential to consider material quality, species (such as birch, oak, or softwood), grading, moisture resistance (e.g., CDX or marine-grade for outdoor use), and compliance with industry standards.

Sourcing options include local lumber yards, specialty woodworking suppliers, or direct manufacturing partners capable of bonding panels to specification. While this approach may increase lead time and cost, it ensures structural integrity and project-specific requirements are met. Furthermore, evaluating sustainable sourcing practices and certifications (such as FSC or PEFC) supports environmentally responsible construction.

In conclusion, successfully sourcing 1.5-inch plywood requires a strategic approach involving custom solutions, reliable suppliers, and careful material selection to balance performance, availability, and cost-effectiveness for the intended application.