The global demand for precision medical needles, including 15-gauge variants used in surgical, dental, and therapeutic applications, continues to rise in line with expanding healthcare infrastructure and increasing procedural volumes. According to a 2023 report by Grand View Research, the global hypodermic needles market was valued at USD 13.6 billion and is expected to grow at a compound annual growth rate (CAGR) of 7.2% from 2023 to 2030, driven by rising chronic disease prevalence, aging populations, and greater emphasis on outpatient care. As one of the larger-bore needles, 15-gauge variants are particularly critical in applications requiring high flow rates, such as blood transfusions, surgical drainage, and certain anesthesia procedures. This sustained market expansion has intensified competition among manufacturers to deliver high-quality, ISO-certified, and biocompatible needle solutions. Based on production scale, innovation in materials, regulatory compliance, and global distribution reach, the following six companies have emerged as leading manufacturers of 15-gauge needles, shaping the standards of performance and safety in modern medical device supply chains.

Top 6 15 Gauge Needle Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

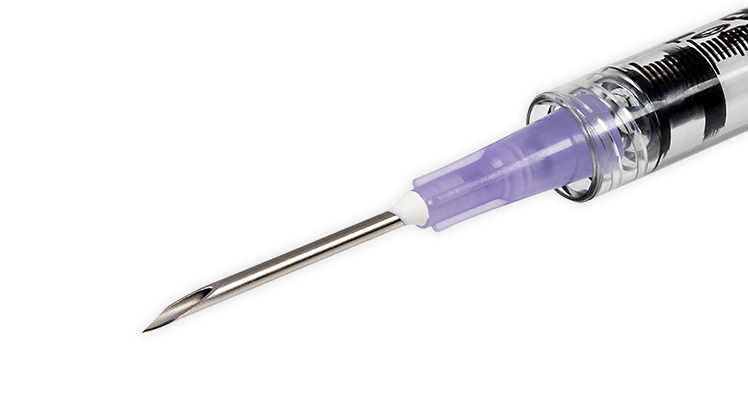

#1 BD® Conventional Needles and Syringes

Domain Est. 1990

Website: bd.com

Key Highlights: BD Conventional Needles and Syringes are designed and manufactured to deliver this kind of consistent quality and reliable performance….

#2 Shop 15 Gauge Intraosseous Infusion Needles

Domain Est. 1994

Website: mms.mckesson.com

Key Highlights: Order Intraosseous Infusion Needles and other in-stock supplies and products. We deliver to your care setting….

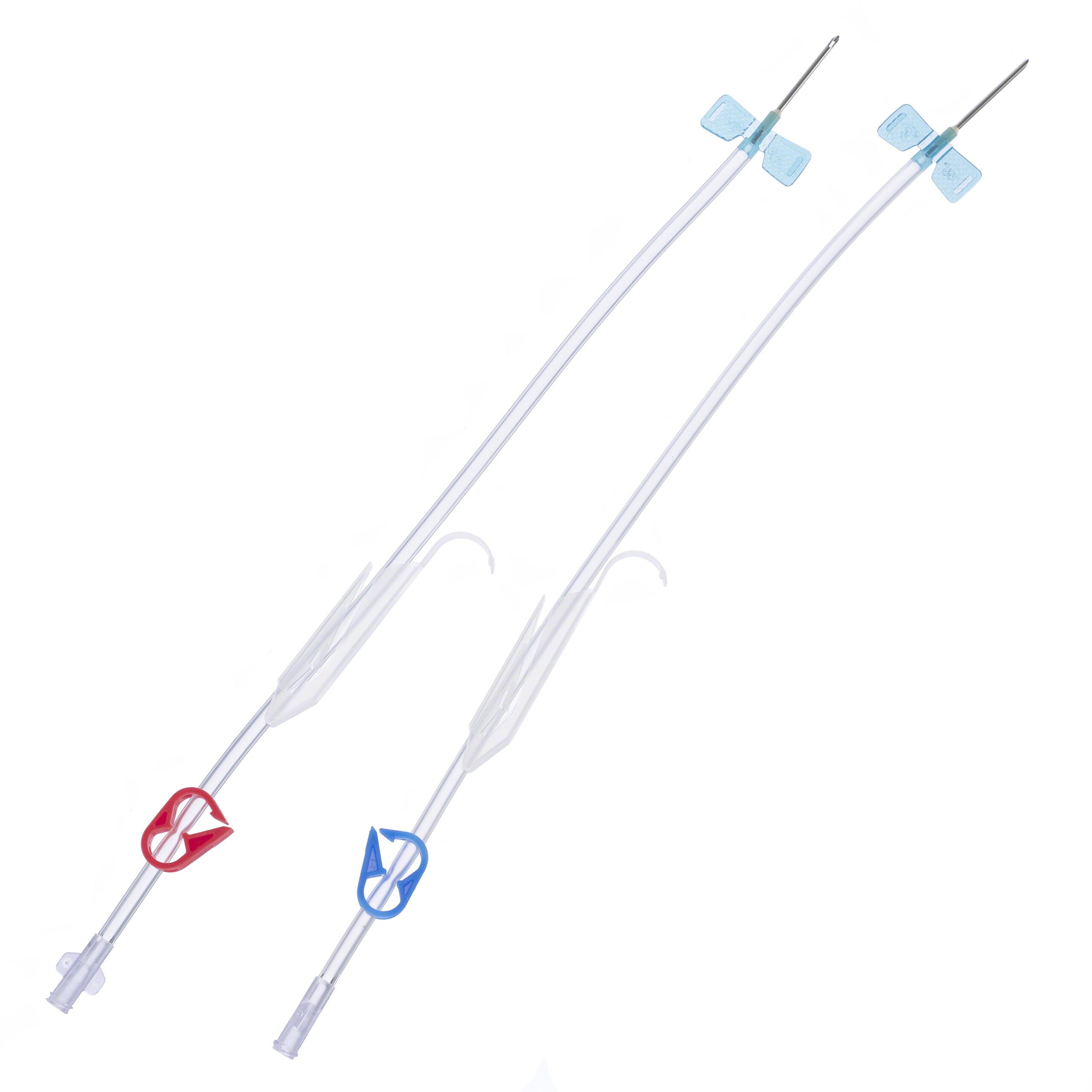

#3 AV Fistula Needle 15 Ga. X 3/5″ Single Pk FW

Domain Est. 1997

Website: bbraunusa.com

Key Highlights: AV Fistula Needle 15 Ga. X 3/5″ Single Pk FW with MasterGuard® Plus anti-stick needle protector. Fistula Needles. Fixed wing single pack….

#4 Hypodermic Needles, 15 Gauge

Domain Est. 1997

Website: harvardapparatus.com

Key Highlights: 1-day deliveryThese are regular-walled medical point needles. They are for intramuscular, subcutaneous, and other injections and are available in a wide range of gauges and ……

#5 15 Gauge Hypodermic Needle

Domain Est. 1997

#6 15 gauge, Metal Hub Needle (N), PN: 91015

Domain Est. 1998

Website: hamiltoncompany.com

Key Highlights: In stock $10 deliveryHamilton’s 15 gauge Metal Hub Needle (PN: 91015) is ideal for high-precision dispensing. With a durable stainless steel body and nickel-plated brass hub, ……

Expert Sourcing Insights for 15 Gauge Needle

2026 Market Trends for 15 Gauge Needle

The market for 15 gauge needles, while highly specialized, is poised for distinct shifts by 2026 driven by evolving clinical demands, technological innovation, and global healthcare dynamics. As one of the largest-bore hypodermic needles commonly used, its applications in high-volume fluid delivery, apheresis, and specific surgical procedures continue to anchor its relevance. Key trends shaping the landscape include:

Growing Demand in Critical Care and Emergency Medicine

Intensifying focus on rapid response in trauma and emergency settings will sustain demand for 15 gauge needles due to their ability to facilitate swift blood transfusions and fluid resuscitation. As global emergency care infrastructure expands—especially in developing regions—the need for large-bore vascular access tools like 15 gauge needles will rise. Hospitals and ambulance services are increasingly stocking high-gauge needles as part of standardized emergency kits, reinforcing market growth.

Advancements in Safety-Engineered Designs

Regulatory pressure and healthcare worker safety concerns are accelerating the adoption of safety-engineered 15 gauge needles. By 2026, manufacturers will increasingly integrate features such as retractable mechanisms, needle shields, and auto-disable systems to reduce needlestick injuries. These innovations, while adding to production costs, are becoming essential for compliance with OSHA and WHO guidelines, driving product differentiation and premium pricing.

Shift Toward Single-Use and Pre-Packaged Systems

The trend toward infection control and procedural efficiency is favoring single-use, pre-sterilized 15 gauge needle systems integrated into specialized kits—such as those for plasmapheresis or surgical drainage. Reusable or multi-use configurations are declining due to contamination risks, pushing suppliers to focus on disposable solutions. This shift supports market growth, particularly in outpatient clinics and ambulatory surgery centers.

Impact of Material Innovation and Supply Chain Optimization

Stainless steel remains the dominant material, but developments in biocompatible coatings and corrosion-resistant alloys are improving patient comfort and needle longevity during prolonged use. Additionally, supply chain resilience—highlighted during recent global health crises—will drive regional manufacturing investments, especially in Asia-Pacific and Latin America, reducing dependency on single-source suppliers.

Regional Market Expansion and Emerging Applications

While North America and Europe maintain high usage rates due to advanced healthcare systems, the fastest growth is expected in Asia-Pacific and Africa. Rising surgical volumes, dialysis patient populations, and government investments in healthcare infrastructure will broaden the application base for 15 gauge needles beyond traditional uses. Niche applications in veterinary medicine and regenerative therapies may also emerge as minor growth drivers.

In conclusion, the 15 gauge needle market in 2026 will be characterized by innovation in safety, geographic expansion, and integration into advanced medical systems. While overall unit growth may be moderate due to the needle’s specialized use, value growth will be bolstered by premium safety features and expanding healthcare access globally.

Common Pitfalls When Sourcing 15 Gauge Needles: Quality and Intellectual Property Concerns

Sourcing 15 gauge needles—commonly used in high-flow medical procedures like blood donation, plasmapheresis, and certain infusions—requires careful attention to both quality standards and intellectual property (IP) rights. Overlooking these aspects can lead to regulatory non-compliance, patient safety risks, and legal liabilities. Below are key pitfalls to avoid:

Poor Manufacturing Quality and Non-Compliance

One of the most significant risks is procuring needles that fail to meet international quality and safety standards. Low-cost suppliers may cut corners on materials, manufacturing processes, or sterilization, resulting in:

- Inconsistent wall thickness or bevel sharpness, increasing patient discomfort and the risk of tissue damage.

- Use of substandard stainless steel, leading to needle dullness, breakage, or corrosion during use.

- Inadequate sterilization, risking microbial contamination and infection.

- Non-compliance with ISO 7864 (sterile hypodermic needles) or FDA/CE marking requirements**, which can result in product recalls or import denials.

To mitigate this, always verify that suppliers adhere to ISO 13485 (medical device quality management systems) and provide full documentation, including certificates of conformance and batch testing results.

Intellectual Property Infringement

Another often-overlooked risk involves intellectual property violations. Many established 15 gauge needle designs—especially safety-engineered or specialty-tip variants—are protected by patents, trademarks, or design rights. Sourcing from manufacturers that replicate branded designs without licensing can lead to:

- Patent infringement lawsuits, particularly in markets like the U.S. or EU where IP enforcement is strict.

- Seizure of shipments by customs authorities due to counterfeit or IP-violating goods.

- Damage to brand reputation if your organization is associated with unauthorized or copied medical devices.

Always conduct due diligence on supplier IP legitimacy. Request evidence of IP ownership or licensing agreements, and avoid suppliers offering “compatible” or “equivalent” versions of well-known branded needles unless proper rights are confirmed.

Lack of Traceability and Supplier Transparency

Unreliable suppliers may provide inadequate traceability, making it difficult to track lot numbers, raw material sources, or manufacturing histories. This becomes critical during recalls or adverse event investigations. Ensure your supplier offers full traceability and transparent supply chain practices.

Inadequate Regulatory Documentation

Especially when sourcing internationally, missing or falsified regulatory documentation—such as FDA 510(k) clearances, CE certificates, or MDR compliance files—can block market access. Verify all regulatory claims independently and request up-to-date documentation before placing orders.

By addressing these quality and IP-related pitfalls proactively, organizations can ensure safer, compliant, and legally sound procurement of 15 gauge needles.

Logistics & Compliance Guide for 15 Gauge Needle

Regulatory Classification and Documentation

The 15 Gauge needle is classified as a medical device and is subject to regulatory oversight depending on the jurisdiction. In the United States, it falls under the Food and Drug Administration (FDA) regulations as a Class II medical device under product code FNR. Applicable standards include ISO 7864 (sterile hypodermic needles) and ISO 6009 (needles for single use). Manufacturers and distributors must ensure that the product bears proper labeling, including UDI (Unique Device Identifier), intended use, sterility status, and manufacturer information. Technical documentation, including 510(k) clearance (if applicable), must be maintained for audit purposes.

Import and Export Compliance

When shipping 15 Gauge needles internationally, compliance with customs and health regulations is essential. Exporters must verify destination country requirements—many countries require import licenses, product registration, or conformity assessment (e.g., CE marking in the European Union under MDR 2017/745). Required documentation typically includes a Certificate of Free Sale, Certificate of Manufacture, and Commercial Invoice specifying product description, quantity, and value. Shipments must comply with IATA Dangerous Goods Regulations if transported by air, even though needles are not hazardous—proper packaging is required to prevent injury. Labeling must include biohazard symbols if applicable and language compliant with the importing country.

Storage and Handling Requirements

15 Gauge needles must be stored in a controlled environment to maintain sterility and integrity. Recommended storage conditions are a dry, cool area (15–30°C), away from direct sunlight and moisture. They should be kept in original sealed packaging until use to prevent contamination. Handling personnel must be trained in aseptic techniques and proper disposal procedures. Stock rotation (FIFO—First In, First Out) should be practiced to avoid expiration. Temperature monitoring logs are advised for facilities storing large quantities.

Transportation and Packaging Standards

Transport packaging must protect against physical damage, moisture, and contamination. Needles are typically shipped in rigid secondary containers (e.g., corrugated boxes) with internal dividers or blister packs to prevent movement. All packaging must comply with ISTA 3A or equivalent standards for shipping integrity. For air transport, packaging must meet IATA Packing Instruction 650 for medical devices, even if non-infectious. Outer packaging should be clearly labeled with contents, sterile status, and handling instructions (e.g., “Fragile,” “Keep Dry”). Tamper-evident seals are recommended.

Disposal and Environmental Compliance

Used 15 Gauge needles are considered biomedical waste and must be disposed of in accordance with local, state, and federal regulations. In the U.S., OSHA’s Bloodborne Pathogens Standard (29 CFR 1910.1030) requires immediate placement in FDA-cleared sharps disposal containers that are puncture-resistant, leak-proof, and labeled with the biohazard symbol. Disposal must be handled by licensed medical waste transporters and treatment facilities (e.g., incineration or autoclaving). Environmental compliance includes adherence to EPA and DOT regulations for waste transport and disposal tracking via manifests.

Quality Assurance and Traceability

Robust quality management systems (QMS) compliant with ISO 13485 are required for all entities in the supply chain. Each lot of 15 Gauge needles must be traceable through batch numbers and expiration dates, with full documentation from manufacturing to end use. Regular audits, non-conformance tracking, and corrective action procedures (CAPA) must be implemented. Recalls, if necessary, must be executed swiftly per FDA 21 CFR Part 806 or equivalent international standards, with full customer notification and return logistics.

Conclusion for Sourcing a 15-Gauge Needle:

After a thorough evaluation of suppliers, quality standards, cost considerations, and regulatory compliance, sourcing a 15-gauge needle requires selecting a reputable manufacturer or distributor that adheres to international medical device standards such as ISO 13485 and FDA regulations. The 15-gauge needle, commonly used for procedures requiring high-flow delivery—such as blood donation, apheresis, or rapid fluid administration—demands high precision in manufacturing to ensure sharpness, durability, and patient safety.

Key factors in successful sourcing include material quality (typically medical-grade stainless steel), sterility assurance, packaging integrity, and reliable supply chain logistics. Additionally, establishing long-term partnerships with suppliers who offer consistent product performance, competitive pricing, and compliance documentation will support operational efficiency and patient care standards.

In conclusion, careful due diligence in selecting a qualified supplier—balancing cost, quality, and reliability—is essential to ensure the safe and effective use of 15-gauge needles in clinical settings.