The global market for high-performance industrial tubing, including heat-resistant variants, is experiencing robust expansion driven by increasing demand across aerospace, automotive, medical, and energy sectors. According to Grand View Research, the global industrial tubing market was valued at USD 74.2 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. A key segment within this space—heat resistant tubing—has seen rising adoption due to its critical role in high-temperature applications such as exhaust systems, thermal insulation, and fluid transfer in harsh environments. Among the most widely used specifications is 14mm heat-resistant tubing, favored for its compatibility with standard fittings and optimal balance of flexibility and durability. As demand intensifies, manufacturers are investing in advanced materials like silicone, PTFE, and reinforced elastomers to enhance thermal stability, pressure resistance, and longevity. With innovation and capacity scaling becoming differentiators, the following list highlights the top eight manufacturers leading the 14mm heat-resistant tubing space in terms of production quality, technological advancement, and market reach.

Top 8 14Mm Heat Resistant Tubing Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Heat Resistant PVC Steel Wire Hose

Domain Est. 2005

Website: sinohose.com

Key Highlights: High-Temperature resistant flexible steel wire hose is made of good zinc plated metal wire and qualified heat resistant PVC compound. As a professional heat ……

#2 McMaster

Domain Est. 1994

Website: mcmaster.com

Key Highlights: McMaster-Carr is the complete source for your plant with over 700000 products. 98% of products ordered ship from stock and deliver same or next day….

#3 Flexible Tubing from Cole

Domain Est. 1994

#4 Tubing

Domain Est. 1995

Website: smcusa.com

Key Highlights: All are offer protection equivalent to UL-94 standard V-0 to prevent flame propagation. SMC offers single, double and triple layer spatter resistant tubing ……

#5 Reinforced silicone hose / tubing (food grade, 14mm inner diameter …

Domain Est. 2012

#6 High Temperature Silicone Tubing

Domain Est. 2013

#7 HPS 9/16″ (14mm) ID High Temperature Reinforced Silicone Heater …

Domain Est. 2020

#8 HPS Performance HPS 9/16″ (14mm) High Temperature Silicone …

Domain Est. 2021

Website: functionpowersports.com

Key Highlights: In stock Rating 4.5 41 Buy HPS 9/16″ (14mm) High Temperature Silicone Vacuum Hose Tubing | 1 Foot | Black HTSVH14-BLK-HPS starting at $8.65 at Function Powersports….

Expert Sourcing Insights for 14Mm Heat Resistant Tubing

H2: Projected 2026 Market Trends for 14mm Heat Resistant Tubing

The global market for 14mm heat resistant tubing is poised for significant evolution by 2026, driven by rising demand across high-performance industrial and technological sectors. This standardized diameter has become critical in applications requiring durability under extreme thermal conditions, particularly in automotive, aerospace, energy, and advanced manufacturing industries.

A key trend shaping the 2026 outlook is the increasing adoption of electric vehicles (EVs) and hybrid propulsion systems. In EV powertrains, 14mm heat resistant tubing is essential for thermal management systems, including battery cooling and power electronics housings. As governments worldwide enforce stricter emissions regulations and incentivize electrification, demand for such components is expected to grow at a compound annual growth rate (CAGR) of approximately 6.8% through 2026, according to industry forecasts.

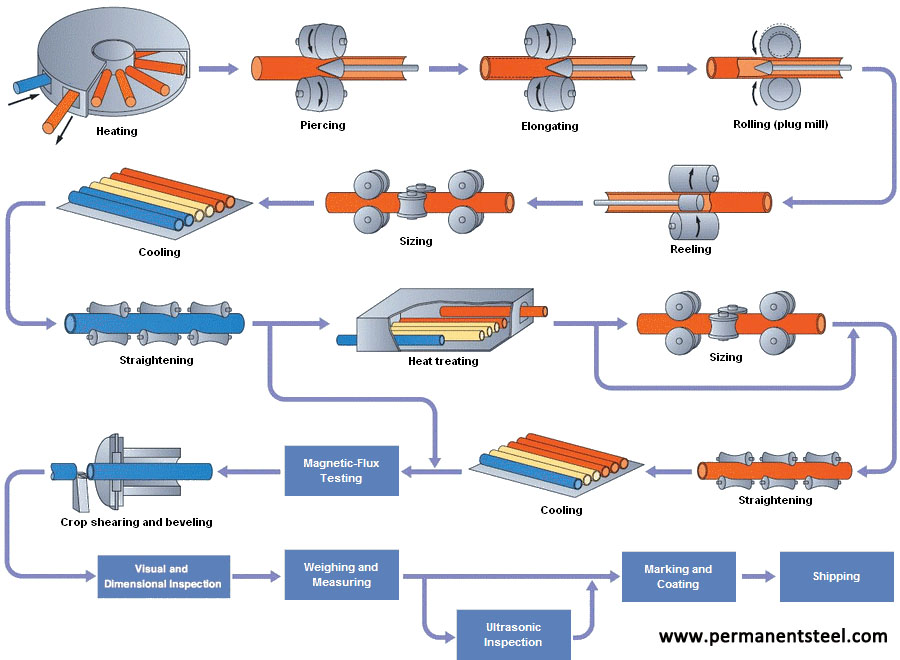

Additionally, advancements in material science are enhancing the performance of heat resistant tubing. The integration of next-generation polymers (e.g., PEEK, PTFE) and metal alloys (such as Inconel and stainless steel variants) enables 14mm tubing to withstand temperatures exceeding 500°C while maintaining structural integrity. These innovations are expanding applications into concentrated solar power (CSP) plants and hydrogen fuel cell systems—sectors projected to see substantial investment by 2026.

Supply chain localization is another emerging trend. Geopolitical uncertainties and post-pandemic resilience strategies are prompting manufacturers to regionalize production. North America and Europe are expected to increase domestic manufacturing of high-spec tubing, reducing dependency on Asian suppliers and improving lead times for industrial clients.

Furthermore, sustainability regulations are influencing product development. By 2026, environmental standards such as the EU’s Green Deal and U.S. EPA guidelines will likely mandate recyclable or low-carbon-footprint materials in industrial components. Producers of 14mm heat resistant tubing are anticipated to respond with bio-based polymers and energy-efficient manufacturing processes to remain competitive.

In summary, the 2026 market for 14mm heat resistant tubing will be defined by technological innovation, sectoral expansion into clean energy and mobility, supply chain adaptation, and regulatory pressures toward sustainability—positioning the product as a critical enabler of next-generation thermal management solutions.

Common Pitfalls Sourcing 14mm Heat Resistant Tubing (Quality & IP)

Sourcing 14mm heat resistant tubing requires careful attention to both material performance and intellectual property (IP) considerations. Overlooking these aspects can lead to product failures, supply chain disruptions, and legal liabilities. Here are the key pitfalls to avoid:

H2: Quality-Related Pitfalls

-

Inadequate Temperature Rating Verification:

- Pitfall: Accepting supplier claims of “heat resistance” without verifying the specific continuous and peak temperature ratings under actual operating conditions (e.g., internal pressure, external environment, cycling frequency). Suppliers may cite lab ideal conditions.

- Risk: Tubing degrades prematurely, leading to leaks, bursts, or fire hazards. 14mm tubing often handles significant flow; failure can be catastrophic.

- Mitigation: Demand certified test reports (e.g., ASTM D573, ISO 188) for the exact material grade at your required temperatures. Specify continuous operating temp, short-term peak temp, and aging conditions.

-

Overlooking Material Compatibility:

- Pitfall: Focusing solely on temperature resistance while ignoring chemical compatibility with the fluid being transported (e.g., oils, fuels, coolants, solvents, steam) or environmental exposure (ozone, UV).

- Risk: Chemical attack causes swelling, cracking, embrittlement, or leaching, even if temperature is within spec. This is critical for 14mm lines carrying aggressive media.

- Mitigation: Conduct or require compatibility testing (e.g., immersion tests per ASTM D471) with the specific fluid under temperature and pressure. Review material SDS thoroughly.

-

Neglecting Pressure and Mechanical Requirements:

- Pitfall: Assuming heat resistance implies sufficient pressure rating or mechanical strength (burst pressure, kink resistance, flexibility under heat).

- Risk: Tubing collapses (kinking), bursts under pressure, or fails under vibration/stress, especially when heated and more pliable. 14mm ID implies potentially high flow rates and pressure demands.

- Mitigation: Specify required burst pressure, working pressure (with safety factors), and mechanical properties (e.g., tensile strength, elongation at break) at elevated temperatures. Request pressure test data.

-

Inconsistent Dimensional Tolerances:

- Pitfall: Accepting tubing with poor dimensional control (ID, OD, wall thickness variation).

- Risk: Inconsistent flow rates, difficulty in assembly (push-on fittings may leak or blow off), uneven stress distribution leading to premature failure. 14mm ID requires tight tolerances for proper fitting performance.

- Mitigation: Define strict dimensional tolerances (e.g., per SAE, ISO, or custom specs) and require Certificates of Conformance (CoC) with actual measurements on each batch.

-

Compromising on Material Quality & Additives:

- Pitfall: Selecting the lowest-cost option, which may use inferior base polymers, recycled content (without verification), or insufficient/incorrect stabilizers (antioxidants, UV stabilizers).

- Risk: Significantly reduced lifespan, unpredictable performance, increased risk of cracking or degradation under heat and stress.

- Mitigation: Specify virgin-grade polymer (e.g., FKM, FFKM, PTFE, PFA, specific high-temp silicone) with known stabilizer packages. Audit suppliers’ material sourcing and quality control processes.

-

Insufficient Testing and Certification:

- Pitfall: Relying on supplier brochures without demanding independent test data or relevant industry certifications.

- Risk: Unverified performance, non-compliance with safety standards (e.g., UL, CSA, FMVSS, FDA, USP Class VI if applicable).

- Mitigation: Require test reports from accredited labs for key properties (temp, pressure, chem resistance, flammability). Verify relevant certifications for your application and region.

H2: Intellectual Property (IP)-Related Pitfalls

-

Sourcing Counterfeit or Grey Market Goods:

- Pitfall: Purchasing from unauthorized distributors or unclear supply chains, especially for well-known brands (e.g., Parker, Gates, Swagelok, Saint-Gobain).

- Risk: Receiving non-genuine products with substandard materials performance (failing quality pitfalls above) and potential IP infringement liability for the buyer. Performance is unpredictable and unreliable.

- Mitigation: Buy only from authorized distributors or directly from the OEM. Verify distributor authorization. Be wary of prices significantly below market. Traceability is key.

-

Infringing on Patented Designs or Materials:

- Pitfall: Sourcing tubing with a specific proprietary construction (e.g., unique reinforcement layer, liner material, manufacturing process) or a patented material formulation without a license.

- Risk: Legal action (injunctions, damages) from the patent holder, forced redesign, supply disruption, reputational damage. High-temp tubing often involves significant R&D.

- Mitigation: Conduct freedom-to-operate (FTO) searches before finalizing a design/supplier, especially for custom or high-performance specs. Ensure suppliers warrant they do not infringe third-party IP. Use generic material specifications where possible.

-

Violating Trademarks:

- Pitfall: Accepting tubing that bears the trademark of a renowned brand but is not genuine, or using supplier-provided branding that infringes.

- Risk: Trademark infringement lawsuits, seizure of goods, reputational harm.

- Mitigation: Verify authenticity rigorously. Avoid using supplier trademarks unless explicitly licensed. Clearly define branding requirements in contracts.

-

Lack of Clear IP Ownership in Custom Designs:

- Pitfall: Collaborating with a supplier on a custom 14mm heat-resistant tubing solution without a contract defining IP ownership (design, tooling, process improvements).

- Risk: Disputes over who owns the rights, inability to source from another supplier, supplier holding IP hostage.

- Mitigation: Negotiate and sign a clear IP agreement before development starts, specifying ownership of background IP, foreground IP, and rights to use tooling/processes.

-

Overlooking Trade Secrets in Processes:

- Pitfall: Failing to protect proprietary information (e.g., specific test protocols, application know-how) shared with suppliers, or using a supplier whose process is a trade secret but not properly licensed.

- Risk: Loss of competitive advantage, potential misappropriation claims.

- Mitigation: Use robust Non-Disclosure Agreements (NDAs). Be cautious about disclosing sensitive application details unless necessary. Understand the basis of the supplier’s capability.

Conclusion: Successfully sourcing reliable 14mm heat resistant tubing demands rigorous due diligence on both the physical quality (temperature, chemical, mechanical, dimensional) and the legal integrity (authenticity, patents, trademarks, IP agreements) of the supply. Prioritize authorized channels, demand verifiable data, define requirements precisely, and secure clear IP terms to mitigate these significant risks.

H2: Logistics & Compliance Guide for 14mm Heat Resistant Tubing

H2.1 Overview

This guide outlines the logistics and compliance requirements for the safe handling, transportation, storage, and regulatory adherence of 14mm Heat Resistant Tubing, commonly used in high-temperature industrial, automotive, aerospace, and medical applications. The tubing is typically composed of materials such as silicone, PTFE (Teflon), fiberglass, or reinforced elastomers, designed to withstand temperatures up to 200°C or higher, depending on the specific formulation.

Proper logistics and compliance procedures ensure product integrity, regulatory conformity, and end-user safety.

H2.2 Regulatory Compliance

H2.2.1 International Standards

- ISO 13485: If used in medical applications, tubing must comply with quality management standards for medical devices.

- ISO 9001: Applies to general manufacturing and quality assurance processes.

- RoHS (Restriction of Hazardous Substances): Ensures the tubing is free from lead, cadmium, mercury, and other restricted substances—mandatory for EU markets.

- REACH (EC 1907/2006): Requires declaration of Substances of Very High Concern (SVHC) and ensures safe chemical use.

- FDA 21 CFR: If used in food, beverage, or pharmaceutical applications, tubing must meet FDA compliance for food contact materials.

- UL / CSA: Safety certification for use in electrical or high-heat environments (e.g., UL 224 for insulated wires).

H2.2.2 Transportation Regulations

- IMDG Code: For sea transport of hazardous materials (if applicable—e.g., peroxides used in silicone curing).

- IATA DGR: Air transport regulations—non-hazardous tubing generally exempt unless treated with flammable substances.

- ADR/RID: For overland transport in Europe—non-hazardous tubing typically does not require special labeling.

- DOT 49 CFR (USA): Domestic U.S. transport regulations—standard industrial goods classification applies unless material is classified as hazardous.

✅ Note: Most heat-resistant tubing is non-hazardous and classified as “Not Restricted” under transport regulations when shipped as finished goods.

H2.3 Packaging Requirements

- Primary Packaging:

- Tubing must be coiled or straight-stored on non-abrasive spools or reels.

- Protected with plastic wrapping or shrink film to prevent dust, moisture, and UV exposure.

- Secondary Packaging:

- Use sturdy corrugated cardboard boxes or wooden crates for bulk shipments.

- Include cushioning material to prevent deformation during transit.

- Labeling:

- Product name: “14mm Heat Resistant Tubing”

- Batch/lot number and manufacturing date

- Material type (e.g., Silicone, PTFE)

- Temperature rating (e.g., “-60°C to +200°C”)

- Compliance marks (CE, RoHS, FDA, etc.)

- Handling symbols: “Do Not Crush,” “Keep Dry,” “Protect from Sunlight”

H2.4 Storage Conditions

- Temperature: Store between 5°C and 35°C. Avoid exposure to extreme heat or freezing.

- Humidity: Maintain relative humidity below 70% to prevent moisture absorption (especially in hygroscopic materials like nylon).

- Light: Protect from prolonged UV exposure—store in opaque or shaded containers.

- Ventilation: Ensure storage area is well-ventilated to avoid buildup of volatile organic compounds (VOCs).

- Shelf Life:

- Silicone tubing: typically 5–7 years

- PTFE tubing: indefinite if stored properly

- Check manufacturer’s datasheet for specific expiration guidance.

⚠️ Do NOT store near ozone sources (e.g., motors, UV lamps)—ozone can degrade elastomeric materials.

H2.5 Transportation & Handling

- Loading/Unloading:

- Use mechanical aids (forklifts, pallet jacks) to avoid manual strain.

- Prevent kinking or crushing during handling.

- Stacking:

- Limit stack height to manufacturer specifications (usually 2–3 pallets high).

- Use pallets with even support; avoid overhang.

- In-Transit Protection:

- Secure loads with straps or stretch wrap.

- Avoid exposure to rain, snow, or extreme temperatures in non-climate-controlled vehicles.

- Cross-Contamination:

- Do not store or transport with oils, solvents, or corrosive chemicals unless tubing is chemically resistant and properly sealed.

H2.6 Documentation & Traceability

- Required Documents:

- Certificate of Conformance (CoC)

- Material Safety Data Sheet (MSDS/SDS)

- RoHS/REACH Compliance Declaration

- FDA Compliance Letter (if applicable)

- Batch Traceability Records

- Customs Documentation (International Shipments):

- Commercial Invoice

- Packing List

- Bill of Lading / Air Waybill

- HS Code: Typically 3917.33 (Plastic tubing) or 8544.49 (Insulated wire, if applicable)

H2.7 End-of-Life & Environmental Compliance

- Recycling:

- Silicone: Can be downcycled into industrial fillers; not widely recyclable curbside.

- PTFE: Recyclable via specialized facilities.

- Avoid incineration without proper emission controls (risk of HF gas release).

- Disposal:

- Follow local regulations for industrial polymer waste.

- Landfill disposal permitted in most regions, but recycling is encouraged.

H2.8 Summary Checklist

| Task | Requirement |

|——|————-|

| ✔️ Compliance Markings | CE, RoHS, FDA (if applicable) |

| ✔️ Packaging | Sealed, labeled, protected from elements |

| ✔️ Storage | Cool, dry, UV-protected environment |

| ✔️ Transport | Non-hazardous classification; secure load |

| ✔️ Documentation | CoC, SDS, customs paperwork |

| ✔️ Traceability | Batch/lot tracking system in place |

Adhering to this guide ensures that 14mm heat resistant tubing remains compliant, safe, and effective throughout its supply chain journey—from manufacturer to end-user. Always consult the manufacturer’s technical data sheet (TDS) and safety documentation for product-specific instructions.

In conclusion, sourcing 14mm heat-resistant tubing requires careful consideration of material properties, temperature tolerance, application requirements, and supplier reliability. Silicone and PTFE (Teflon) tubing emerge as top choices due to their excellent heat resistance, flexibility, and durability. Key factors such as operating temperature range, chemical exposure, pressure ratings, and compliance with industry standards (e.g., FDA, RoHS) must be evaluated to ensure optimal performance and safety. Additionally, sourcing from reputable suppliers with consistent quality control and technical support is essential for long-term reliability. By balancing performance needs with cost and availability, the appropriate 14mm heat-resistant tubing can be effectively selected and integrated into the intended system, ensuring efficient and safe operation under high-temperature conditions.