The global hydraulic equipment market, driven by rising demand across construction, manufacturing, and agriculture sectors, is projected to grow at a CAGR of 4.2% from 2023 to 2028, according to Mordor Intelligence. A critical component within this ecosystem is the 13B rebuild kit—a key enabler of hydraulic pump longevity and performance. As industrial maintenance shifts toward cost-effective remanufacturing and sustainability, the demand for high-quality 13B rebuild kits has surged. With North America and Asia Pacific leading in industrial equipment utilization, OEMs and aftermarket suppliers are scaling production and innovation in seal materials, precision tolerances, and compatibility standards. This growth trajectory, supported by increasing fleet ages and extended equipment life cycles, has elevated competition among rebuild kit manufacturers, making supplier selection a strategic decision grounded in reliability, availability, and technical compliance.

Top 6 13B Rebuild Kit Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

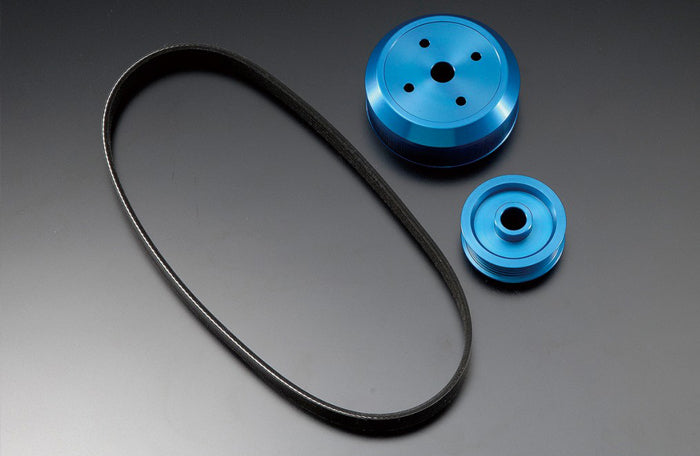

#1 GReddy Performance Products

Domain Est. 1996

Website: greddy.com

Key Highlights: This is the official North American GReddy Online Catalog / Official ShopGreddy.com Online Store for GReddy Performance Products, Inc….

#2 86

Domain Est. 1997

Website: atkinsrotary.com

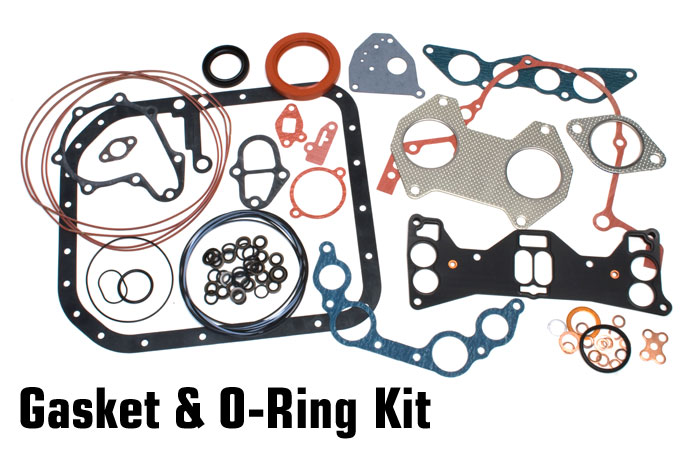

Key Highlights: In stock 30-day returnsThis rebuild kit includes the following parts: Specification SKU ARE153 Weight 3 lbs Dimensions (L x W x H) 18 x 13 x 3 in Manufacturer Atkins Rotary ……

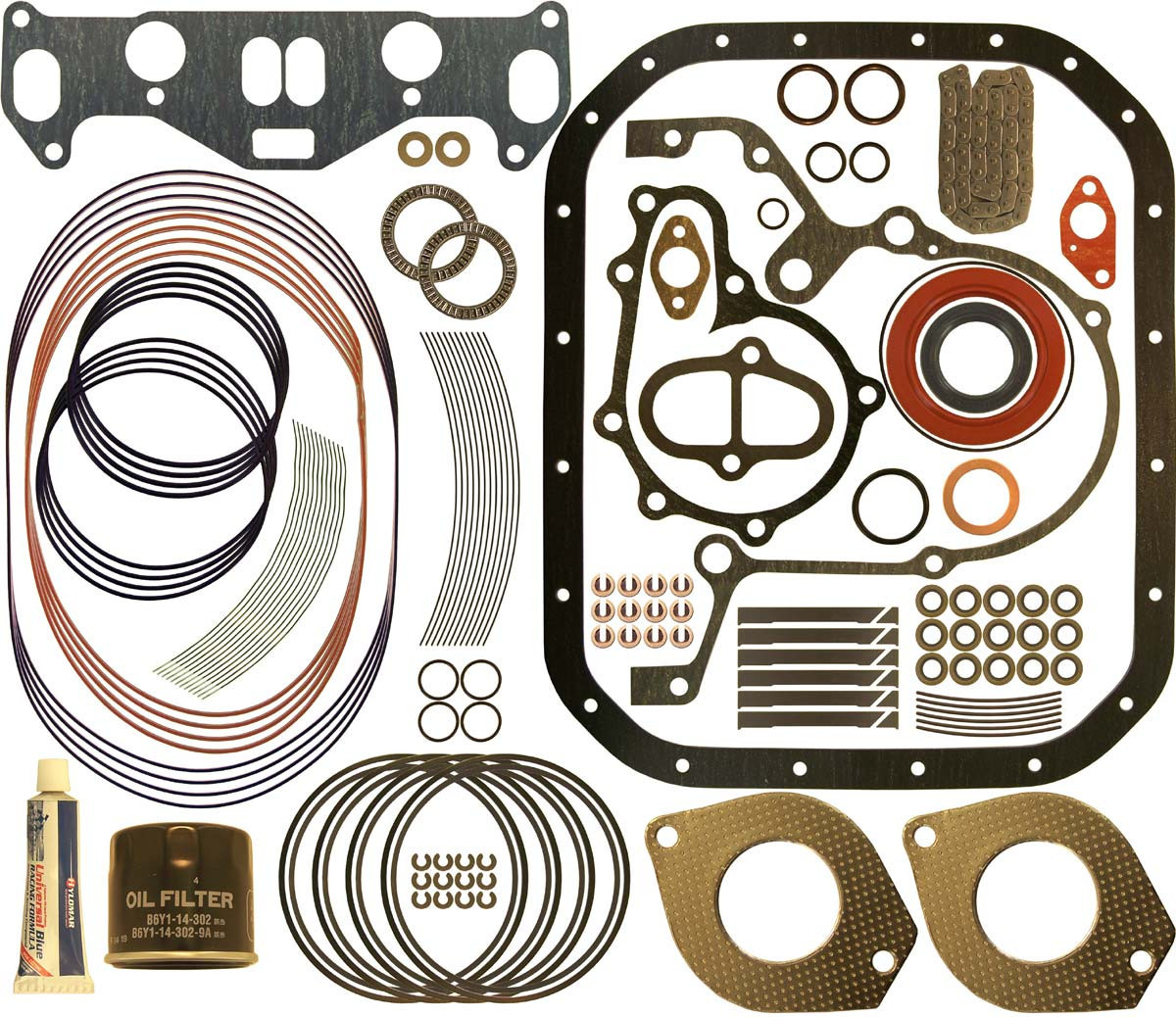

#3 Engine Rebuild Kit for 89

Domain Est. 1996

Website: racingbeat.com

Key Highlights: Racing Beat offers a complete rebuild kit for use on all 1989-91 13B TURBO II engines. Determining all of the correct components that are required to rebuild a ……

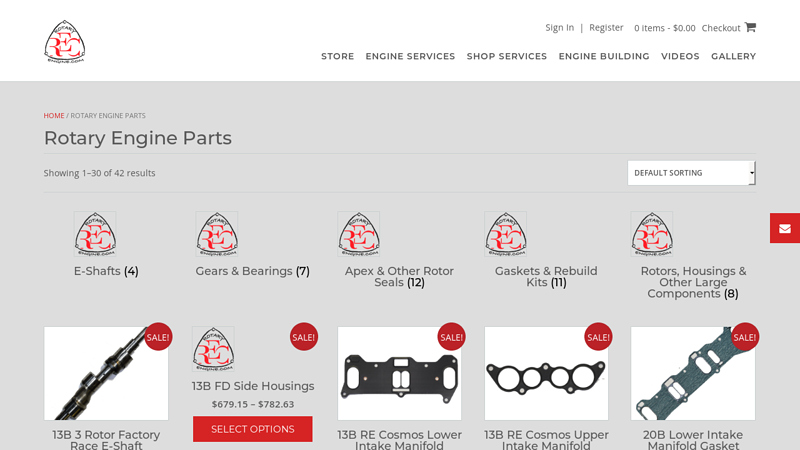

#4 Rotary Engine Parts – RotaryEngine.com

Domain Est. 1998

Website: rotaryengine.com

Key Highlights: Rotary Engine Parts ; 13B FD Side Housings · 679.15 – $782.63 Price range: $679.15 through $782.63 ; 20B/Cosmos Side Housings · 2,395.95 – $6,890.95 Price range: $ ……

#5 1993

Domain Est. 1998

Website: mazdamotorsports.com

Key Highlights: The following parts are recommended for all 1993-95 13B rebuilds. These are the parts normally sent out with our rebuild kit, K-9395-3B-STK….

#6 RX7 13B Turbo Gearbox Bearing Rebuild Kit

Website: mnmracing.shop

Key Highlights: Suits Mazda rx7 gearboxes from series 4 turbo to series 8 turbo rx7. All bearings are genuine Japanese brand NSK,Nachi and NTN not cheap Chinese rubbish….

Expert Sourcing Insights for 13B Rebuild Kit

H2: 2026 Market Trends for 13B Rebuild Kit

The market for 13B rotary engine rebuild kits is expected to experience notable shifts by 2026, driven by evolving consumer demand, technological advancements, and the growing popularity of rotary engine restoration. As a niche but passionate segment within the automotive aftermarket, the 13B rebuild kit market is poised for moderate but steady growth, supported by several key trends:

-

Increased Demand from Enthusiast and Classic Vehicle Communities

By 2026, the resurgence of interest in classic and performance Japanese sports cars—particularly the Mazda RX-7 (FC and FD models) and Mazda RX-8—will continue to fuel demand for authentic, high-quality 13B rebuild components. Online communities, social media platforms, and dedicated rotary events are amplifying global awareness and driving DIY restoration projects, thereby increasing the need for comprehensive rebuild kits. -

Expansion of Aftermarket Supplier Ecosystem

More manufacturers and specialty suppliers are expected to enter or expand within the 13B rebuild space, offering upgraded materials such as plasma-moly seals, ceramic-coated rotors, and high-temperature apex seals. This competition will improve product availability, reduce lead times, and drive innovation in durability and performance, catering to both street and track applications. -

Rise in Engine Conversions and Hybrid Projects

The trend of rotary engine swaps—especially into lightweight platforms like the MX-5 Miata or kit cars—will contribute to market growth. Additionally, experimental hybrid-electric rotary builds, inspired by concepts like Mazda’s e-Skyactiv R-EV, may increase interest in reliable, rebuildable 13B cores, further boosting demand for rebuild kits tailored to modified applications. -

Aging Inventory and Scarcity of OEM Parts

As original 13B engines become rarer and OEM support remains limited, rebuild kits will serve as essential tools for engine longevity. The scarcity of original equipment parts is pushing consumers toward aftermarket solutions, with an increased preference for kits that include modern improvements over stock components. -

Geographic Market Shifts

While North America and Japan remain core markets, Europe and Australia are expected to see rising demand due to expanding rotary communities and favorable regulations for classic vehicle ownership. This will encourage suppliers to localize distribution and offer region-specific packaging and compliance. -

Sustainability and Circular Economy Considerations

Environmental awareness is influencing consumer behavior. Rebuilding 13B engines is increasingly viewed as a sustainable alternative to new engine production, aligning with circular economy principles. This perception supports long-term market legitimacy and appeals to eco-conscious enthusiasts.

Conclusion:

By 2026, the 13B rebuild kit market will be shaped by passionate enthusiast demand, innovation in component technology, and a growing ecosystem of specialized suppliers. While remaining a niche segment, the market is expected to mature with better product offerings, broader availability, and enhanced support for both restoration and performance applications. Strategic investment in quality, education, and community engagement will be key for suppliers aiming to capitalize on these emerging trends.

Common Pitfalls When Sourcing a 13B Rebuild Kit (Quality & Intellectual Property)

Sourcing a reliable 13B rotary engine rebuild kit presents unique challenges, particularly concerning component quality and intellectual property (IP) legitimacy. Avoiding these pitfalls is crucial for a successful, durable engine restoration.

Poor Material Quality and Manufacturing Tolerances

Many budget rebuild kits use substandard materials and imprecise manufacturing, leading to premature failure. Seals, apex seals, and side seals made from inferior rubber or low-grade carbon/steel wear quickly under the high heat and stress of a rotary engine. Poorly machined housings or rotors with incorrect tolerances cause excessive oil consumption, loss of compression, and catastrophic engine damage. Always verify material specifications (e.g., OEM-grade elastomers, proper seal alloys) and favor suppliers with documented quality control processes.

Counterfeit or IP-Infringing Components

The 13B engine, particularly variants like the 13B-REW from the Mazda RX-7, involves protected designs and trademarks. Unscrupulous vendors often sell “OEM-style” or “direct replacement” parts that infringe on Mazda’s intellectual property, including patented seal geometries, housing coatings (like the proprietary chrome plating process), and rotor designs. These counterfeit parts not only pose legal risks but typically lack the engineering refinement and durability of genuine or licensed components. Sourcing from authorized distributors or reputable aftermarket brands with proper licensing helps avoid IP violations and ensures better performance.

Incomplete or Mismatched Kit Contents

Some rebuild kits omit critical components (e.g., eccentric shaft oil seals, gear sets, or proper fasteners) or include parts not specifically engineered for the target 13B variant (e.g., non-turbo vs. turbo models). This forces buyers into additional purchases, increasing cost and risking incompatibility. Always cross-reference the kit contents with a full OEM parts diagram for your specific engine model to ensure completeness and compatibility.

Lack of Technical Support and Documentation

Rebuilding a rotary engine requires precise procedures and specifications. Many low-cost kits come without torque specs, assembly instructions, or technical support. This increases the risk of improper installation, especially for less experienced builders. Choose suppliers that provide comprehensive documentation and access to technical expertise to ensure correct assembly and optimal engine longevity.

Logistics & Compliance Guide for 13B Rebuild Kit

This guide outlines the essential logistics and compliance considerations for the shipment, handling, and distribution of the 13B Rebuild Kit to ensure timely delivery and adherence to regulatory requirements.

Packaging and Labeling Requirements

Ensure each 13B Rebuild Kit is securely packaged in durable, moisture-resistant materials to prevent damage during transit. All packages must display accurate labeling, including: part number (13B Rebuild Kit), quantity, gross weight, and handling symbols (e.g., “Fragile,” “This Side Up”). Include a packing slip inside and affixed externally for easy verification.

Shipping and Transportation

Shipments must comply with applicable domestic and international transportation regulations. Use carriers certified for automotive parts handling. For air freight, confirm compliance with IATA Dangerous Goods Regulations if applicable—note that most rebuild kits do not contain hazardous materials, but verification is required. Maintain proper shipping documentation, including commercial invoices and bills of lading.

Import/Export Compliance

For cross-border shipments, ensure the 13B Rebuild Kit is correctly classified under the appropriate Harmonized System (HS) code. Prepare necessary documentation such as export declarations, certificates of origin, and comply with destination country import regulations (e.g., CE marking in the EU, DOT standards in the US if applicable). Sanction screening of end-users and destinations must be conducted prior to export.

Regulatory and Environmental Standards

Confirm that all components within the 13B Rebuild Kit meet relevant environmental regulations, including RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) where applicable. Maintain compliance records and material declarations for audit readiness.

Inventory and Traceability

Implement a serial or batch tracking system for all 13B Rebuild Kits to support traceability throughout the supply chain. Log receipt, storage conditions, and distribution details in inventory management software. Retain records for a minimum of seven years to support warranty claims and regulatory audits.

Storage Conditions

Store kits in a climate-controlled environment (15–25°C, 30–60% relative humidity) away from direct sunlight and contaminants. Use first-in, first-out (FIFO) inventory rotation to prevent obsolescence and ensure product integrity.

Returns and Reverse Logistics

Establish a clear returns process for defective or incorrect 13B Rebuild Kits. All returned items must be inspected, documented, and dispositioned in compliance with environmental and safety regulations. Coordinate with certified recycling partners for disposal of non-reusable components.

Compliance Training and Audits

Ensure all logistics personnel are trained on relevant compliance procedures, including handling, documentation, and incident reporting. Conduct internal audits annually to verify adherence to logistics and regulatory standards.

Conclusion for Sourcing a 13B Rebuild Kit:

Sourcing a 13B engine rebuild kit requires careful consideration of quality, compatibility, and supplier reliability. Given the complexity and unique design of the rotary 13B engine—commonly found in Mazda RX-7 and RX-8 models—it is essential to select a rebuild kit that includes all critical components such as apex seals, side seals, O-rings, gaskets, bearings, and seals, preferably from a reputable manufacturer. After evaluating multiple suppliers, OEM+ or performance-oriented brands like Nippon Denso, MPS, or HKS consistently offer reliable kits with proven durability.

Additionally, verifying the kit’s compatibility with the specific 13B variant (e.g., 13B-REW, 13B-RESI, or later models) is crucial to ensure proper fit and long-term performance. While cost is a factor, opting for the lowest-priced option may lead to premature failure and increased long-term expenses. Therefore, investing in a high-quality rebuild kit from a trusted source, supported by customer reviews and technical documentation, provides the best balance of performance, reliability, and value.

In summary, successfully sourcing a 13B rebuild kit hinges on prioritizing component quality, correct application, and supplier reputation to ensure a durable and efficient engine rebuild.