The global packaging market, particularly in the e-commerce and logistics sectors, continues to expand rapidly, driven by increasing demand for protective and sustainable packaging solutions. According to Grand View Research, the global corrugated packaging market size was valued at USD 68.7 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 4.8% from 2023 to 2030. This growth is fueled by rising online retail activity and stricter shipping regulations that necessitate durable packaging, such as 12x12x6 white safety chute packs—commonly used for safeguarding fragile items during transit. As demand surges, manufacturers specializing in these precise configurations are gaining prominence, with innovation in materials, automation, and scalability becoming key differentiators. Based on production capacity, geographic reach, and customer reviews from B2B platforms like Thomasnet and Alibaba, the following three manufacturers have emerged as leaders in producing high-quality 12x12x6 white safety chute packs.

Top 3 12X12X6 White Safety Chute Pack Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 14

Domain Est. 1999

Website: lfws.tfid.org

Key Highlights: The code official must approve the floor or roof manufacturer’s installation instructions and this report, construction supporting the suspended ceiling ……

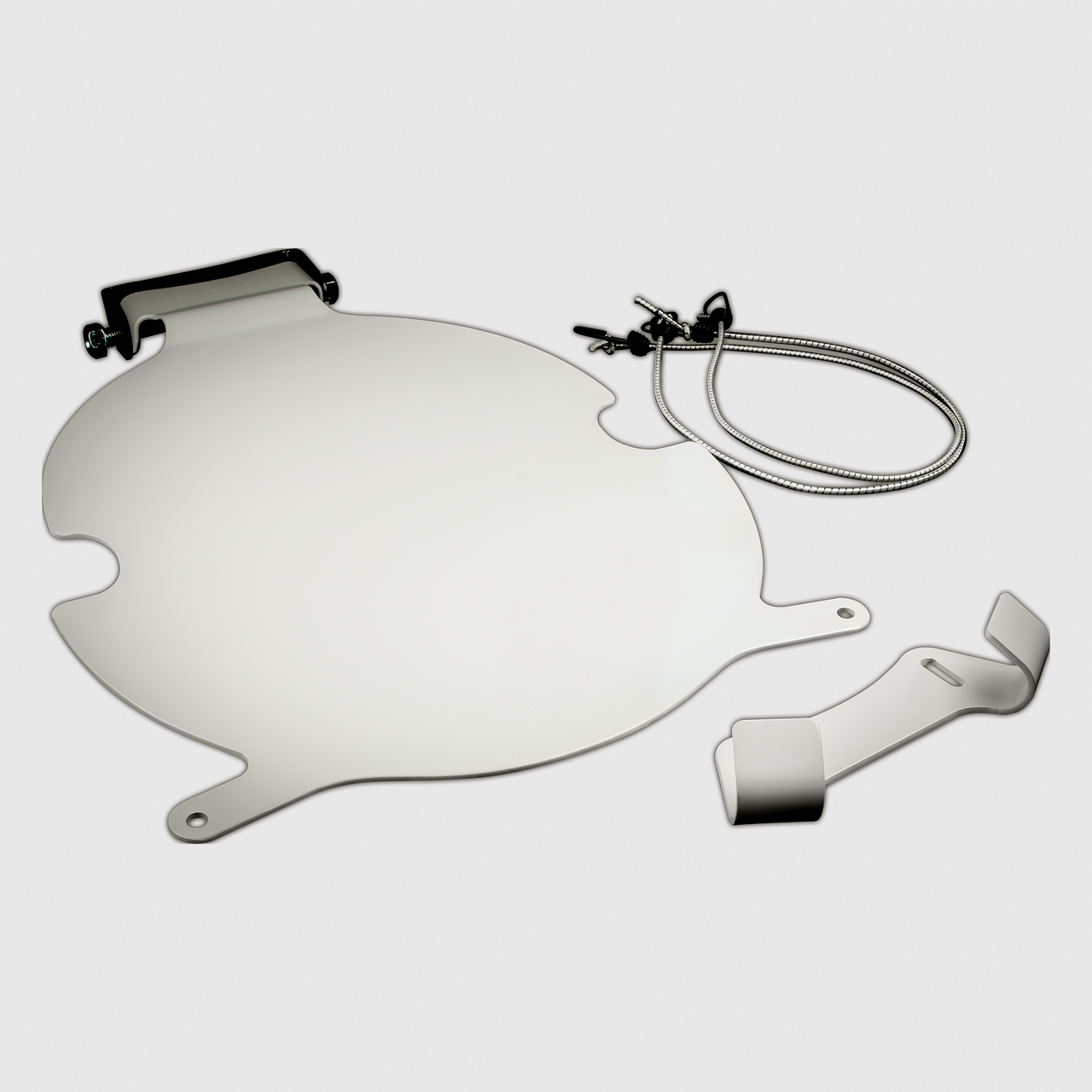

#2 [PDF] Retail Price List Cover with FAQ 2025

Domain Est. 1998

Website: hadarathletic.com

Key Highlights: Single-Man 4ft Lineman Chute. $787.50 each (ea). Hadar Skus:American Football – Metal. HXSPEEDCHUTEX. One Chute Addition to Single-Man 4ft Lineman Chute….

#3 Charlie 1

Domain Est. 2010

Website: charlie1-506.com

Key Highlights: This is a chronicle of Charlie Company, 1-506 th Infantry’s service during the Viet Nam war from arrival in late 1967 until the unit’s departure in early ……

Expert Sourcing Insights for 12X12X6 White Safety Chute Pack

H2: Market Trends Analysis for 12X12X6 White Safety Chute Pack in 2026

The 12X12X6 white safety chute pack, commonly used in pharmaceutical, food & beverage, and medical device packaging for sterile or sensitive product transfer, is expected to experience notable shifts in demand and application by 2026. This analysis explores key market trends shaping its trajectory.

1. Growth in Aseptic and Cleanroom Manufacturing

By 2026, continued expansion in biopharmaceuticals, personalized medicine, and contract development and manufacturing organizations (CDMOs) will drive demand for reliable cleanroom transfer solutions. The 12X12X6 white safety chute pack—designed for controlled environments—will benefit from stricter regulatory standards (e.g., FDA, EU GMP) and increased investments in isolator and RABS (Restricted Access Barrier Systems) technologies. Its role in minimizing contamination during material passage through cleanroom walls will remain critical.

2. Adoption of Single-Use and Disposable Systems

The pharmaceutical and biotech industries are increasingly shifting toward single-use technologies to reduce cross-contamination risks and operational downtime. The 12X12X6 white safety chute pack aligns with this trend, especially when integrated with disposable liners or used in single-batch processes. By 2026, manufacturers are likely to offer pre-sterilized, gamma-compatible versions of this product to meet demand for ready-to-use solutions.

3. Material Innovation and Sustainability Pressures

Environmental regulations and corporate ESG goals will push suppliers to develop more sustainable versions of safety chute packs. While the standard 12X12X6 white variant is typically made from polypropylene or HDPE, innovations in recyclable or bio-based polymers may emerge. However, material changes must not compromise integrity, sterility, or particulate shedding performance—key factors in cleanroom environments.

4. Regional Market Expansion

Asia-Pacific (particularly India and China) and Latin America are expected to see increased pharmaceutical manufacturing capacity by 2026. This will create new demand for cleanroom consumables, including standardized safety chute packs. Localized production and distribution of the 12X12X6 white model may rise to reduce lead times and tariffs.

5. Integration with Smart Monitoring Systems

While still emerging, smart packaging and IoT-enabled monitoring could influence future iterations of safety chute systems. By 2026, early adopters may begin integrating RFID tags or sensors into chute pack workflows to log transfer events, verify compliance, and enhance traceability—especially in high-value or regulated processes.

6. Supply Chain Resilience and Localization

Post-pandemic supply chain lessons will continue influencing procurement strategies. Companies may favor regional suppliers of safety chute packs to ensure continuity. This could lead to higher inventory buffering and dual sourcing for critical components like the 12X12X6 pack, especially in North America and Europe.

Conclusion

By 2026, the market for the 12X12X6 white safety chute pack will be shaped by rising aseptic processing needs, sustainability initiatives, regional manufacturing growth, and incremental technological enhancements. While the core design remains functionally stable, competitive differentiation will come from sterility assurance, material transparency, and integration readiness with modern cleanroom workflows. Suppliers who align with regulatory trends and offer scalable, sustainable solutions will capture stronger market positions.

Common Pitfalls When Sourcing a 12x12x6 White Safety Chute Pack (Quality and IP Considerations)

Sourcing a 12x12x6 white safety chute pack—commonly used in medical, pharmaceutical, or laboratory settings for safe disposal of sharps or biohazardous materials—requires careful attention to both product quality and intellectual property (IP) compliance. Below are key pitfalls to avoid:

Quality-Related Pitfalls

1. Inadequate Material Specifications

One common issue is sourcing chute packs made from substandard or non-compliant plastics. The material must be durable, puncture-resistant, and capable of containing biohazardous waste safely. Using low-grade polyethylene or incorrect thickness can lead to leaks, ruptures, or non-compliance with safety standards like OSHA or CDC guidelines.

2. Poor Manufacturing Consistency

Units may vary in dimensions, seal integrity, or color consistency when sourced from unreliable manufacturers. A deviation in size (e.g., less than 12x12x6 inches) can impact compatibility with disposal systems or regulatory compliance. Inconsistent sealing may compromise sterility or containment.

3. Lack of Regulatory Certification

Many suppliers claim compliance with standards such as ISO 22442 or UN 3291 without proper documentation. Always verify certifications for medical-grade safety, biohazard resistance, and shipping compliance (e.g., for transport of infectious substances).

4. Insufficient Testing for Real-World Use

Some products pass basic inspections but fail under actual use conditions—such as impact resistance during transit or exposure to fluids. Ensure the supplier conducts drop tests, leak tests, and load-bearing evaluations.

Intellectual Property (IP) Pitfalls

1. Infringement of Patented Designs

The design of safety chute packs—including latching mechanisms, fold patterns, or stackability features—may be protected by patents. Sourcing generic copies from manufacturers that replicate patented designs can expose your business to legal action, especially in markets like the U.S. or EU.

2. Unauthorized Use of Trademarks or Branding

Using product names, logos, or packaging elements that mimic established brands (e.g., “similar to Brand X”) may violate trademark laws. Even color schemes and packaging layouts can be subject to IP protection.

3. Lack of Design Rights Clearance

In regions like Europe, design rights protect the aesthetic appearance of functional products. Copying the visual design of a safety chute pack—even if functionally altered—may still constitute infringement.

4. Supply Chain IP Risks

OEM or private-label suppliers may unknowingly (or deliberately) use IP-infringing tooling or molds. Without contractual IP indemnification clauses, your company could be held liable for third-party infringement claims.

Best Practices to Avoid Pitfalls

- Request full compliance documentation, including material safety data sheets (MSDS), test reports, and certifications.

- Conduct factory audits or third-party inspections to verify production standards.

- Perform due diligence on IP status, including patent searches and legal review of design elements.

- Include IP warranties in supplier contracts, requiring the manufacturer to assume liability for infringement.

- Opt for custom-designed products where possible to avoid resemblance to existing protected designs.

By proactively addressing both quality and IP concerns, businesses can mitigate risks and ensure reliable, compliant, and legally sound sourcing of 12x12x6 white safety chute packs.

Logistics & Compliance Guide for 12x12x6 White Safety Chute Pack

Product Overview

The 12x12x6 White Safety Chute Pack is a protective packaging solution designed to safely transport small to medium-sized goods. Measuring 12 inches in length, 12 inches in width, and 6 inches in height, this rigid chute-style box features a white corrugated fiberboard construction. It is ideal for e-commerce, retail distribution, and industrial shipping applications requiring durability and stackability.

Packaging Specifications

- Dimensions (L x W x H): 12″ x 12″ x 6″ (30.5 cm x 30.5 cm x 15.2 cm)

- Material: Single-wall corrugated fiberboard (C-flute or equivalent)

- Color: White exterior, natural kraft interior

- Weight Capacity: Up to 30 lbs (13.6 kg)

- Edge Crush Test (ECT): ≥ 32 ECT (ensures stacking strength)

- Bursting Strength: ≥ 200 lbs/in² (9.8 kg/cm²)

- Sustainability: 70–100% recycled content; curbside recyclable

- Printability: Suitable for flexographic or digital printing (FSC-certified options available)

Handling & Storage Guidelines

- Stacking: Do not exceed 5 layers when fully loaded. Store on flat, dry pallets to prevent deformation.

- Environment: Store in a climate-controlled area (50–75°F / 10–24°C; 40–60% RH). Avoid prolonged exposure to moisture, direct sunlight, or extreme temperatures.

- Handling: Use mechanical aids (e.g., pallet jacks) for full pallets. Avoid dragging or dropping packaged units.

- Pallet Configuration: Standard pallet load: 60 units per layer, 5 layers = 300 units per 48″ x 40″ GMA pallet (approx. 800–900 lbs total). Secure with stretch wrap.

Shipping & Transportation

- Carrier Compatibility: Suitable for UPS, FedEx, USPS, and LTL freight carriers.

- Dimensional Weight: Monitor carrier-specific DIM weight rules; actual weight typically governs for this size.

- Labeling: Apply shipping labels to the top panel. Avoid placing labels over seams or edges. Barcodes must be scannable.

- Hazardous Materials: This packaging is not certified for hazardous materials (HAZMAT). Do not use for flammable, toxic, or pressurized contents.

- International Shipments: Acceptable for export; ensure compliance with destination country’s packaging regulations (e.g., ISPM-15 not required for corrugated boxes).

Regulatory & Compliance Standards

- FSC Certification: Available upon request (FSC Mix or FSC Recycled). Documentation provided for chain-of-custody claims.

- FDA Compliance: Safe for indirect food contact; not intended for direct food packaging unless specifically certified.

- RoHS/REACH: Compliant with EU RoHS and REACH regulations for restricted substances.

- ASTM Standards: Meets ASTM D642 (compression), D3951 (commercial packaging), and D4169 (performance testing).

- Recyclability: Labeled with “Recycle” symbol (♻️) and material code #11 (Old Corrugated Containers).

Sustainability & Disposal

- End-of-Life: 100% recyclable in standard paperboard streams. Remove non-paper components (e.g., plastic tape, labels) before recycling.

- Landfill: Biodegrades under industrial composting conditions; not recommended for home compost.

- Carbon Footprint: Average footprint: 0.25 kg CO₂e per unit (based on recycled content and regional manufacturing).

Quality Assurance

- Incoming Inspection: Verify dimensions, structural integrity, and print accuracy upon receipt.

- Performance Testing: Random samples undergo drop tests (ISTA 1A), vibration tests, and compression tests quarterly.

- Non-Conformance: Report defects (e.g., warping, delamination) to supplier within 10 days of delivery.

Supplier & Support Information

- Manufacturer: [Insert Manufacturer Name]

- Contact: [Insert Email/Phone]

- Documentation: SDS (upon request), Certificates of Compliance, FSC Chain-of-Custody Certificates available.

- Revision Date: [Insert Date]

Note: Always confirm regulatory requirements with local authorities for specific use cases or destinations. This guide applies to standard configurations; custom versions may have different specifications.

In conclusion, sourcing a 12x12x6-inch white safety chute pack requires careful consideration of material quality, compliance with safety standards, supplier reliability, and cost-effectiveness. It is essential to partner with reputable suppliers who can provide durable, high-performance chutes designed for safe load handling in material transport systems. Verifying product specifications, evaluating customization options, and ensuring timely delivery are critical steps to meet operational requirements. By conducting thorough due diligence and maintaining clear communication with vendors, organizations can secure a reliable supply of safety chute packs that enhance workplace safety, improve efficiency, and support long-term operational success.

![[PDF] Retail Price List Cover with FAQ 2025](https://www.sohoinchina.com/wp-content/uploads/2026/01/pdf-retail-price-list-cover-with-faq-2025-833.jpg)