The global demand for industrial automation and energy-efficient control systems has driven significant growth in the market for AC input modules, particularly those operating at 120VAC—commonly used in North American industrial and commercial applications. According to Grand View Research, the global industrial automation market size was valued at USD 192.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 9.3% from 2023 to 2030. A key enabler within this ecosystem, 120Vac input modules serve as critical interfaces between field devices and control systems, ensuring reliable signal transmission and system safety. Mordor Intelligence projects similar momentum, forecasting the industrial I/O modules market to grow at a CAGR of over 6.5% through 2028, driven by rising adoption in manufacturing, oil & gas, and infrastructure sectors. With increasing deployment of programmable logic controllers (PLCs) and distributed control systems (DCS), manufacturers of high-performance, interoperable 120Vac input modules are positioned at the forefront of this transformation. The following list highlights the top seven manufacturers leading innovation, reliability, and market penetration in this specialized segment.

Top 7 120Vac Input Module Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Allen

Domain Est. 1996

Website: stateelectric.com

Key Highlights: 6–10 day deliveryAllen-Bradley, 1769-IA16, 16 Point 120 VAC Input Module. … Manufacturer Part Number: 1769-IA16. UPC: 662468992800. $546.23/ea. Login for ……

#2 MEAN WELL Switching Power Supply Manufacturer

Domain Est. 1997

Website: meanwell.com

Key Highlights: Wattage : 35W~1200W. Features : Non-PFC, most economical models; Ultra compact and 1U low profile; 300VAC input surge; No load power consumption: 0.2W~0.75W ……

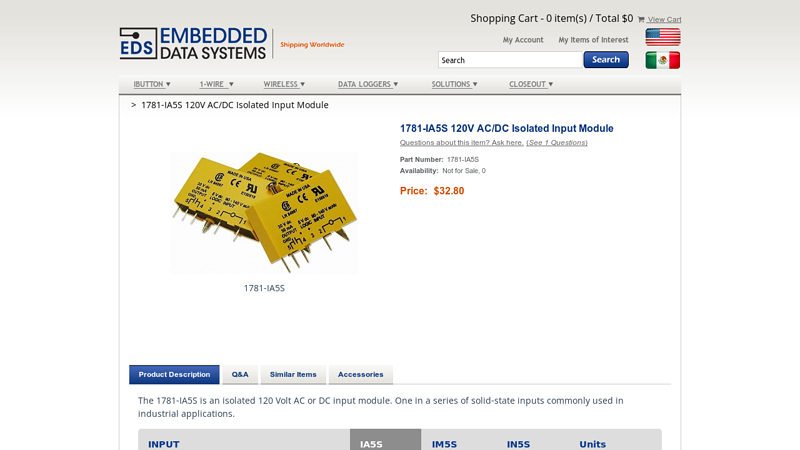

#3 1781

Domain Est. 2003

Website: embeddeddatasystems.com

Key Highlights: Out of stockThe 1781-IA5S is an isolated 120 Volt AC or DC input module. One in a series of solid-state inputs commonly used in industrial applications….

#4 Discrete 120V AC/DC Input Module (Yellow)

Domain Est. 1994

Website: sealevel.com

Key Highlights: In stock $22.57 deliveryThe IA5S provides a discrete input, Nominal 120V AC/DC, 5V Logic, with LED. Specifications. Specifications. Operating Temperature. -30°C to 80°C (-22° ……

#5 POINT I/O Modules

Domain Est. 1997

Website: rockwellautomation.com

Key Highlights: 1734-IA4 POINT I/O 4 Point Digital Input Module. active. Product. 120 Vac 4 Channel Input Module. Compare. Chevron Up. Product information ……

#6 RX3I Input Module, 120 Vac, 16

Domain Est. 1997

Website: stokeselectric.com

Key Highlights: Input modules provide the interface between the PLC and external input devices such as proximity sensors, push buttons, switches, and BCD thumbwheels….

#7 INPUT MODULE 120 VAC IN 24 VDC OUT 90

Domain Est. 2004

Website: verticalxpress.com

Key Highlights: INPUT MODULE 120 VAC IN 24 VDC OUT 90-140 VAC C4IAC. Part Number. 9103042. Login to see price. In stock. Quantity: − +. Add to Cart. Add to Quote….

Expert Sourcing Insights for 120Vac Input Module

H2: Analysis of 2026 Market Trends for 120Vac Input Modules

The market for 120Vac Input Modules in 2026 is poised for continued evolution, driven by technological advancements, shifting industrial demands, and global sustainability initiatives. While maintaining its core function as a critical interface between standard North American AC power (120V, 60Hz) and control systems (like PLCs, DCS, or industrial PCs), the landscape will be shaped by several key trends:

1. Increased Demand for Energy Efficiency and Power Quality:

* Focus: Reducing energy consumption and minimizing harmonic distortion will be paramount. Regulations (like ENERGY STAR for industrial equipment) and corporate sustainability goals will push manufacturers towards more efficient designs.

* Impact: Modules will feature lower power dissipation, higher efficiency power supplies (potentially using advanced topologies like resonant converters), and integrated power factor correction (PFC). Expect tighter specifications on standby power consumption and harmonics (THDi).

* 2026 Outlook: Modules meeting stringent efficiency standards (e.g., Level VI or beyond) will become the norm, not a premium option. Demand will rise for modules with active PFC, especially in applications sensitive to power quality.

2. Enhanced Integration and Connectivity (IIoT/Industry 4.0):

* Focus: The convergence of Operational Technology (OT) and Information Technology (IT) demands smarter, more connected field devices.

* Impact: Basic on/off status reporting will be insufficient. Modules will integrate:

* Diagnostics: Real-time monitoring of voltage, current, power consumption, temperature, and fault conditions (overvoltage, undervoltage, overload).

* Communications: Embedded support for industrial Ethernet protocols (Profinet, EtherNet/IP, Modbus TCP) or fieldbuses (Modbus RTU) directly on the module or via companion communication modules. This enables remote monitoring, predictive maintenance, and easier troubleshooting.

* Configurability: Software-configurable parameters (e.g., input thresholds, debounce times, diagnostic alarms) via configuration tools or web interfaces.

* 2026 Outlook: “Smart” 120Vac input modules with integrated diagnostics and communication will capture significant market share, particularly in new automation projects and retrofits aiming for digital transformation. Plug-and-play capability will be highly valued.

3. Heightened Focus on Reliability, Safety, and Resilience:

* Focus: Minimizing unplanned downtime in critical infrastructure and industrial processes.

* Impact:

* Robustness: Increased demand for modules with wider operating temperature ranges, higher surge immunity (e.g., meeting IEC 61000-4-5 Level 4), and resistance to vibration and harsh environments.

* Safety: Stricter adherence to safety standards (UL, CSA, IEC) regarding creepage, clearance, and isolation. Features like redundant isolation barriers or self-monitoring circuits may emerge.

* Predictive Maintenance: Integration of diagnostic data (from trend 2) enables predictive maintenance, shifting from reactive to proactive upkeep.

* 2026 Outlook: Reliability and safety will be key differentiators. Modules designed for mission-critical applications (power generation, water treatment, data centers) will command premium pricing. Cybersecurity features for connected modules will also gain importance.

4. Miniaturization and Space Optimization:

* Focus: Reducing control panel footprint and material costs.

* Impact: Continued pressure to pack more functionality into smaller form factors. This involves advanced PCB design, higher component density, and potentially new packaging materials/techniques (e.g., molded modules).

* 2026 Outlook: High-density modules (e.g., 16+ channels in a single 20-30mm width) will be standard. Expect innovations in thermal management to handle increased power density within smaller enclosures.

5. Supply Chain Resilience and Regionalization:

* Focus: Mitigating risks from global disruptions and geopolitical factors.

* Impact: Increased scrutiny on component sourcing (especially semiconductors), lead times, and geographic manufacturing footprint. Demand may rise for modules sourced or manufactured closer to key markets (North America, Europe).

* 2026 Outlook: Manufacturers with diversified, resilient supply chains and regional production capabilities will have a competitive advantage. “Reshoring” or “friend-shoring” trends may influence sourcing decisions for some customers.

6. Sustainability and Circular Economy:

* Focus: Reducing environmental impact throughout the product lifecycle.

* Impact: Growing emphasis on:

* Materials: Use of RoHS-compliant, recyclable materials, and reduction of hazardous substances.

* Longevity & Repairability: Design for longer service life and easier repair/recycling.

* Packaging: Minimalist, recyclable packaging.

* 2026 Outlook: Environmental credentials (e.g., EPDs – Environmental Product Declarations) will become more important in procurement decisions, especially for large industrial and governmental projects.

Conclusion:

The 120Vac Input Module market in 2026 will be characterized by a shift from simple, passive components towards intelligent, connected, and highly efficient devices. Success will depend on manufacturers’ ability to integrate advanced diagnostics and communication, enhance energy efficiency and reliability, ensure supply chain stability, and meet growing sustainability demands. While the fundamental electrical interface remains, the value proposition will increasingly lie in the data, intelligence, and resilience the module provides to the broader industrial automation ecosystem.

Common Pitfalls When Sourcing a 120Vac Input Module (Quality & IP Protection)

Sourcing a reliable 120Vac input module requires careful attention to both electrical quality and ingress protection (IP) ratings. Overlooking key factors can lead to premature failures, safety hazards, and system downtime. Below are the most common pitfalls to avoid:

Inadequate Electrical Safety and Compliance

One of the most critical mistakes is selecting modules that lack proper safety certifications. Using non-compliant input modules can pose serious fire or electric shock risks. Always verify that the module is certified by recognized bodies such as UL, CE, CSA, or IEC. Modules must comply with standards like IEC 61010 for measurement and control equipment or IEC 60950/62368 for IT equipment. Absence of these certifications may indicate substandard insulation, creepage, and clearance distances.

Poor Power Quality Handling

Many low-cost modules fail under real-world electrical conditions. Common issues include susceptibility to voltage sags, surges, and electrical noise. A quality 120Vac input module should include built-in surge protection (e.g., MOVs), EMI filtering, and wide input tolerance (e.g., 90–132Vac). Neglecting these features leads to unreliable operation in industrial environments with fluctuating line voltages or nearby inductive loads.

Misunderstanding or Ignoring IP Ratings

The IP (Ingress Protection) rating defines the level of protection against solids and liquids. A frequent error is assuming that any enclosure offers sufficient protection. For example, an IP20-rated module may be acceptable indoors but will fail in dusty or humid environments. Always match the IP rating to the operating environment—IP65 or higher is recommended for outdoor, washdown, or industrial settings. Beware of vague marketing claims; insist on verified IP test reports.

Compromising on Isolation and Insulation

Insufficient galvanic isolation between input and output circuits can result in ground loops, noise coupling, or damage to downstream electronics. High-quality modules provide reinforced insulation with adequate isolation voltage (e.g., 2.5kVac or higher) and meet creepage/clearance requirements based on pollution degree and overvoltage category (e.g., CAT II or CAT III). Skipping this verification risks system integrity and user safety.

Overlooking Long-Term Reliability and Component Quality

Cheap modules often use low-grade components (e.g., electrolytic capacitors with short lifespans, undersized relays) that degrade quickly under continuous load or thermal stress. This leads to higher failure rates and increased maintenance. Evaluate the manufacturer’s MTBF (Mean Time Between Failures) data and component sourcing. Reputable suppliers provide detailed datasheets and reliability testing information.

Assuming Universal Compatibility

Not all 120Vac input modules are compatible with every control system or PLC. Issues may arise with signal type (dry contact vs. wetted input), input impedance, or required pull-up/down resistors. Always cross-check the module’s electrical specifications with your control system’s input requirements to avoid false triggering or detection failures.

Neglecting Thermal and Environmental Performance

Even with the correct IP rating, poor thermal design can lead to overheating, especially in enclosed or high-ambient-temperature environments. Check the operating temperature range and derating curves. Modules that lack adequate thermal management may fail prematurely despite meeting other specs.

By addressing these common pitfalls—prioritizing certified quality, robust electrical design, appropriate IP protection, and environmental suitability—you ensure reliable and safe integration of 120Vac input modules into your system. Always source from reputable suppliers with technical support and transparent documentation.

Logistics & Compliance Guide for 120Vac Input Module

This guide outlines the logistics handling, shipping, storage, and regulatory compliance requirements for the 120Vac Input Module to ensure safe, efficient, and legally compliant operations throughout the supply chain.

Logistics Handling & Transportation

-

Packaging Requirements:

The 120Vac Input Module must be shipped in ESD-safe packaging with sufficient cushioning to prevent mechanical damage. Each unit should be individually sealed in static-dissipative bags and placed in a rigid container with foam inserts. -

Labeling:

All shipments must include: - Product name and part number

- Electrostatic discharge (ESD) sensitive symbol

- “Fragile” and “This Way Up” indicators

- Country of origin

-

Handling instructions in accordance with IEC 61340-5-1

-

Shipping Conditions:

- Temperature: -20°C to +60°C during transit

- Humidity: 10% to 90% non-condensing

- Avoid exposure to water, dust, and corrosive atmospheres

-

Stack limit: Maximum of 5 cartons high

-

Storage Conditions (Pre-Installation):

- Store in a clean, dry, temperature-controlled environment

- Recommended storage temperature: +15°C to +35°C

- Relative humidity: 30% to 60% RH

- Shelf life: 24 months from date of manufacture when unopened

Regulatory Compliance

- Electrical Safety:

The 120Vac Input Module complies with: - UL 60950-1 / UL 62368-1 (USA and Canada)

- IEC 62368-1 (International)

- CSA C22.2 No. 62368-1

-

Meets reinforced insulation requirements for 120Vac operation

-

Electromagnetic Compatibility (EMC):

Certified to: - FCC Part 15, Subpart B – Class A (USA)

- ICES-003 (Canada)

- EN 55032 / EN 55035 (Europe)

-

Immunity per EN 61000-6-2 and EN 61000-6-4

-

RoHS Compliance:

The module is RoHS 3 (Directive 2015/863/EU) compliant. Contains no restricted substances above threshold limits (Pb, Cd, Hg, Cr⁶⁺, PBB, PBDE, and four phthalates). -

REACH Regulation:

Compliant with REACH (EC 1907/2006). No Substances of Very High Concern (SVHC) above 0.1% weight by weight. -

CE Marking:

Bears the CE mark indicating conformity with European health, safety, and environmental standards. Technical documentation available upon request. -

UKCA Marking:

For UK market, complies with UKCA requirements under the UK’s post-Brexit regulatory framework. -

Packaging & Disposal:

- Packaging marked with recyclable symbols per ISO 18601-18606

- WEEE-compliant: Must be disposed of through certified electronic waste channels

- Do not dispose of in household waste (symbol: crossed-out wheeled bin)

Import/Export Considerations

- HS Code: 8537.10.00 (Control panels incorporating semiconductor devices)

- Export Control Classification Number (ECCN): 3A999 (No license required for most destinations)

- Documentation: Commercial invoice, packing list, and RoHS/REACH compliance certificate must accompany international shipments

- Battery/Chemical Content: None – no special handling under IATA/IMDG regulations

Declaration of Conformity

A full Declaration of Conformity (DoC) is available upon request and includes compliance statements for all applicable directives and standards listed above.

For questions or compliance documentation, contact:

[email protected]

+1 (800) XXX-XXXX

Conclusion for Sourcing 120VAC Input Module:

After evaluating technical requirements, availability, cost, and reliability, sourcing a 120VAC input module from established industrial automation suppliers (such as Allen-Bradley, Siemens, Omron, or Phoenix Contact) is recommended. These modules offer proven compatibility with PLC systems, provide necessary electrical isolation, surge protection, and noise immunity, and meet safety standards (UL, CE, etc.). Prioritizing modules with modular expandability, diagnostic features, and local supplier support ensures long-term maintainability and system uptime. A thorough assessment of lead times, total cost of ownership, and vendor reliability will further support a successful integration into the control system.