The global AC transformer market is experiencing steady growth, driven by rising electricity demand, infrastructure development, and the expansion of renewable energy systems. According to Grand View Research, the global transformer market size was valued at USD 45.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 7.3% from 2023 to 2030. A significant segment of this demand comes from step-down transformers, particularly 120V to 12V AC models, widely used in residential, commercial, and industrial applications such as lighting systems, HVAC controls, and low-voltage power supplies. With increasing adoption of smart buildings and energy-efficient technologies, the need for reliable and efficient transformers has never been higher. This growing demand has elevated the prominence of leading manufacturers who specialize in precision, durability, and compliance with international safety standards. Below are the top four manufacturers excelling in the production of 120V to 12V AC transformers, recognized for their innovation, global reach, and strong performance metrics.

Top 4 120V To 12V Ac Transformer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

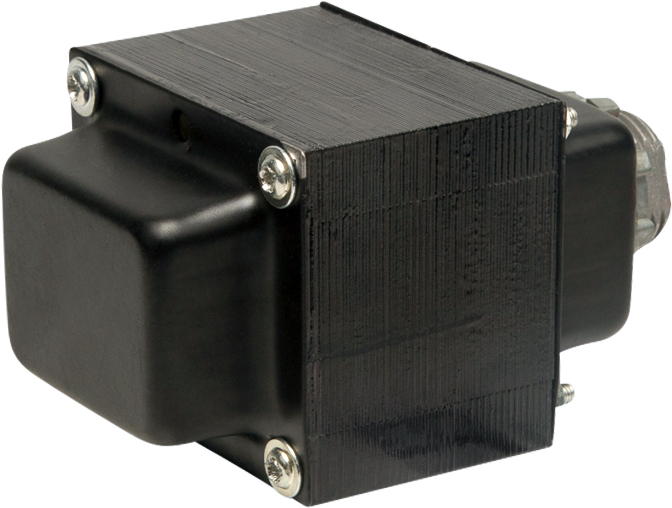

#1 FX Step Down Transformer (120V to 12V)

Domain Est. 1995

Website: siteone.com

Key Highlights: Converts 120V to 12V for versatile power options. Reliable FX brand ensures durability and long-lasting performance. Step down transformer for safe and ……

#2 Magnetic Transformers 120V and 277V to 12V or … – ELCO Lighting

Domain Est. 1997

Website: elcolighting.com

Key Highlights: Product Features · 20, 50, 250W Magnetic Transformers. · ETR12, ETR12-20: 120V AC Input to 12V AC Output · ETR-277, ETR277-20: 277V AC Input to 120V AC Output….

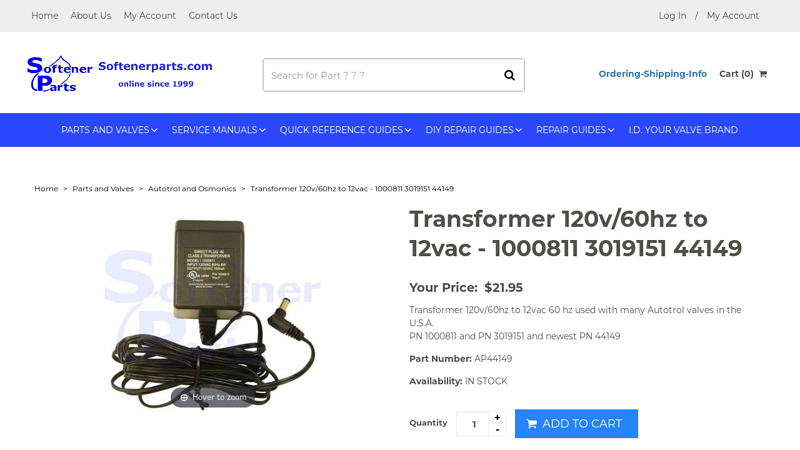

#3 Transformer 120v/60hz to 12vac

Domain Est. 1999

Website: softenerparts.com

Key Highlights: In stock $6 deliveryTransformer 120v/60Hz to 12 volt AC 60Hz used with many Autotrol valves in the USA ( North America Plug ). PN 1000811 and PN 3019151 and newest PN 44149…

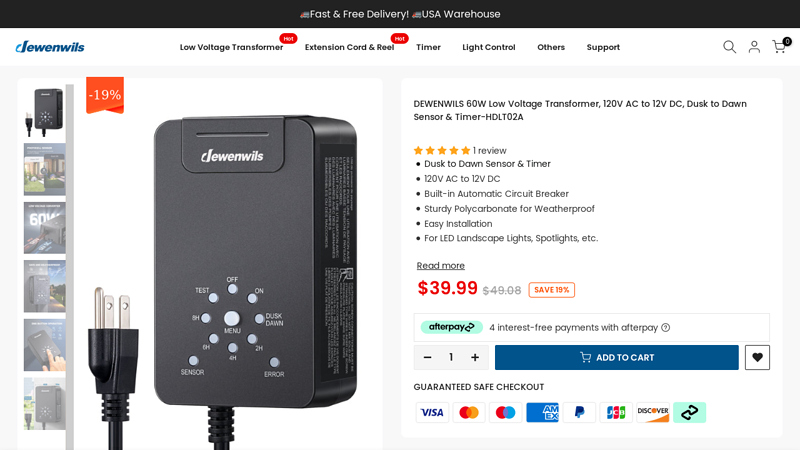

#4 60W Low Voltage Transformer 120V AC to 12V DC

Domain Est. 2016

Website: dewenwils.com

Key Highlights: 60W Low Voltage Transformer converts 120V AC to 12V DC, featuring dusk-to-dawn sensor and timer for automatic, safe, and efficient control of outdoor ……

Expert Sourcing Insights for 120V To 12V Ac Transformer

2026 Market Trends for 120V to 12V AC Transformers

The market for 120V to 12V AC transformers is undergoing significant transformation driven by technological advancements, shifting consumer demands, and evolving regulatory landscapes. By 2026, several key trends are expected to shape the industry, influencing product design, market dynamics, and competitive positioning.

Rising Demand for Energy Efficiency and Regulatory Compliance

By 2026, stringent global energy efficiency standards such as the U.S. Department of Energy (DOE) Level VI and EU Ecodesign Directive will dominate the market. Consumers and commercial users will increasingly favor 120V to 12V transformers with ultra-low no-load power consumption and high operational efficiency. Manufacturers will respond by integrating advanced core materials (e.g., amorphous metal, nanocrystalline) and improved winding techniques to reduce energy losses. Compliance will no longer be optional but a prerequisite for market entry, pushing legacy, inefficient models out of mainstream distribution.

Shift Toward Compact, Integrated, and Smart Power Solutions

The trend toward miniaturization and multifunctionality will accelerate. Traditional standalone 120V to 12V AC transformers will face growing competition from compact switch-mode power supplies (SMPS) and integrated power modules that offer higher efficiency, lighter weight, and smaller footprints. Additionally, demand for smart transformers with built-in monitoring, surge protection, and remote control capabilities—especially in home automation and IoT ecosystems—will rise. These intelligent systems will enable real-time energy tracking and predictive maintenance, appealing to tech-savvy consumers and industrial users alike.

Growth in Niche and Retrofit Applications

While general-purpose AC transformers face commoditization, specialized segments are projected to grow. These include applications in landscape lighting, HVAC control systems, security systems, and legacy equipment maintenance. The need to retrofit older buildings or replace outdated power supplies will sustain demand for reliable, durable 12V AC solutions. Furthermore, regions with inconsistent power grids will continue to rely on robust transformers for voltage stabilization, supporting continued demand in emerging markets.

Supply Chain Diversification and Regional Manufacturing

Geopolitical tensions and supply chain disruptions will drive a trend toward regionalized production. By 2026, manufacturers may shift assembly or sourcing closer to end markets—particularly in North America and Europe—to reduce lead times and mitigate risks. This localization will support faster delivery and customization, especially for industrial and commercial clients requiring specific certifications or configurations. Simultaneously, cost pressures will keep a portion of manufacturing in Asia, fostering a hybrid supply model.

Environmental and Sustainability Pressures

End-of-life management and material sustainability will gain prominence. Demand for recyclable materials, lead-free soldering, and reduced packaging waste will influence product design. Some manufacturers may introduce take-back programs or eco-labeling to appeal to environmentally conscious buyers. Additionally, the long-term phase-out of certain materials due to RoHS and REACH regulations will necessitate ongoing R&D investment to maintain compliance without sacrificing performance.

In summary, the 2026 market for 120V to 12V AC transformers will be defined by efficiency, intelligence, and specialization. While traditional linear transformers persist in niche roles, innovation and regulation will push the industry toward smarter, greener, and more compact alternatives. Companies that adapt to these trends—through technological investment, regulatory foresight, and customer-centric design—will be best positioned to capture value in an evolving landscape.

Common Pitfalls When Sourcing a 120V to 12V AC Transformer (Quality and IP Rating)

Sourcing a reliable and safe 120V to 12V AC transformer requires careful attention to both quality and Ingress Protection (IP) rating. Overlooking these factors can lead to premature failure, safety hazards, or unsuitability for the intended environment. Below are the most common pitfalls to avoid:

Underestimating Quality Differences

Not all transformers are built to the same standard. Prioritizing low cost over quality often leads to significant issues:

- Poor Core and Winding Materials: Low-grade steel in the core increases hysteresis and eddy current losses, resulting in overheating and reduced efficiency. Similarly, undersized or poorly insulated copper windings can degrade quickly under load.

- Inadequate Insulation and Isolation: Substandard insulation between windings or from primary to secondary can compromise safety, increasing the risk of electric shock or short circuits—especially critical in medical or damp environments.

- Lack of Safety Certifications: Avoid transformers without recognized certifications (e.g., UL, CSA, CE). These indicate compliance with safety, efficiency, and electromagnetic interference (EMI) standards. Uncertified units may not meet local electrical codes.

- Inaccurate Voltage Regulation: Cheap transformers often exhibit poor voltage regulation, delivering significantly higher than 12V under light load, which can damage sensitive loads like control relays or lighting systems.

Ignoring Ingress Protection (IP) Rating Needs

The IP rating defines protection against solids and liquids—overlooking this can lead to premature failure in harsh environments:

- Using Indoor Transformers Outdoors: Standard open-frame or encapsulated transformers without adequate IP ratings (e.g., IP20) will fail quickly when exposed to moisture, dust, or insects. Always match the IP rating to the environment.

- Overestimating Enclosure Protection: Assuming that placing a low-IP transformer in a cabinet is sufficient can be misleading. Condensation, dust ingress through vents, or inadequate sealing still pose risks. Use transformers with appropriate IP ratings (e.g., IP65 or higher for outdoor/wet locations).

- Confusing IP Ratings: Misinterpreting what the two digits mean—e.g., IP65 (dust-tight and protected against water jets) vs. IP44 (protected against solid objects >1mm and splashing water)—can result in selecting the wrong product for the application.

Additional Considerations

- Thermal Management: Even high-quality transformers can overheat if undersized or installed in poorly ventilated enclosures. Always verify thermal performance under expected load and ambient conditions.

- EMI and Noise: Low-quality transformers may generate excessive electromagnetic interference, disrupting nearby electronics. Look for units with proper shielding and low hum design.

- Long-Term Availability and Support: Sourcing from obscure brands or suppliers may lead to difficulties in replacing units or obtaining technical support down the line.

By carefully evaluating transformer quality and selecting the correct IP rating for the operating environment, you can ensure reliability, safety, and longevity in your application.

Logistics & Compliance Guide for 120V to 12V AC Transformer

This guide provides essential information for the safe and compliant handling, shipping, customs clearance, and use of 120V to 12V AC transformers. Adhering to these guidelines ensures regulatory compliance, protects personnel, and supports smooth international trade.

Classification & Documentation

- HS Code (Harmonized System Code): Typically classified under 8504.31.40 or 8504.31.80 (Other electrical transformers, with input voltage ≤ 1,000V), depending on specific design and power rating. Confirm with local customs authority.

- Commercial Invoice: Must include detailed product description (e.g., “Step-Down AC Transformer, Input: 120V, Output: 12V, Frequency: 60Hz, Power: XX VA”), quantity, unit price, total value, country of origin, and HS code.

- Packing List: Itemize contents per package, including weights and dimensions.

- Certificate of Origin: Required in some countries for tariff determination and trade agreements.

- Safety Certification Marks: Include copies of certification documentation (e.g., UL, CSA, CE) where applicable.

Regulatory Compliance

- North America (USA/Canada):

- UL Certification (Underwriters Laboratories): Required for sale in the U.S. Look for UL 506 or UL 1012 listing.

- CSA Certification (Canadian Standards Association): Required for Canada. CSA C22.2 No. 66 or similar.

- FCC Compliance: Must meet electromagnetic interference (EMI) standards under Part 15 if applicable.

-

Energy Efficiency: No specific DOE rules for low-voltage transformers, but efficiency may be considered under voluntary programs.

-

European Union:

- CE Marking: Mandatory. Must comply with:

- Low Voltage Directive (LVD) 2014/35/EU: Electrical safety.

- EMC Directive 2014/30/EU: Electromagnetic compatibility.

- RoHS Directive 2011/65/EU: Restriction of hazardous substances (e.g., lead, cadmium).

-

Ecodesign Directive (ErP): May apply to energy efficiency for certain transformer types (check EU Regulation 548/2014).

-

Other Regions:

- UK: UKCA marking required post-Brexit (similar requirements to CE).

- Australia/NZ: RCM (Regulatory Compliance Mark) under AS/NZS 61558.1.

- Asia (e.g., China, Korea): May require CCC, KC, or other local certifications.

Shipping & Handling

- Packaging:

- Use sturdy, double-walled corrugated boxes with internal cushioning (e.g., foam, bubble wrap).

- Protect terminals and windings from physical shock and moisture.

-

Clearly label with orientation arrows (“This Side Up”) and fragile indicators.

-

Labeling Requirements:

- Include input/output voltage (120V → 12V), frequency (e.g., 60Hz), power rating (VA or watts), model number, and manufacturer.

- Apply required safety marks (UL, CE, etc.).

-

Include warnings: “Caution: Risk of Electric Shock,” “Do Not Open,” and “For Indoor Use Only” if applicable.

-

Transportation:

- Ship via standard freight (air or sea); no special hazardous material designation required unless containing PCBs (obsolete).

- Avoid extreme temperatures and humidity during storage and transit.

- Stack loads properly; do not exceed pallet weight limits.

Import/Export Considerations

- Import Duties & Taxes: Vary by country. Use correct HS code to determine duty rates.

- Restricted Materials: Ensure compliance with RoHS, REACH (EU), and TSCA (USA) regarding banned substances.

- End-of-Life Disposal: Must comply with WEEE (Waste Electrical and Electronic Equipment) in the EU and similar e-waste programs elsewhere. Inform customers of proper recycling procedures.

Safety & Usage Guidelines

- Installation:

- Use only with properly rated input voltage (120V AC, 60Hz typical in North America).

- Ensure adequate ventilation to prevent overheating.

-

Mount on non-combustible surfaces if required.

-

User Instructions:

- Do not overload beyond rated VA/wattage.

- Disconnect power before servicing.

-

Use only with compatible 12V AC loads (e.g., doorbells, low-voltage lighting).

-

Maintenance:

- Inspect for damage, overheating, or unusual noise before use.

- Clean only with dry cloth; do not immerse in liquid.

Record Keeping & Traceability

- Maintain records of certifications, test reports, and compliance documentation for a minimum of 10 years.

- Assign batch/lot numbers for traceability in case of recalls or quality issues.

By following this guide, manufacturers, distributors, and importers can ensure that 120V to 12V AC transformers meet global logistics and compliance requirements while promoting safe and reliable operation.

In conclusion, sourcing a 120V to 12V AC transformer requires careful consideration of several key factors including power rating (VA or wattage), primary and secondary voltage compatibility, physical size, mounting style, efficiency, and safety certifications. It is essential to match the transformer specifications with the load requirements of the intended application—such as doorbells, HVAC systems, or low-voltage lighting—to ensure reliable and safe operation. Additionally, opting for a UL-listed or similarly certified transformer ensures compliance with safety standards and reduces risks of overheating or electrical hazards. Whether purchasing from electrical suppliers, online marketplaces, or industrial distributors, verifying product authenticity and specifications will lead to a successful integration into your electrical system. With the right selection, a 120V to 12V AC transformer provides a dependable solution for stepping down household voltage to a safer, usable level for various low-voltage applications.