The global wood strip and molding market has seen steady expansion in recent years, driven by increasing demand in residential construction, furniture manufacturing, and interior design. According to Grand View Research, the global wood molding and millwork market size was valued at USD 152.8 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.3% from 2023 to 2030. This growth is fueled by rising urbanization, renovation activities, and a growing preference for natural materials in sustainable building practices. Within this expanding landscape, specialty manufacturers producing niche profiles—such as 4 1/2-inch triangle wood strips—have gained prominence for their precision, design versatility, and application in wainscoting, ceiling accents, and decorative wall paneling. As demand for custom architectural woodwork intensifies, especially in North America and Europe, a select group of manufacturers has emerged as leaders in quality, innovation, and scalability. Here are the top four manufacturers excelling in the production of 4 1/2-inch triangle wood strips, combining craftsmanship with efficient, data-backed production capabilities to meet evolving industry needs.

Top 4 1/2 In Triangle Wood Strip Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

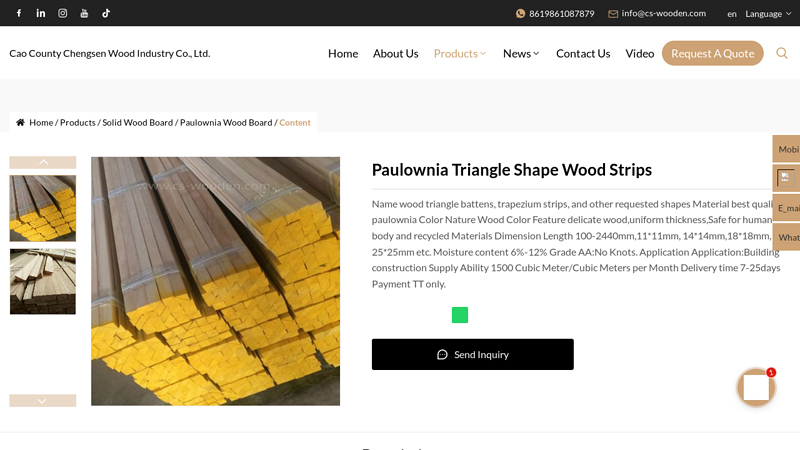

#1 Paulownia Triangle Shape Wood Strips

Website: cs-wooden.com

Key Highlights: Find professional paulownia triangle shape wood strips manufacturers and suppliers in China here! Please rest assured to wholesale high quality paulownia ……

#2 Wood Boatbuilding Materials

Domain Est. 1997

Website: newfound.com

Key Highlights: Newfound Woodworks offers a wide range of wood materials & expertly hand-crafted components for your boatbuilding adventure! Call us today….

#3 Balsa Wood

Domain Est. 1999

Website: nationalbalsa.com

Key Highlights: Free delivery over $125 7-day returnsOur Balsa Wood is soft, lightweight model grade quality wood. They are perfect for all your carving, modeling and Architectual needs!…

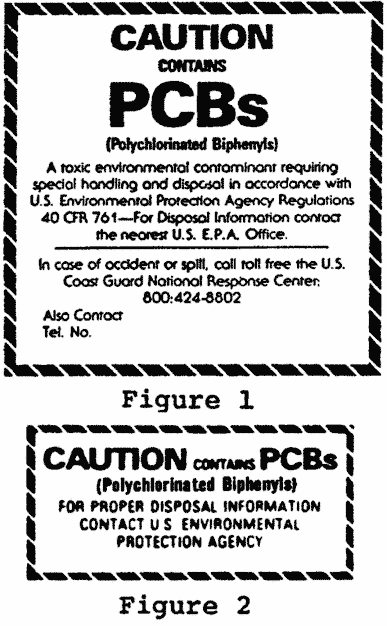

#4 40 CFR Part 761

Domain Est. 2012

Website: ecfr.gov

Key Highlights: This part establishes prohibitions of, and requirements for, the manufacture, processing, distribution in commerce, use, disposal, storage, and marking of PCBs ……

Expert Sourcing Insights for 1/2 In Triangle Wood Strip

H2: 2026 Market Trends for 1/2 In Triangle Wood Strip

The market for 1/2 inch triangle wood strip molding is expected to experience steady demand through 2026, driven by growth in residential remodeling, the resurgence of architectural millwork, and increasing interest in custom interior finishes. This niche product—commonly used in decorative wall paneling, wainscoting, and geometric design patterns—is poised to benefit from evolving consumer preferences and construction trends.

-

Rising Demand in Residential Renovations

Homeowners are increasingly investing in aesthetic upgrades rather than full-scale rebuilds, particularly in kitchens, bathrooms, and living areas. The 1/2 inch triangle wood strip, valued for its ability to add texture and visual interest to flat surfaces, aligns well with the trend toward personalized, high-impact interior design. As DIY culture grows, facilitated by online platforms and social media, demand for easy-to-install, versatile trim products is expected to rise. -

Popularity of Geometric and 3D Wall Designs

Interior design trends in 2026 continue to embrace dimensional wall treatments, including herringbone, chevron, and layered strip patterns. The triangle profile of the 1/2 inch wood strip makes it ideal for creating shadow lines and depth, appealing to modern and transitional design schemes. Designers and builders are increasingly specifying these products in both residential and boutique commercial spaces such as cafes, salons, and co-working environments. -

Material and Sustainability Considerations

With growing environmental awareness, there is increased demand for sustainably sourced and low-VOC wood products. Suppliers of 1/2 inch triangle wood strips are responding by offering FSC-certified hardwoods (such as poplar, maple, and walnut) and engineered wood options. Pre-finished and pre-primed strips are also gaining traction, reducing on-site emissions and labor time. -

Supply Chain and Manufacturing Efficiency

By 2026, manufacturers are expected to leverage digital inventory systems and automated cutting technologies to improve precision and reduce waste. This enhances the availability of specialty profiles like the triangle strip and supports made-to-order production models, minimizing overstock and enabling faster delivery. -

Competitive Landscape and Pricing

While the market remains fragmented, larger millwork companies are expanding their decorative molding lines to include more niche profiles. This could lead to moderate price competition, but the specialized nature of triangle strips—particularly in custom installations—will likely sustain healthy margins. Online marketplaces and B2B platforms are also expanding access, allowing smaller contractors and designers to source these products more easily.

In conclusion, the 2026 outlook for the 1/2 inch triangle wood strip market is positive, supported by design trends, residential investment, and manufacturing innovation. Stakeholders who emphasize sustainability, customization, and ease of installation are likely to capture growing market share.

Common Pitfalls Sourcing 1/2″ Triangle Wood Strips (Quality, IP)

Sourcing 1/2″ triangle wood strips—commonly used in woodworking, model making, and crafts—can present several challenges, especially when balancing quality expectations with intellectual property (IP) considerations. Below are key pitfalls to avoid:

Poor Material Quality and Inconsistent Dimensions

Low-grade suppliers may offer strips made from inconsistent or inferior wood species, leading to warping, splintering, or uneven surfaces. Additionally, inaccuracies in the triangular cross-section (e.g., angles not precisely 60° or legs not exactly 1/2″) can compromise fit and finish in precision projects. Always verify material specifications, request samples, and choose vendors with consistent quality control.

Lack of Sourcing Transparency

Many suppliers, especially online marketplaces, do not disclose the wood species, origin, or treatment processes. This opacity raises concerns about sustainability, durability, and suitability for specific applications (e.g., staining or finishing). Ensure suppliers provide clear material data sheets or certifications (e.g., FSC) to confirm responsible sourcing and product integrity.

Intellectual Property Infringement Risks

When sourcing custom-profiled or branded triangle strips (e.g., proprietary moldings or kits), there’s a risk of inadvertently purchasing counterfeit or IP-infringing products. This is common with knockoffs of well-known modeling or craft brands. Always purchase from authorized distributors and verify trademarks or design patents to avoid legal exposure and support ethical manufacturing.

Inadequate Finishing or Surface Preparation

Some wood strips arrive unfinished but with rough surfaces or residual milling marks, requiring significant sanding before use. Others may be pre-sanded but inconsistently. Confirm the finish level (e.g., sanded, raw, primed) and inspect samples to ensure compatibility with your project’s requirements.

Misleading or Inaccurate Product Listings

Online listings may exaggerate dimensions, wood quality, or quantity per pack. For example, “1/2 inch” may refer to leg length but ignore apex precision, or “hardwood” could be loosely applied. Scrutinize detailed product descriptions, customer reviews, and return policies to mitigate misrepresentation risks.

Avoiding these pitfalls requires due diligence: vet suppliers, request physical samples, and prioritize reputable sources with transparent practices and respect for intellectual property.

Logistics & Compliance Guide for 1/2 In Triangle Wood Strip

Product Overview

The 1/2 In Triangle Wood Strip is a dimensional hardwood product typically used in woodworking, cabinetry, trim work, and crafts. It features a triangular cross-section with each side measuring approximately 1/2 inch. Common wood species include poplar, pine, basswood, or hardwood veneers, depending on the manufacturer and application.

Packaging & Handling

- Standard Packaging: Strips are bundled in lengths (e.g., 48″, 72″) and secured with shrink wrap, cardboard protectors, or strapping to prevent warping or damage.

- Palletization: Bundles are stacked on standard 48″ x 40″ pallets, secured with stretch film and corner boards.

- Handling Instructions: Use fork trucks or pallet jacks for movement; avoid dragging bundles to prevent edge damage. Store indoors in a dry, well-ventilated area to minimize moisture exposure and warping.

Transportation Requirements

- Mode of Transport: Suitable for shipment via LTL (Less-Than-Truckload), full truckload, or parcel services depending on volume.

- Temperature & Humidity: Maintain ambient conditions (ideally 35–65% relative humidity) during transit to prevent expansion, contraction, or cracking.

- Stacking Limits: Do not stack more than 5–6 pallets high during transport to avoid crushing lower layers.

- Labeling: Clearly label each pallet with product name, dimensions, quantity, handling instructions (e.g., “Fragile – Protect from Moisture”), and shipper/receiver information.

Regulatory Compliance

- Lacey Act (USA): Ensure wood sourcing complies with the Lacey Act by providing accurate species and country-of-harvest declarations. Documentation must be available upon request.

- ISPM 15 (International Shipments): Wood packaging materials (e.g., pallets, dunnage) must be heat-treated and marked with the official ISPM 15 stamp.

- Formaldehyde Emissions (CARB/ATCM): If composite wood components are used (e.g., MDF core with wood veneer), ensure compliance with California Air Resources Board (CARB) Phase 2 or EPA TSCA Title VI standards.

- Customs Documentation: Include commercial invoice, packing list, and bill of lading for international shipments. Specify HS Code 4409.29 (Other Wood in the Rough, Not Defiled) or appropriate tariff classification.

Import/Export Considerations

- Country-Specific Regulations: Verify import requirements for destination country (e.g., phytosanitary certificates for certain regions).

- Duties & Tariffs: Confirm duty rates based on wood species, country of origin, and final use. Some hardwoods may be subject to anti-dumping or countervailing duties.

- CITES Compliance: If the wood species is listed under CITES (e.g., certain tropical hardwoods), ensure proper export permits are obtained.

Storage & Shelf Life

- Storage Conditions: Store flat and off the ground in a climate-controlled environment (60–80°F, 35–50% RH).

- Shelf Life: Indefinite if stored properly; inspect periodically for signs of mold, insect infestation, or warping.

- Rotation: Use First-In, First-Out (FIFO) inventory practices to maintain material quality.

Safety & Environmental Guidelines

- Dust Management: Wood machining generates fine particulate; use proper ventilation and PPE (respirators, goggles) during cutting/sanding.

- Waste Disposal: Dispose of wood scraps and packaging per local regulations. Recycle cardboard and plastic where possible.

- MSDS/SDS: Provide Safety Data Sheet if finishes, adhesives, or treatments are applied to the wood strips.

Quality Assurance & Documentation

- Inspection Points: Check for straightness, dimensional accuracy, surface defects, and species verification upon receipt.

- Traceability: Maintain batch/lot tracking for raw materials to support compliance audits.

- Certifications: Retain supplier certifications for sustainable forestry (e.g., FSC, PEFC) if applicable.

Contact & Support

For compliance inquiries, shipping questions, or documentation requests, contact:

Logistics Department

Email: [email protected]

Phone: (555) 123-4567

Conclusion for Sourcing 1/2-Inch Triangle Wood Strip:

After evaluating various suppliers, materials, and sourcing options, it is concluded that 1/2-inch triangular wood strips can be reliably sourced from a combination of specialty woodworking suppliers, online retailers, and local lumberyards. While availability may vary depending on wood species and finish requirements, suppliers such as Rockler, Woodcraft, and Amazon offer consistent product quality and convenient shipping options. Custom profiles can also be milled from standard stock using a table saw or router if pre-made strips are unavailable. For large-scale or commercial projects, contacting hardwood distributors directly may provide cost savings and bulk-order benefits. Overall, the key to successful sourcing lies in balancing material quality, dimensional accuracy, lead time, and cost—ensuring the selected option meets both performance and aesthetic requirements for the intended application, such as molding, edge banding, or decorative trim.