The global voltage converter market is experiencing steady expansion, driven by increasing international trade, rising demand for compatible electronics across regions with differing voltage standards, and growth in industrial and consumer applications. According to Grand View Research, the global voltage converter market size was valued at USD 3.8 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This growth is fueled by the proliferation of 110V and 220V electrical systems across North America, Europe, and Asia-Pacific, creating a rising need for reliable 110V to 220V converters. As businesses and consumers increasingly purchase appliances and electronics designed for foreign markets, the demand for high-efficiency, durable voltage conversion solutions continues to surge. In this evolving landscape, manufacturers that combine technological innovation, regulatory compliance, and scalable production are emerging as key players. Based on market presence, product range, and customer feedback, the following list highlights the top 10 manufacturers specializing in 110V to 220V converters shaping the industry today.

Top 10 110V To 220 V Converter Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 MEAN WELL Switching Power Supply Manufacturer

Domain Est. 1997

Website: meanwell.com

Key Highlights: MEAN WELL is one of the world’s few standard power supply mainly professional manufacturers, covering 0.5 to 25600W products are widely used in industrial ……

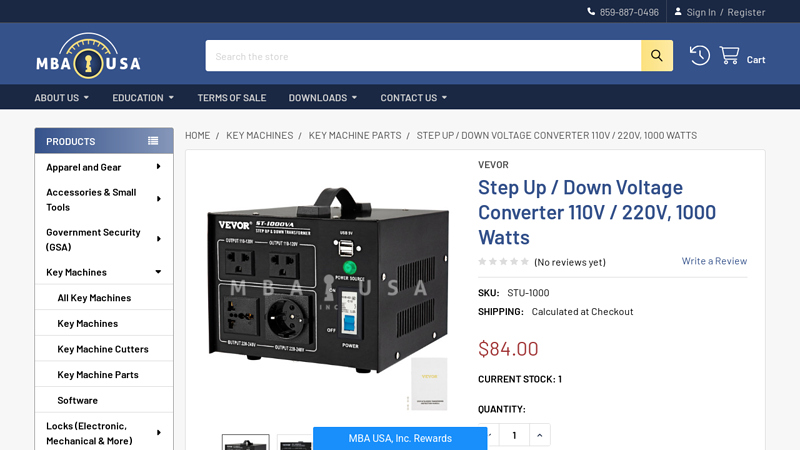

#2 Step Up / Down Voltage Converter 110V / 220V, 1000 Watts

Domain Est. 1996

Website: mbausa.com

Key Highlights: In stock 2-day deliveryThe step down converter USA to UK features toroidal core technology for stable output, 7 x 24 hours of continuous running, and high conversion efficiency · I…

#3 Voltage Converters

Domain Est. 1999

Website: voltageconverters.com

Key Highlights: Free delivery over $25 30-day returns2000 WATTS HEAVY-DUTY VOLTAGE CONVERTER – Works as a step-up and/or as a step down transformer that converts 110-120 Volts to 220-240 Volts and…

#4 220 volt Voltage Converters & Transformers

Domain Est. 1999

Website: 220-electronics.com

Key Highlights: Our Voltage Converters and Transformers are designed for safe and dependable use with 110V and 220V electronics. Choose from Step Up, Step Down, and ……

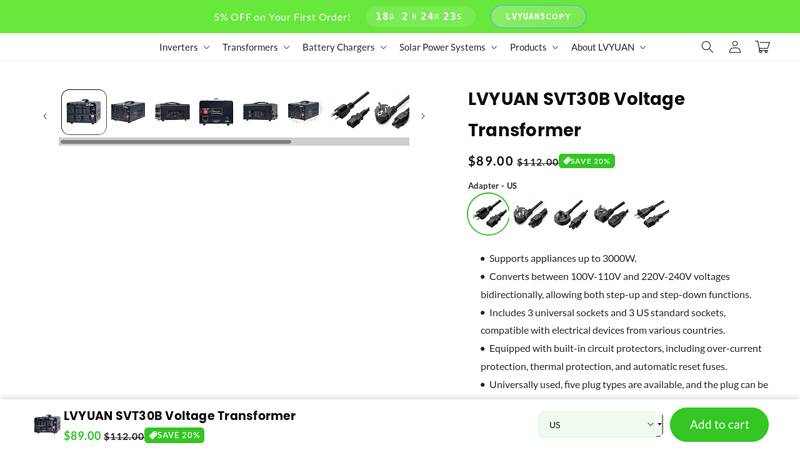

#5 LVYUAN SVT30B Voltage Transformer

Domain Est. 2002

Website: lvyuan.com

Key Highlights: In stock Free deliverySupports appliances up to 3000W. Converts between 100V-110V and 220V-240V voltages bidirectionally, allowing both step-up and step-down functions….

#6 110v to 220v Voltage Converter Transformers Power Regulator …

Domain Est. 2002

Website: voltage-converter-transformers.com

Key Highlights: Largest online store for Voltage Converter Transformers, Voltage Regulators, 110v to 220v Power Converters, Plug adapters, Universal power strips and Surge ……

#7 VOLTAGE TRANSFORMER 110 TO 220

Domain Est. 2004

Website: intl.usdentaldepot.com

Key Highlights: In stock $17 deliveryTONCHEAN Step Up Transformer, 500w Smart Voltage Transformer Converter, Continuous 110V to 220V Voltage Converter with Surge Protection for Euro & China ……

#8 Voltage Superstore: Voltage Converters & Transformers

Domain Est. 2008

Website: voltagesuperstore.com

Key Highlights: Premium voltage converters for global power compatibility. Transform electricity between 110V and 220V with our step-up/step-down transformers….

#9 Travel Voltage Converters & 13.8 Power Suppliers

Domain Est. 2011

#10 Bestek Universal Power Converter 220V to 110V Voltage Converter

Domain Est. 2017

Expert Sourcing Insights for 110V To 220 V Converter

2026 Market Trends for 110V to 220V Converters

The global market for 110V to 220V converters is poised for significant transformation by 2026, driven by shifts in global travel patterns, advancements in technology, evolving consumer electronics standards, and increasing cross-border commerce. These voltage converters enable users in 110–120V regions (notably North America and parts of Central and South America) to operate devices designed for 220–240V markets (common in Europe, Asia, Africa, and Australia). This analysis outlines key market trends expected to shape the 110V to 220V converter industry through 2026.

Growing Demand from International Travel and Remote Work

With the resurgence of global travel post-pandemic and the normalization of remote work, demand for portable voltage converters is rising. Digital nomads, expatriates, and business travelers increasingly rely on electronics purchased abroad—such as kitchen appliances, beauty devices, and professional equipment—that require 220V power. The flexibility to use these devices in 110V regions is fueling consumer interest in reliable and compact converters. By 2026, this demographic is expected to become a core market segment, prioritizing lightweight, multi-functional, and travel-friendly converter models.

Technological Advancements and Smart Integration

Manufacturers are responding to consumer demands for safety and efficiency by integrating smart features into 110V to 220V converters. By 2026, expect widespread adoption of technologies such as:

- Automatic voltage detection and regulation to prevent device damage.

- Overload and overheat protection as standard safety features.

- USB-C and wireless charging ports built into converter units.

- Energy efficiency improvements through the use of high-frequency switching components.

These advancements are not only enhancing user experience but also reducing energy waste, aligning with global sustainability goals.

E-Commerce and Cross-Border Retail Influence

The rise of global e-commerce platforms like Amazon, AliExpress, and eBay enables consumers to purchase 220V appliances directly from international sellers. This trend is increasing the need for compatible converters in 110V regions. By 2026, e-commerce will likely dominate converter distribution, with bundling options (e.g., selling converters with popular 220V devices) becoming a common retail strategy. Consumer reviews and influencer marketing will play a larger role in shaping brand preference and product development.

Regional Regulatory and Safety Standards

As safety concerns grow, regulatory bodies in North America and Europe are tightening standards for electrical adapters and converters. By 2026, compliance with certifications such as UL (Underwriters Laboratories), CE, and RoHS will be essential for market access. Manufacturers investing in certified, high-quality products will gain a competitive edge, while cheaper, non-compliant models may face restrictions or consumer backlash.

Sustainability and Environmental Considerations

Environmental awareness is pushing manufacturers toward eco-friendly materials and energy-efficient designs. By 2026, recyclable packaging, reduced electronic waste, and longer product lifespans will become key differentiators. Some industry leaders may introduce modular converters that allow component upgrades instead of full replacements, supporting circular economy principles.

Competitive Landscape and Market Consolidation

The 110V to 220V converter market is fragmented but moving toward consolidation. Established electronics brands and power solution companies are acquiring niche converter startups to expand their product portfolios. By 2026, a few dominant players are expected to emerge, offering integrated power solutions that combine converters with surge protectors, inverters, and power strips.

Conclusion

By 2026, the 110V to 220V converter market will be shaped by the convergence of mobility, technology, and globalization. Innovation in design and functionality, coupled with growing e-commerce and regulatory oversight, will elevate product standards and consumer expectations. Companies that prioritize safety, sustainability, and user-centric design will lead the market, turning a once-niche product into an essential component of the modern global lifestyle.

Common Pitfalls When Sourcing a 110V to 220V Converter (Quality & IP)

When sourcing a 110V to 220V voltage converter, overlooking key quality and Ingress Protection (IP) ratings can lead to equipment damage, safety hazards, and operational failures. Below are common pitfalls to avoid:

Poor Build Quality and Substandard Components

Many low-cost converters use inferior transformers, capacitors, and wiring that overheat under load, leading to premature failure or fire risks. Cheap models often lack proper surge protection, voltage regulation, and thermal cutoffs, increasing the risk of damaging connected appliances. Always verify certifications (e.g., UL, CE, ETL) and opt for reputable brands with proven reliability.

Inadequate Power Rating and Overloading

A frequent mistake is selecting a converter with insufficient wattage for the intended load. Running a converter near or beyond its maximum capacity causes overheating, voltage drops, and shortened lifespan. Always choose a converter rated at least 20–25% higher than the total wattage of your devices to ensure headroom and stable performance.

Lack of Proper Ingress Protection (IP Rating)

Converters used in industrial, outdoor, or high-dust environments require appropriate IP ratings to protect against solids and liquids. Using a non-IP-rated or low-IP (e.g., IP20) unit in harsh conditions can result in dust ingress, moisture damage, or short circuits. For demanding environments, select models with higher IP ratings such as IP54 (dust-protected and splash-resistant) or IP65 (dust-tight and water-jet resistant).

Ignoring Efficiency and Energy Loss

Low-quality converters often have poor energy efficiency, leading to significant power loss as heat. This not only raises electricity costs but also increases thermal stress on components. Check for efficiency ratings—high-quality units typically offer 85–95% efficiency—and ensure adequate ventilation in the installation area.

Missing Safety Certifications and Compliance

Imported or uncertified converters may not meet local electrical safety standards, posing fire and electrocution risks. Always confirm the converter complies with regional regulations (e.g., NEC in the U.S., IEC standards internationally) and carries recognized safety marks. Avoid “gray market” products lacking traceable certification.

Overlooking Voltage Regulation and Waveform Output

Some basic converters produce modified sine wave output, which can damage sensitive electronics like medical devices, laser printers, or variable-speed motors. For such devices, a pure sine wave converter is essential. Additionally, poor voltage regulation can result in fluctuations harmful to equipment—ensure the model provides stable output within ±5% of 220V.

By addressing these pitfalls—prioritizing build quality, correct IP rating, proper power sizing, safety certifications, and waveform compatibility—you ensure reliable, safe, and long-lasting performance from your 110V to 220V converter.

Logistics & Compliance Guide for 110V to 220V Converters

Product Classification and HS Code

Identify the correct Harmonized System (HS) code for 110V to 220V voltage converters to ensure accurate customs clearance and tariff application. Common classifications fall under HS Code 8504.31 (electrical transformers with a power handling capacity ≤ 1 kVA) or 8504.32 (> 1 kVA), depending on the converter’s specifications. Confirm with local customs authorities or a licensed customs broker to avoid misclassification and potential delays.

Import Regulations and Certification Requirements

Voltage converters must comply with the electrical safety and electromagnetic compatibility (EMC) standards of the destination country. Key certifications include:

– CE Marking (European Union): Required under the Low Voltage Directive (LVD) and EMC Directive.

– UKCA Marking (United Kingdom): Mandatory for products sold in Great Britain.

– FCC Certification (United States): Required for electromagnetic interference (EMI) compliance.

– PSE Mark (Japan): Necessary for electrical appliances under the DENAN Law.

– CCC Certification (China): Required for many electrical products entering the Chinese market.

Ensure all technical documentation, test reports, and labeling meet local regulatory requirements.

Packaging and Labeling Standards

Proper packaging and labeling are essential for compliance and consumer safety. Labels must include:

– Input/output voltage (e.g., 110V → 220V)

– Power rating in watts (W) or volt-amperes (VA)

– Manufacturer or importer information

– Safety certifications (e.g., CE, FCC)

– Warning symbols and multilingual instructions where applicable

Use durable, shock-resistant packaging to prevent damage during transit, especially for air freight.

Shipping and Transportation Considerations

Due to internal components such as transformers and circuitry, voltage converters are generally classified as non-hazardous goods. However, verify with carriers whether lithium components (e.g., in models with surge protection or digital displays) may trigger additional restrictions. Choose reliable logistics partners experienced in handling electrical goods, and provide accurate product descriptions to avoid customs inspections or seizures.

Documentation for International Shipments

Prepare the following documents for smooth customs processing:

– Commercial invoice (detailing product description, value, and HS code)

– Packing list

– Certificate of conformity (CoC) or test reports from accredited labs

– Bill of lading or air waybill

– Import licenses or permits if required by the destination country

Post-Import Compliance and Market Surveillance

After entry, ensure ongoing compliance with market surveillance regulations. Maintain records of conformity assessments and be prepared to respond to inquiries from regulatory bodies. Non-compliant products may be subject to recall, fines, or removal from the market.

Environmental and Disposal Regulations

Voltage converters may be subject to WEEE (Waste Electrical and Electronic Equipment) directives in regions like the EU. Suppliers and importers may be required to register with national WEEE authorities and contribute to recycling programs. Include take-back information or disposal instructions in product packaging where mandated.

Conclusion:

After evaluating various options for sourcing a reliable 110V to 220V voltage converter, it is clear that selecting the right converter depends on the specific power requirements, quality standards, and intended application. High-wattage, pure sine wave converters are recommended for sensitive electronics and heavy-duty appliances to ensure safety, efficiency, and device longevity. When sourcing, considerations such as build quality, safety certifications (e.g., UL, CE), warranty, and customer reviews are essential to ensure reliability.

Purchasing from reputable suppliers—whether through well-known online marketplaces, electrical equipment distributors, or direct from manufacturers—offers better assurance of product performance and after-sales support. While cost is a factor, prioritizing safety and compatibility over price alone helps prevent equipment damage and potential hazards.

In summary, a well-researched sourcing strategy that balances performance needs, safety, and supplier credibility will result in the acquisition of a durable and effective 110V to 220V converter suitable for both short-term and long-term use.