The global ultraviolet (UV) laser market is experiencing robust growth, driven by rising demand for high-precision manufacturing in industries such as electronics, semiconductors, and medical devices. According to Mordor Intelligence, the UV laser market was valued at approximately USD 1.2 billion in 2023 and is projected to grow at a CAGR of over 9.5% during the forecast period from 2024 to 2029. This expansion is fueled by the increasing adoption of UV lasers in micro-machining, marking, and lithography applications, where their short wavelength enables superior accuracy and minimal thermal impact. In particular, 10W UV lasers have emerged as a sweet spot between performance and cost-effectiveness, making them highly sought after in industrial automation and advanced manufacturing environments. With technological advancements and growing demand for miniaturized components, manufacturers capable of delivering reliable, high-power UV solutions are positioned at the forefront of this upward trend. The following list highlights the top eight manufacturers leading innovation and market share in the 10W UV laser segment, based on production capacity, R&D investment, global reach, and customer application support.

Top 8 10W Uv Laser Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 RFH Laser

Website: rfhtech.com

Key Highlights: As the leading industrial solid-state laser manufacturer, RFH laser company offer 355nm ultraviolet laser, 532nm green laser and customized laser….

#2 Green laser, Blue laser, Infra Red laser, IR laser, UV DPSS laser.

Founded: 1996

Website: cnilaser.com

Key Highlights: (CNI), founded in 1996, is the manufacturer of lasers, spectrometers, power meters and optical systems in China. … Laser delivers an output power of up to 10W ……

#3 JPT Laser

Website: en.jptoe.com

Key Highlights: As a leading laser manufacturer in China, JPT offers a full range of lasers, including MOPA laser, CW laser, DPSS laser, and diode lasers. JPT delivers ……

#4 Laser Marking Machine & Industrial Laser Marking Systems

Website: videojet.com

Key Highlights: These compact and easy to operate 10W and 20W fiber lasers offer high-speed marking of complex codes on metal, plastic, and many other substrates. Read more….

#5 Deep UV Lasers

Website: ipgphotonics.com

Key Highlights: IPG deep UV lasers are made with unique optical materials and coatings to provide thousands of hours of reliable operation….

#6 Beamer Laser Marking Systems

Website: beamerlasermarking.com

Key Highlights: Discover the new 10W IR Picosecond B-Series IR Laser Marking System … DPSS Lasers specializes in manufacturing ultraviolet (UV 355nm) laser markers….

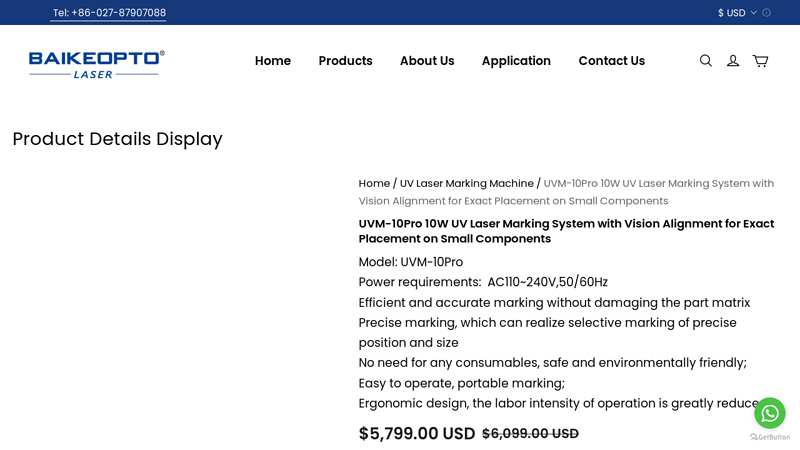

#7 UVM

Website: baikeopto.com

Key Highlights: In stockModel: UVM-10Pro Power requirements: AC110~240V,50/60Hz Efficient and accurate marking without damaging the part matrix Precise marking, which can realize ……

#8 UV Lasers

Website: haotianlaser.store

Key Highlights: Discover Haotian Laser’s UV Laser Engravers – precision, speed, and versatility for marking metals, plastics, glass, and more….

Expert Sourcing Insights for 10W Uv Laser

H2: 2026 Market Trends for 10W UV Lasers

The global market for 10W ultraviolet (UV) lasers is projected to experience robust growth and transformation by 2026, driven by advancements in laser technology, rising demand across key industries, and increasing adoption in precision manufacturing applications. As industries continue to prioritize miniaturization, high-precision processing, and non-thermal material treatment, the 10W UV laser segment is emerging as a critical enabler. Below are the key market trends shaping the 10W UV laser landscape in 2026:

-

Expansion in Microfabrication and Electronics Manufacturing

The electronics industry remains the largest consumer of 10W UV lasers, particularly for applications such as PCB (printed circuit board) cutting, semiconductor scribing, and micro-drilling. With the proliferation of 5G devices, wearable electronics, and IoT components, manufacturers require finer feature sizes and higher throughput. The cold ablation properties of UV lasers make them ideal for processing sensitive materials without thermal damage, driving demand for 10W systems that balance power and precision. -

Growth in Medical Device and Biotech Applications

The medical sector is increasingly adopting 10W UV lasers for micromachining stents, catheters, lab-on-a-chip devices, and diagnostic equipment. In 2026, regulatory approvals for laser-based manufacturing in sterile environments and the trend toward personalized medical devices are accelerating adoption. UV lasers offer clean, burr-free cuts in polymers and biocompatible materials, aligning with stringent quality standards. -

Advancements in Laser Source Technology

By 2026, diode-pumped solid-state (DPSS) UV lasers dominate the 10W segment due to improved efficiency, longer lifetimes, and reduced maintenance. Innovations in frequency-tripling techniques and thermal management are enhancing beam quality and stability. Additionally, integration with fiber delivery systems is improving flexibility and ease of integration into automated production lines. -

Increased Automation and Industry 4.0 Integration

The convergence of UV laser systems with smart manufacturing platforms is a defining trend. In 2026, 10W UV lasers are increasingly embedded in robotic workcells with real-time monitoring, AI-driven process optimization, and predictive maintenance. This integration boosts productivity and reduces downtime, making UV laser processing more scalable for high-volume applications. -

Regional Market Shifts and Supply Chain Localization

Asia-Pacific, particularly China, South Korea, and Japan, continues to lead in both production and consumption of 10W UV lasers, fueled by strong electronics and semiconductor industries. However, geopolitical factors and supply chain resilience concerns are prompting North America and Europe to invest in domestic laser manufacturing. This trend is expected to diversify the supplier base and reduce dependency on single-region sourcing. -

Sustainability and Energy Efficiency Focus

As environmental regulations tighten, manufacturers are favoring UV lasers with lower power consumption and reduced hazardous waste generation. The 10W range offers an optimal balance—sufficient power for most industrial tasks while maintaining energy efficiency. OEMs are also focusing on recyclable components and longer operational lifespans to meet ESG (Environmental, Social, and Governance) goals. -

Competitive Landscape and Price Pressure

The 10W UV laser market is becoming increasingly competitive, with both established players (e.g., Coherent, Trumpf, IPG Photonics) and emerging Chinese manufacturers (e.g., JPT Opto-electronics, HC Photonics) offering cost-effective solutions. Price erosion is expected, but value-added features such as software integration, reliability, and service support will differentiate premium offerings.

In conclusion, the 2026 market for 10W UV lasers is characterized by technological maturity, broader industrial adoption, and integration into advanced manufacturing ecosystems. As industries demand higher precision and throughput, the 10W UV laser will remain a pivotal tool across electronics, medical, automotive, and renewable energy sectors.

Common Pitfalls When Sourcing a 10W UV Laser (Quality and IP)

Sourcing a 10W UV (ultraviolet) laser involves navigating significant technical and commercial challenges. While attractive for high-precision applications like micro-machining, marking, and semiconductor processing, buyers often encounter critical issues related to actual laser quality, performance consistency, and intellectual property (IP) risks. Being aware of these pitfalls is essential for making a reliable and legally sound procurement decision.

Overestimating Real-World Output Power and Stability

Many suppliers advertise “10W” UV lasers, but the actual stable, usable output power in real operating conditions may be significantly lower. Key issues include:

– Peak vs. Average Power: Some vendors quote peak power instead of continuous average power, leading to inflated expectations.

– Power Drift: Low-quality diodes and inadequate thermal management cause power fluctuations over time, affecting process repeatability.

– Environmental Sensitivity: Poorly engineered systems degrade in performance under temperature or humidity variations common in industrial environments.

Buyers should insist on independent test reports showing sustained average power over extended run times under specified conditions.

Poor Beam Quality and Focusability

UV lasers are valued for their fine feature resolution, but beam quality (M² value) varies greatly:

– Inconsistent M² Values: Cheap or uncertified lasers often have high M² (>1.5), limiting focusability and cutting/marking precision.

– Misaligned Optics: Poor manufacturing leads to beam pointing instability and asymmetric profiles.

– Lack of Documentation: Reputable suppliers provide beam profiling data; unreliable vendors often omit this.

Verify beam quality with third-party certification or in-house testing before integration.

Short Lifespan and High Failure Rates

UV lasers, especially DPSS (Diode-Pumped Solid-State) types, are sensitive and demand precision engineering:

– Diode Degradation: Low-grade pump diodes degrade rapidly under high stress, reducing output within months.

– Crystal Damage: UV generation involves nonlinear crystals (e.g., LBO, BBO); poor cooling or contamination causes gray tracking or cracking.

– Cooling System Deficiencies: Inadequate TEC (thermoelectric cooling) or water cooling leads to thermal lensing and premature failure.

Ask for MTBF (Mean Time Between Failure) data and warranty terms. Reputable manufacturers typically offer 10,000+ hours MTBF.

Lack of IP Protection and Risk of Infringement

Sourcing from unverified suppliers, particularly in regions with weak IP enforcement, poses legal risks:

– Cloned or Reverse-Engineered Designs: Some “OEM” lasers replicate patented technology from leading brands (e.g., Coherent, Spectra-Physics), exposing end-users to infringement claims.

– No IP Warranty: Unethical suppliers often disclaim responsibility for IP violations, leaving the buyer liable.

– Export Compliance Issues: Use of stolen or unlicensed technology may violate international trade regulations (e.g., U.S. export controls).

Conduct supplier due diligence: request IP ownership documentation, design origin, and legal warranties. Prefer suppliers with clear R&D credentials.

Inadequate Support, Documentation, and Compliance

Low-cost suppliers may lack the infrastructure for professional integration:

– Missing Safety Certifications: Absence of IEC 60825 laser safety certification or CE/UL marks increases liability and regulatory risk.

– Poor Technical Documentation: Incomplete manuals, unclear wiring diagrams, and missing API/software SDKs delay integration.

– Unresponsive Support: Limited English support or lack of application engineers makes troubleshooting difficult.

Ensure compliance with local safety standards and evaluate technical support responsiveness before purchase.

Conclusion

Procuring a 10W UV laser requires more than comparing price and power specs. Quality pitfalls—such as unstable output, poor beam quality, and short lifespan—can undermine process reliability and ROI. Simultaneously, IP risks from cloned or infringing designs expose buyers to legal and financial liability. To mitigate these risks, prioritize transparent suppliers with verifiable performance data, robust certifications, clear IP ownership, and strong technical support. Due diligence upfront prevents costly disruptions down the line.

H2: Logistics & Compliance Guide for 10W UV Laser

1. H2: Regulatory Compliance

Laser Safety Standards

- IEC 60825-1: Ensure the 10W UV laser complies with the International Electrotechnical Commission standard for laser product safety. Class 3B or Class 4 laser classification typically applies to 10W UV lasers; confirm classification and labeling.

- FDA/CDRH (USA): If exporting to or selling in the U.S., comply with FDA 21 CFR Part 1040.10 and 1040.11. A Laser Product Report and variance (if applicable) must be submitted.

- CE Marking (EU): Comply with the EU’s Machinery Directive (2006/42/EC), Electromagnetic Compatibility (EMC) Directive (2014/30/EU), and the Low Voltage Directive (2014/35/EU). Include a Declaration of Conformity and technical file.

Hazard Communication

- Labeling Requirements: Clearly label the laser with warning labels indicating Class, wavelength (typically 355 nm for UV), power output, and laser radiation hazard.

- User Manual: Include safety instructions, interlock requirements, maintenance procedures, and emergency shutdown protocols.

Chemical & Environmental Regulations

- RoHS (EU): Confirm the laser and its components comply with Restriction of Hazardous Substances directives.

- REACH: Verify no restricted substances are present above threshold levels.

- WEEE Compliance: Provide information on proper disposal and recycling of electronic components.

2. H2: International Shipping & Export Controls

Export Classification

- ECCN (Export Control Classification Number): Determine if the 10W UV laser falls under ECCN 6A003 or 6A005 (lasers capable of metal processing or exceeding performance thresholds). If so, a license may be required for export to certain countries.

- ITAR/EAR: Confirm whether the laser is subject to the International Traffic in Arms Regulations (ITAR) or Export Administration Regulations (EAR). Most industrial UV lasers fall under EAR.

- End-Use Screening: Conduct due diligence on end-users to avoid prohibited destinations or applications (e.g., military, weapons development).

Documentation for Shipping

- Commercial Invoice: Include full product description, technical specs (wavelength, power, pulse frequency), value, country of origin, and reason for export (e.g., sale, repair).

- Packing List: Detail packaging contents, weight, dimensions, and serial numbers.

- Certificate of Origin: Required by some countries for tariff determination.

- Dangerous Goods Declaration: While lasers themselves are not typically classified as dangerous goods under IATA/IMDG, associated power supplies or batteries may require special handling.

3. H2: Packaging & Handling

Packaging Requirements

- Use anti-static, shock-resistant packaging with internal cushioning to protect optical components.

- Include desiccant packs to prevent moisture damage during transit.

- Secure all moving or sensitive parts (e.g., galvo scanners, lenses) with transit locks or foam inserts.

Environmental Protection

- Avoid exposure to extreme temperatures, humidity, or direct sunlight during storage and transport.

- Store in a clean, dry environment to prevent lens contamination or corrosion.

4. H2: Import Regulations by Region

United States

- CBP Entry: File entry with U.S. Customs and Border Protection; provide Harmonized Tariff Schedule (HTS) code (e.g., 8543.70.96 for optical instruments).

- Duties & Tariffs: Be aware of Section 301 tariffs on Chinese-origin goods, if applicable.

European Union

- EORI Number: Required for importers.

- Customs Declaration: Submit via the Import Control System (ICS2) with full product details.

- VAT & Duties: Apply based on declared value and product classification.

Other Regions (e.g., Canada, Australia, Japan)

- Check local laser import requirements and safety certifications (e.g., ICES-001 in Canada, RCM in Australia, MIC in Japan).

- Some countries may require pre-shipment inspection or local agent representation.

5. H2: Operational & Installation Compliance

Workplace Safety

- Laser Controlled Area: Establish a designated area with restricted access, interlocks, and warning signs.

- Personal Protective Equipment (PPE): Operators must use UV-blocking safety goggles, protective clothing, and face shields.

- Ventilation & Fume Extraction: UV laser processing may produce hazardous fumes; install local exhaust ventilation (LEV) systems.

Electrical Compliance

- Ensure power supply meets local voltage and frequency standards (e.g., 110V/60Hz in North America, 230V/50Hz in EU).

- Ground the unit properly to prevent electrical hazards.

6. H2: Maintenance & Recordkeeping

- Service Logs: Maintain records of calibration, maintenance, and repairs.

- Compliance Audits: Periodically audit safety and regulatory compliance, especially if operating in a regulated industry (medical, aerospace).

- Software Updates: Apply firmware updates that may affect safety or performance; ensure traceability.

Conclusion:

Compliance with international safety, export, and environmental regulations is critical when shipping and operating a 10W UV laser. Proactive documentation, proper packaging, and adherence to regional import laws will ensure smooth logistics and legal operation. Always consult with regulatory experts or legal counsel when in doubt.

Conclusion for Sourcing a 10W UV Laser

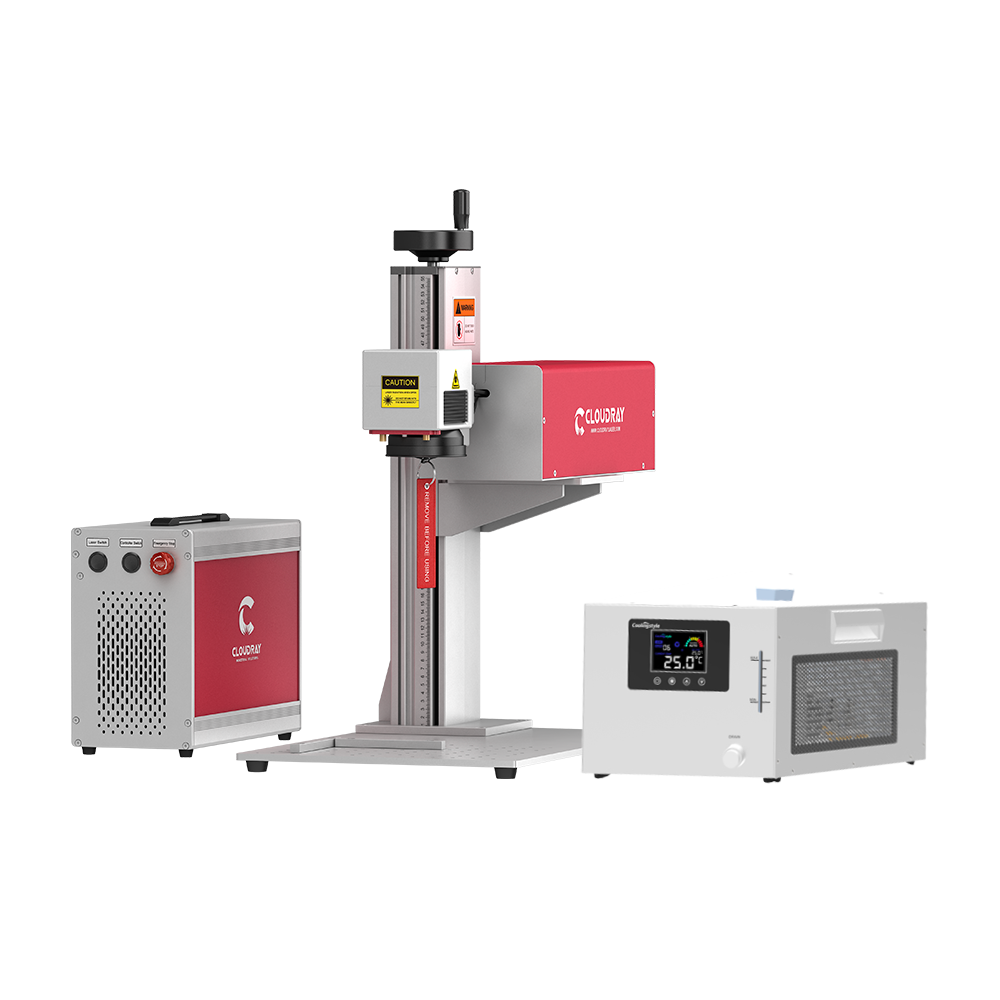

After a thorough evaluation of technical requirements, supplier capabilities, cost considerations, and long-term operational needs, sourcing a 10W UV laser is a strategic decision that aligns well with high-precision applications such as fine engraving, micro-machining, semiconductor processing, and marking sensitive materials. UV lasers offer superior beam quality, minimal thermal impact, and the ability to process a wide range of materials—including plastics, glass, and ceramics—with exceptional accuracy.

Key findings from the sourcing process include:

- Performance: A 10W UV laser provides an optimal balance between power and precision, enabling high-speed processing without compromising detail or material integrity.

- Supplier Selection: Reputable manufacturers from both domestic and international markets offer reliable systems, with key differentiators being build quality, service support, warranty terms, and technical expertise.

- Cost-Benefit: While the initial investment is significant, the long-term ROI is justified by improved production quality, reduced rework, and increased throughput.

- Integration & Support: Choosing a supplier with strong technical support, training, and compatibility with existing systems ensures smooth integration and minimal downtime.

- Future-Proofing: Opting for a scalable and maintainable system allows for adaptability as production demands evolve.

In conclusion, procuring a 10W UV laser is a sound investment for operations requiring micron-level precision and material versatility. By selecting a trusted supplier and ensuring proper implementation, organizations can significantly enhance their manufacturing capabilities, product quality, and competitive advantage in the market.