The global propane regulator market is experiencing steady growth, driven by increasing demand for efficient and safe gas pressure regulation across residential, commercial, and industrial applications. According to Grand View Research, the global LPG regulator market size was valued at USD 1.2 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.3% from 2023 to 2030, fueled by rising LPG consumption, expanding off-grid energy solutions, and stringent safety regulations. As demand for reliable propane systems grows—especially in rural heating, outdoor cooking, and recreational vehicle applications—the need for high-performance regulators compatible with common 100-pound propane tanks becomes critical. In this context, identifying leading manufacturers with proven engineering, compliance with industry standards (such as CSA and ASME), and strong distribution networks is essential for distributors, retailers, and end-users. Based on market presence, product innovation, customer reviews, safety certifications, and sales performance across e-commerce and wholesale platforms, here are the top eight manufacturers producing high-quality regulators for 100-pound propane tanks.

Top 8 100 Pound Propane Tank Regulator Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Propane

Domain Est. 2020

Website: lindedirect.com

Key Highlights: Linde offers quality Industrial Propane in compressed gas cylinders, liquid containers and bulk containers. Click to learn about Propane properties….

#2 Propane Tank Components

Domain Est. 1995

Website: amerigas.com

Key Highlights: Your guide to understanding the basic components of your propane tank and how key parts like gauges and valves function….

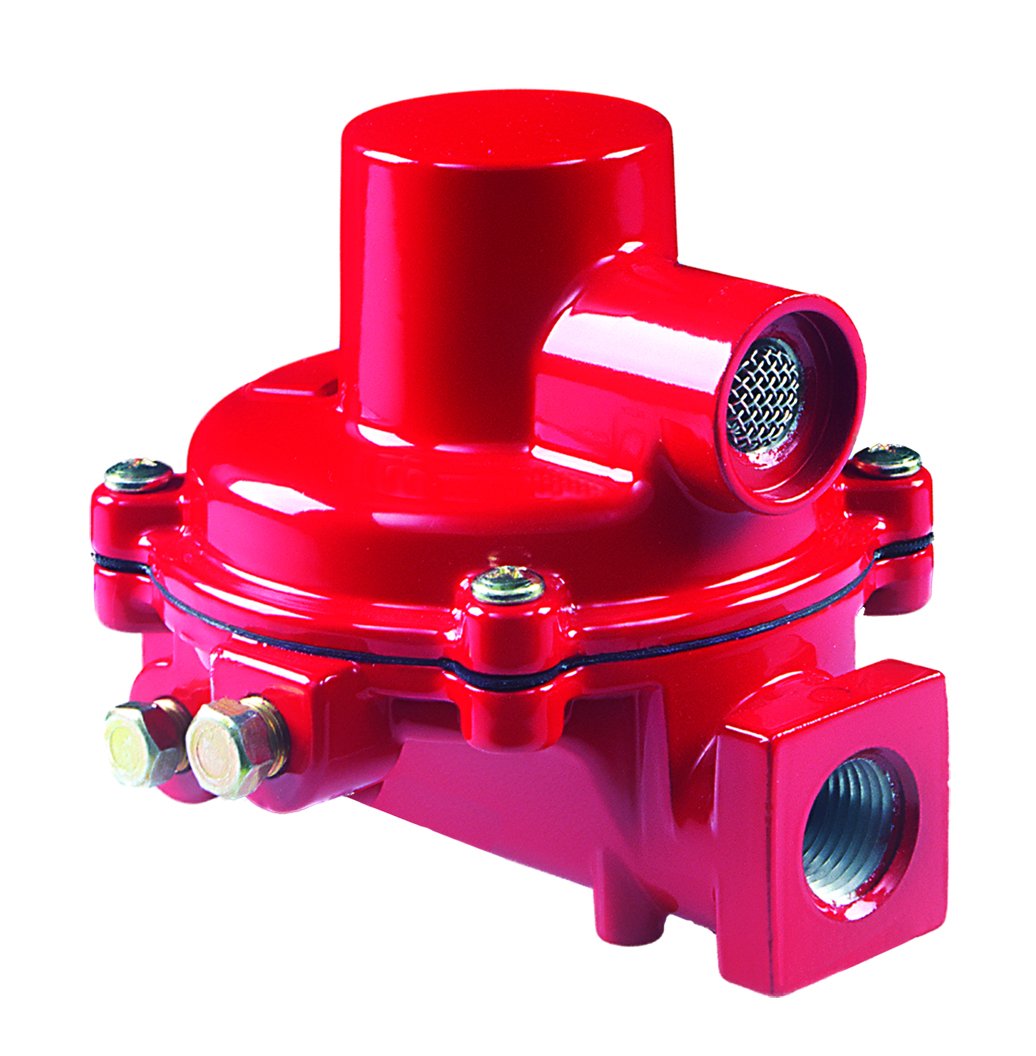

#3 Pressure Reducing Regulators

Domain Est. 1995

Website: emerson.com

Key Highlights: Browse Pressure Reducing Regulators products….

#4 Propane/Natural Gas Equipment & Parts

Domain Est. 1996

Website: fwwebb.com

Key Highlights: Cylinders with a capacity of 100 pounds or less without the 1¾¨ ACME fill connection may be sold to other customers. F.W. Webb sells gas regulators to licensed ……

#5 Emerson Fisher Natural Gas & Propane Regulators & Valves

Domain Est. 1998

Website: jmesales.com

Key Highlights: 1–2 day delivery 30-day returnsShop propane regulators from trusted brands like Emerson Fisher and Fairview Fittings. Propane regulators are commonly installed at the outlet of a p…

#6 Holston Gases

Domain Est. 1999

Website: holstongases.com

Key Highlights: Our specialty gas department offers an array of products ranging from Ultra High Purity, Zero-Grade, Laser, PPM mixes, and many more. All specialty gases can be ……

#7 Regulators

Domain Est. 2005

Website: propanewarehouse.com

Key Highlights: High and Low Pressure Propane gas regulator for propane tank regulation. Preset or Adjustable pressure regulators (eleven inches water column is the norm)…

#8 Propane Regulators

Domain Est. 2018

Website: propane-regulators.com

Key Highlights: Free delivery 30-day returnsHigh pressure and low pressure regulators, featuring brands: Cavagna, Marshall, Rego, Camco, Bayou Classic, Fairview, Fisher, Mr. Heater, Precimex, ……

Expert Sourcing Insights for 100 Pound Propane Tank Regulator

H2: 2026 Market Trends for 100-Pound Propane Tank Regulators

The market for 100-pound propane tank regulators in 2026 is expected to experience steady growth, driven by rising demand for portable and reliable energy sources across residential, commercial, and industrial sectors. As propane continues to serve as a clean-burning alternative to traditional fossil fuels, regulators—essential for controlling gas pressure and ensuring safe usage—will play a critical role in system performance and safety.

Key trends shaping the 2026 landscape include:

-

Increased Adoption in Recreational and Off-Grid Applications:

The surge in outdoor recreation—such as RV travel, camping, and backyard living—has amplified demand for 100-pound propane tanks and their associated regulators. These large-capacity tanks are ideal for prolonged use, and advanced regulators with dual-stage pressure control are becoming standard for maintaining consistent appliance performance. -

Focus on Safety and Compliance:

Regulatory bodies such as the National Fire Protection Association (NFPA) and Underwriters Laboratories (UL) are tightening safety standards. By 2026, regulators are expected to increasingly feature built-in excess flow valves, leak detection capabilities, and tamper-resistant designs to comply with updated codes and reduce accident risks. -

Smart and Digital Integration:

A notable trend is the integration of smart technology into propane systems. While still emerging, some 2026 models may offer Bluetooth-enabled regulators that connect to mobile apps, providing real-time monitoring of tank pressure, usage rates, and low-fuel alerts. This IoT (Internet of Things) trend enhances user convenience and supports predictive maintenance. -

Growth in Residential Heating and Backup Power:

With climate volatility and grid instability concerns rising, more homeowners are turning to propane for space heating, water heating, and backup generators. The 100-pound tank is a popular choice for whole-home propane systems in rural or off-grid areas, driving demand for high-performance, weather-resistant regulators. -

Sustainability and Efficiency Improvements:

Manufacturers are focusing on energy-efficient regulator designs that minimize pressure fluctuations and propane waste. Improved materials, such as UV-resistant polymers and corrosion-proof metals, extend product lifespan and support sustainability goals. -

Supply Chain and Cost Considerations:

Global supply chain dynamics and raw material costs (e.g., brass, rubber, and electronics) will continue to influence pricing. However, economies of scale and regional manufacturing shifts—particularly in North America—are expected to stabilize costs by 2026. -

Expansion in Commercial and Agricultural Use:

In agriculture, propane powers irrigation engines, grain dryers, and poultry heating systems. Commercial sectors, including food trucks and event catering, also rely on 100-pound tanks. These applications require durable, high-flow regulators capable of handling variable demand.

In conclusion, the 2026 market for 100-pound propane tank regulators will be defined by innovation in safety, connectivity, and efficiency. Driven by energy independence trends and environmental considerations, the sector is poised for moderate but sustained growth, with manufacturers focusing on reliability, compliance, and user-centric design enhancements.

Common Pitfalls When Sourcing 100 Pound Propane Tank Regulators (Quality & IP)

Sourcing a reliable and safe 100-pound propane tank regulator requires careful attention to avoid significant risks related to performance, safety, and legal compliance. Here are the most common pitfalls to watch for, focusing on quality and intellectual property (IP) concerns:

H2: Quality-Related Pitfalls

- Substandard Materials and Construction: Low-cost regulators often use inferior brass alloys, weak diaphragms, or poorly machined components. This leads to premature failure, leaks, inconsistent pressure output, and potential safety hazards like over-pressurization of appliances.

- Inadequate Pressure Regulation: Poorly designed or manufactured regulators may not maintain the required 11 inches water column (or equivalent) output pressure consistently, especially under varying inlet pressures (tank level/temperature) or flow demands. This causes appliance malfunctions (flame lift, sooting, extinguishing).

- Lack of Overfill/Overpressure Protection: Reputable regulators include safety features like pressure relief valves (PRVs) or overfill protection devices (OPDs) integrated into the valve assembly (though OPD is typically on the tank valve). Sourcing regulators without these critical safety features, or with ineffective ones, is a major hazard.

- Poor Sealing and Leak Points: Inferior O-rings, gaskets, or thread sealing can lead to gas leaks at connection points (tank valve, outlet). Leaks pose fire, explosion, and asphyxiation risks.

- Non-Compliance with Safety Standards: Avoid regulators not certified to relevant standards like CSA (Canadian Standards Association) or UL (Underwriters Laboratories) for the US/Canada market, or equivalent bodies elsewhere (e.g., CE marking in Europe with notified body assessment). Non-compliant units lack independent safety verification.

- Inaccurate or Missing Flow Ratings: The regulator must match the BTU/hour requirements of the connected appliances. Sourcing a regulator with insufficient flow capacity (e.g., < 400,000 BTU/hr for common 100-lb tank setups) causes performance issues. Beware of units with no clear, verified flow rating.

- Incompatible Connections: Ensure the inlet thread (typically ACME 11/16″-16 for US 100-lb tanks) and outlet connection (e.g., 3/8″ NPT, POL) match your tank and hose/appliance. Using adapters incorrectly introduces leak points and safety risks.

H2: Intellectual Property (IP) and Compliance Pitfalls

- Counterfeit or “Knock-Off” Products: Be wary of regulators priced significantly below market rate, especially from unknown online sellers. These are often counterfeits that mimic branding (logos, model numbers) of reputable manufacturers (e.g., Fisher, Honeywell, Johnstone) but lack genuine quality, safety testing, and IP licensing. They pose severe safety risks.

- Trademark Infringement: Purchasing or distributing counterfeit regulators involves using protected brand names, logos, and trade dress without authorization, constituting trademark infringement.

- Patent Infringement: Reputable regulator designs often incorporate patented technologies (e.g., specific diaphragm designs, locking mechanisms, PRV systems). Copying these features without a license violates patent rights.

- Lack of Traceability and Genuine Certification: Counterfeit or non-compliant regulators lack legitimate certification marks (e.g., a valid CSA/UL file number traceable to the certification body) or use fake marks. This makes it impossible to verify safety compliance and voids insurance in case of incidents.

- Voided Warranties and Lack of Support: Using non-genuine or counterfeit regulators typically voids the warranty on connected appliances. Reputable manufacturers also won’t provide technical support or replacement parts for non-OEM regulators.

- Liability Exposure: Sourcing and installing a regulator that causes an accident due to poor quality or IP infringement (like a counterfeit) exposes the buyer (homeowner, business, installer) to significant legal and financial liability, especially if negligence in sourcing is proven. Insurance may be denied.

Mitigation: Always purchase regulators from authorized distributors or reputable suppliers. Verify certification marks directly with the certifying body if possible. Prioritize known brands with established safety records, even at a higher initial cost – the investment in safety and reliability is paramount. Be highly skeptical of deals that seem too good to be true.

H2: Logistics & Compliance Guide for 100-Pound Propane Tank Regulators

Purpose: This guide outlines the critical logistics handling, transportation, and regulatory compliance requirements for 100-pound propane tank regulators. These components are integral to propane systems but have distinct handling characteristics separate from the propane cylinder itself. Proper management ensures safety, regulatory adherence, and supply chain efficiency.

H2: Regulatory Classification & Key Agencies

- Not a Hazardous Material (Generally): The regulator itself (a brass/aluminum valve assembly) is typically not classified as a hazardous material for transportation when empty, clean, and not containing residual propane under pressure. It is considered general freight.

- Key Agencies & Standards:

- DOT (Department of Transportation): Governs the transportation of hazardous materials (49 CFR). While the regulator body isn’t hazmat, rules apply if it’s attached to a cylinder or contains residue.

- PHMSA (Pipeline and Hazardous Materials Safety Administration): Issues and enforces DOT regulations; sets safety standards for propane equipment.

- NFPA (National Fire Protection Association): NFPA 58 (Liquefied Petroleum Gas Code) governs the installation, use, and safety of propane systems, including regulator requirements (e.g., Type, rating, venting).

- ASME (American Society of Mechanical Engineers): Sets design and manufacturing standards for pressure vessels and components (relevant to regulator construction).

- CGA (Compressed Gas Association): Provides safety guidelines and standards for gas equipment, including connections (e.g., CGA 510 POL valve for propane).

- State & Local Fire Codes: Often adopt NFPA 58; local authorities having jurisdiction (AHJ) may have additional requirements.

H2: Logistics Handling & Transportation

- Packaging:

- Use sturdy, protective packaging (e.g., corrugated boxes with ample cushioning) to prevent physical damage (dents, scratches, thread damage) during transit.

- Protect inlet and outlet ports with plastic caps or plugs to prevent contamination (dirt, moisture) and thread damage.

- Clearly label packages with contents (“Propane Regulator,” “Fragile,” “This Side Up”).

- Transportation (Regulator Only – Empty & Clean):

- Can generally be shipped via standard freight carriers (LTL, parcel, UPS/FedEx) without requiring hazardous material declarations or placards.

- Follow carrier-specific packaging and labeling requirements.

- Transportation (Regulator Attached to Cylinder):

- Critical: When the regulator is attached to a 100-lb propane cylinder (whether full, partially full, or “empty” with residual vapor), the entire assembly is regulated as hazardous material (UN 1075, Class 2.1 Flammable Gas).

- Transportation must comply fully with 49 CFR regulations:

- Proper cylinder labeling and certification (DOT 4BW, etc.).

- Securement to prevent movement during transit.

- Vehicle ventilation requirements (e.g., tailgate down with chains for open beds, no enclosed passenger compartments).

- Driver training (HazMat Endorsement may be required depending on quantity).

- Shipping papers (Bill of Lading) must include proper hazmat description if transporting cylinders with regulators attached and containing propane.

- Storage (Before/After Installation):

- Store in a clean, dry, well-ventilated area, protected from weather, direct sunlight, and extreme temperatures.

- Keep away from sources of ignition, heat, sparks, and corrosive materials.

- Protect threads and ports; avoid stacking heavy items on regulators.

H2: Critical Compliance Requirements

- Regulator Type & Rating:

- Mandatory: Must be a regulator specifically designed and rated for Liquefied Petroleum (LP) Gas (Propane).

- Venting: Must have a vented design (e.g., single-stage, two-stage, high-flow) to safely release excess pressure. Non-vented regulators are unsafe and non-compliant.

- Outlet Pressure: Must match the required downstream pressure for the appliances (typically 11″ W.C. for residential, but verify appliance specs).

- Flow Capacity: Must have sufficient BTU/hr capacity to meet the total demand of all connected appliances plus a safety factor (consult NFPA 58 or appliance manuals).

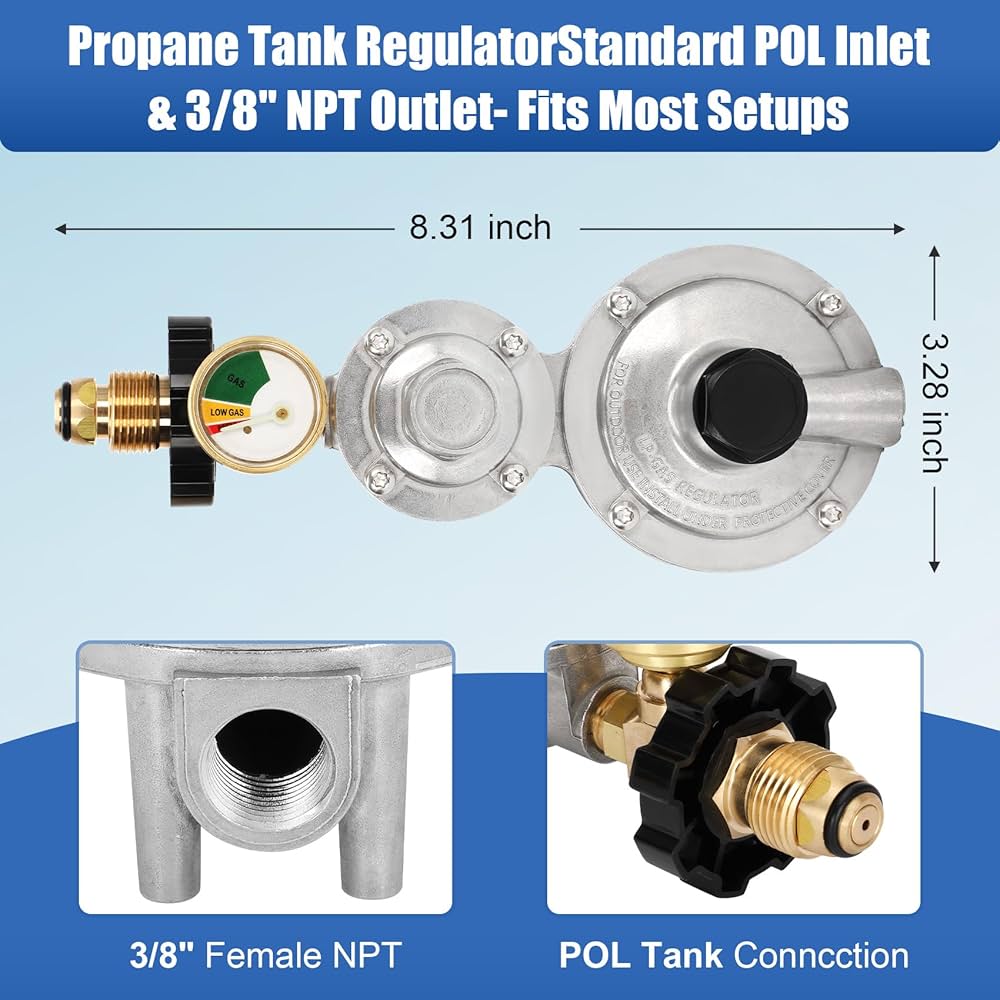

- Connection Standards:

- Inlet (Cylinder Side): Must have a CGA 510 (POL – Pudgeon Lock) connection to fit the standard 100-lb propane tank valve. Ensure thread integrity.

- Outlet (Appliance Side): Must match the downstream piping/fittings (commonly 3/8″ NPT or 1/2″ NPT).

- Certification & Markings:

- Must bear permanent, legible markings including:

- Manufacturer’s name/trademark.

- Model number.

- “LP-GAS” or “PROPANE” designation.

- CGA connection type (e.g., “CGA 510”).

- Outlet pressure (e.g., “11 W.C.”).

- Flow capacity (e.g., “X lbs/hr” or “Y BTU/hr”).

- Relevant standards met (e.g., “Meets ANSI Z21.22” or “CSA 6.22”).

- No Reconditioning/Repair: Damaged or non-compliant regulators cannot be repaired or reconditioned in the field. They must be replaced with new, certified units.

- Must bear permanent, legible markings including:

- Installation & Use (Per NFPA 58):

- Must be installed by a qualified professional according to manufacturer instructions and local codes.

- Must be installed in a vertical position (unless specifically designed otherwise) with the vent tube pointing downward and unobstructed.

- Requires a shutoff valve downstream of the regulator for system isolation.

- Regular inspection and maintenance are required.

H2: Key Safety Considerations

- Leak Testing: Always perform a leak test (using soapy water solution) on all connections (cylinder valve/regulator inlet, regulator outlet/piping) after installation or reconnection, before opening the cylinder valve, and periodically during use. Never use a flame.

- Physical Damage: Never drop, strike, or modify the regulator. Damaged regulators are unsafe and must be replaced.

- Contamination: Keep ports clean and capped when not in use. Dirt or debris can cause leaks or malfunctions.

- Freezing: In cold weather, regulators can ice up due to the Joule-Thomson effect during high flow. This is normal but can reduce flow. Use a two-stage regulator or a regulator heater if freezing causes operational issues. Never apply external heat to a regulator.

- End of Life: Regulators have a finite lifespan (often 15-25 years, check manufacturer). Replace if leaking, damaged, showing signs of corrosion, or if required by code/manufacturer.

Summary: While the 100-lb propane tank regulator itself is generally non-hazmat freight, its critical role in a hazardous system demands strict adherence to design, handling, and installation standards (especially NFPA 58). Logistics must ensure physical protection, and transportation rules become stringent if the regulator is attached to a cylinder containing propane. Always prioritize certified components, proper installation by qualified personnel, and rigorous leak testing.

In conclusion, sourcing a regulator for a 100-pound propane tank requires careful consideration of safety, compatibility, durability, and regulatory compliance. It is essential to select a regulator specifically designed for high-capacity propane systems, typically featuring an inlet pressure rating suitable for ASME tanks and an outlet pressure of around 11 inches water column for use with most appliances. Key factors to evaluate include CSA or UL certification, hose length and connection type (such as POL or ACME), freeze-resistant design for cold climates, and built-in excess flow protection.

Purchasing from reputable suppliers—whether hardware stores, propane dealers, or online retailers—ensures product quality and access to warranty support. Additionally, proper installation and periodic maintenance are crucial for long-term safety and performance. By prioritizing certified, high-quality components from trusted sources, users can ensure reliable and safe operation of their propane systems.