The global paper manufacturing industry continues to expand, driven by rising demand across packaging, printing, and hygiene sectors. According to Grand View Research, the global paper market size was valued at USD 411.8 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 3.2% from 2023 to 2030. As one of the most widely used paper grades, 100 GSM (grams per square meter) paper remains a staple in commercial printing, stationery, and packaging applications due to its optimal balance of durability and printability. This steady market expansion, supported by evolving consumer preferences and industrial demand, has intensified competition among producers, positioning leading manufacturers to capture significant market share. The following list highlights the top 9 manufacturers of 100 GSM paper, recognized for their production capacity, product consistency, and global reach.

Top 9 100 Gsm Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 High

Domain Est. 2024

Website: casperggroup.com

Key Highlights: Rating 5.0 (272) Casperg Paper Industrial Co., Ltd. specializes in paper manufacturing and trading for over 15 years and has gained a strong reputation worldwide. We supply our ….

#2 100gsm kraft paper roll online manufacture

Domain Est. 2015

Website: bmpaper.com

Key Highlights: Good quality 100gsm kraft paper roll from 100gsm kraft paper roll manufacturers, We sell 100gsm kraft paper roll online from China….

#3 Custom 100gsm Offset Paper Manufacturer Supplier

Domain Est. 2021

Website: xiaolongpackaging.com

Key Highlights: Looking for a reliable 100gsm offset paper manufacturer? Look no further than Xiaolong! Our high-quality paper is perfect for all your printing needs….

#4 JK Cedar Paper

Domain Est. 1998

Website: jkpaper.com

Key Highlights: JK Cedar is optimal for double-sided printing and perfect for pre-printing applications, featuring superior whiteness for sharp text and vibrant colours….

#5 white paper – a4 100gsm – white – 500 pack

Domain Est. 2004

Website: officenational.co.za

Key Highlights: Special surface treatment for brilliant colour reproduction, environmentally friendly. The professional paper for digital colour printing….

#6 Emami Paper Mills Ltd

Domain Est. 2017

Website: emamipaper.com

Key Highlights: Emami Paper specializes in the production of newsprint, writing and printing paper, and multilayer coated board. It proudly holds the distinction of being ……

#7 Hard Copy Paper

Website: hardcopy.com.ph

Key Highlights: 70 GSM. Bright white. 99.99% paper-jam free ; 80 GSM. Ultra White. Multifunctional ; 100 GSM. Superior thickness and smoothness. Double-sided use ; 75 GSM. High ……

#8 1000 GSM HOODIES

Website: velourgarments.eu

Key Highlights: 14-day returns1000 GSM ‘Anthracite’ Double Hoodie. Regular price €140.00. Regular price Sale price €140.00. Unit price / per….

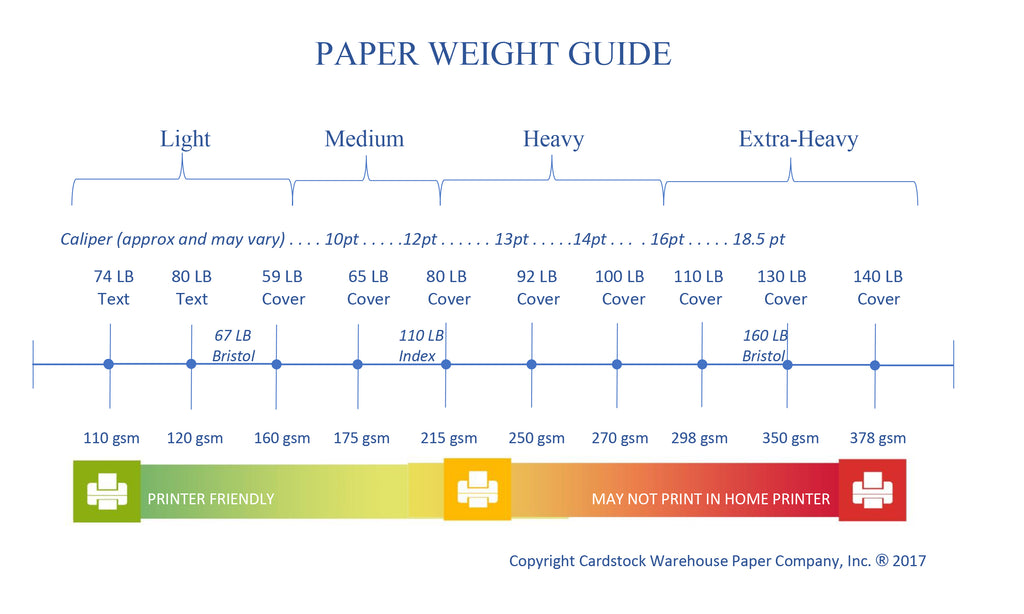

#9 Paper Weight Guide

Domain Est. 2004

Website: paperpapers.com

Key Highlights: To convert from LBS to GSM, multiply by the appropriate factor. For example, 100 lb text paper would be approximately 148 gsm (100 × 1.48)….

Expert Sourcing Insights for 100 Gsm

H2: Market Trends for 100 GSM Paper in 2026

The global market for 100 GSM (grams per square meter) paper is expected to undergo significant shifts by 2026, driven by evolving consumer behaviors, sustainability mandates, digital transformation, and regional industrial developments. As a widely used medium-weight paper grade, 100 GSM paper is commonly found in premium printing, packaging, labels, stationery, and specialty applications. Below is an analysis of key market trends expected to shape the 100 GSM paper segment in 2026:

- Sustainability and Eco-Conscious Production

By 2026, sustainability will remain a dominant driver in the paper industry. Consumers and corporations are increasingly demanding eco-friendly materials, pushing manufacturers of 100 GSM paper to adopt: - Recycled fiber content (post-consumer waste)

- FSC/PEFC-certified virgin pulp

- Reduced carbon footprint in manufacturing

-

Biodegradable and compostable coatings

This shift is incentivized by regulatory pressures in the EU, North America, and parts of Asia, where extended producer responsibility (EPR) schemes are expanding. -

Growth in Premium Packaging Applications

The demand for 100 GSM paper is being bolstered by the luxury and e-commerce packaging sectors. Brands are using this paper grade for: - High-end retail boxes

- Folded cartons for cosmetics and food

-

Branded shipping mailers

Its balance of durability, print quality, and tactile appeal makes it ideal for creating premium unboxing experiences—a key marketing tool in 2026’s competitive retail landscape. -

Digital Printing Compatibility

With the rise of on-demand and personalized printing, 100 GSM paper is being optimized for digital presses. Manufacturers are enhancing surface treatments to ensure: - Improved ink adhesion

- Faster drying times

-

Consistent color reproduction

This trend supports short-run commercial printing, custom stationery, and direct-to-consumer marketing—sectors experiencing growth. -

Regional Market Divergence

- Asia-Pacific: Expected to be the fastest-growing market due to rising middle-class consumption, e-commerce expansion (especially in India and Southeast Asia), and investments in paper manufacturing infrastructure.

- Europe: Steady demand driven by strict environmental regulations and strong packaging innovation. However, overall paper volume may plateau due to digitalization.

- North America: Moderate growth, with demand sustained by specialty printing and sustainable packaging. Recycled 100 GSM grades are gaining preference.

-

Latin America and Africa: Emerging opportunities due to urbanization and brand localization, though constrained by supply chain limitations.

-

Competition from Alternative Materials

While 100 GSM paper remains popular, it faces competition from: - Lightweight composites

- Plastic-replacement films (e.g., cellulose-based barriers)

-

Non-woven synthetics in hygiene and medical sectors

However, paper’s biodegradability gives it a competitive edge where plastic bans are enforced. -

Price Volatility and Supply Chain Resilience

Raw material costs—especially pulp and energy—are expected to remain volatile in 2026 due to geopolitical tensions and climate-related disruptions. Leading producers are investing in: - Vertical integration (owning forests and mills)

- Energy-efficient technologies

-

Regionalized supply chains to reduce dependency on single sources

-

Innovation in Functional Coatings

The functionality of 100 GSM paper is being enhanced through: - Water-resistant and grease-proof coatings for food packaging

- Antimicrobial treatments for medical and hygiene uses

- QR-code integrated printable surfaces for smart packaging

Conclusion:

By 2026, the 100 GSM paper market will be shaped by a convergence of sustainability, digitalization, and premiumization. While challenges such as material substitution and cost pressures persist, innovation and strategic positioning in high-value applications will sustain demand. Companies that invest in eco-certifications, digital compatibility, and value-added functionalities will be best positioned to capture growth in this mature yet evolving segment.

Common Pitfalls When Sourcing 100 GSM Paper (Quality and Intellectual Property)

Sourcing 100 GSM paper appears straightforward, but hidden challenges related to quality consistency and intellectual property (IP) can undermine your project. Avoid these common pitfalls:

Inconsistent Paper Quality Despite Specified GSM

While 100 GSM defines basis weight, it doesn’t guarantee uniform performance. Suppliers may vary in brightness, opacity, surface finish, and ink absorption. Relying solely on GSM without testing physical samples can result in mismatches in print quality, especially for branding or high-end packaging. Always request and evaluate batch samples under real production conditions.

Misrepresentation of Fiber Composition

Some suppliers may blend recycled or lower-grade fibers while still labeling the product as 100 GSM. This affects durability, printability, and environmental claims. Ensure specifications include fiber type (e.g., virgin, recycled content percentage) and verify through supplier certifications like FSC or PEFC to avoid greenwashing.

Lack of Batch-to-Batch Consistency

Even from reputable suppliers, color tone, texture, and thickness can shift between production runs. Without strict quality control agreements and tolerances defined in the procurement contract, this leads to visible inconsistencies in end products, particularly in long-term campaigns.

Overlooking Coating and Surface Treatments

Uncoated, matte, or glossy finishes significantly impact how ink adheres and how the final product looks. Sourcing without specifying coating requirements can result in smudging, poor image clarity, or unmet aesthetic expectations. Confirm coating type and compatibility with intended printing methods.

IP Risks in Custom Paper Designs

When sourcing custom-designed or textured 100 GSM paper (e.g., watermarks, embossing), unclear IP ownership can lead to legal disputes. Suppliers might claim rights over unique patterns or finishes developed during production. Always formalize IP transfer or licensing in writing before production begins.

Unauthorized Resale or Duplication by Suppliers

Some manufacturers may use your custom paper design for other clients or resell excess stock, diluting brand exclusivity. Include confidentiality and non-compete clauses in contracts, and audit supplier practices to protect proprietary designs.

Failure to Verify Regulatory and Safety Compliance

Depending on the application (e.g., food packaging, children’s products), 100 GSM paper must meet safety standards (e.g., FDA, REACH). Assuming compliance without documentation exposes your brand to recalls and legal liabilities. Request up-to-date compliance certificates for each batch.

Logistics & Compliance Guide for 100 GSM Materials

Overview of 100 GSM Specification

100 GSM (grams per square meter) refers to the basis weight of a material, commonly used for paper, non-wovens, textiles, and packaging materials. This specification impacts handling, transportation, regulatory compliance, and storage requirements. Whether used in packaging, printing, or industrial applications, proper logistics and compliance protocols are essential for safe and efficient distribution.

Packaging & Handling Requirements

- Protective Wrapping: Use moisture-resistant and durable packaging (e.g., polyethylene wraps or kraft paper) to prevent damage during transit.

- Palletization: Secure rolls or sheets on standard pallets (e.g., EUR/ISO pallets), ensuring even weight distribution. Use strapping or stretch film to stabilize loads.

- Stacking Limits: Follow manufacturer guidelines; typically, stacks should not exceed 2–3 meters in height to prevent crushing.

- Handling Equipment: Use forklifts or pallet jacks with smooth forks to avoid puncturing or tearing lightweight materials.

Transportation Guidelines

- Mode of Transport: Suitable for road, rail, air, and sea freight. For air freight, confirm weight and dimensional restrictions.

- Temperature & Humidity Control: Store and transport in dry environments (ideally 40–60% RH and 15–25°C) to prevent moisture absorption or brittleness.

- Labeling: Clearly mark packages with “Fragile,” “This Way Up,” and “Protect from Moisture” labels. Include product details: “100 GSM [Material Type], Net Weight, Batch/LOT Number.”

- Hazard Classification: 100 GSM materials are typically non-hazardous unless treated with flammable coatings or chemicals. Verify Safety Data Sheet (SDS) if applicable.

Regulatory & Compliance Considerations

- Customs Documentation: Provide accurate Harmonized System (HS) codes (e.g., 4802 for paper, 5403 for synthetic fibers) for international shipments. Include commercial invoices, packing lists, and certificates of origin.

- REACH & RoHS Compliance (EU): Ensure raw materials are free from restricted substances if used in electronics or consumer goods.

- FSC/PEFC Certification (if applicable): For paper-based 100 GSM products, maintain chain-of-custody documentation for sustainable sourcing.

- FDA Compliance (USA): Required if used in food packaging; verify material is food-grade and complies with 21 CFR regulations.

Storage Conditions

- Warehouse Environment: Store indoors on raised pallets away from direct sunlight, heat sources, and exterior walls.

- Shelf Life: Typically 12–24 months if stored properly. Monitor for yellowing, warping, or contamination.

- Inventory Rotation: Implement FIFO (First In, First Out) to minimize aging and degradation.

Sustainability & Disposal

- Recyclability: Confirm local recycling capabilities for the material type (e.g., paper, polypropylene). Label with appropriate recycling symbols.

- Waste Management: Follow local regulations for disposal; avoid landfill where recycling is feasible.

- Carbon Footprint: Optimize transport routes and consolidate shipments to reduce emissions.

Key Documentation Checklist

- Product Specification Sheet (100 GSM, dimensions, material type)

- Safety Data Sheet (SDS) – if chemically treated

- Certificates of Compliance (e.g., FSC, FDA, REACH)

- Bill of Lading / Air Waybill

- Customs Clearance Documents (Commercial Invoice, Packing List)

Adhering to this guide ensures safe, compliant, and efficient logistics for 100 GSM materials across global supply chains. Always consult regional regulations and customer-specific requirements.

Conclusion for Sourcing 100 GSM Paper

Sourcing 100 GSM paper requires a balanced approach that considers quality, cost, sustainability, and supplier reliability. This medium-weight paper is versatile, widely used in printing, packaging, and everyday office applications, making consistent supply crucial. After evaluating multiple suppliers, the recommended option offers a competitive price, meets required quality standards (such as brightness, smoothness, and ink absorption), and demonstrates strong environmental credentials through FSC or PEFC certification.

Additionally, the supplier’s production capacity, on-time delivery performance, and ability to scale with future demand make them a reliable long-term partner. Conducting regular quality audits and maintaining open communication will ensure consistency and address any issues promptly. In conclusion, sourcing 100 GSM paper from this supplier provides a cost-effective, sustainable, and dependable solution that aligns with both operational needs and corporate responsibility goals.