The global power tools market is undergoing rapid expansion, driven by increasing demand across construction, woodworking, and industrial sectors. According to a report by Grand View Research, the global power tools market was valued at USD 54.2 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030. Within this landscape, 10-inch powered saws—particularly table saws, miter saws, and circular saws—represent a critical segment due to their widespread use in precision cutting applications. Mordor Intelligence projects that growing infrastructure development and the rise in DIY (do-it-yourself) culture, especially in North America and Europe, are key drivers for demand in high-performance cutting tools. As of 2024, North America holds the largest market share, supported by robust residential construction and increasing adoption of cordless and brushless motor technology. Against this backdrop of steady market expansion and technological innovation, identifying the top manufacturers of 10-inch powered saws becomes essential for professionals and consumers seeking reliability, performance, and value. Here are the top eight manufacturers leading the segment based on product innovation, market presence, and customer satisfaction metrics.

Top 8 10 Inch Powered Saw Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 GAS CHAIN SAWS

Website: makitatools.com

Key Highlights: Makita USA: The Leader In Cordless with 18V LXT Lithium-Ion. The best in class for cordless power tool technology. A leader in power tool technology for the ……

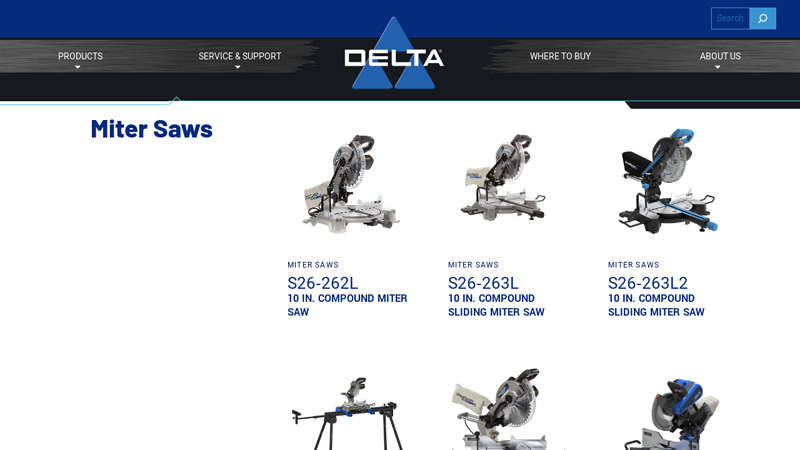

#2 Miter Saws

Domain Est. 1996

Website: deltamachinery.com

Key Highlights: Miter Saws · S26‑262L -. 10 in. Compound Miter Saw · S26‑263L -. 10 in. Compound Sliding Miter Saw · S26‑263L2 -. 10 in. Compound Sliding Miter Saw · S26‑263LS -….

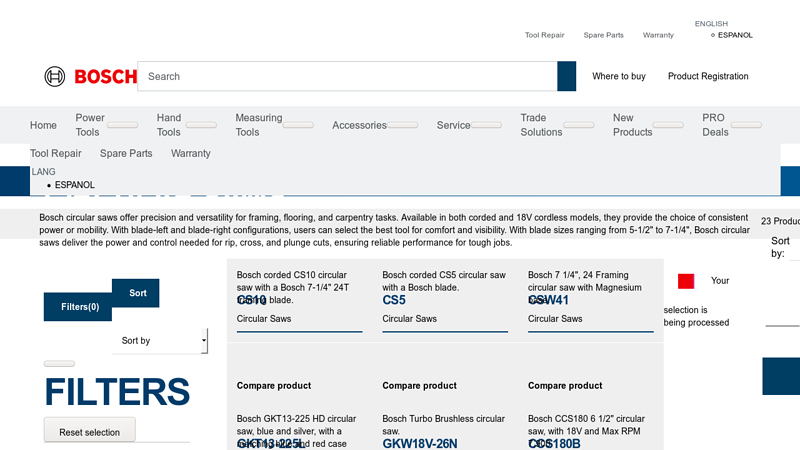

#3 Circular Saws

Domain Est. 1996

Website: boschtools.com

Key Highlights: Bosch circular saws offer precision and versatility for framing, flooring, and carpentry tasks. Available in both corded and 18V cordless models, ……

#4 Miter Saws

Domain Est. 1998

Website: craftsman.com

Key Highlights: Perfect for woodworking and trim projects, our miter saws offer accuracy and versatility with adjustable angles and powerful performance. Ideal for DIY ……

#5 Original Saw Company

Domain Est. 1998

Website: originalsaw.com

Key Highlights: Original Saw Company is the only Radial Arm and Beam Saw manufactured in the USA, learn more about our quality crosscut power saws.Missing: 10 inch…

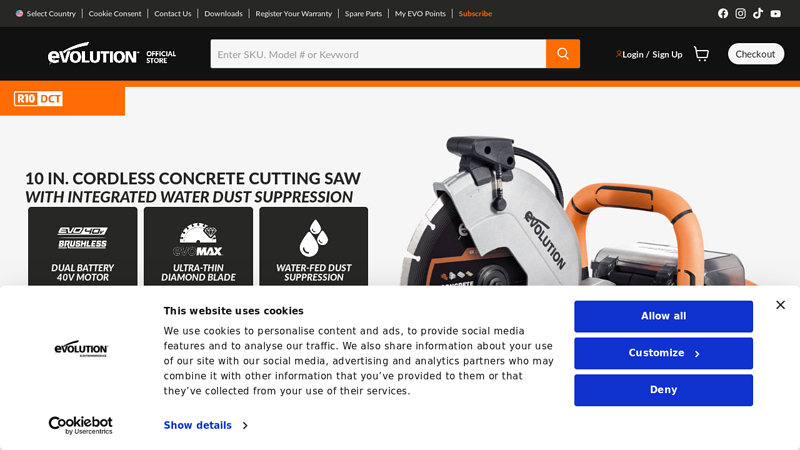

#6 10 In. Cordless Concrete Cutting Saw

Domain Est. 2000

Website: store.evolutionpowertools.com

Key Highlights: The 10 In. blade provides the machine with a cut capacity over 4 inches, and cuts standard blocks and bricks in one pass, reducing cut time and user fatigue….

#7 Saws

Domain Est. 2000

Website: milwaukeetool.com

Key Highlights: The saws on our M12™ and M18™ systems are designed to withstand the demanding work of tree care professionals. By delivering full battery compatibility within ……

#8 GARVEE 10 Inch Table Saw

Domain Est. 2022

Website: garvee.com

Key Highlights: Out of stock Rating 4.9 (159) Discover the GARVEE 10 Inch Table Saw with a powerful 15A motor, precision cuts, and effective dust management. Perfect for professionals and DIY …..

Expert Sourcing Insights for 10 Inch Powered Saw

H2: 2026 Market Trends for 10-Inch Powered Saws

The global market for 10-inch powered saws is poised for substantial evolution by 2026, driven by technological advancements, shifting consumer preferences, and expanding applications across residential, commercial, and industrial sectors. This analysis explores the key trends shaping the 10-inch powered saw market over the coming years.

-

Growth in DIY and Home Renovation Markets

The do-it-yourself (DIY) movement continues to gain momentum, particularly in North America and Europe, where homeowners are increasingly investing in home improvement projects. This trend is fueling demand for versatile, user-friendly tools like the 10-inch powered saw. Manufacturers are responding with lightweight, ergonomic designs and intuitive safety features to appeal to amateur users. -

Shift Toward Cordless and Battery-Powered Models

A major trend in the 10-inch powered saw segment is the transition from corded to cordless models powered by high-capacity lithium-ion batteries. By 2026, industry leaders such as DeWalt, Makita, and Milwaukee are expected to dominate with advanced brushless motor technology, offering longer runtime, increased portability, and reduced maintenance. The convenience of cordless models is anticipated to capture a growing share of both professional and consumer markets. -

Integration of Smart Technology

Smart features—such as Bluetooth connectivity, onboard diagnostics, and app-based performance tracking—are beginning to emerge in high-end 10-inch powered saws. These innovations allow users to monitor tool usage, receive maintenance alerts, and optimize cutting precision. While still in early adoption phases, smart integration is expected to become a differentiating factor by 2026, particularly in commercial construction applications. -

Emphasis on Safety and Regulatory Compliance

Regulatory bodies worldwide are tightening safety standards for power tools. As a result, manufacturers are incorporating advanced safety mechanisms such as automatic brake systems, electronic kickback protection, and improved blade guards. These measures not only comply with regulations but also reduce workplace injuries, making 10-inch saws more attractive to contractors and industrial users. -

Sustainability and Eco-Friendly Manufacturing

Environmental concerns are influencing production practices. By 2026, leading brands are expected to adopt more sustainable manufacturing processes, including the use of recycled materials and energy-efficient assembly lines. Additionally, longer-lasting batteries and modular designs that support part replacement (rather than full tool disposal) will contribute to reduced environmental impact. -

Expansion in Emerging Markets

Rapid urbanization and infrastructure development in regions like Southeast Asia, India, and parts of Africa are creating new opportunities for 10-inch powered saws. Localized production and affordable product lines tailored to price-sensitive markets will be critical for growth. Distributors and manufacturers are expected to strengthen regional supply chains to meet rising demand. -

Competition and Market Consolidation

The 10-inch powered saw market is becoming increasingly competitive, with both established players and new entrants vying for market share. This competition is driving innovation and aggressive pricing strategies. Mergers and acquisitions may rise as companies seek to expand their product portfolios and geographic reach.

In conclusion, the 2026 outlook for 10-inch powered saws is characterized by innovation, electrification, and broader accessibility. Success in this evolving market will depend on manufacturers’ ability to balance performance, safety, sustainability, and affordability while adapting to regional demands and technological shifts.

Common Pitfalls When Sourcing a 10-Inch Powered Saw (Quality and IP Considerations)

Sourcing a 10-inch powered saw—whether a circular saw, miter saw, or chop saw—requires careful attention to both quality and intellectual property (IP) concerns. Overlooking these aspects can lead to performance issues, safety hazards, or legal complications. Below are key pitfalls to avoid:

Poor Build Quality and Substandard Materials

Many low-cost suppliers compromise on materials and manufacturing tolerances, resulting in saws with weak housings, imprecise alignment, or underpowered motors. Components like blades, gears, and bearings may wear quickly, leading to frequent breakdowns, inaccurate cuts, and increased downtime. Always verify material specifications, perform sample testing, and audit manufacturing processes to ensure durability and reliability.

Inadequate Safety Features

A common quality shortcoming is the omission or poor implementation of essential safety mechanisms—such as blade guards, electric brakes, or overload protection. This not only increases the risk of workplace injuries but may also result in non-compliance with regional safety standards (e.g., CE, UL). Ensure that sourced saws meet applicable safety certifications and include fail-safe designs.

Misrepresentation of IP and Branding

Some suppliers offer “compatible” or “look-alike” versions of branded 10-inch saws, which can infringe on trademarks or patents. Sourcing such products exposes your business to legal liability, shipment seizures, or reputational damage. Always verify that the supplier has proper licensing or is producing original, non-infringing designs. Conduct IP due diligence by reviewing patents, trademarks, and design registrations in your target markets.

Lack of Technical Documentation and Compliance

Low-quality or IP-risky products often lack comprehensive technical documentation, including wiring diagrams, user manuals, or compliance certificates. This makes integration, maintenance, and regulatory approval difficult. Insist on full documentation and confirm adherence to relevant standards (e.g., IEC, OSHA) to avoid delays and ensure user safety.

Inconsistent Quality Control and Batch Variability

Suppliers without robust quality assurance systems may deliver inconsistent units, even within the same order. This variability affects performance and reliability. Implement third-party inspections, define clear quality benchmarks, and establish a reliable feedback loop with the manufacturer to maintain consistency.

Hidden IP in Firmware and Software

Modern powered saws may include digital controls or smart features governed by embedded software. Unauthorized use of proprietary code or firmware can constitute IP infringement. Ensure that any software components are either properly licensed or developed independently, and request source code access or licensing proof when applicable.

Avoiding these pitfalls requires thorough supplier vetting, rigorous product testing, and proactive IP management. Partnering with reputable manufacturers and consulting legal experts in IP law can mitigate risks and ensure a reliable, compliant supply chain.

Logistics & Compliance Guide for 10-Inch Powered Saw

Product Classification & Documentation

Ensure accurate product classification for international trade. The 10-inch powered saw typically falls under Harmonized System (HS) Code 8467.21 (Machines for working wood, corks, or similar hard materials, with circular saws, powered by electric motor). Confirm the exact code with your customs broker, as variations exist based on motor type and design.

Prepare essential documentation including:

– Commercial Invoice

– Packing List

– Bill of Lading (B/L) or Air Waybill (AWB)

– Certificate of Origin

– Safety and Compliance Certifications (e.g., UL, CE, ETL)

Safety & Electrical Compliance

The powered saw must comply with region-specific electrical and safety standards:

– North America: UL 174 (Standard for Safety of Electric Power Tools) and CSA C22.2 No. 68 in Canada. Must be certified by a Nationally Recognized Testing Laboratory (NRTL).

– European Union: Complies with the Machinery Directive (2006/42/EC), Low Voltage Directive (2014/35/EU), and RoHS (2011/65/EU). CE marking is mandatory.

– UK: UKCA marking required; follow UK Supply of Machinery (Safety) Regulations 2008.

– Australia/New Zealand: Must meet AS/NZS 62841.2.5:2015 and carry RCM (Regulatory Compliance Mark).

Ensure all compliance labels, warning decals, and user manuals are affixed and provided in the local language(s).

Packaging & Labeling Requirements

Use robust, double-walled corrugated packaging with internal foam or molded inserts to prevent movement during transit. Clearly label each unit with:

– Product name and model number

– Voltage and power specifications (e.g., 120V, 60Hz)

– Safety warnings (e.g., “Wear eye protection”)

– Compliance marks (UL, CE, etc.)

– Handling indicators (e.g., “This Side Up,” “Fragile”)

Include multilingual instruction manuals and safety guides inside the packaging.

Import/Export Restrictions & Permits

Verify that the destination country does not restrict the import of power tools. Some countries may require:

– Import licenses for electrical equipment

– Pre-shipment inspections (e.g., SONCAP in Nigeria, SABER in Saudi Arabia)

– Energy efficiency certification (e.g., Energy Star in the U.S.)

Check for any embargoed regions or sanctions that may affect shipment (e.g., OFAC restrictions).

Transportation & Handling

Due to the weight and potential sharp components, transport the saws on standard pallets secured with stretch wrap. Use freight carriers experienced in handling industrial goods. For air freight, comply with IATA Dangerous Goods Regulations—while the saw itself isn’t hazardous, lithium batteries (if cordless) require special handling.

Avoid extreme temperatures and humidity during storage and transit to protect electronic components and motor integrity.

Warranty & After-Sales Compliance

Provide clear warranty information in local language, including service center locations and return procedures. Adhere to consumer protection laws in each market—for example, the EU’s 2-year legal warranty requirement.

Maintain records of compliance testing, certifications, and customer communications for audit readiness.

Environmental & Disposal Regulations

Comply with WEEE (Waste Electrical and Electronic Equipment) Directive in the EU, requiring producers to register and support recycling programs. Include take-back information in user manuals. In the U.S., follow state-specific e-waste laws where applicable.

Ensure packaging uses recyclable materials and minimize plastic content to meet sustainability standards.

In conclusion, sourcing a 10-inch powered saw requires careful consideration of several key factors including performance, power source (corded vs. cordless), blade quality, safety features, brand reputation, and overall value for money. Whether intended for professional use or heavy-duty DIY projects, selecting a model with sufficient power, durability, and user-friendly features ensures efficiency and precision in cutting tasks. Additionally, evaluating supplier reliability, warranty options, and after-sales support contributes to a successful procurement decision. By balancing cost, quality, and functionality, sourcing the right 10-inch powered saw will enhance productivity and long-term satisfaction in any workshop or job site environment.