The global masonry drill bit market is experiencing steady growth, driven by rising construction activities and expanding infrastructure development worldwide. According to a report by Mordor Intelligence, the construction tools market—including masonry bits—is projected to grow at a CAGR of over 5.8% from 2023 to 2028. Similarly, Grand View Research estimates that the global power tools market, which encompasses masonry drilling equipment, was valued at USD 37.8 billion in 2022 and is expected to expand at a CAGR of 5.1% through 2030. With demand fueled by both professional contractors and the growing DIY sector, the competitive landscape for masonry bit manufacturing has intensified. In this evolving market, product durability, material innovation (such as carbide-tipped designs), and performance under extreme conditions are key differentiators. Based on market presence, manufacturing quality, and technological advancement, the following six manufacturers have emerged as leaders in the 1/4 inch masonry bit segment.

Top 6 1 4 Masonry Bit Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Milwaukee® Tool

Domain Est. 2000

Website: milwaukeetool.com

Key Highlights: Milwaukee Tool is the most respected manufacturer of heavy-duty power tools, hand tools, instruments, and accessories….

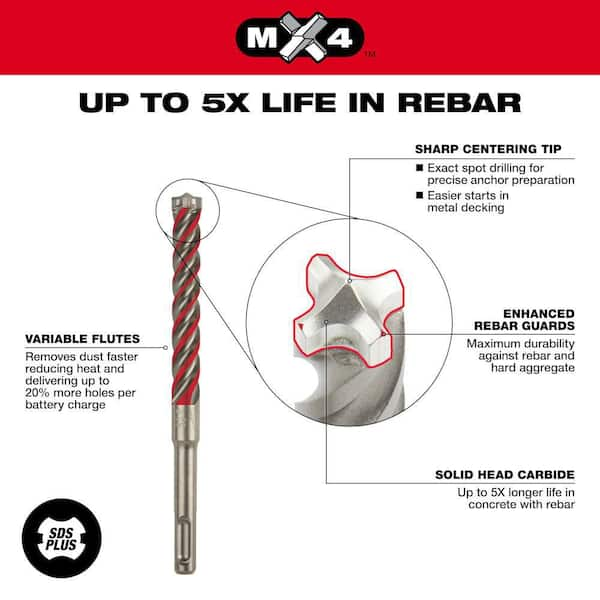

#2 Milwaukee® SDS

Domain Est. 1996

Website: dunnlumber.com

Key Highlights: 7-day returnsBuilt to take on masonry and rebar, Milwaukee SDS bits feature 2-cutter geometry for fast drilling and debris removal. The patented, reinforced flute design ……

#3 Carbide Tipped Masonry Drill Bit 1/4”

Domain Est. 1998

Website: kleintools.com

Key Highlights: Carbide Tipped Masonry Drill Bit 1/4”. This product is no longer in production. Drills through hard materials such as brick, concrete, plaster, ……

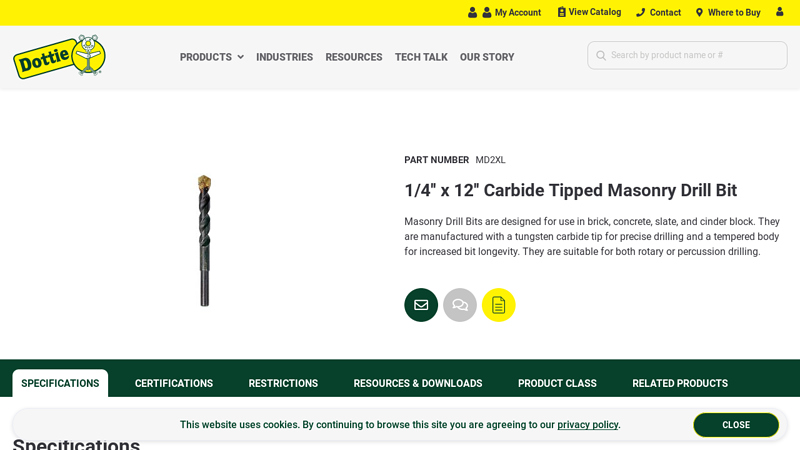

#4 1/4” x 12” Carbide Tipped Masonry Drill Bit

Domain Est. 1998

#5 Champion Cutting Tool

Domain Est. 1998

Website: championcuttingtool.com

Key Highlights: Metal Cutting · Twist Drills / Drill Bits · Drill Sets / Dispensers · Jobber / Mechanics Length Drills · Metric Drills · Hex Shank Drills ……

#6 MDB14

Website: braxtonharris.com

Key Highlights: Product Description. BIT SIZE: 1/4″, BIT LENGTH: 4″. DESIGNED FOR PERCUSSION AND ROTARY DRILLING IN CONCRETE, BRICK, MARBLE, STONE, WALL BOARD OR PLASTER….

Expert Sourcing Insights for 1 4 Masonry Bit

H2: 2026 Market Trends for 1/4 Inch Masonry Drill Bits

The global market for 1/4 inch masonry drill bits is poised for steady growth through 2026, driven by advancements in construction technology, rising infrastructure development, and increased demand for durable, high-performance drilling tools. Key market trends indicate a shift toward enhanced material quality, smart tool integration, and sustainability in manufacturing.

-

Rising Demand in Residential and Commercial Construction

The expansion of urbanization and housing projects—particularly in emerging economies in Asia-Pacific, Africa, and Latin America—is fueling demand for reliable masonry tools. The 1/4 inch masonry bit, commonly used for anchoring, HVAC installations, and electrical fittings, remains a staple in both professional and DIY construction applications. As modular and prefabricated building methods grow, so does the need for precision drilling, boosting sales of standardized bits like the 1/4 inch size. -

Adoption of Advanced Materials and Coatings

Manufacturers are increasingly using carbide-tipped and cobalt-infused alloys to improve durability and heat resistance. By 2026, expect broader adoption of nano-coatings (e.g., titanium nitride or diamond-like carbon) that extend bit life and reduce wear during high-volume drilling in concrete, brick, and stone. These enhancements improve performance in tough materials, aligning with contractors’ demands for efficiency and reduced tool replacement costs. -

Growth of Cordless Power Tools and Compatibility Needs

The surge in cordless drill and hammer drill usage is influencing masonry bit design. 1/4 inch bits are being optimized for high-torque, variable-speed cordless systems. Quick-change shank designs (e.g., SDS-plus compatibility) are gaining traction, ensuring faster bit swaps and better energy transfer. By 2026, compatibility with popular cordless platforms will be a key selling point. -

E-Commerce and Direct-to-Consumer Channels

Online retail continues to reshape distribution. Platforms like Amazon, Home Depot’s digital storefront, and specialized tool marketplaces are making 1/4 inch masonry bits more accessible to both trade professionals and home users. Brands are investing in digital marketing, customer reviews, and bundled tool kits to gain visibility and market share. -

Sustainability and Circular Economy Initiatives

Environmental regulations and consumer preferences are pushing manufacturers toward recyclable packaging and energy-efficient production. Some companies are exploring bit refurbishment and recycling programs, particularly in regions with strong green building standards. This trend is expected to grow as part of broader ESG (Environmental, Social, and Governance) commitments in the tools sector. -

Regional Market Dynamics

North America and Europe will remain strong markets due to ongoing renovation projects and strict building codes requiring robust anchoring solutions. However, the fastest growth is anticipated in India, Southeast Asia, and the Middle East, where large-scale infrastructure investments—such as smart cities and transportation hubs—are creating sustained demand for construction tools.

In conclusion, the 1/4 inch masonry drill bit market in 2026 will be shaped by technological innovation, evolving construction practices, and digital commerce. Manufacturers who prioritize performance, compatibility, and sustainability will be best positioned to capitalize on global opportunities.

Common Pitfalls When Sourcing 1/4-Inch Masonry Bits (Quality & IP Considerations)

Sourcing the right 1/4-inch masonry bit is critical for drilling efficiency, tool longevity, and safety—especially in demanding construction or renovation projects. However, several common pitfalls can compromise quality and lead to performance issues or safety hazards. Understanding these risks helps ensure you select a reliable, high-performance bit.

Choosing Low-Quality Materials

One of the most frequent mistakes is selecting masonry bits made from substandard carbide or steel. Low-cost bits often use inferior tungsten carbide tips that chip or dull quickly when drilling into concrete, brick, or stone. Similarly, poor-grade steel shafts may bend or break under stress. Always verify that the bit uses high-grade materials, such as solid tungsten carbide tips and hardened chrome-vanadium steel shafts, for optimal durability.

Ignoring International Standards and IP Ratings

Many buyers overlook the importance of International Protection (IP) ratings and industry standards. While IP ratings typically apply to electrical enclosures rather than drill bits, confusion may arise when sourcing bits online—especially from suppliers marketing “IP-rated” tools incorrectly. Ensure the product specifications refer to relevant standards such as ISO 5390 for masonry drill bits, rather than misleading claims about IP ratings that don’t apply.

Purchasing Non-Original or Counterfeit Products

Counterfeit masonry bits flooded in online marketplaces often mimic reputable brands but lack the quality control and performance. These knock-offs may have improperly brazed carbide tips or inconsistent flute designs, leading to overheating or bit failure. Source from authorized distributors or directly from trusted manufacturers to avoid counterfeit goods and protect intellectual property (IP) rights.

Overlooking Shank Type Compatibility

Using a 1/4-inch bit with an incompatible shank type (e.g., SDS-plus vs. straight round shank) can result in slippage, reduced drilling efficiency, and potential damage to the drill or bit. Always confirm that the shank type matches your hammer drill or rotary hammer’s chuck system. This compatibility is crucial for effective energy transfer during masonry drilling.

Neglecting Heat Resistance and Cooling Features

Masonry drilling generates significant heat. Low-quality bits lack proper flute design or heat-treated surfaces to dissipate heat, increasing the risk of overheating and premature failure. Opt for bits with optimized flute geometry and thermal protection features to maintain performance during extended use.

Failing to Verify Supplier Reputation

Purchasing from unknown or unverified suppliers increases the risk of receiving off-spec or unsafe products. Always assess supplier credibility by checking reviews, certifications, and return policies. Reputable suppliers provide detailed product specifications and comply with safety and quality regulations.

Avoiding these pitfalls ensures you source a durable, high-performance 1/4-inch masonry bit that meets your project requirements while respecting quality standards and intellectual property integrity.

Logistics & Compliance Guide for 1/4″ Masonry Bit

Product Overview

The 1/4″ masonry bit is a rotary drill bit designed for drilling into hard materials such as concrete, brick, stone, and block. Constructed with a durable tungsten carbide tip and a heavy-duty steel body, this bit is compatible with hammer drills and ensures efficient, precise drilling in masonry applications.

Packaging & Labeling Requirements

- Each 1/4″ masonry bit must be individually packaged in protective blister cards or sealed plastic sleeves to prevent damage during transit.

- Bulk packaging (e.g., multi-packs) should use sturdy cardboard boxes with internal dividers to minimize movement.

- Labels must include:

- Product name: “1/4\” Masonry Drill Bit”

- Size (1/4″ or 6.35mm)

- Material composition (e.g., “Tungsten Carbide Tip, Alloy Steel Body”)

- Manufacturer name and country of origin

- Barcode (UPC or EAN)

- Safety warnings (e.g., “Use Eye Protection,” “For Use with Hammer Drill Only”)

Shipping & Handling

- Weight & Dimensions: Typical single bit weight is 50–70g. Standard parcel dimensions apply for small packages.

- Stackability: Packaged units should be designed for stable stacking. Max stack height: 6 feet (1.8 meters) for palletized shipments.

- Temperature & Environment: Store and ship in dry conditions. Avoid exposure to moisture or extreme temperatures (below -10°C or above 50°C).

- Handling: Use gloves when handling bulk shipments to prevent cuts from sharp tips.

- Carrier Requirements: Compliant with standard ground or air freight regulations. No hazardous material classification.

Import/Export Compliance

- HS Code: 8207.50.60 (Drill bits, for working stone, ceramics, concrete, etc.)

- Country of Origin Marking: Required per U.S. CBP, EU, and other major market regulations.

- Import Duties: Vary by country; verify based on destination market (e.g., 3–7% in the U.S., duty-free under certain trade agreements).

- Documentation: Commercial invoice, packing list, and certificate of origin must accompany international shipments.

- REACH & RoHS (EU): Verify raw materials comply with EU chemical regulations. Steel and tungsten carbide generally comply, but coatings or additives must be assessed.

Safety & Regulatory Standards

- ANSI B212.15: Standard for performance and safety of masonry drill bits (U.S.)

- ISO 5416: International standard for masonry drill bits

- OSHA/Workplace Safety: Bits must be used with appropriate personal protective equipment (PPE), including safety glasses and gloves.

- CE Marking (EU): Required for sale in European markets; indicates compliance with health, safety, and environmental standards.

Warranty & Returns

- Standard warranty: 30-day satisfaction guarantee or 90-day limited warranty against manufacturing defects.

- Returns: Accept unopened, undamaged products within 30 days of delivery. Defective items will be replaced or refunded.

- Logistics for Returns: Prepaid return label provided for warranty claims. Returned items must be properly packaged to avoid damage in transit.

Environmental & Disposal Considerations

- Recyclable Materials: Steel and tungsten carbide components are recyclable.

- Disposal: Do not dispose of in regular trash if locally regulated. Follow local guidelines for metal waste.

- Sustainability: Encourage return or recycling programs for end-of-life bits to reduce environmental impact.

Supplier & Quality Assurance

- All suppliers must adhere to ISO 9001 quality management standards.

- Incoming inspection: Random sampling to verify dimensions, material quality, and performance.

- Batch traceability: Maintain lot numbers and production dates for quality control and recalls if necessary.

This guide ensures safe, compliant, and efficient logistics handling of 1/4″ masonry bits across global supply chains. Always verify local regulations and update procedures as standards evolve.

In conclusion, sourcing a 1/4-inch masonry bit requires careful consideration of factors such as material quality (e.g., carbide-tipped for durability), shank type (e.g., SDS-plus or standard round shank depending on your drill), and intended application (e.g., drilling into concrete, brick, or stone). It’s important to purchase from reputable suppliers or trusted brands to ensure performance and longevity. Comparing prices, reading customer reviews, and verifying compatibility with your power tool will help you make a cost-effective and reliable choice. Whether buying online or in-store, confirming specifications and warranty options contributes to a successful sourcing decision.