The global market for electronic interface components, including adapter sockets, is experiencing steady growth driven by rising demand in consumer electronics, telecommunications, and industrial automation. According to a report by Grand View Research, the global connector market was valued at USD 83.5 billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 5.4% from 2024 to 2030. Similarly, Mordor Intelligence projects the electronic connectors market to grow at a CAGR of over 5.8% during the forecast period of 2024–2029, fueled by advancements in miniaturization, increased PCB complexity, and the proliferation of IoT-enabled devices. Amid this expansion, the demand for specialized adapter sockets—such as 1.438 mm (0.055″) pitch models used in high-density board testing and signal integrity applications—has intensified. These components are critical for prototyping, in-circuit testing, and semiconductor validation, making reliable manufacturing partners essential. As industry standards evolve and product life cycles shorten, sourcing high-precision adapter sockets from technically capable and scalable manufacturers has become a strategic imperative. The following list highlights seven leading manufacturers excelling in quality, innovation, and global supply chain performance in this niche segment.

Top 7 1 4 3 8 Adapter Socket Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

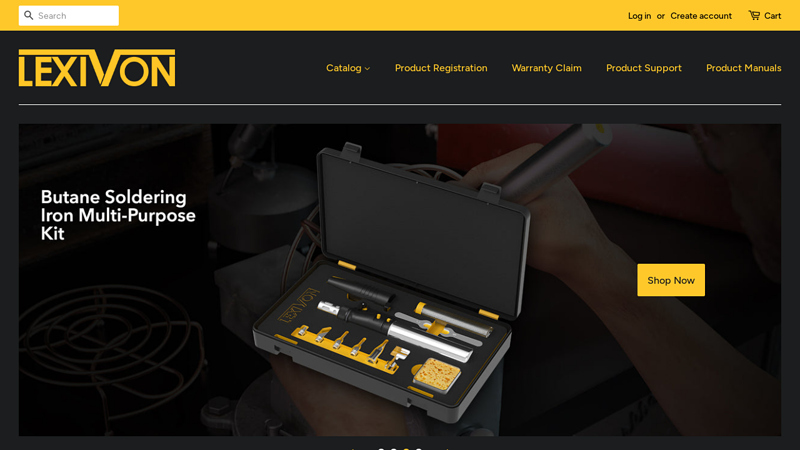

#1 Lexivon.com

Domain Est. 2005

Website: lexivon.com

Key Highlights: Lexivon.com Catalog Automotive Torque Wrenches, Impact Adapters, Bit Sockets, Spark plug sockets, Socket adapters, Lug nut tools, Industrial & Scientific Tools….

#2 Socket Adapter/Reducer 3/8

Domain Est. 1996

#3

Domain Est. 1997

Website: dmctools.com

Key Highlights: For 75 years, DMC® has manufactured tooling for mission-critical electrical systems in aerospace and defense, rail, marine, and several other industries….

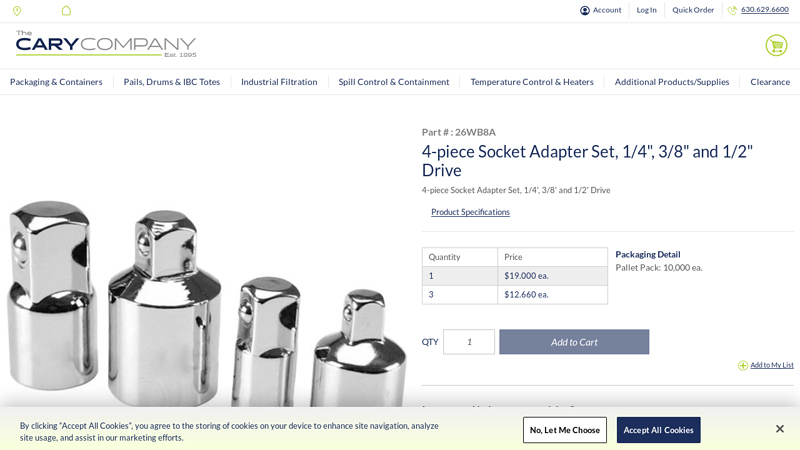

#4 4

Domain Est. 1999

Website: thecarycompany.com

Key Highlights: 4-piece Socket Adapter Set, 1/4″, 3/8″ and 1/2″ Drive are made of steel and is triple chrome plated. — The Cary Company, Since 1895!…

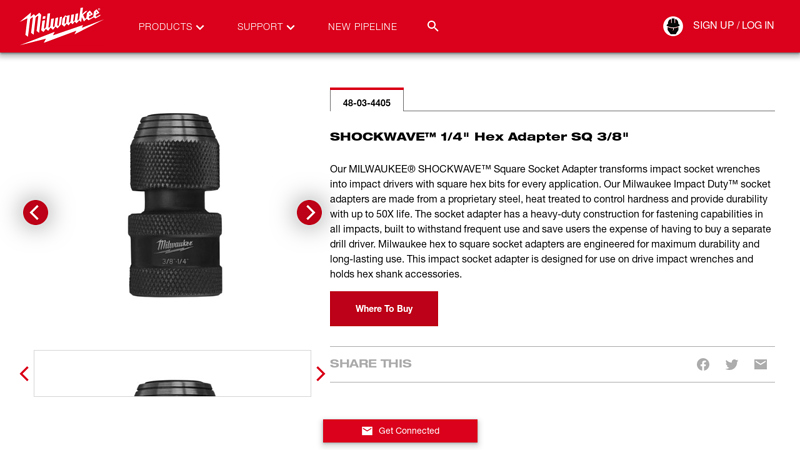

#5 SHOCKWAVE™ 1/4″ HEX ADAPTER SQ 3/8″

Domain Est. 2000

#6 1/4 Inch Drive (F) x 3/8 Inch (M) Adapter

Domain Est. 2001

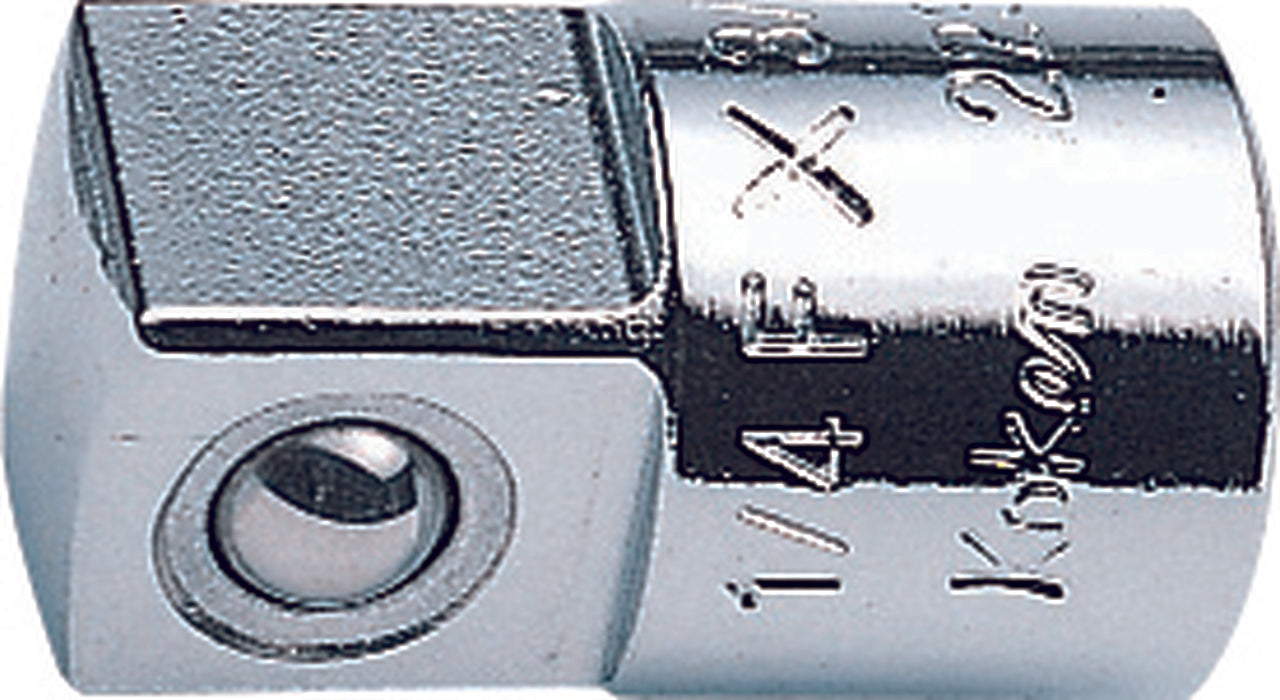

#7 1/4 Sq. Dr. Adaptor 3/8 Square Length 22mm

Domain Est. 2010

Expert Sourcing Insights for 1 4 3 8 Adapter Socket

H2: 2026 Market Trends for 1/4″ to 3/8″ Adapter Socket

The global market for tool accessories, including the 1/4″ to 3/8″ adapter socket, is projected to experience steady growth through 2026, driven by increasing demand in automotive repair, construction, and DIY sectors. The 1/4″ to 3/8″ adapter socket—used to connect smaller drive tools to larger sockets or accessories—plays a critical role in enhancing tool versatility across professional and consumer applications.

Key market trends shaping the 2026 outlook include:

-

Rising Demand for Multi-Drive Tool Compatibility

As toolkits become more modular, users seek greater compatibility between drive sizes. The 1/4″ to 3/8″ adapter socket enables seamless transitions between precision tools (1/4″ drive) and higher-torque applications (3/8″ drive), making it a staple in mechanic kits. This trend is amplified by the growing popularity of universal tool systems. -

Expansion of the Automotive Aftermarket

With the global vehicle parc increasing and average vehicle age rising, the need for repair and maintenance tools continues to grow. The 1/4″ to 3/8″ adapter socket is widely used in automotive diagnostics and repairs where space constraints and torque requirements vary. Emerging markets in Asia-Pacific and Latin America are particularly driving demand. -

Growth in DIY and Home Improvement Markets

Consumer interest in home repair and DIY projects has surged post-pandemic and remains strong. Retailers report increased sales of compact, versatile hand tools, including adapter sockets. Affordable, durable adapters appeal to casual users who own limited tool sets. -

Material and Design Innovation

By 2026, manufacturers are expected to adopt advanced materials such as chrome-molybdenum alloys and surface treatments that improve durability and corrosion resistance. Ergonomic designs and compact profiles are also being introduced to meet professional demands for efficiency and safety. -

E-Commerce and Distribution Channels

Online sales of tool accessories are growing rapidly, especially via platforms like Amazon, Home Depot, and Alibaba. This trend allows smaller manufacturers to access global markets, increasing competition and driving down prices, which benefits end-users. -

Sustainability and Longevity Focus

Environmental awareness is prompting both consumers and industrial buyers to prefer high-quality, long-lasting tools. Reusable and recyclable metal adapters are gaining preference over disposable or plastic alternatives.

In summary, the 1/4″ to 3/8″ adapter socket market is poised for stable expansion through 2026, supported by technological adaptability, rising repair economies, and evolving consumer behavior. Manufacturers who invest in quality, innovation, and digital distribution will be best positioned to capitalize on these trends.

Common Pitfalls When Sourcing 1/4″ to 3/8″ Adapter Sockets (Quality & IP Rating)

Sourcing 1/4″ to 3/8″ adapter sockets—especially those requiring specific quality standards or Ingress Protection (IP) ratings—can present several challenges. Avoiding these common pitfalls ensures reliability, safety, and compatibility in your applications.

Poor Material Quality and Durability

Many low-cost adapter sockets are manufactured using substandard alloys or inferior heat treatment processes. This results in sockets that are prone to stripping, cracking, or rounding off under load. Always verify material specifications—such as chrome vanadium steel (Cr-V) or S2 steel—and confirm compliance with recognized standards like ISO 1174 or ANSI B107.100 to ensure mechanical strength and longevity.

Lack of Standardization and Dimensional Inaccuracy

Non-compliant or counterfeit adapters often exhibit dimensional inconsistencies, such as incorrect drive sizes or misaligned sockets. This can cause improper tool engagement, leading to slippage, tool damage, or safety hazards. Ensure products are certified by accredited bodies and measure critical dimensions like drive tang width and socket internal diameter to confirm conformance.

Inadequate or Misrepresented IP Ratings

When environmental protection is required (e.g., in outdoor, wet, or dusty environments), sourcing adapters with appropriate IP ratings is crucial. A common pitfall is assuming that all sealed or coated adapters meet specific IP standards like IP54 or IP67. However, many suppliers exaggerate or inaccurately label IP ratings without proper testing. Always demand third-party test reports or certification documentation to verify the claimed IP protection level.

Insufficient Corrosion Resistance

Adapters used in humid or chemically aggressive environments must resist corrosion. Low-quality plating (e.g., thin chrome or non-uniform coatings) can wear off quickly, exposing the base metal to rust. Specify adapters with robust surface treatments such as electroless nickel plating or black oxide with supplementary oil coating, particularly for industrial or marine applications.

Compatibility Issues with Tools and Fasteners

Not all adapters are universally compatible. Some may not fit securely with certain ratchets or impact tools, especially if brands use proprietary drive designs. Similarly, socket depth and wall thickness can affect access to recessed fasteners. Confirm compatibility with your existing tooling and evaluate real-world fit before bulk procurement.

Overlooking Application-Specific Requirements

Using general-purpose adapters in high-torque or precision applications can lead to premature failure. For example, impact-rated adapters require different heat treatment and material toughness compared to hand-tool variants. Similarly, applications in explosive atmospheres may require non-sparking materials (e.g., beryllium copper), which are often overlooked in standard sourcing.

By addressing these pitfalls—focusing on verified quality, accurate specifications, and genuine IP certification—you can ensure that your 1/4″ to 3/8″ adapter sockets perform reliably and safely in their intended environments.

H2: Logistics & Compliance Guide for 1-4-3-8 Adapter Socket

This guide outlines the key logistics and compliance considerations for the safe, legal, and efficient handling, transportation, and use of the 1-4-3-8 Adapter Socket.

H3: Regulatory Compliance

-

Electrical Safety Standards:

The adapter socket must comply with relevant electrical safety standards in target markets (e.g., UL 498 in the US, CSA C22.2 No. 42 in Canada, IEC 60884-1 internationally). Ensure certification marks are present and valid. -

RoHS (Restriction of Hazardous Substances):

Verify compliance with RoHS directives (EU, UK, China, etc.), restricting substances like lead, mercury, cadmium, and specific phthalates. A Declaration of Conformity (DoC) should be available. -

REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals):

Confirm compliance with EU REACH regulations regarding the use of Substances of Very High Concern (SVHCs). Supplier documentation is required. -

WEEE (Waste Electrical and Electronic Equipment):

Adhere to WEEE regulations for end-of-life management. Ensure proper labeling (wheelie bin symbol) and provide take-back information where applicable. -

Country-Specific Markings:

Include required markings such as voltage rating (e.g., 125V), current rating (e.g., 15A), manufacturer ID, and certification marks specific to each market.

H3: Packaging & Labeling

-

Protective Packaging:

Use durable, anti-static packaging to prevent physical damage and electrostatic discharge during transit. Individual blister packs or clamshells are recommended for retail. -

Clear Product Labeling:

Label must include:- Product name: “1-4-3-8 Adapter Socket”

- Electrical ratings (Voltage, Current, Frequency)

- Certification marks (UL, CSA, CE, etc.)

- Manufacturer or importer information

- WEEE symbol (if applicable)

- RoHS compliance statement

- Country of origin

-

Shipping Labels:

Ensure outer cartons display:- Product description and part number

- Quantity per carton

- Gross/Net weight

- Handling symbols (e.g., “Fragile,” “This Side Up”)

- Shipping address and tracking information

H3: Transportation & Handling

-

Hazard Classification:

The 1-4-3-8 Adapter Socket is not classified as hazardous material under IATA, IMDG, or 49 CFR regulations. No special hazardous goods documentation is required. -

Storage Conditions:

Store in a dry, temperature-controlled environment (10°C to 30°C recommended). Avoid exposure to direct sunlight, moisture, and corrosive atmospheres. -

Handling Precautions:

Handle with care to avoid dropping or impact. Use appropriate lifting equipment for palletized shipments. Avoid stacking beyond recommended limits. -

Palletization & Unit Load:

Securely stack cartons on standard pallets (e.g., 48” x 40”) and wrap with stretch film. Maximum stack height should be determined by packaging strength and warehouse safety guidelines.

H3: Import/Export Documentation

- Commercial Invoice: Must include detailed product description, HTS code (e.g., 8536.69 for electrical apparatus for switching), quantity, value, country of origin, and Incoterms® (e.g., FOB, EXW).

- Packing List: Itemizes contents per shipment, weights, dimensions, and packaging types.

- Certificate of Origin: Required for tariff determination and trade agreement eligibility.

- Bill of Lading / Air Waybill: Primary transport document.

- Compliance Declarations: RoHS, REACH, and electrical safety certifications may be required by customs authorities.

H3: Environmental & Disposal Compliance

- End-of-Life Management:

Do not dispose of in regular household waste. Follow local WEEE regulations for collection and recycling. - Recycling Instructions: Provide clear disposal guidance to end users (e.g., via packaging or website).

H3: Quality & Traceability

- Batch/Lot Tracking: Maintain records of production batches for traceability in case of recalls or compliance audits.

- Supplier Qualification: Ensure all components (brass contacts, thermoplastic housing) are sourced from certified suppliers with valid compliance documentation.

Note: Always confirm specific requirements with local regulatory bodies and logistics partners based on the destination country and transportation method. Regulations may vary and are subject to change.

In conclusion, sourcing a 1/4″ to 3/8″ adapter socket is a practical solution for enhancing tool versatility and compatibility between different drive sizes. This small but essential accessory allows users to seamlessly connect 3/8″ drive sockets or tools to a 1/4″ drive ratchet or impact driver, expanding the functionality of existing toolsets without the need for duplicate purchases. When sourcing this adapter, it is important to consider factors such as build quality, material durability (preferably chrome vanadium steel), secure locking mechanisms, and reputable suppliers to ensure long-term reliability and performance. Whether for automotive repairs, DIY projects, or professional use, the 1/4″ to 3/8″ adapter socket proves to be a valuable addition, offering flexibility, cost-efficiency, and convenience in a wide range of applications.