The global exhaust system market is experiencing steady expansion, driven by increasingly stringent emissions regulations, rising automotive production, and growing demand for high-performance aftermarket components. According to Grand View Research, the global automotive exhaust system market size was valued at USD 37.8 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This growth trajectory highlights the critical role of key components such as 1 1/2-inch exhaust tubing, widely used in performance vehicles, light-duty trucks, and off-road applications due to its optimal balance of flow efficiency and fitment flexibility. As emissions standards evolve and the aftermarket performance sector continues to expand—particularly in North America and Asia Pacific—manufacturers specializing in precision exhaust tubing are well-positioned to meet rising demand. With industry consolidation and technological advancements in materials like aluminized steel and stainless steel, the competitive landscape is shifting toward innovation, durability, and scalability. In this context, the following list highlights the top 10 manufacturers of 1 1/2 exhaust tubing, selected based on production capacity, material quality, global reach, and market reputation.

Top 10 1 1/2 Exhaust Tubing Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Exhaust Products

Domain Est. 2006

Website: apemissions.com

Key Highlights: AP offers a full line of pre-bent pipes, flexible and straight tubing, elbows, stack pipes, connectors and adapters. AP is a leading manufacturer of steel ……

#2 Patriot Exhaust H6902 304 Stainless Steel 1 1/2″ tube diameter, 2″ rad

Domain Est. 2020

Website: pertronixbrands.com

Key Highlights: In stock Rating 4.7 (1,342) It is 50 State Legal when installed on the Specified vehicle per the Manufacturer’s Current Application Guide, the CARB EO, and Installation Instructi…

#3 Tubing

Domain Est. 1998

Website: exhaustdirect.com

Key Highlights: All tubing is special order only! Please call 1-888-544-2222 and one of our sales representatives will be happy to assist you. All Tubing is sold in 10′ foot ……

#4 Walker Exhaust Systems

Domain Est. 1999

Website: walkerexhaust.com

Key Highlights: Providing performance-grade mufflers and exhaust kits for a wide variety of makes and models, Walker is the name to trust in OE-quality exhaust parts….

#5 Stainless Works

Domain Est. 2000

Website: stainlessworks.net

Key Highlights: Shop Stainless Works for premium American-made 304 stainless steel headers and exhaust systems. Build your perfect setup with header kits, muffler kits, ……

#6 Pypes Performance Exhaust

Domain Est. 2003

Website: pypesexhaust.com

Key Highlights: Pypes Performance Exhaust supplies complete mandrel bent, performance exhaust systems for American performance vehicles ranging from the 1950’s to the present ……

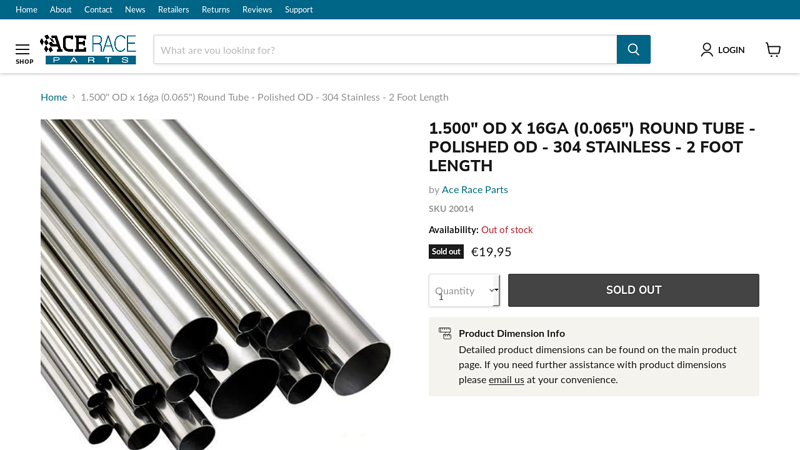

#7 1

Domain Est. 2014

Website: aceraceparts.com

Key Highlights: Out of stock Rating 5.0 (2) Our polished 304 Stainless tubing offers a consistent, high quality welding experience with virtually no need for surface preparation prior to welding…

#8 Stainless Bros

Domain Est. 2016

Website: stainlessbros.com

Key Highlights: 30-day returnsShop high-quality stainless steel 304, SS321, Inconel Alloy 625 exhaust components, elbows, flanges, and tubing for race, street, and custom fabrication….

#9 GenExhaust.com

Domain Est. 2017

Website: genexhaust.com

Key Highlights: Through-wall exhaust ports for 1” and 1-1/2” ID tubing are available to complete your project. These kits are constructed from stainless steel to give you years ……

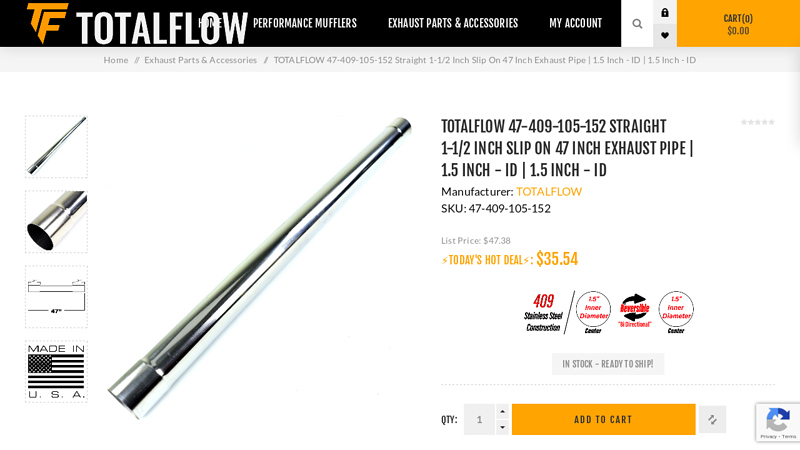

#10 1.5″ Inch Slip

Domain Est. 2018

Website: totalflowusa.com

Key Highlights: In stock Rating 5.0 (1) 1.5″ inch exhaust tube replacement, made of high-quality 409 stainless steel materials to serve you for years to come. Designed with customers in mind….

Expert Sourcing Insights for 1 1/2 Exhaust Tubing

H2: Projected Market Trends for 1 1/2-Inch Exhaust Tubing in 2026

The market for 1 1/2-inch exhaust tubing is poised for notable shifts by 2026, driven by evolving automotive demands, advancements in materials, and broader industry trends. This analysis explores key drivers, regional dynamics, technological developments, and economic factors shaping the trajectory of this niche but vital component in exhaust systems.

1. Increasing Demand from the Automotive Aftermarket

The aftermarket segment is expected to remain a primary growth engine for 1 1/2-inch exhaust tubing. Enthusiasts and performance vehicle owners continue to favor this diameter for its balance of flow efficiency and compatibility with mid-sized engines. As customization and vehicle tuning gain popularity—especially in North America and Europe—demand for standardized tubing like 1 1/2-inch will likely rise. Additionally, the growing used car market supports aftermarket exhaust repairs and upgrades, further sustaining demand.

2. Material Innovation and Lightweighting Trends

By 2026, manufacturers are anticipated to increasingly adopt advanced materials such as aluminized steel and stainless steel alloys with improved corrosion resistance and thermal efficiency. While traditional aluminized steel remains cost-effective, the shift toward stainless steel—particularly 304 and 409 grades—is accelerating due to its durability and cleaner aesthetic. Innovations in coating technologies may also enhance lifespan and reduce emissions, aligning with stricter environmental standards.

3. Environmental and Emission Regulations

Stringent global emissions regulations, including Euro 7 (in Europe) and EPA Tier 4 standards (in the U.S.), are indirectly influencing exhaust system design. While 1 1/2-inch tubing is typically used in performance or light-duty applications, regulatory pressure may drive integration with advanced catalytic systems and sensors, requiring precise tubing dimensions and improved weldability. This trend could favor standardized sizes like 1 1/2-inch in hybrid or retrofit exhaust configurations.

4. Growth in Off-Highway and Specialty Vehicle Sectors

Beyond passenger vehicles, demand for 1 1/2-inch exhaust tubing is expanding in off-highway equipment, agricultural machinery, and recreational vehicles (RVs). These sectors value the tubing’s versatility and availability. As emissions standards for non-road engines tighten, original equipment manufacturers (OEMs) may adopt modular exhaust designs where 1 1/2-inch tubing serves as a standard component.

5. Regional Market Dynamics

North America is expected to dominate the 1 1/2-inch exhaust tubing market in 2026, supported by a robust automotive aftermarket and strong culture of vehicle customization. Asia-Pacific, particularly China and India, will see rising demand due to expanding automotive production and increasing consumer interest in performance upgrades. Meanwhile, Europe’s market will be shaped by sustainability mandates, potentially favoring recyclable materials and precision-engineered tubing.

6. Supply Chain and Cost Considerations

Fluctuations in raw material prices—especially chromium and nickel used in stainless steel—could impact profitability. However, increased regional manufacturing and improved supply chain resilience post-pandemic may stabilize costs. Automation in tube production is also expected to reduce labor expenses and improve dimensional consistency, benefiting standard sizes like 1 1/2-inch.

7. E-Commerce and Distribution Channels

Online platforms will play a growing role in distributing 1 1/2-inch exhaust tubing, offering consumers easier access to standardized parts. Marketplaces like Amazon, Summit Racing, and RockAuto are likely to expand their inventory, supported by detailed product specifications and compatibility tools.

Conclusion

By 2026, the 1 1/2-inch exhaust tubing market will be shaped by performance demand, regulatory changes, and material innovation. While not the largest diameter in use, its optimal balance for mid-range applications ensures continued relevance. Stakeholders should focus on quality standardization, sustainability, and digital distribution to capitalize on emerging opportunities.

Common Pitfalls When Sourcing 1 1/2″ Exhaust Tubing (Quality & IP)

Sourcing 1 1/2″ exhaust tubing may seem straightforward, but several critical pitfalls related to quality and intellectual property (IP) can lead to performance issues, safety risks, and legal complications. Being aware of these can save time, money, and potential liability.

Quality-Related Pitfalls

Inconsistent Material Composition

Not all 1 1/2″ tubing is made from the same grade of stainless steel or aluminized steel. Substandard suppliers may use lower-grade materials (e.g., 409 stainless instead of 304) or misrepresent alloy content. This results in reduced corrosion resistance, shorter lifespan, and potential failure under high heat or stress.

Poor Dimensional Accuracy

Tubing that does not meet precise outer diameter (OD), wall thickness, or roundness tolerances can cause installation issues, leaks, or misalignment with mufflers, catalytic converters, or hangers. Variations as small as 0.010″ can compromise weld integrity and system performance.

Inadequate Surface Finish and Weld Quality

Low-cost tubing often exhibits rough internal weld seams or inconsistent surface finishes. These imperfections increase exhaust flow resistance and promote carbon buildup. Poor weld seams may also crack or leak under thermal cycling, reducing efficiency and increasing emissions.

Lack of Traceability and Certification

Reputable suppliers provide mill test reports (MTRs) or material certifications verifying composition and compliance with standards like ASTM A269 or SAE J525. Sourcing without documentation risks unknowingly using non-compliant or counterfeit materials, especially in regulated or performance-critical applications.

Intellectual Property (IP) Pitfalls

Use of Proprietary Designs Without Authorization

Certain exhaust tubing profiles, mandrel-bent configurations, or patented flange designs may be protected by IP rights. Sourcing custom or OEM-replica tubing from unauthorized manufacturers can lead to infringement claims, especially if the design mimics a branded performance system (e.g., Borla, MagnaFlow).

Counterfeit or Knockoff Products

Some suppliers market tubing as “equivalent to” or visually copy branded systems without proper licensing. These products may not only violate design patents or trademarks but also fail to meet the performance claims of the original, exposing the buyer to liability if sold downstream.

Misrepresentation of Branding or Origin

Suppliers may falsely claim tubing is “USA-made,” “TIG-welded,” or “304 stainless” to increase perceived value. Such misrepresentations can constitute false advertising and may breach IP or consumer protection laws, particularly if used in resale or branded assemblies.

Mitigation Strategies

- Verify Material Certifications: Always request and review MTRs for alloy content and compliance.

- Inspect Samples: Physically measure dimensions and examine welds and surface finish before bulk ordering.

- Audit Suppliers: Choose vendors with established reputations, ISO certification, and transparent manufacturing practices.

- Conduct IP Due Diligence: Ensure custom designs do not infringe on existing patents; use legal counsel if replicating branded components.

- Use Reputable Distributors: Source from authorized dealers or manufacturers with clear IP policies.

Avoiding these pitfalls ensures reliable performance, regulatory compliance, and protection from legal risk when sourcing 1 1/2″ exhaust tubing.

H2: Logistics & Compliance Guide for 1 1/2″ Exhaust Tubing

Proper logistics and compliance management are critical when transporting and handling 1 1/2″ exhaust tubing to ensure safety, regulatory adherence, and supply chain efficiency. This guide outlines key considerations for the safe and compliant handling, storage, transportation, and documentation of 1 1/2″ exhaust tubing, commonly used in automotive, marine, and industrial exhaust systems.

H3: Material Classification and Handling

- Product Description: 1 1/2″ exhaust tubing is typically made from aluminized steel, stainless steel, or mild steel. It is used to route exhaust gases from engines to mufflers and out through tailpipes.

- Hazard Classification: Generally non-hazardous (non-regulated under DOT, IATA, or IMDG when empty and clean). However, oily residues or cutting debris may require evaluation under local environmental regulations.

- Handling Precautions:

- Use mechanical aids (e.g., forklifts, tube racks) for lifting and moving to prevent injury.

- Wear cut-resistant gloves and eye protection during handling.

- Store horizontally on racks to prevent bending or deformation.

H3: Packaging and Unit Load Design

- Packaging Requirements:

- Bundled securely with metal or synthetic banding.

- Protective end caps or plugs to prevent deformation.

- Water-resistant wrapping or shrink wrap to prevent corrosion during transit.

- Unit Load Standards:

- Stacked on standard 48″ x 40″ pallets.

- Max load height: 60″ (to ensure stability).

- Weight per bundle: Typically 50–150 lbs depending on length and material.

H3: Transportation and Shipping

- Modes of Transport:

- Truck (Domestic): Compliant with FMCSA standards. Load must be secured per DOT 49 CFR Part 393 (e.g., tiedowns, load blocks).

- Rail: Use secure rail cars with protection from shifting.

- Ocean (International): Palletized and secured in containers; ISPM 15-compliant wooden pallets required.

- Labeling Requirements:

- Product ID: “1 1/2” Exhaust Tubing – [Material Type]”

- Handling labels: “Fragile – Protect from Bending,” “This Side Up” if applicable.

- No hazardous labels unless contaminated (verify with SDS).

H3: Regulatory Compliance

- DOT (U.S. Department of Transportation):

- Non-hazardous when clean and dry.

- No placarding required unless transporting contaminated tubing.

- EPA & Environmental Compliance:

- Dispose of cutting oil or metal shavings per RCRA regulations if generated during processing.

- Prevent stormwater contamination during outdoor storage.

- OSHA Workplace Safety:

- Sharp edges must be controlled; implement PPE protocols.

- Material Safety Data Sheet (MSDS/SDS) must be available, especially if tubing is coated or treated.

- Customs & International Trade:

- HS Code Example: 7306.61.10 (Stainless steel tubes, circular, seamless) or 7306.69.10 (Other steel tubes).

- Provide accurate country of origin, weight, quantity, and value on commercial invoice.

- Verify anti-dumping duties may apply on steel tubing from certain countries (e.g., China, South Korea).

H3: Storage and Inventory Management

- Storage Conditions:

- Indoor, dry environment recommended to prevent rust.

- If stored outdoors, elevate off ground and cover with UV-resistant tarps.

- Shelf Life: Indefinite if protected from moisture and corrosion.

- Inventory Best Practices:

- FIFO (First In, First Out) rotation.

- Segregate by material type and finish (e.g., aluminized vs. stainless).

H3: Documentation Requirements

Required documents for domestic and international shipments:

– Bill of Lading (BOL)

– Commercial Invoice (for exports)

– Packing List

– Certificate of Origin (if claiming tariff preferences)

– SDS (Safety Data Sheet) – available upon request

– Export Declaration (if applicable, e.g., AES filing for shipments >$2,500)

H3: Special Considerations

- RoHS/REACH Compliance: Not typically applicable unless tubing includes coated or treated components. Confirm with supplier.

- Customer-Specific Requirements: Some OEMs require serialization, barcoding, or AS9100/ISO 14001 compliance.

- Returns & Reverse Logistics: Defective or excess tubing should be repackaged securely and labeled for return.

H2: Summary

The logistics and compliance of 1 1/2″ exhaust tubing involve attention to physical handling, secure packaging, regulatory alignment, and proper documentation. By following this guide, distributors, manufacturers, and carriers can ensure safe, efficient, and legally compliant movement of exhaust tubing throughout the supply chain.

Note: Always consult local, state, and federal regulations for updates, and verify compliance with your legal or compliance department prior to shipment.

In conclusion, sourcing 1 1/2-inch exhaust tubing requires careful consideration of material type (such as aluminized steel, stainless steel, or mandrel-bent variants), wall thickness, tubing length, and compatibility with existing exhaust components. It is essential to verify the tubing’s diameter accuracy and bending radius to ensure a proper fit, especially for custom exhaust builds or performance applications. Sourcing from reputable suppliers or automotive specialty stores—whether locally or online—helps ensure quality and durability. Additionally, comparing prices, reading customer reviews, and confirming return policies can lead to a cost-effective and reliable purchase. Proper selection and installation of 1 1/2-inch exhaust tubing will contribute to improved exhaust flow, engine performance, and overall vehicle efficiency.