The global automotive air conditioning compressor market is on a robust growth trajectory, driven by rising vehicle production, increasing demand for passenger comfort, and advancements in energy-efficient cooling technologies. According to Grand View Research, the market was valued at USD 11.6 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is further fueled by steady demand for replacement parts in aging vehicle fleets, particularly for popular models like the 2003 Honda CR-V. As one of the most reliable compact SUVs of its era, the 2003 Honda CR-V continues to see strong aftermarket support, with a growing need for high-quality, OEM-equivalent AC compressors. In this competitive landscape, a select group of manufacturers has emerged as leaders in producing durable, performance-optimized compressors tailored to the specifications of this model, combining engineering precision with cost-efficiency to meet the demands of both repair shops and DIY enthusiasts.

Top 8 03 Honda Crv Ac Compressor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

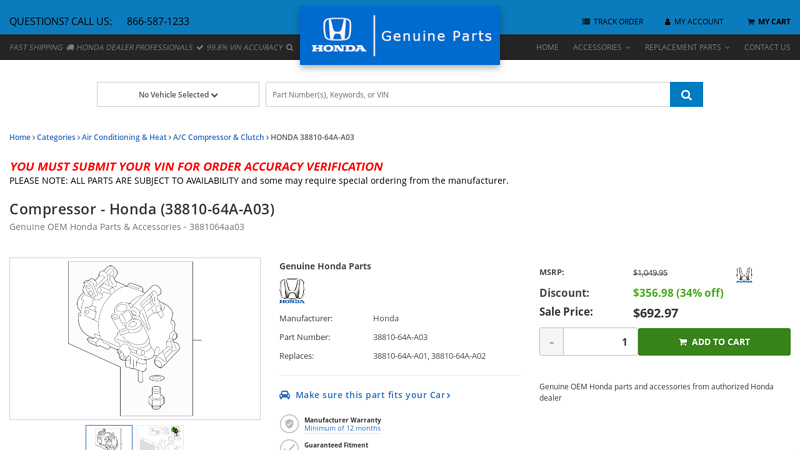

#1 38810-64A-A03 – Compressor

Domain Est. 2017

Website: hondapartsconnection.com

Key Highlights: In stock $34.98 deliverySALE: Compressor Genuine OEM Honda® Part # 3881064aa03. Manufacturer Warranty, Fast Shipping. Genuine OEM Parts & Accessories….

#2 Genuine Honda CR

Domain Est. 2007

Website: hondapartsnow.com

Key Highlights: 1–4 day deliveryWarranty: This genuine part is guaranteed by Honda’s factory warranty. Fits the following Vehicles: 2002-2006 Honda CR-V | 5 Door EX, 5 Door ……

#3 Recall Search

Domain Est. 1989

Website: mygarage.honda.com

Key Highlights: See recall details by selecting your product. Enter your year, model, and trim for information about your Honda. Year. Year. Select Year. Model. Model….

#4 A/C going on and off

Domain Est. 2005

Website: crvownersclub.com

Key Highlights: The compressor clutch is known to wear on Gen3s. If the gap gets too large the compressor will not operate reliably. Failure mode is just as you ……

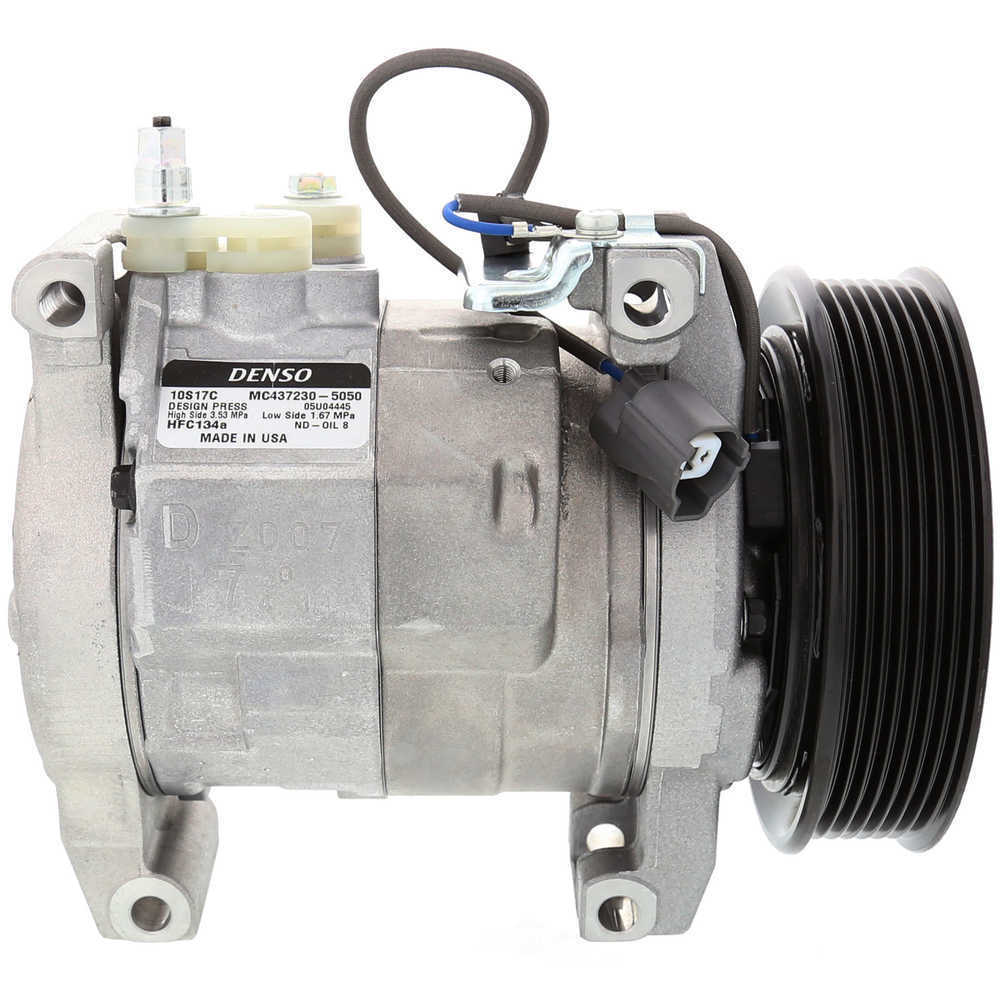

#5 DENSO Auto Parts

Domain Est. 2006

Website: densoautoparts.com

Key Highlights: DENSO is a global choice for top automakers, with multiple vehicle models rolling off the assembly line with DENSO auto parts under the hood….

#6 Bypassing ac compressor on 07 Honda crv

Domain Est. 2009

Website: mechanics.stackexchange.com

Key Highlights: I can confirm that the Gates K070553 belt will work to bypass the AC pulley on a 2002 Honda CR-V. I got one at Autozone today to bypass a noisy ……

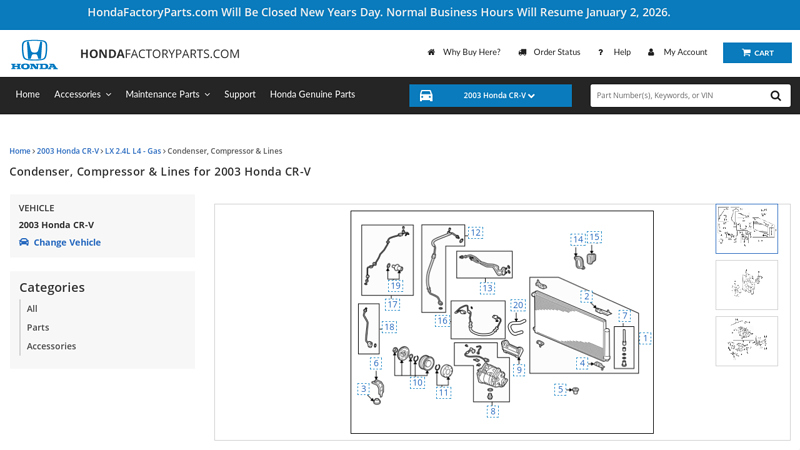

#7 Condenser, Compressor & Lines for 2003 Honda CR

Domain Est. 2017

Website: hondafactoryparts.com

Key Highlights: 3-day delivery · 30-day returnsNotes: PARTS: Part included with condenser assembly. Description: Japan built. MSRP $27.78. $22.50. – +….

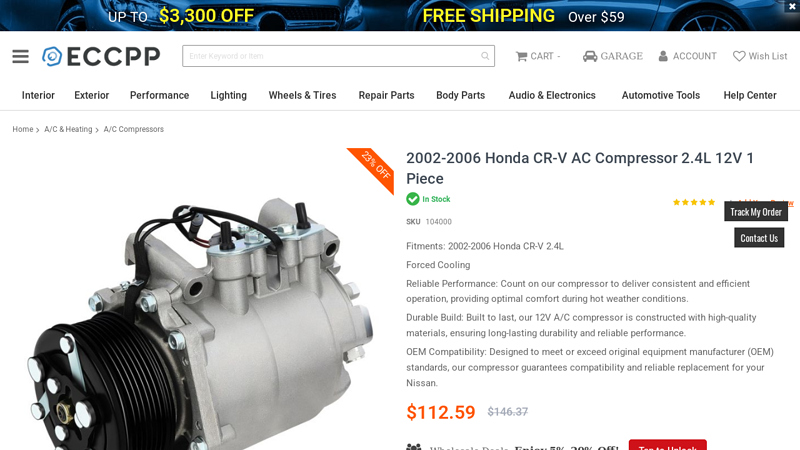

#8 2002

Domain Est. 2017

Website: eccppautoparts.com

Key Highlights: In stock Rating 5.0 (1) Fitments: 2002-2006 Honda CR-V 2.4L; Forced Cooling; Reliable Performance: Count on our compressor to deliver consistent and efficient operation, ……

Expert Sourcing Insights for 03 Honda Crv Ac Compressor

H2: 2026 Market Trends for 2003 Honda CR-V AC Compressor

As of 2026, the market for the 2003 Honda CR-V AC compressor reflects broader trends in the automotive aftermarket, driven by aging vehicle fleets, increasing demand for affordable repairs, and shifts in consumer behavior toward vehicle longevity over replacement. Despite the 2003 model being over two decades old, a dedicated base of owners continues to maintain these reliable SUVs, sustaining demand for replacement parts like the AC compressor.

-

Continued Demand from Aging Vehicle Fleet

The 2003 Honda CR-V is known for its durability, and many units remain on the road in 2026. As vehicles age, components like AC compressors—subject to wear from constant thermal cycling and mechanical stress—begin to fail. This creates steady demand for replacements. The reliability of the CR-V encourages owners to invest in repairs rather than replacements, supporting a persistent aftermarket for critical components. -

Growth in Aftermarket and Remanufactured Parts

In 2026, the market is heavily supplied by aftermarket and remanufactured AC compressors. OEM options are scarce or overpriced due to discontinued production, making remanufactured units the preferred choice. These remanufactured compressors offer cost savings of 30–50% compared to new OEM equivalents and often come with warranties, increasing consumer confidence. Brands like Denso, Four Seasons, and ATP have expanded their reman programs specifically for older Honda models. -

E-Commerce Dominance and Price Competition

Online marketplaces such as Amazon, RockAuto, and eBay dominate AC compressor sales in 2026. Consumers increasingly rely on customer reviews, compatibility filters, and fast shipping options when purchasing. Intense competition among sellers has driven prices down, with quality remanufactured compressors available for $150–$250. However, this has also led to concerns over counterfeit or low-quality units, prompting buyers to prioritize reputable sellers and verified parts. -

Environmental and Regulatory Influences

Environmental regulations continue to shape the HVAC repair market. The phaseout of R-134a refrigerant in favor of newer, more eco-friendly alternatives like R-1234yf has limited direct implications for 2003 models, as they are “grandfathered” for R-134a use. However, shops and DIYers are more conscious of refrigerant handling and recycling, increasing demand for kits and services that comply with EPA Section 608 requirements when replacing compressors. -

DIY Repair Culture and Information Accessibility

The rise of video tutorials, online forums (e.g., Honda-Tech, Reddit’s r/MechanicAdvice), and digital repair databases (e.g., ALLDATA, Mitchell1) has empowered DIY mechanics. In 2026, many 2003 CR-V owners opt to replace the AC compressor themselves, further fueling demand for complete kits that include O-rings, fittings, and PAG oil. This trend supports a niche market for comprehensive, user-friendly repair solutions. -

Supply Chain and Inventory Challenges

While demand remains stable, some suppliers report inventory shortages for specific compressor models due to declining production runs. Distributors are increasingly relying on global sourcing, particularly from Japan and South Korea, to meet demand. However, geopolitical tensions and shipping disruptions remain potential risks to consistent supply.

Conclusion:

In 2026, the market for the 2003 Honda CR-V AC compressor remains active, sustained by a loyal owner base, cost-effective remanufactured options, and robust online distribution. While the vehicle is no longer in production, its reputation for reliability ensures continued relevance in the aging vehicle aftermarket. Suppliers who offer quality assurance, compatibility accuracy, and comprehensive support are best positioned to succeed in this niche but enduring segment.

H2. Common Pitfalls When Sourcing a 03 Honda CR-V AC Compressor (Quality and Intellectual Property Concerns)

When sourcing an AC compressor for a 2003 Honda CR-V, buyers often encounter several critical pitfalls related to both component quality and intellectual property (IP) issues. Being aware of these can help avoid costly repairs, performance issues, and legal complications.

1. Poor Quality Control in Aftermarket Parts

Many aftermarket or third-party AC compressors marketed for the 2003 Honda CR-V lack adherence to OEM (Original Equipment Manufacturer) standards. Common quality issues include:

– Substandard internal components leading to premature failure

– Inconsistent tolerances affecting fitment and performance

– Use of inferior seals and lubricants, increasing the risk of leaks

These issues often result in shorter lifespan, reduced cooling efficiency, and potential damage to other parts of the AC system.

2. Counterfeit or Replica Components

A significant risk when sourcing online or from unverified suppliers is encountering counterfeit compressors. These parts may be:

– Labeled as OEM or reputable brands but are actually knockoffs

– Missing proper certifications or compliance markings (e.g., ISO, SAE)

– Built with recycled or reconditioned parts falsely advertised as new

These replicas often infringe on the intellectual property of genuine manufacturers like Denso or Sanden, the original suppliers for Honda vehicles.

3. Intellectual Property and Trademark Infringement

Purchasing a compressor that uses a trademarked design or branding without authorization can pose indirect legal risks, especially for commercial repair shops. While individual consumers are rarely targeted, distributors and installers may face liability if they knowingly sell or use counterfeit components. Look for:

– Unauthorized use of brand logos (e.g., “Denso-style” vs. genuine Denso)

– Misleading packaging that mimics OEM appearance

– Parts sold under names that closely resemble established brands (e.g., “Denco” instead of “Denso”)

4. Lack of Warranty and Support

Low-cost compressors from dubious sources often come with limited or no warranty. If the unit fails prematurely:

– Replacement may not be covered

– Technical support might be unavailable

– Diagnostic and labor costs fall entirely on the buyer

This can negate any initial savings from choosing a cheaper, non-OEM part.

5. Incompatibility and Fitment Issues

Even if a compressor looks identical, dimensional or mounting differences can cause installation problems. Non-OEM versions may not align with the bracket, belt, or hoses, leading to:

– Increased labor time

– Need for modifications

– Risk of improper operation and system damage

6. Missing or Incorrect Lubricant Type

The 2003 Honda CR-V AC system requires a specific type and amount of refrigerant oil (typically PAG 46). Many low-quality compressors either:

– Come pre-filled with the wrong oil type

– Are not pre-lubricated at all

– Use contaminated or degraded oil

This can lead to poor lubrication, increased wear, and compressor failure.

Conclusion

To avoid these pitfalls, always source AC compressors from reputable suppliers, verify part authenticity, and prioritize OEM or certified aftermarket brands. Check for proper documentation, warranty coverage, and compliance with industry standards to ensure long-term reliability and avoid IP-related risks.

Logistics & Compliance Guide for 03 Honda CR-V AC Compressor

This guide outlines key logistics considerations and compliance requirements for handling, transporting, and installing the air conditioning compressor in a 2003 Honda CR-V. Proper adherence ensures safety, system performance, and regulatory compliance.

Product Identification & Specifications

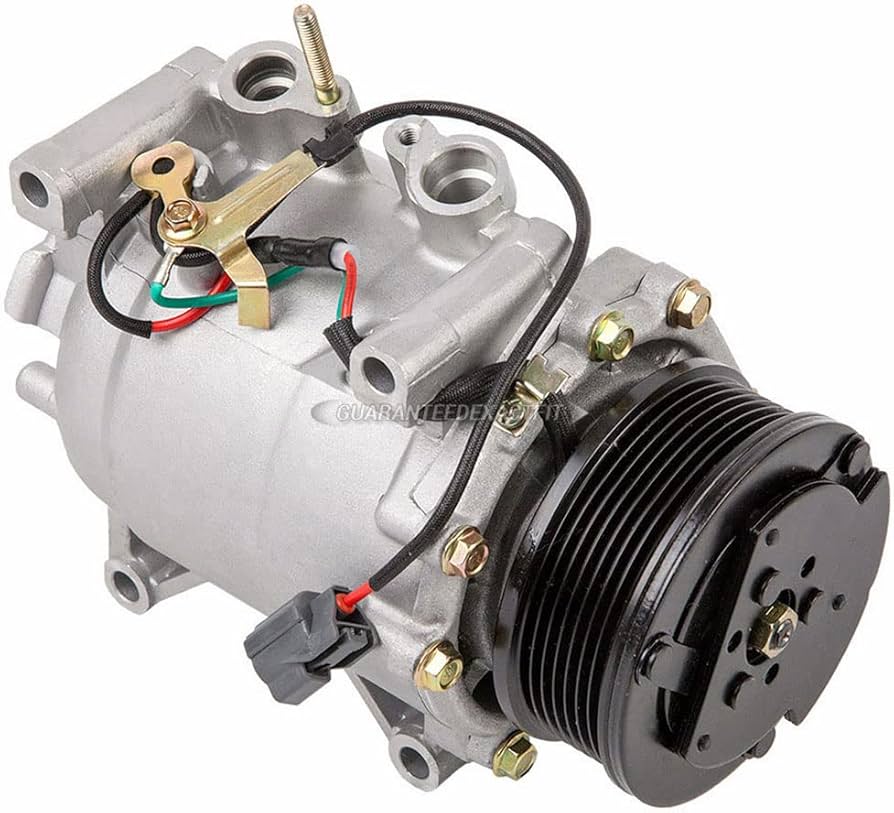

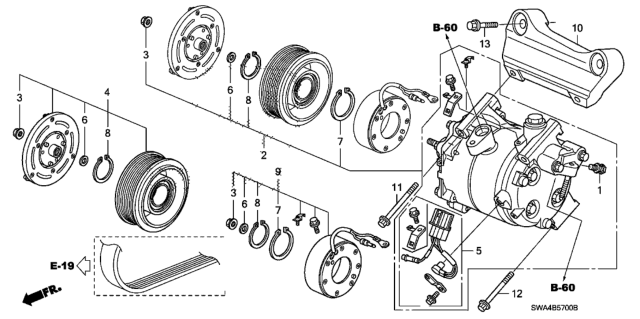

- Vehicle Compatibility: 2003 Honda CR-V (all trims and engine types—2.4L 4-cylinder)

- OEM Part Number: Varies by supplier (e.g., Denso 601-0083, Sanden SD7H15)

- Refrigerant Type: R-134a

- Lubricant Type: ND-8 or ND-9 PAG oil (typically 8 oz / 236 ml)

- Compressor Type: Swash plate, fixed displacement

- Pulley Drive: Serpentine belt-driven with electromagnetic clutch

Handling & Storage Requirements

- Seal Integrity: Ensure all service ports and openings are capped to prevent moisture and debris contamination.

- Orientation: Store compressor upright to avoid oil migration and potential internal damage.

- Environment: Keep in a dry, temperature-controlled area (ideally 40°F–100°F / 4°C–38°C).

- Shock & Vibration: Avoid dropping or subjecting the compressor to impact during transport or storage.

Transportation & Shipping Compliance

- Packaging: Use manufacturer-recommended or equivalent protective packaging with cushioning.

- Labeling: Clearly mark as “Fragile,” “This Side Up,” and include hazardous material labels if refrigerant is present (rare for new compressors).

- Regulatory Compliance: Follow DOT (Department of Transportation) and IATA (if air shipped) regulations for mechanical components. No special hazmat classification for empty compressors.

- Documentation: Include packing slip, purchase order, and any import/export documentation (for cross-border shipments).

Environmental & Refrigerant Handling Regulations

- EPA Section 608 Compliance (USA):

- Certified technicians must recover refrigerant before compressor removal.

- Use EPA-approved recovery/recycling equipment.

- Never vent R-134a into the atmosphere—penalties apply.

- Refrigerant Recovery: All refrigerant must be evacuated using a recovery machine prior to system opening.

- Recycling & Disposal: Used refrigerant must be recycled or properly disposed of per local environmental regulations.

Installation Best Practices & Compliance

- Oil Management:

- Measure and record oil removed from the old compressor.

- Refill the new compressor with the correct amount and type of PAG oil (ND-8 or ND-9).

- Avoid overfilling or mixing oil types.

- Filter/Orifice Tube Replacement: Always replace the receiver-drier or accumulator and orifice tube when replacing the compressor.

- System Flushing: Recommended if old compressor failed catastrophically (metal debris). Use approved A/C flushing solvent.

- Evacuation & Charging:

- Evacuate system to at least 29 in Hg for 30–45 minutes to remove air and moisture.

- Charge with correct amount of R-134a per Honda specifications (typically 1.22 lbs / 550 g).

- Leak Testing: Perform electronic or UV dye leak test after installation.

Worker Safety & PPE

- Personal Protective Equipment (PPE): Safety glasses, gloves, and workshop-appropriate clothing.

- Ventilation: Work in well-ventilated areas, especially during refrigerant handling.

- Pressure Safety: Never pressurize the system with oxygen or compressed air—risk of explosion.

Documentation & Recordkeeping

- Service Records: Document compressor replacement, refrigerant recovery/recycling, oil quantity, evacuation time, and final charge.

- EPA Compliance Logs: Maintain records of refrigerant recovery for at least 3 years (per EPA 608).

- Warranty Registration: Submit required forms if installing a new OEM or aftermarket warranted unit.

Disposal of Old Compressor & Components

- Refrigerant Residue: Ensure all refrigerant is recovered before disposal.

- Recycling: Metal components can be recycled through authorized scrap metal facilities.

- Hazardous Waste: If compressor contains significant oil or refrigerant residue, dispose of as hazardous waste per local/state regulations.

Adhering to this guide ensures safe, legal, and efficient handling of the 03 Honda CR-V AC compressor throughout its logistics lifecycle—from shipment to installation and disposal.

In conclusion, sourcing a 03 Honda CR-V AC compressor requires careful consideration of several factors to ensure optimal performance, reliability, and cost-effectiveness. It is essential to confirm the correct compressor type and specifications—such as OE match, pulley style, refrigerant compatibility (R134a), and mounting configuration—to ensure a proper fit and function with your vehicle’s AC system. Whether opting for a new, remanufactured, or used unit, purchasing from reputable suppliers or OEM sources helps minimize the risk of premature failure. Additionally, proper installation, including replacement of the accumulator, orifice tube, and appropriate oil, is critical to the longevity and performance of the new compressor. While cost is a factor, investing in a quality compressor and professional installation can save time and money in the long run by preventing recurring AC issues. Ultimately, thorough research and attention to detail will lead to a successful repair and reliable cooling performance for your 2003 Honda CR-V.