The global market for electrical wiring, including specialized products like 0000 AWG (American Wire Gauge) wire, continues to expand in response to growing demand across industries such as renewable energy, electric vehicles, industrial manufacturing, and infrastructure development. According to a report by Mordor Intelligence, the global electrical wire and cable market was valued at USD 226.5 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2029. This growth is driven by increased investments in grid modernization, rising urbanization, and the proliferation of clean energy projects requiring high-capacity conductors like 0000 AWG wire. Similarly, Grand View Research projects that the Asia Pacific region will dominate market expansion due to rapid industrialization and government-led infrastructure initiatives. As demand for high-performance, large-diameter conductors intensifies, manufacturers capable of producing reliable, high-conductivity 0000 AWG wire are becoming increasingly critical to the global supply chain. The following analysis highlights the top six manufacturers leading innovation and scale in this segment, selected based on production capacity, global reach, product certifications, and market presence.

Top 6 0000 Awg Wire Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Copper Wire Products

Domain Est. 1997

Website: alphawire.com

Key Highlights: Alpha Wire EcoGen™ and Hook-Up Wire is designed with the range of materials to meet any environmental, mechanical, or electrical needs….

#2 51 Foot Spool 1/0 AWG Frosted Red Wire RFW1R

Domain Est. 1997

Website: rockfordfosgate.com

Key Highlights: Full Spec Cable meets or exceeds AWG (American Wire Gauge) requirements · Pure Crystal-Oxygen Free Copper (PC-OFC) · Frosted outer jacket for maximum flexibility ……

#3 MTW Rated Cable #4/0 (0000) AWG in Black

Domain Est. 1998

#4 SGR Automotive Battery Cable

Domain Est. 2007

Website: lapptannehill.com

Key Highlights: 5-day deliverySGR automotive battery cable is used for connecting batteries and starters in vehicles. It has a flexible EPDM jacket. 1/0 AWG 975 strand, color red….

#5 1/0 Gauge Gauge (AWG) Single Black Pure Copper Battery Cable …

Domain Est. 2008

Website: windynation.com

Key Highlights: Excellent choice for battery bank wiring, inverter cables, grounding cables, or any other application where a highly flexible pure copper conductor is required….

#6 4/0 Gauge Battery Cables (0000 AWG)

Domain Est. 2014

Expert Sourcing Insights for 0000 Awg Wire

H2: Projected Market Trends for 0000 AWG Wire in 2026

The global market for 0000 AWG (also known as 4/0 AWG) wire is expected to experience notable growth and transformation by 2026, driven primarily by surging demand in renewable energy, electric vehicle (EV) infrastructure, and industrial electrification. As one of the largest standardized wire sizes, 0000 AWG is essential for high-current applications, making it a critical component in power transmission, battery systems, and heavy-duty electrical installations.

-

Increased Demand from Renewable Energy Projects

By 2026, solar and wind energy installations are projected to expand significantly, particularly in North America, Europe, and parts of Asia-Pacific. These systems often require robust cabling to handle high DC currents from photovoltaic arrays and battery storage units. 0000 AWG wire is frequently used in combiner boxes, inverters, and interconnections due to its ability to carry up to 195–230 amps (depending on insulation and conditions). Government incentives and net-zero commitments are expected to accelerate adoption, boosting demand for large-gauge wires. -

Growth in Electric Vehicle Charging Infrastructure

The rollout of Level 2 and DC fast-charging stations is a key driver for 0000 AWG wire. These high-power charging systems require thick conductors to minimize voltage drop and resistive losses. With global EV adoption on the rise, governments and private companies are investing heavily in charging networks. By 2026, the need for reliable, high-capacity cabling in EVSE (Electric Vehicle Supply Equipment) will likely increase the consumption of 0000 AWG copper wire. -

Industrial and Commercial Electrification

As industries move toward electrification to reduce carbon emissions, applications such as large motors, transformers, and data center power distribution will rely on heavy-gauge wiring. 0000 AWG is commonly used in main service entrances, busbars, and UPS systems. Urban development and smart building initiatives will further support market expansion. -

Material and Cost Considerations

Copper remains the dominant material for 0000 AWG wire due to its superior conductivity. However, price volatility in copper markets could push some applications toward aluminum alternatives, despite aluminum’s larger cross-section for equivalent performance. Innovations in alloying and insulation materials (e.g., cross-linked polyethylene) may help improve efficiency and reduce weight, supporting broader deployment. -

Regional Market Dynamics

North America and Europe are expected to lead in demand due to regulatory pushes for clean energy and EV infrastructure. Meanwhile, Asia-Pacific—especially China and India—will see rapid growth in industrial and renewable sectors. Supply chain resilience and localized manufacturing may become strategic priorities by 2026. -

Sustainability and Recycling Trends

With growing emphasis on circular economy principles, the recyclability of copper 0000 AWG wire will enhance its long-term market appeal. Recycling infrastructure improvements could stabilize supply and reduce environmental impact, aligning with ESG (Environmental, Social, Governance) goals of major buyers.

In conclusion, the 0000 AWG wire market in 2026 will be shaped by clean energy transitions, technological advancements in electrified transport, and industrial modernization. Stakeholders across manufacturing, distribution, and installation sectors should prepare for rising demand, fluctuating raw material costs, and evolving technical standards to remain competitive.

Common Pitfalls When Sourcing 0000 AWG Wire (Quality and IP)

Sourcing 0000 AWG (also known as 4/0 AWG) wire—commonly used in high-current applications such as power distribution, automotive systems, and renewable energy setups—can be fraught with challenges, especially concerning quality assurance and intellectual property (IP). Being aware of these pitfalls helps ensure reliability, safety, and compliance.

Low-Quality Materials and Construction

One of the most frequent issues when sourcing 0000 AWG wire is encountering substandard materials. Some suppliers may use copper that is not 100% electrolytic-tough pitch (ETP) copper, instead substituting with lower-conductivity alternatives like oxygen-free copper (OFC) without proper certification or even copper-clad aluminum (CCA). CCA wire, in particular, presents significant safety risks due to higher resistance and lower thermal stability, increasing the risk of overheating and fire. Always verify material certifications and conduct independent conductivity testing when possible.

Inaccurate Gauge and Dimensional Tolerances

Despite standardized specifications, some manufacturers—particularly those outside regulated markets—may produce wire that does not meet true 0000 AWG dimensions. Under-sized conductors increase resistance and reduce current-carrying capacity, leading to inefficiency and potential system failure. It’s crucial to audit samples using calibrated calipers and compare them against the National Electrical Code (NEC) and ASTM B3/B8 standards for diameter and cross-sectional area.

Poor Insulation Quality and Rating Mismatches

The insulation on 0000 AWG wire must withstand high temperatures, mechanical stress, and environmental exposure. A common pitfall is receiving wire with insulation rated below the application requirements (e.g., using 60°C-rated insulation in a high-temperature environment). Additionally, some suppliers misrepresent insulation thickness or material type (e.g., claiming XLPE when using inferior PVC). Always request and verify UL, CSA, or other third-party certification documents.

Misrepresentation of Intellectual Property and Branding

Counterfeit or gray-market wire often carries fake brand labels or mimics patented designs from reputable manufacturers (e.g., Southwire, General Cable). This includes forged part numbers, logos, or packaging. Such IP violations not only undermine trust but also signal potential quality issues, as counterfeit products bypass rigorous quality controls. Conduct supplier due diligence and purchase only through authorized distributors to avoid IP infringement and ensure authenticity.

Inadequate Traceability and Documentation

Reputable sourcing requires full traceability—batch numbers, mill test reports, and compliance certificates (RoHS, REACH, etc.). Many low-cost suppliers fail to provide these, making it difficult to verify quality or respond to failures. Lack of documentation also complicates compliance with regulatory or project-specific requirements, especially in commercial or industrial installations.

Supply Chain and Lead Time Risks

Due to the size and weight of 0000 AWG wire, logistics can be complex. Unreliable suppliers may promise short lead times but fail to deliver, disrupting project timelines. Additionally, inconsistent supply batches can result in variations in wire quality across deliveries. Establish clear delivery terms and consider working with suppliers who maintain inventory or offer just-in-time solutions with proven track records.

By understanding and addressing these pitfalls—ranging from material integrity and dimensional accuracy to IP compliance and supply reliability—buyers can significantly reduce risk and ensure they source high-quality, safe, and legally compliant 0000 AWG wire.

Logistics & Compliance Guide for 0000 AWG Wire

Overview of 0000 AWG Wire

0000 AWG (also known as 4/0 AWG) wire is a large-gauge electrical conductor commonly used in high-current applications such as power distribution, industrial machinery, battery systems, and utility infrastructure. Due to its size and weight, special considerations are required for handling, transportation, storage, and regulatory compliance.

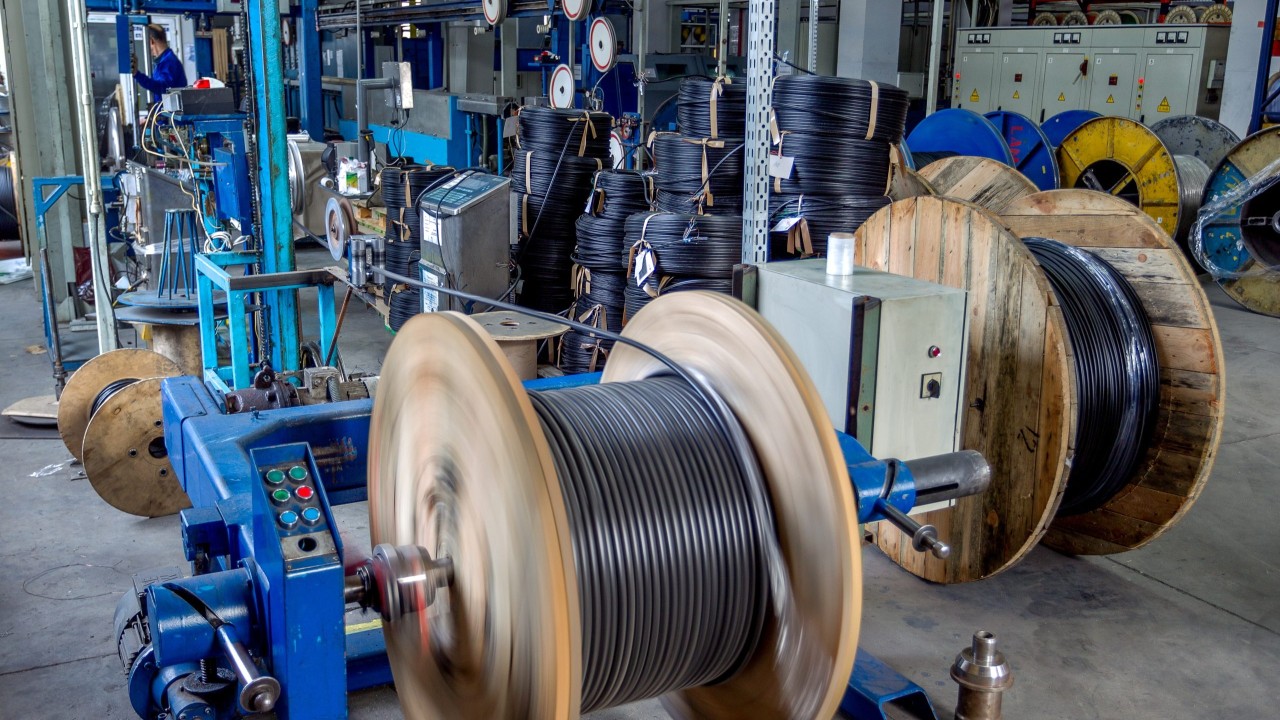

Packaging and Handling Requirements

- Coiling and Spooling: 0000 AWG wire is typically supplied on heavy-duty wooden or steel reels due to its substantial weight (up to several hundred pounds per reel).

- Protective Covering: Reels must be wrapped in moisture-resistant materials (e.g., shrink wrap or vapor barriers) to prevent corrosion, especially for copper conductors.

- Lifting and Transport: Use forklifts or overhead cranes with appropriate slings or lifting beams; never lift by the reel flanges. Mark reels with center-of-gravity and lifting points.

- Labeling: Each reel must be clearly labeled with wire gauge (0000 AWG or 4/0), conductor material (e.g., Cu for copper, Al for aluminum), insulation type, voltage rating, length, manufacturer, and batch/lot number.

Transportation and Shipping

- Weight Considerations: Confirm vehicle weight limits and secure loads properly. 0000 AWG reels can exceed 1,000 lbs, requiring freight-class shipping.

- Securement: Use ratchet straps, chains, or load bars to prevent shifting during transit.

- Carrier Requirements: Use freight carriers experienced in handling oversized or heavy electrical materials. Notify carriers in advance of weight and dimensions.

- Hazard Classification: While not typically hazardous, insulated variants containing halogenated materials may require specific documentation under IATA/IMDG if shipped internationally.

Storage Guidelines

- Environment: Store indoors in a clean, dry, and temperature-controlled environment to prevent oxidation and insulation degradation.

- Reel Positioning: Store reels vertically on their side or horizontally on supports—never directly on bare concrete.

- Stacking: Avoid stacking reels unless designed for it; if stacking, follow manufacturer guidelines to prevent crushing.

- Inventory Control: Implement FIFO (First In, First Out) to prevent long-term storage that may degrade insulation or lead to surface oxidation.

Regulatory and Compliance Standards

- National Electrical Code (NEC): Compliance with NEC Article 310 for conductor use, ampacity, and installation methods is mandatory in the U.S.

- UL and CSA Certification: Ensure wire carries UL 44 (Rubber-Insulated Wire) or UL 83 (Thermoplastic-Insulated Wire) listing, and CSA certification for Canadian markets.

- RoHS and REACH: Confirm compliance with Restriction of Hazardous Substances (RoHS) and REACH regulations for wires exported to the EU.

- Country-Specific Approvals: For international shipments, verify local standards (e.g., BS 6724 in the UK, IS 694 in India).

Import and Export Documentation

- HS Code: Use appropriate Harmonized System code (e.g., 8544.49 for insulated copper wire) for customs declarations.

- Certificates of Conformity: Provide test reports, CoC, and material safety data sheets (MSDS) when required.

- Origin and Tariff Information: Accurately declare country of origin to determine duty rates and trade agreement eligibility (e.g., USMCA).

Safety and Handling Training

- Personnel Training: Ensure staff are trained in safe lifting practices and use of material handling equipment.

- PPE Requirements: Provide gloves, safety footwear, and eye protection when handling sharp wire ends or during cutting operations.

- Arc Flash Awareness: Educate teams on risks associated with high-current conductors during installation and termination.

Environmental and Disposal Considerations

- Recycling: 0000 AWG wire, especially copper, has high scrap value. Partner with certified recyclers for end-of-life or damaged material.

- Insulation Disposal: Follow local regulations for disposal of PVC or other insulating materials; some may require special handling as e-waste.

Quality Assurance and Traceability

- Batch Traceability: Maintain records linking reel serial numbers to production batches, test results, and certifications.

- Incoming Inspection: Verify wire diameter, insulation thickness, and markings upon receipt to ensure conformance to specifications (e.g., ASTM B3 for copper).

By adhering to this guide, organizations can ensure safe, compliant, and efficient logistics operations for 0000 AWG wire across the supply chain.

In conclusion, sourcing 0000 AWG (4/0 AWG) wire requires careful consideration of application requirements, material specifications, and compliance standards. Due to its large cross-sectional area, 0000 AWG wire is ideal for high-current applications such as power distribution, battery systems, automotive, and solar installations. When sourcing, it is essential to select the appropriate conductor material—typically copper or aluminum—based on conductivity, weight, and cost constraints. Additionally, ensure the insulation type (e.g., THHN, XHHW, or SAE) matches the environmental and safety requirements of the installation, including temperature rating and resistance to oil, moisture, or abrasion.

Reliable suppliers, adherence to industry standards (such as NEC, UL, or ASTM), and proper certification are critical to guaranteeing performance and safety. While 0000 AWG wire may be more expensive and less flexible than smaller gauges, its ability to carry substantial current with minimal voltage drop makes it a vital component in high-power electrical systems. Therefore, investing time in sourcing high-quality 0000 AWG wire from reputable suppliers ensures long-term reliability, safety, and efficiency in demanding electrical applications.