The global laser cutting machine market is experiencing robust expansion, driven by increasing demand for precision manufacturing across industries such as automotive, aerospace, and electronics. According to Grand View Research, the market was valued at USD 4.8 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 7.2% from 2024 to 2030. This growth is fueled by advancements in fiber laser technology, rising automation in production processes, and the need for energy-efficient cutting solutions. As industries prioritize accuracy, speed, and operational efficiency, the prominence of leading חיתוך בלייזר (laser cutting) manufacturers continues to rise. The following list highlights the top eight manufacturers demonstrating technological innovation, global reach, and strong market presence in this evolving landscape.

Top 8 חיתוך בלייזר Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laser cutting of profiles and pipes

Website: everest-machine.co.il

Key Highlights: Laser cutting for profiles and tubes – precision metal processing technology. Maximum accuracy, excellent finish quality, and optimal ……

#2 Laser cutting in the industry

Website: moraltec.co.il

Key Highlights: In recent decades, laser cutting technology has emerged as a formidable force in the world of manufacturing, laser technology has revolutionized the way ……

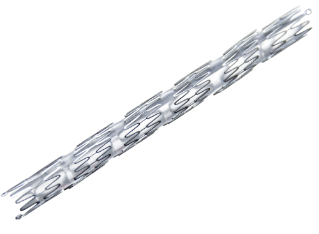

#3 GTI Medical

Website: gti-medical.com

Key Highlights: Precision laser cutting, welding, electropolishing for medical devices & prototyping, providing essential services for companies and startups….

#4 Services

Website: laseraccess.com

Key Highlights: יכולות. חיתוך שטוח בלייזר · פרס ברייק CNC · Gantry CNC Milling · כרסום וחריטה CNC · ריתוך MIG / TIG · פעולות משניות · CMM & Scanning Inspection. מקורות….

#5 Die

Website: cutandmor.com

Key Highlights: CUT & MOR is a dynamic company specializing in precise cutting and supplying raw materials to the various electronics industries, with an emphasis on quality ……

#6 Laser Cut

Website: oman-laser.co.il

Key Highlights: חיתוך בלייזר משמש לחריצת חומרי הגלם להכנת מבלטים. חיתוך לייזר שלנו הוא מהמדויקים בתעשייה. חיתוך בלייזר עץ ופרספקס בלייזר מבוצע בצורה נקיה ללא שבבים ונעשה ……

#7 Laser Cutting

Website: admati.com

Key Highlights: Admati Agencies expertise lies in Laser Micromachining Processes, allowing us to create precise and complex components with exceptional accuracy….

#8 Papercut

Website: papercut.co.il

Key Highlights: אנחנו מאפשרים חיתוך לייזר של מגוון רחב של עצים (לבידים, MDF, פורנירים ופורמיקות). מלבד חיתוך, ניתן לצרוב או לחרוט על גבי חומרי הגלם שונים בהתאם לעובי החומר. על ……

Expert Sourcing Insights for חיתוך בלייזר

H2: 2026 Market Trends for Laser Cutting (חיתוך בלייזר)

The global laser cutting (חיתוך בלייזר) market is expected to experience significant transformation by 2026, driven by technological innovation, growing industrial automation, and increasing demand across key sectors such as automotive, aerospace, electronics, and renewable energy. A detailed analysis of the market trends reveals several pivotal developments shaping the industry.

-

Increased Adoption in Advanced Manufacturing

By 2026, laser cutting technology is projected to be more deeply integrated into smart factories and Industry 4.0 frameworks. Manufacturers are increasingly adopting fiber laser systems due to their superior precision, energy efficiency, and lower maintenance costs compared to traditional CO₂ lasers. This shift is particularly evident in high-precision industries like medical device manufacturing and electric vehicle (EV) production. -

Growth in Fiber Laser Dominance

Fiber lasers continue to dominate the market, accounting for over 70% of new installations by 2026. Their ability to cut reflective metals such as copper and aluminum with high speed and accuracy makes them ideal for the evolving needs of the electronics and EV battery manufacturing sectors. Additionally, advancements in kilowatt-range fiber lasers enable faster processing of thick materials, expanding their application in heavy industry. -

Expansion in Emerging Markets

Regions such as Southeast Asia, India, and Latin America are expected to witness accelerated adoption of laser cutting systems. Rising manufacturing investments, government incentives for industrial modernization, and the localization of supply chains are contributing to this trend. In Israel, a growing high-tech manufacturing ecosystem and defense industry demand are boosting local adoption of advanced חיתוך בלייזר solutions. -

Integration with Automation and AI

Automation is a key driver of market growth. By 2026, most new laser cutting systems will come equipped with robotic loading/unloading systems, real-time monitoring, and AI-powered optimization software. These integrations enhance productivity, reduce waste, and enable predictive maintenance, significantly lowering operational costs. -

Sustainability and Energy Efficiency

Environmental concerns and regulatory pressures are pushing manufacturers toward greener technologies. Laser cutting, particularly fiber laser systems, offers lower energy consumption and reduced material waste compared to mechanical cutting methods. This aligns with global sustainability goals and is a major factor influencing procurement decisions. -

Rise in Hybrid and Multi-Functional Systems

Equipment manufacturers are responding to market demand by developing hybrid solutions that combine laser cutting with welding, marking, or 3D printing capabilities. These multi-functional platforms offer greater flexibility and cost-efficiency, especially for small and medium enterprises (SMEs) aiming to streamline production. -

Impact of Material Innovation

The development of new composite and high-strength materials—especially in aerospace and automotive applications—requires advanced laser solutions capable of precise thermal control. Ultrafast (picosecond and femtosecond) lasers are gaining traction for micro-machining applications, although high costs currently limit widespread use.

In conclusion, the 2026 outlook for חיתוך בלייזר is highly positive, characterized by technological advancements, rising automation, and expanding applications. Companies investing in next-generation laser systems, particularly fiber and AI-integrated platforms, will be well-positioned to capitalize on these trends across both mature and emerging markets.

Common Pitfalls When Sourcing חיתוך בלייזר (Laser Cutting) – Quality and Intellectual Property (IP) Concerns

Sourcing laser cutting services, or “חיתוך בלייזר” in Hebrew, offers precision and efficiency for manufacturing needs. However, businesses often encounter significant challenges related to quality control and intellectual property protection. Being aware of these pitfalls is crucial for ensuring successful outcomes and safeguarding your designs and business interests.

Quality-Related Pitfalls

Inconsistent Material Processing

Not all laser cutting providers handle materials with the same level of expertise. Variations in laser power, focus, and cutting parameters can lead to inconsistent edge quality, warping, or incomplete cuts—especially across different material types (e.g., stainless steel, aluminum, acrylic). Without proper calibration and operator experience, batch-to-batch inconsistencies may occur, affecting final product assembly and appearance.

Poor Tolerance and Dimensional Accuracy

Laser cutting is known for precision, but low-quality machines or poorly maintained equipment may fail to meet tight tolerances. Sourcing from providers without rigorous quality assurance processes can result in parts that don’t fit as designed, leading to delays, rework, and increased costs.

Inadequate Surface Finish and Burr Formation

A common issue in low-quality laser cutting is the formation of burrs or dross (residue) along cut edges, especially in thicker metals. If post-processing (e.g., deburring) is not included or poorly executed, this can compromise both aesthetics and functionality, particularly in applications requiring smooth edges or tight mechanical fits.

Intellectual Property (IP) Risks

Lack of IP Protection Agreements

Many sourcing partners, especially overseas or in less regulated markets, may not have formal non-disclosure agreements (NDAs) or IP ownership clauses in their contracts. Sharing design files (e.g., DXF, CAD) without legal safeguards increases the risk of unauthorized replication, reverse engineering, or sale of your designs to competitors.

Unauthorized Use or Replication of Designs

Once design files are shared, there’s a risk that the service provider could use them for other clients or create similar products independently. This is particularly concerning when sourcing from regions with weaker IP enforcement, where legal recourse may be limited or difficult to pursue.

Data Security and File Handling

Laser cutting requires digital files, which can be vulnerable during transfer or storage. Providers with weak cybersecurity practices may expose your designs to data breaches or accidental leaks. Ensuring encrypted file transfer, secure servers, and restricted access is essential to protect sensitive IP.

Mitigation Strategies

To avoid these pitfalls, always:

– Request samples to verify quality and consistency.

– Audit the provider’s equipment, certifications (e.g., ISO 9001), and quality control procedures.

– Sign comprehensive NDAs and clearly define IP ownership in contracts.

– Limit the distribution of full design files when possible (e.g., provide only necessary sections).

– Choose partners with strong reputations and transparent operations.

By proactively addressing quality and IP concerns, businesses can effectively leverage חיתוך בלייזר services while minimizing risk and ensuring reliable, protected production.

Logistics & Compliance Guide for חיתוך בלייזר (Laser Cutting)

Overview of Laser Cutting Operations

Laser cutting is a precise manufacturing process used to cut materials such as metal, plastic, wood, and composites using a high-powered laser beam. In Israel, where “חיתוך בלייזר” refers to this technology, operations must comply with both international standards and local regulatory requirements. This guide outlines the logistics and compliance considerations essential for safe, efficient, and legally compliant laser cutting activities.

Regulatory Compliance in Israel

All laser cutting facilities in Israel must adhere to regulations set by the Ministry of Environmental Protection, the Ministry of Labor, and the Standards Institution of Israel (SI). Key compliance areas include:

– SI 1261 and IEC 60825: Standards for laser product safety, including classification and labeling of laser systems.

– Workplace Safety Regulations (1994): Mandates protective measures for workers exposed to laser radiation, fumes, and high-pressure systems.

– Environmental Protection Law: Requires proper ventilation, fume extraction, and disposal of hazardous residues (e.g., metal dust, coatings).

Facilities must obtain relevant permits and undergo periodic inspections to maintain compliance.

Material Handling and Logistics

Efficient logistics for laser cutting involve:

– Raw Material Storage: Store sheet metal, plastics, and other substrates in dry, organized areas to prevent warping and contamination.

– Inventory Management: Use barcode or RFID systems to track material batches, thickness, and alloy types to ensure correct job setup.

– Work-in-Progress (WIP) Flow: Design shop floor layout to minimize movement between cutting, deburring, and quality control stations.

– Finished Goods Handling: Package cut parts with protective layers to avoid scratches; use labeled crates or pallets for easy identification.

Safety Protocols and Equipment

Laser cutting poses risks such as fire, eye injury, and exposure to toxic fumes. Required safety measures include:

– Laser Enclosures and Interlocks: Ensure machines are fully enclosed with safety interlocks that disable the laser when opened.

– Personal Protective Equipment (PPE): Provide operators with laser-safe goggles, flame-resistant clothing, and respiratory protection where needed.

– Fume Extraction Systems: Install industrial-grade filtration units (e.g., HEPA and activated carbon) to capture particulates and volatile organic compounds (VOCs).

– Fire Prevention: Equip workstations with Class D fire extinguishers (for metal fires) and automatic shutdown systems.

Transportation and Shipping

When shipping laser-cut parts:

– Packaging Standards: Use anti-static, moisture-resistant packaging for sensitive components. Secure sharp edges with corner protectors.

– Labeling Requirements: Clearly label packages with contents, weight, handling instructions (e.g., “Fragile,” “This Side Up”), and compliance marks (e.g., CE if exported to Europe).

– Export Compliance: For international shipments, comply with customs regulations, provide accurate HS codes (e.g., 8462.21 for CNC laser machines), and include certificates of origin and conformity when required.

Waste Management and Environmental Responsibility

Laser cutting generates waste such as slag, dross, and filter residues. Compliance requires:

– Segregation of Waste: Separate metallic waste, plastic scraps, and hazardous filter media for proper recycling or disposal.

– Licensed Disposal Vendors: Partner with certified waste management companies authorized by the Ministry of Environmental Protection.

– Record Keeping: Maintain logs of waste generation, transfer, and disposal for audit purposes.

Training and Certification

Operators and maintenance staff must undergo certified training programs covering:

– Laser safety (based on ANSI Z136.1 or equivalent)

– Machine operation and emergency procedures

– Hazardous material handling

Training records must be kept on file and updated annually.

Quality Assurance and Documentation

Maintain compliance through rigorous quality control:

– Inspection Procedures: Use calipers, micrometers, and optical comparators to verify dimensional accuracy.

– Traceability: Assign job numbers and maintain logs linking each cut part to material batch, machine settings, and operator.

– Certifications: Provide clients with material certifications (e.g., ISO 9001), test reports, and compliance declarations as needed.

Conclusion

Operating a חיתוך בלייזר facility in Israel demands strict adherence to safety, environmental, and quality standards. By implementing robust logistics systems and maintaining full regulatory compliance, businesses can ensure operational efficiency, worker safety, and market credibility. Regular audits and staff training are essential to stay current with evolving regulations and technological advancements.

לסיכום, חיתוך בלייזר הינו טכנולוגיה מתקדמת ומדויקת המשמשת במגוון רחב של תעשיות לייצור חלקים עם דיוק גבוה וסיביות מוקפדה. היתרונות בבחירת חיתוך בלייזר כוללים דיוק אופטי, מargins קטנים, פינה נקייה וקצוצה, יעילות בייצור ויכולת להתמודד עם חומרים שונים – מתכות דקיקות ועד מתכות עבות.

בהקשר של קניין ותכנון זיכיון, חשוב לבחון מספר גורמים מרכזיים: דיוק המכונה, עובי החומר שנחתך, עוצמת הלייזר, מהירות החיתוך, עלות הפעלה והתחזוקה, וכן שירות פינפוי מהספק. שיווק מקומי מול ספקים בינלאומיים מחייב השוואת יחס תמורה-מחיר, זמינות חלקי חילוף, תמיכה טכנית וזמן משלוח.

לכן, בחירת הספק הנכון לחיתוך בלייזר אמורה להיקבע על פי צורכי הייצור הספציפיים, דרישות האיכות, תחום היישום הסופי, וכן התוכנית הכלכלית והלוגיסטית ארוכת הטווח. השקעה בטכנולוגיית חיתוך בלייזר מתועלת – הן בטווח הקצר והן בטווח הארוך – אך דורשת תכנון אחורי מקיף וביצוע מדויק של תהליכי הזמנה, אינטגרציה ותפעול.